Embedded Solutions Pg 5 of 20

Product Description and Operation

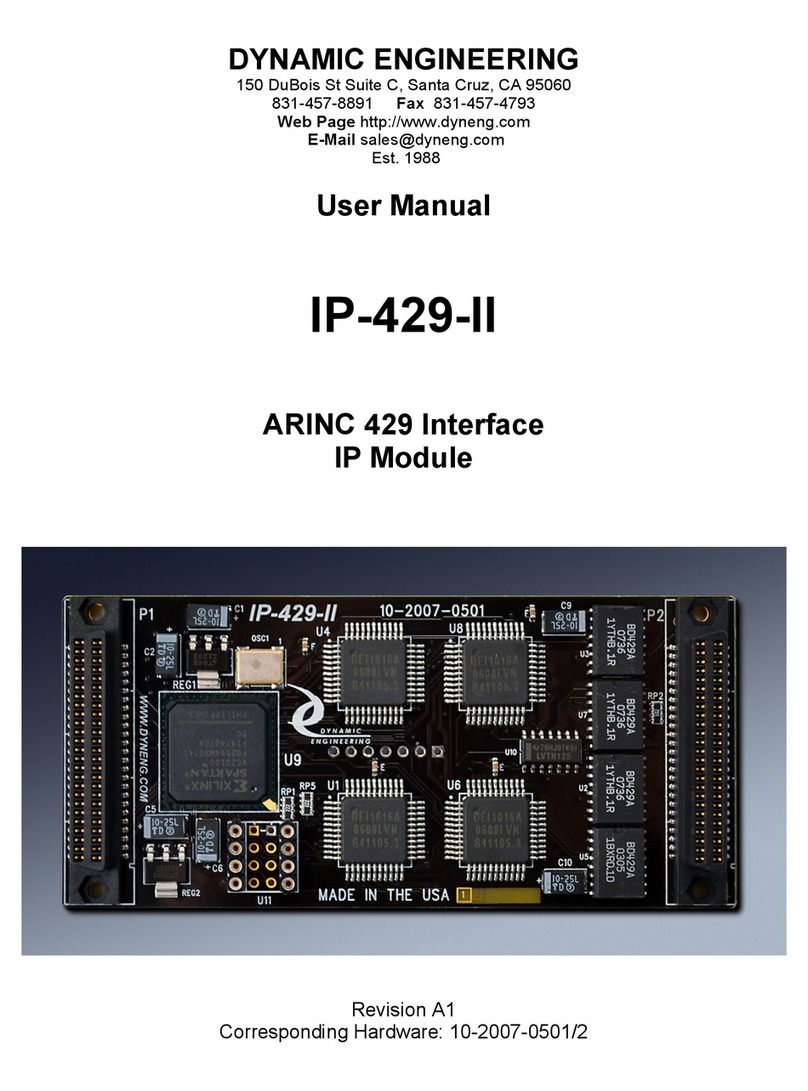

IP-CF is part of the IP Module family of modular I/O components. IP-CF is an adapter

which converts the IP bus protocol to IDE to allow a CompactFLASH module to be

installed into an IP slot. CompactFLASH is available in densities ranging up to

GigaBytes.

CompactFLASH modules can be communicated with in “true IDE” mode or with a

variant specific to CompactFLASH. IP-CF operates in IDE mode to allow other non-

CompactFLASH modules to be installed into the adapter.

The IP specification limits the height of the components above the IP to prevent

interference with the host card. IP-CF meets the type 1 [standard] height requirements

and can be used in any slot. A single socket can be placed on the IP Module and meet

the requirements. The IDE interface can be expanded to allow two CompactFLASH

units to be controlled from one IP-CF. The second unit would be installed on a

transition module.

The internal unit is set to be the master CompactFLASH device. The selection is done

with resistors installed at time of manufacture and can be altered by special request.

IP-CF has an oscillator position which is not used for the standard interface. If you have

a custom module which requires an alternate timing scheme the oscillator position can

be filled to support your requirements.

The state-machine has write-through capability to reduce the overhead on the local

CPU. The acknowledge signal is asserted when the data is captured within the Xilinx

and before the CompactFLASH device is written to. The state-machine completes the

data transfer to the CompactFLASH while the local CPU is completing the access and

potentially going on to the next set of instructions. If the CPU writes again before the

previous transfer is completed the new data is captured and held until the initial write is

completed before performing the second write. The acknowledge is held off until the

second write is protected to allow an overlapped pipeline to be established between the

host and the CompactFLASH with no loss of data.

Reads from the CompactFLASH data space are completed with the data fetched from

the CompactFLASH without hardware acceleration. We may add a pre-read feature in

the future to allow a similar no wait state access for the first read.

IP-CF supports both 8 and 32 Mhz. IP Bus operation. All configuration registers support

read and write operations for maximum software convenience. Word operations are