1 About this manual

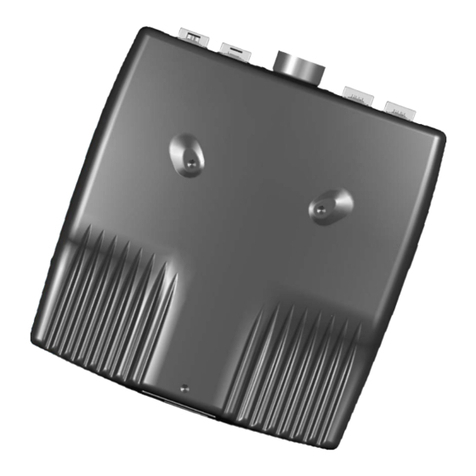

This manual can help you understand and install the

Dynamic Controls (DYNAMIC) RHINO2 scooter controller. It

describes the general principles, but it gives no guidelines

for specific applications. If there is a specific requirement for

your application, please contact Dynamic Controls or one of

the sales and service agents to assist you.

This manual must be read together with all other relevant

scooter component manuals.

In this manual, a few symbols will help you identify the

purpose of the paragraph that follows:

Note

Notes provide supporting information in order to install, configure, and

use the product. Not following the instructions given in notes can lead to

equipment failure.

Warning

Warnings provide important information that must be followed in order to

install, configure, and use the product safely and efficiently. Not following

the instructions given in a warning can potentially lead to equipment

failure, damage to surrounding property, injury or death.

The term ‘programming’ used in this manual refers to

adjusting parameters and configuring options to suit an

application. ‘Programming’ does not change or alter any

software within the controller and is performed using a

controlled programming tool available only to authorised

personnel.

The product is not user serviceable. Specialised tools are

necessary for the repair of any component.

This manual contains integration, set-up, operating

environment, test and maintenance information needed in

order to ensure reliable and safe use of the product.

Warning

Do not install, maintain or operate this equipment without reading,

understanding and following this manual – including the Safety and

Misuse Warnings – otherwise injury or damage may result.

Due to continuous product improvement, DYNAMIC reserves

the right to update this manual.

GBK51948 RHINO2

Installation Manual Issue 5

About this manual - Page 1

About this manual