Rhino to RHINO2 Conversion Guide Page 3

Contents

ABOUT .............................................................................................................................................................2

INTRODUCTION ...............................................................................................................................................4

INTRODUCING THE RHINO2 .............................................................................................................................5

PROCEDURE.....................................................................................................................................................6

STEP 1–CAPTURE THE EXISTING RHINO’S PROFILE ........................................................................................................ 7

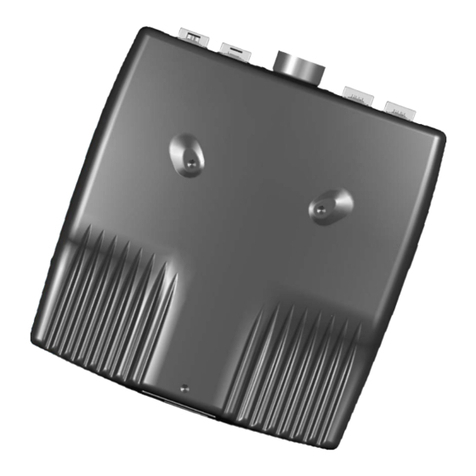

STEP 2–REPLACE THE RHINO CONTROLLER WITH THE RHINO2 CONTROLLER..................................................................... 7

STEP 3–ADAPT THE CABLES ..................................................................................................................................... 7

Install the motor, park brake and battery cable adaptors............................................................................. 7

Install the logic cable adaptor...................................................................................................................... 13

STEP 4–SET UP THE SCOOTER PROFILE...................................................................................................................... 14

Set up throttle parameters........................................................................................................................... 14

Set up drive performance parameters ......................................................................................................... 14

Set up motor management parameters ...................................................................................................... 14

Set up park brake management parameters ............................................................................................... 15

Set up battery management parameters..................................................................................................... 15

Set up actuator parameters (where fitted) .................................................................................................. 15

Fine tune Load Compensation...................................................................................................................... 15

To finish........................................................................................................................................................ 15

STEP 5–TEST DRIVE.............................................................................................................................................. 16

FURTHER INFORMATION ...............................................................................................................................17

PROGRAMMING.................................................................................................................................................... 17

EXTERNAL BATTERY CHARGER SOCKET........................................................................................................................ 17

LOGIC CONNECTOR ................................................................................................................................................ 18

Beeper Output.............................................................................................................................................. 18

Speed Reduction Wiper................................................................................................................................ 18

Forward-reverse input.................................................................................................................................. 18

Status LED .................................................................................................................................................... 19

SPEED SETTINGS.................................................................................................................................................... 19

SPEED REDUCTION ................................................................................................................................................ 19

ACCELERATION AND DECELERATION SETTINGS ............................................................................................................ 19

THROTTLE NEUTRAL OFFSET.................................................................................................................................... 20