4740 W. ELECTRIC AVE. • MILWAUKEE, WISCONSIN 53219 • 414/672-7830 • FAX 414/672-5354 • www.dingsbrakes.com

BK4773S-3 (6/2017) 6

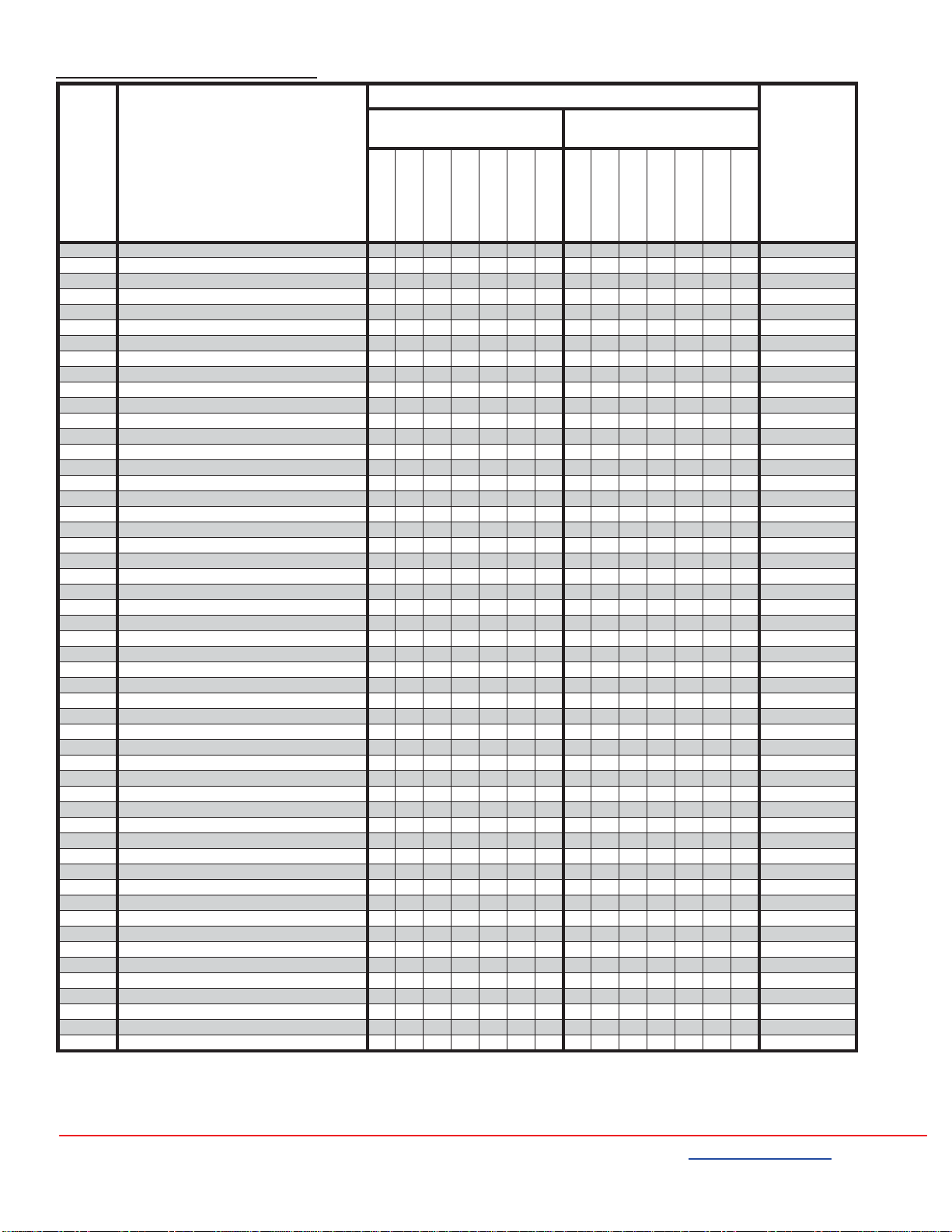

REPLACEMENT PARTS LIST (See Figure 2)

ITEM

NO. DESCRIPTION

MODEL

PART NO.

IP56 (NEMA 4) Endmount

without seal IP56 (NEMA 4) Endmount

with seal

71010-EC6S

71015-EC6S

71025-EC6S

72035-EC6S

72050-EC6S

73075-EC6S

74105-EC6S

71010-SC6S

71015-SC6S

71025-SC6S

72035-SC6S

72050-SC6S

73075-SC6S

74105-SC6S

1 Bracket assembly, 1&2 disc 1111 K070579-XXX

1 Bracket assembly, 1&2 disc with hub seal 1111 K070579-XXX

1 Bracket assembly, 3 disc 1 K070580-XXX

1 Bracket assembly, 3 disc with hub seal 1 K070580-XXX

1 Bracket assembly, 4 disc 1 1 K070581-XXX

1 Bracket assembly, 4 disc with hub seal 1 1 K070581-XXX

7 Handle, manual release 11111111111111H070422-002

11 Spring, return manual release 11111111111111G070846-001

12 Cam, manual release 11111111111111H070393-001

13 Screw, retaining, cam 11111111111111W001045-043

17 Post, pivot 11111111111111W002005-168

19 Stud post, magnet assembly/cover 22222222222222H070395-001

25 Disc, rotating friction 11223441122344H070394-001

26 Disc, stationary 11223441122344K070560-001

27 Spring, pivot 11111111111111G070847-001

28 Bolt, torque spring 22222222222222W001007-069

32 Pressure plate assembly, three phase 11111111111111H070423-001

37 Bushing, flanged 33333333333333W013007-061

42 Spring, torque, silver 2 2 G070848-001

42 Spring, torque, gold 222222 222222 G070849-001

43 Washer, flat 33333333333333W004002-008

44 Nut, adjustment 33333333333333W003013-005

46 Washer, magnet assembly base 22222222222222W004004-018

50A Magnet Assembly, three phase 11111111111111H070402-XXX

50 Magnet frame, three phase 11111111111111K070567-001

51 Coil, magnet, three phase 33333333333333H020003-XXX

54 Clamp, cable 11111111111111W021008-005

55 Screw, cable clamp 11111111111111W001038-143

59 Washer, shock absorber 22222222222222G070850-001

60 Washer, capture 22222222222222W004004-017

61 Nut, nylock magnet assembly 22222222222222W003001-020

65 O-ring, bracket/cover 11111111111111W006001-036

67 Cover, cast iron 11111111111111K070554-001

70 Sealing washer 22222222222222W011002-010

71 Nut, cover 22222222222222W003001-020

84 Nameplate, metal 11111111111111K070574-001

85 Drive screw 22222222222222W001012-048

86 Release label 11111111111111G070852-001

87 Capplug, 1/2 NPT 1111111W008003-001

87 Pipe plug, 1/2 1111111 W010002-004

88 Pipe plug, 1/8 11111111111111W010002-004

91 Bracket gasket 1111111 K070250-005

99 Hub assembly 1 disc 1 1 1 H070409-XXX

99 Hub assembly 2 disc (35lb-ft) 1 H070412-XXX

Hub assembly 2 disc (50lb-ft) 1 H070414-XXX

99 Hub assembly 3 disc 1 H070417-XXX

99 Hub assembly 4 disc 1 H070420-XXX

99 Hub assembly 1 disc w/seal 1 1 1 H070410-XXX

99 Hub assembly 2 disc (35lb-ft) w/seal 1 H070413-XXX

Hub assembly 2 disc (50lb-ft) w/seal 1 H070415-XXX

99 Hub assembly 3 disc w/seal 1 H070418-XXX

99 Hub assembly 4 disc w/seal 1 H070421-XXX

XXX - Part number depends upon brake model number

Table 1. Parts List