From lab to production,

providing a window into the process

-2-

www.dynisco.com

Rev: n/aP/N: n/a ECO: n/a

CAUTION: Installaon should be only performed by technically competent

personnel. Local Regulaons regarding electrical installaon & safety must be

observed. The host equipment is required to provide a suitable electrical, mechanical

and re enclosure to meet relevant safety standards. Impairment of protecon will

occur if the product is used in a manner not specied by the manufacturer.

CAUTION: All power supply connecons to the device must be removed when

carrying out any form of maintenance.

1. Installaon

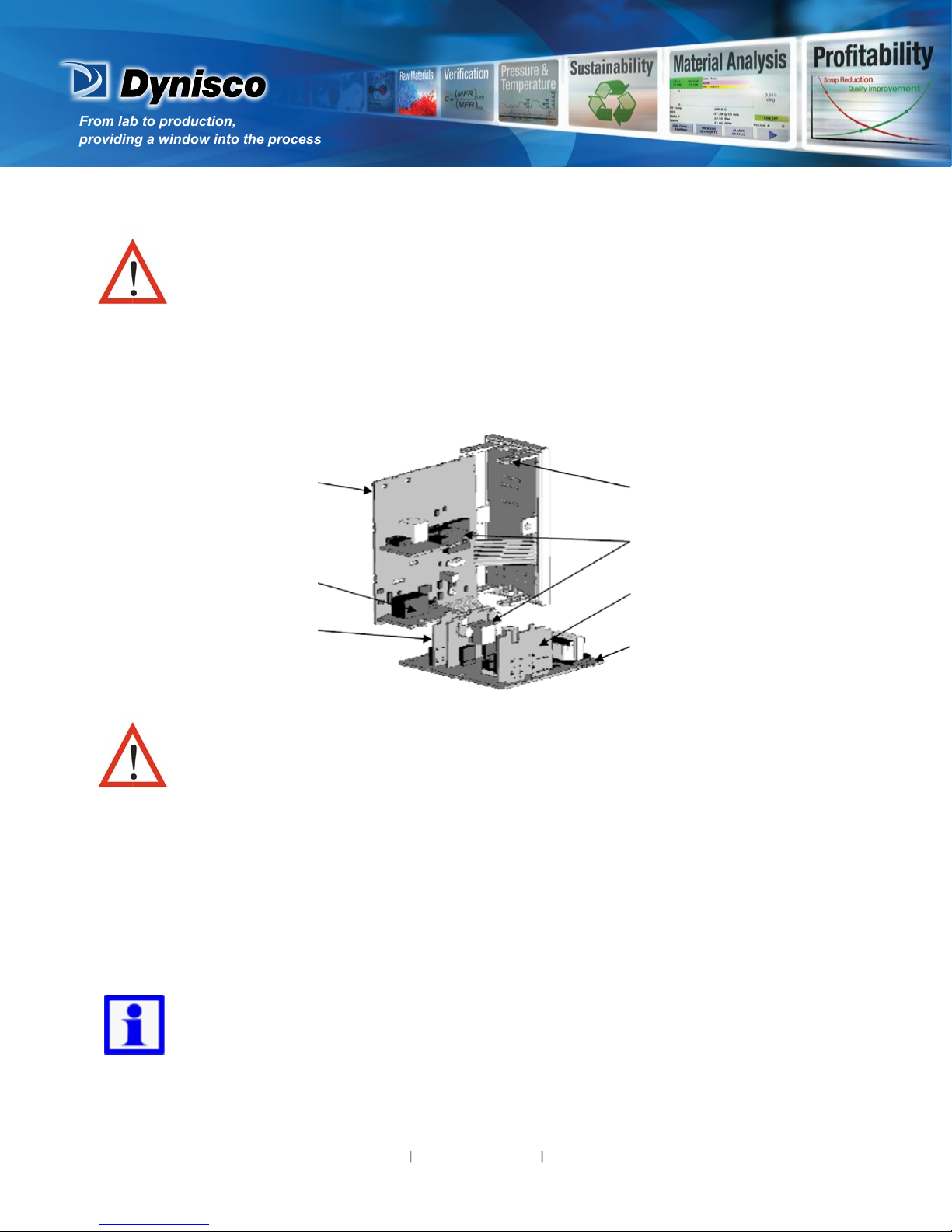

Installing Opon Modules/Maintenance

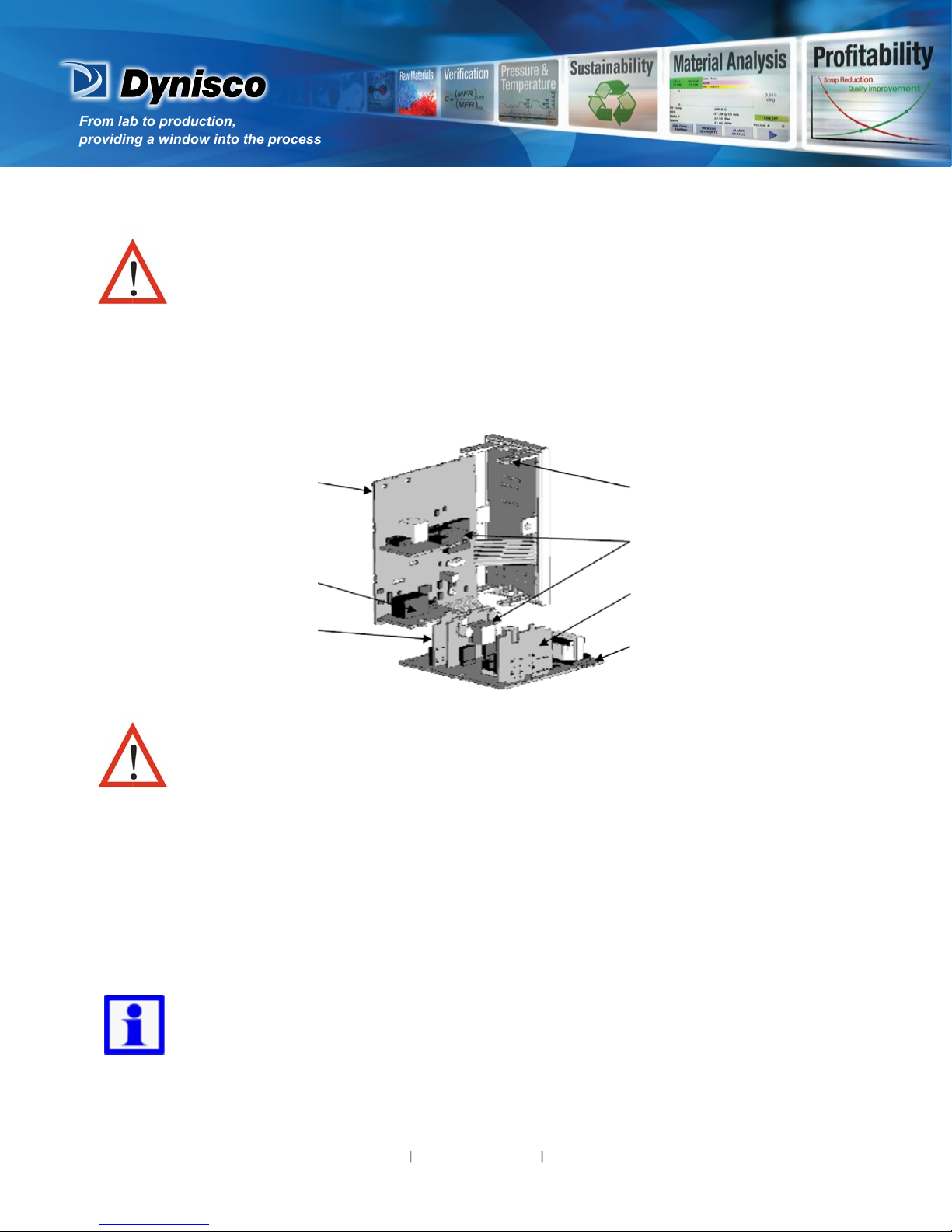

CPU PCB

Opon Module 2

Opon Module 1

Mounng Struts

Opon Module 3

PSU PCB

Future Opons

To access modules, rst detach the PSU and CPU boards from the front by liing rst the upper, and

then lower mounng struts. Gently separate the boards.

a. Plug the required opon modules into the correct connectors, as shown below.

b. Locate the module tongues in the corresponding slot on the opposite board.

c. Hold the main boards together while relocang back on the mounng struts.

Replace the instrument by aligning the CPU and PSU boards with their guides in the housing, then

slowly push the instrument back into posion.

NOTE: Opon modules are automacally detected at power up.