REV A ECN 14100 04/23/18 3

Equation 1 above, defines the low frequency

at which the accelerometer sensitivity will be 3db

down when compared to the reference sensitivity

measured at 100 Hz. The discharge time constant for

Model 3306A is 6.2 Sec. yielding a lower -3db

frequency of 0.03 Hz, from equation 1. Due to the

extremely long dischange time constant the sensor

might exhibit spiking during fast thermal transients

As rule of thumb, the lower -5% frequency is

three times the -3db frequency or 3 x .03 = 0.09 Hz.

INSTALLATION

(Refer to Outline/Installation drawing 127-

3312A2T) To install Model 3312A2T, is necessary to

prepare (or find) a flat mounting area of approximately

1 inch diameter. Ideally, the mounting surface should

be flat to .001 in. TIR. The flat mounting surface

ensures intimate contact between accelerometer base

and mounting surface for best high frequency

transmissibility, thus accuracy.

At the center of the mounting area, drill and

tap a 10-32 mounting port in accordance with

instructions on drawing 127-3312A2T. Clean the area

to remove all traces of machining chips, burrs, etc.

Next, thread the Mod. 6200 mounting stud

into the base of the 3312A2T. The stud should enter

easily and thread in up to the raised collar of the stud

by hand. This collar prevents the stud from bottoming

inside the tapped hole in the 3312A2T where it could

possibly cause stresses in the base structure which

could, in turn, cause anomalous behavior of the

accelerometer at higher frequencies.

After seating the stud, spread a light coating

of silicone grease, or other lubricant, on either of the

mating surfaces and thread the accelerometer/stud

combination into the tapped hole by hand, until the

accelerometer base seats against the mounting

surface. Check to see that the mating surfaces are

meeting properly, i.e., that they are meeting flush and

that there is not an angle formed between the two

surfaces indicating that they are not co-planar. If this

condition is observed, torquing the accelerometer

down will strain the base causing possible poor

frequency response and even erroneous reference

sensitivity. Inspect the perpendicularity of the tapped

hole.

If the hand-tight meeting between the two

surfaces is satisfactory, torque the 3312A2T to the

mating surface with 20 to 25 lb-inches of torque,

preferably measuring the torque with a torque wrench

torquing on the hex surface only.

Proper torque will ensure the best high

frequency performance from the instrument as well as

repeatability of sensitivity when mounting and

remounting.

Connect the cable (typically Model 6019AXX

to the accelerometer snugging up the threaded lock

ring tightly by hand.

NOTE: Do not use a pliers or vise grips on

the knurled lock ring. This could damage the

connector of the 3312A2T and/or the cable

connector.

To avoid stressing the cables which could

lead to early failure, especially under larger

excursions of the test object, it is good practice to tie

the cable down to a fixed surface near the mounting

area at a point approximately one inch from the

accelerometer.

If there is excessive motion between the

accelerometer and the nearest tie point, allow a strain

loop of cable to let relative motion occur without

stressing the cable.

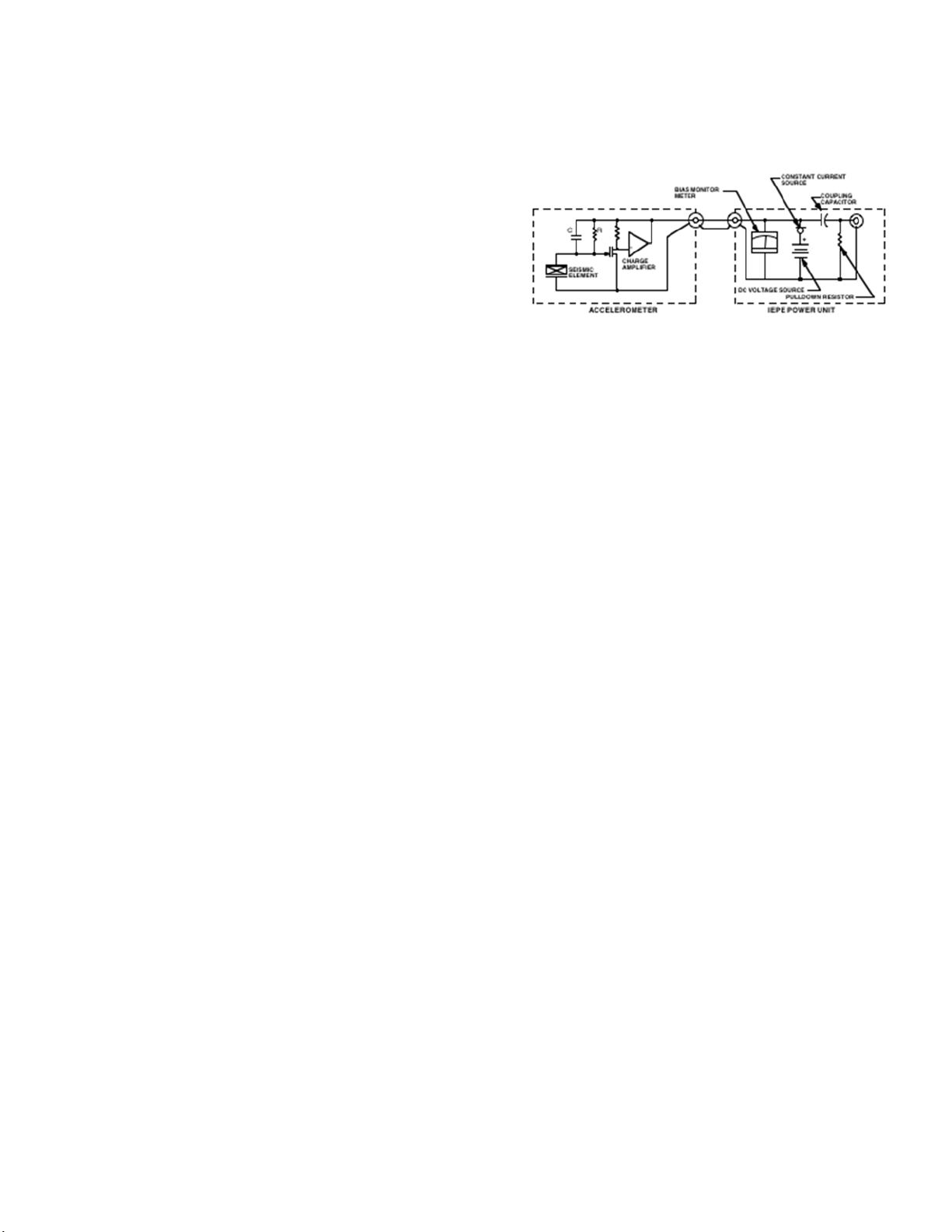

Connect the other end of the cable to the

"Sensor" jack of the Dytran power unit (Models 4102,

4103, 4110, 4114, etc.) and switch the power on.

Observe the monitor voltmeter located at the

front panel of each of the power units. If the meter

reads in the mid-scale region, (labeled "Normal"), this

tells you that the cables, accelerometer and power

unit are functioning normally and you should be able

to proceed with the measurement.

Check for shorts in the cables and connectors

if the meter reads in the "Short" region. Check for

open cables or connections if the meter reads in the

"Open" area. In this manner, the meter becomes a

trouble shooting tool for the measurement system.

HIGH FREQUENCY RESPONSE

All piezoelectric accelerometers are basically

rigid spring mass systems, i.e., second order systems

with essentially zero damping. As a result, these

instruments will exhibit a rising characteristic as the

resonance is approached. A filter incorporated into

Model 3312A2T compensates for this rise.

The frequency at which the sensitivity may

increases or decrease by 5% is approximately 4000

Hz, the frequency to which the 3312A2T is calibrated.

The accelerometer is usable above this frequency but