-1-

[A] Specific Features

1. Combination of Advantages of Reinforced Plastic with Those of Elastomer

The outer shell is made of reinforced plastic formed with glass cloth (=GRP) or cotton cloth (=CRP), and the

sliding face is made of elastomer. Therefore, it is of high adhesive property, excellent corrosion resistance

and light weight.

2. Outstanding Durability and Stable Performance

Shaft load is balanced by high elasticity of rubber and increased coverage area to avoid concentrated load in

the aft end.

3. Effective Absorption of shaft vibration

With the unique features of rubber, the EVR absorbs shaft vibration and prevents premature wear down of

components.

4. Prevention of Electrolytic Corrosion on the Shaft Sleeve

Since the construction materials are non-conducting, EVR bearing cuts the corrosive electric current from

the shaft sleeve and prevents the shaft sleeve surface from getting sough.

5. Easy Handling

The handling is very easier at light weight than metal materials.

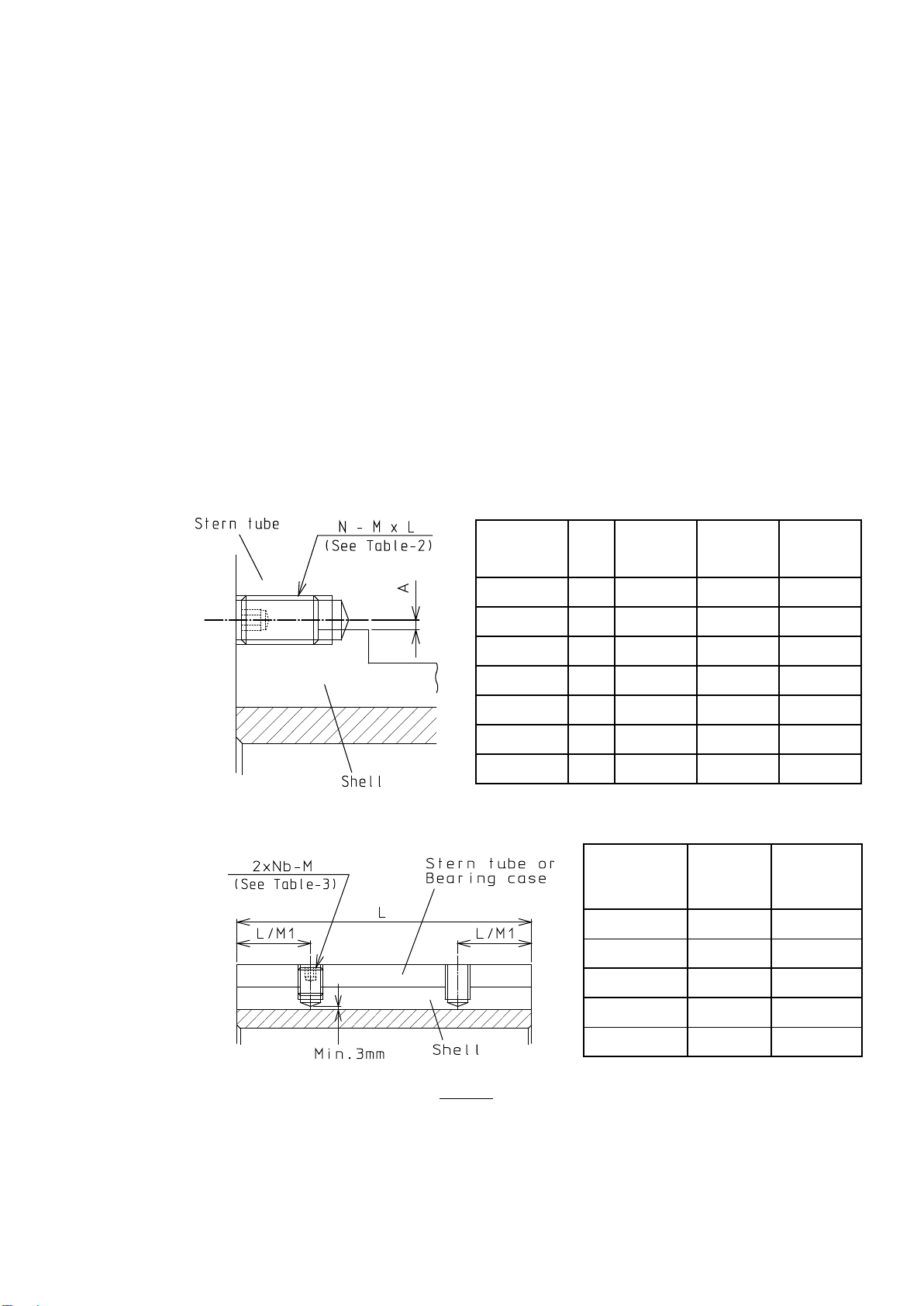

After inserted it in the stern tube, it fits to the stern tube by the imbibition of the outer shell. Therefore, it

can insert to the stern tube by clearance fit. It is not necessary to press fit, and easier.

[B] Handling

Be careful about the following, and handle it until insert to stern tube.

1. Avoid the leaving under direct rays of the sun and the high temperature. And keep it indoors so that it is not

polluted by rain and sludge.

2. Protect it with the vinyl sheet to prevent the alien substance mixture and the paint adhesion.

3. Do not adherence the solvent, the grease and the oil to the Rubber.

4. Do not give a shock during the transportation and storage.

5. Be standing as possible other than transportation.

6. Do not put the thing on the top of EVR.

7. The hue of outer shell may change with progress of the time. But, in product properties, does not have any

problem in performance.