Eagle T20CF User manual

-1 -

Operations Manual

Eagle T20CF Carton Erector

READ ALL INSTRUCTIONS CONTAINED IN THIS

MANUAL PRIOR TO MACHINE INSTALLATION!

- 2 -

Contents

page

1. Safety & Warnings 3

2. Specifications 4

3. Setup and Installation 5

3.1 Transportation 5

3.2 Tape Head Installation 5

3.3 Power Supply 5

4. Operation 6

4.1 Standard Operation 6

4.2 Case Erector 6

4.3 Carton Size Adjustment 7

4.4 Feeding Adhesive Tape 8

4.5 Control Panel Operation 8

4.6 LCD Display Operation 9

5. Maintenance & Troubleshooting 10

5.1 Maintenance 10

5.2 Troubleshooting 10

6. Illustrations & Parts List 12

6.1 Replacement Parts 12

6.2 Carton Storage Shelf 13

6.3 Carton Storage Table 14

6.4 Carton Pre-Storage Table Lifting Body 16

6.5 Back Cover Carton Push & Fold 18

6.6 Machine Frame 20

6.7 Front Cover Folder 22

6.8 Conveyer Belt 23

6.9 Vacuum-Assisted Carton Placer 25

6.10 Blocking Pin & Press Plate 27

6.11 Left & Right Cover Folder 29

6.12 Carton Sealer –Front Roller 31

6.13 Carton Sealer –Rear Roller 33

6.14 Carton Sealer –Roller 34

6.15 Guide Pulley 35

6.16 Tape Knife 36

6.17 Tape Dispenser 37

6.18 Tape Wheel 38

6.19 Tape Press 39

6.20 Tape Guide 40

6.21 Electrical Diagrams 41

- 3 -

1. Safety and Warnings

WHILE OPERATING THE MACHINE, OPERATORS MUST REFRAIN FROM

WEARING CLOTHING OR ACCESSORIES THAT MAY GET CAUGHT IN THE

MOVING PARTS OF THE MACHINE

(WATCHES, RINGS, BRACELETS, TIES, LOOSE CLOTHING, ETC…)

This manual covers safety precautions, parameters, machine operation, maintenance, and troubleshooting

information.

Prior to setting up the machine

1. Verify the model number matches the model number addressed in this manual.

2. Verify that no parts of the machine have been removed or are missing.

3. Remove all packaging or shipping materials used during transport or storage of the machine.

4. Check for any damage that may have occurred during shipping or transport.

Prior to operating the Eagle T20CF, verify

•Verify power supply voltage matches the requirements of the machine.

•Protective shielding and covers are properly installed

•Machine is on stable ground and casters are in the locked position.

The Eagle T20CF is designed to automatically shut down if the control panel is opened while the machine is in

operation.

- 4 -

2. Specifications

Power Requirement

220VAC, 50/60Hz (Single Phase)

Air Supply

85psi (6Kgf/cm2)

Tape Width

2-3in (48-72mm)

Working Speed

0-12 cases per minute

Carton Length

11-20.5in

Carton Width

7-11in

Carton Height

11-24in

Machine Length

80.7in

Machine Width

86.6in

Machine Height

53in

Weight

882lbs

Operational Environment

32-104ºF (0-40ºC) @ ≤ 98% Humidity

Machine Noise Levels

≤ 75db

- 5 -

3. Machine Setup and Installation

TAKE CARE TO AVOID DAMAGE TO THE MOTOR AND ASSEMBLY WHILE LIFTING

OR TRANSPORTING THE MACHINE!

3.1 Transportation

Use a fork lift or tow motor to remove the machine from its shipping container or pallet.

3.2 Tape Head Installation

Remove the front supporting shaft. Rest the rear of the tape head on the rear supporting shaft. Place the front

supporting shaft on the angled notches in the front of the tape head and lower the tape head down guiding

the pin into the notches in the frame.

Check tape cutter position and adjust as needed.

3.3 Connect Power Supply

Connect the machine to the power supply.

Note: Prior to connecting the machine to the power supply, verify that the power switch is set to the ‘OFF’

position and that the work area is clean and clear of any items.

- 6 -

4. Operation

4.1 Standard Operation

Prior to operating the machine, please confirm that

1. The proper voltage is being supplied to the motor

2. All fasteners and protective covers are securely in place

3. All electronic components are dry

Machine Operation

1. Plug the machine into the power source

a. DO NOT hard wire the machine to the power source

2. Turn on air supply.

3. Feed cartons to be erected into storage tray

4.2 Case Erection

1. Adjust the machine for the size of the cartons to be erected.

2. Place the cartons on the carton storage shelf.

3. Machine will place carton, fold front and rear lower flaps, fold left and right lower flaps, and seal

bottom of the carton.

- 7 -

4. Operation

4.3 Carton Size Adjustment

Width/2 Adjustment

Width Adjustment

Press Plate Height

Adjustment

Length + Width Adjustment

Length Adjustment

Width Adjustment

- 8 -

4. Operation

4.4 Feeding the Adhesive Tape

Guide tape roller

Rubber roller

Adhesive tape core adjustment button

Adhesive tape

Adhesive tape

Press tape board

Guide tape board

Unidirectional

lozenge pattern roller

Guide tape roller

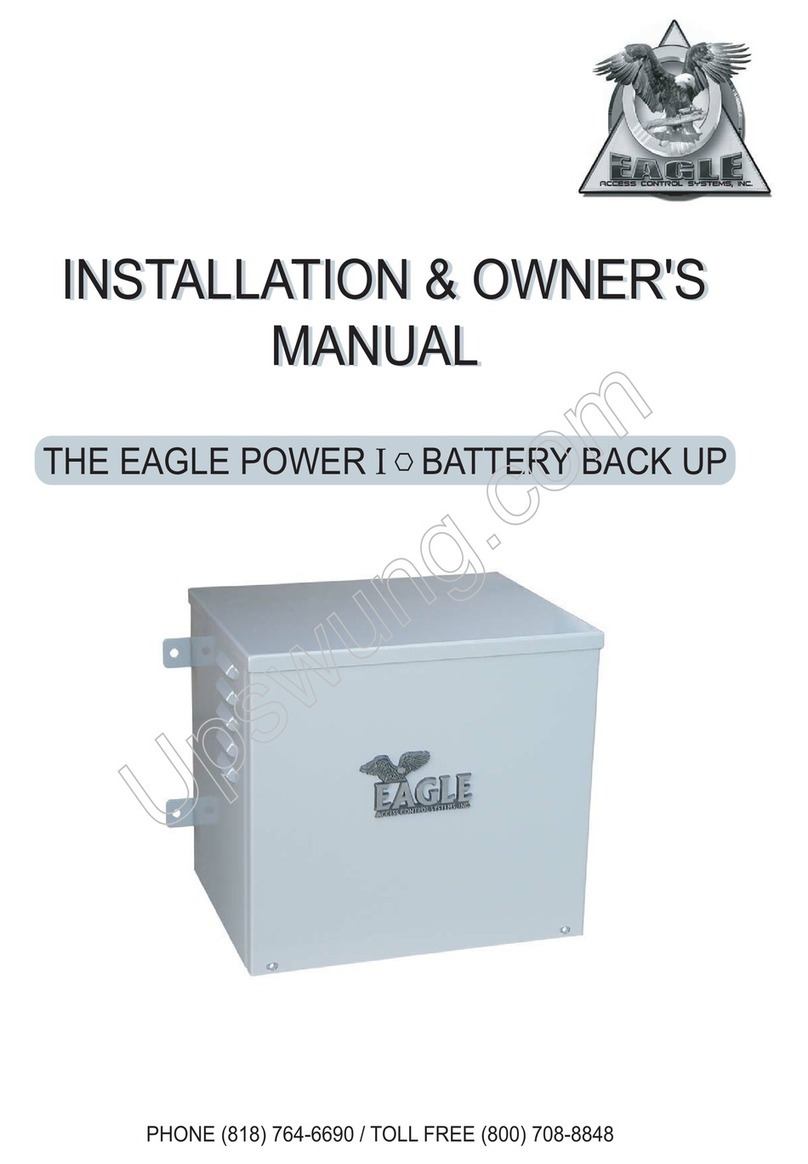

4.5 Control Panel Operation

Before operating the machine, the operator should review the features and functions of every switch to

ensure the correct and safe operation of the machine.

1. Power Indicator

2. Power Switch

3. LCD Display Screen

4. Emergency Stop Button

5. Start Button

6. Stop Button

7. Reset Button

5

3

7

1

6

4

2

- 9 -

4.6 LCD Display Operation

Start Screen

Once the machine has fully powered up, this

screen will be displayed. Continue by

pressing the button labeled “CONTINUE”.

Automatic Mode

There are two automatic operation modes.

In the first mode, the machine will run

continuously until carton stock has been

exhausted. The second mode, called “Set

Qty”, will erect a preset number of cartons

and will stop the machine once the preset

number of cartons have been completed.

Manual Mode

While in manual mode, the machine will

allow for operation in which it will pause

after each step and wait for input from the

operator before continuing.

- 10 -

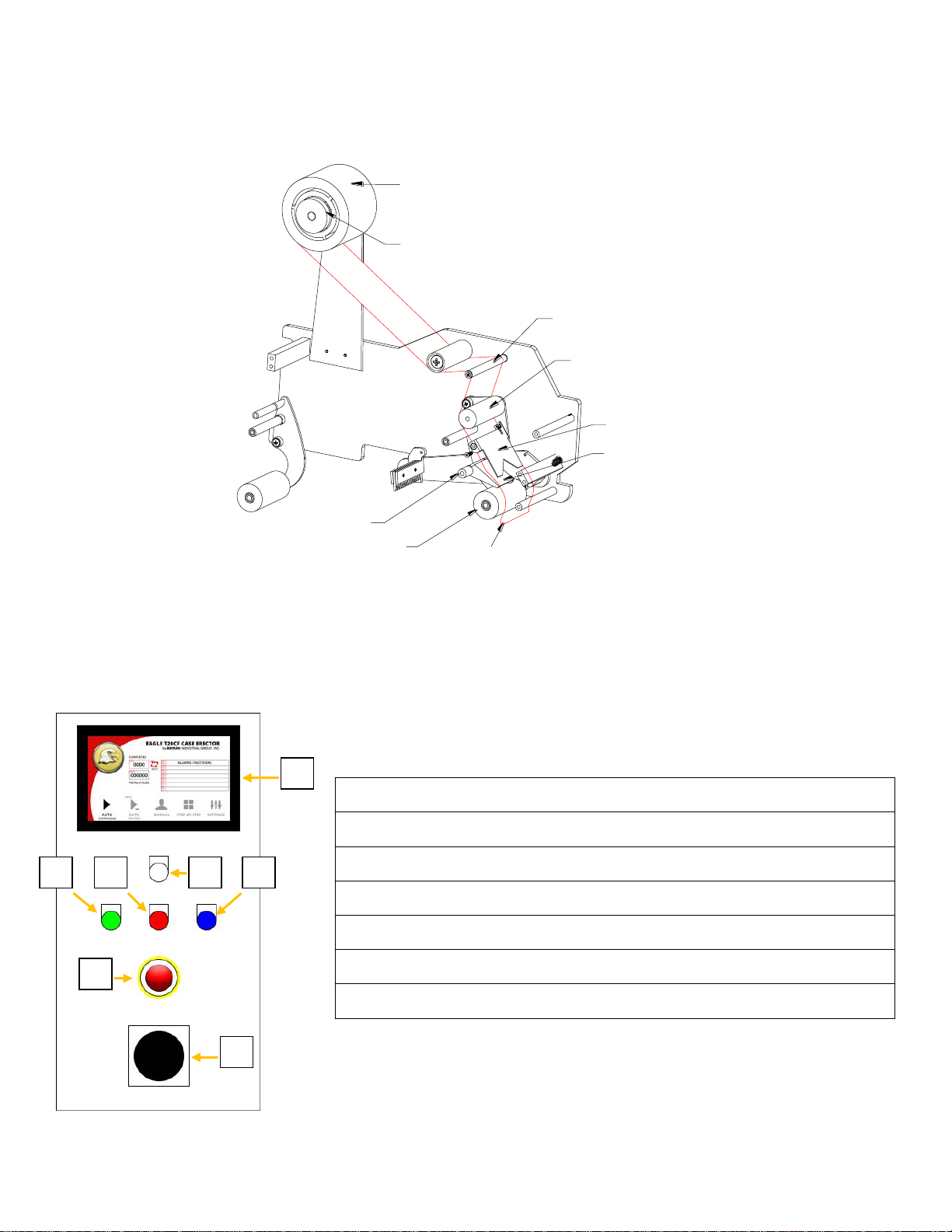

4.6 LCD Display Operation

Step-by-Step

This screen permits the user to run the

machine one step at a time. The first step is

to load the carton into the folding position.

This is accomplished by pressing the green

icon labeled “LOAD BOX INTO FOLDING

POSITION”. Then press “PROCEED TO NEXT

STEP” to move through each step until the

completed carton is driven out of the

machine.

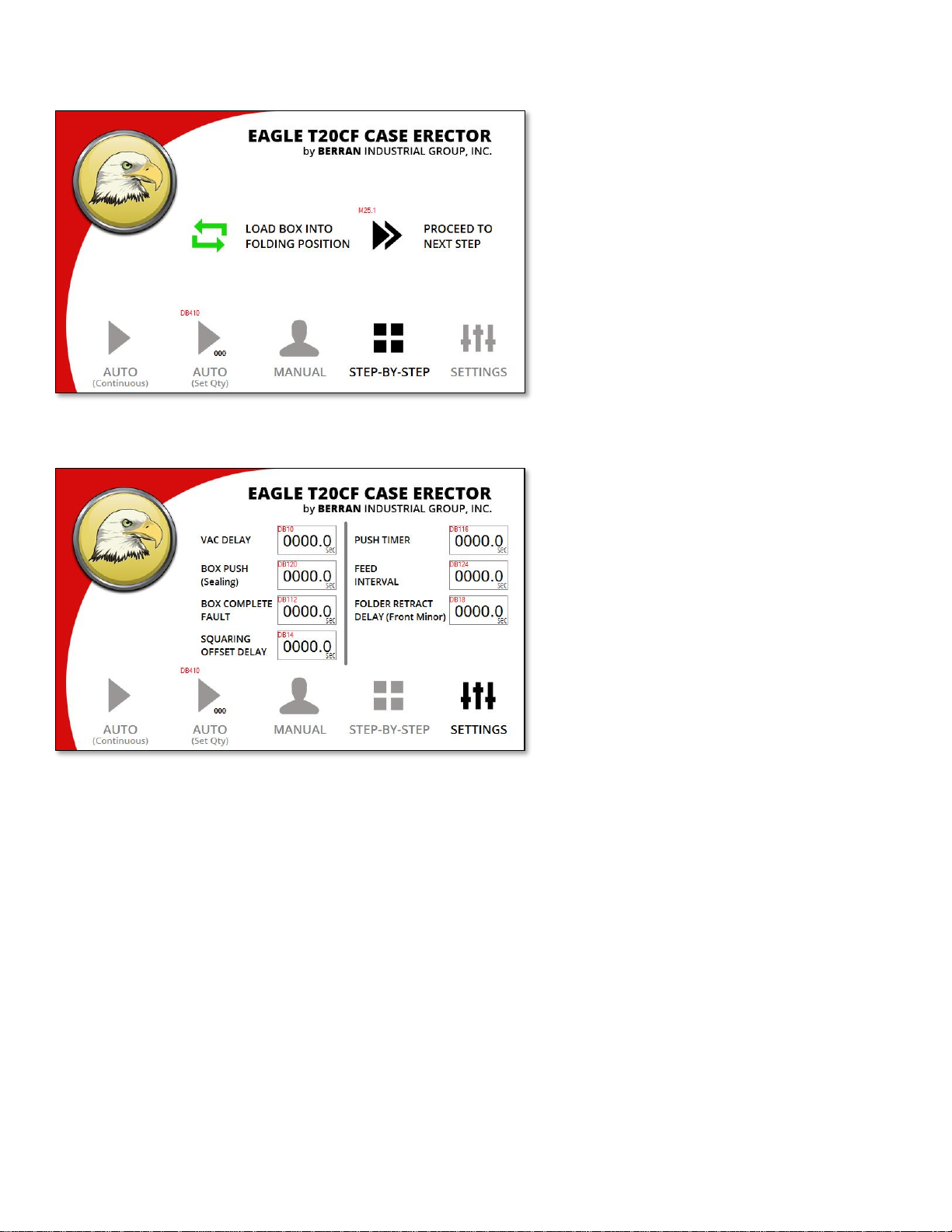

Settings

This is the screen where fault timers and

action timers can be modified.

Table of contents

Other Eagle Industrial Equipment manuals