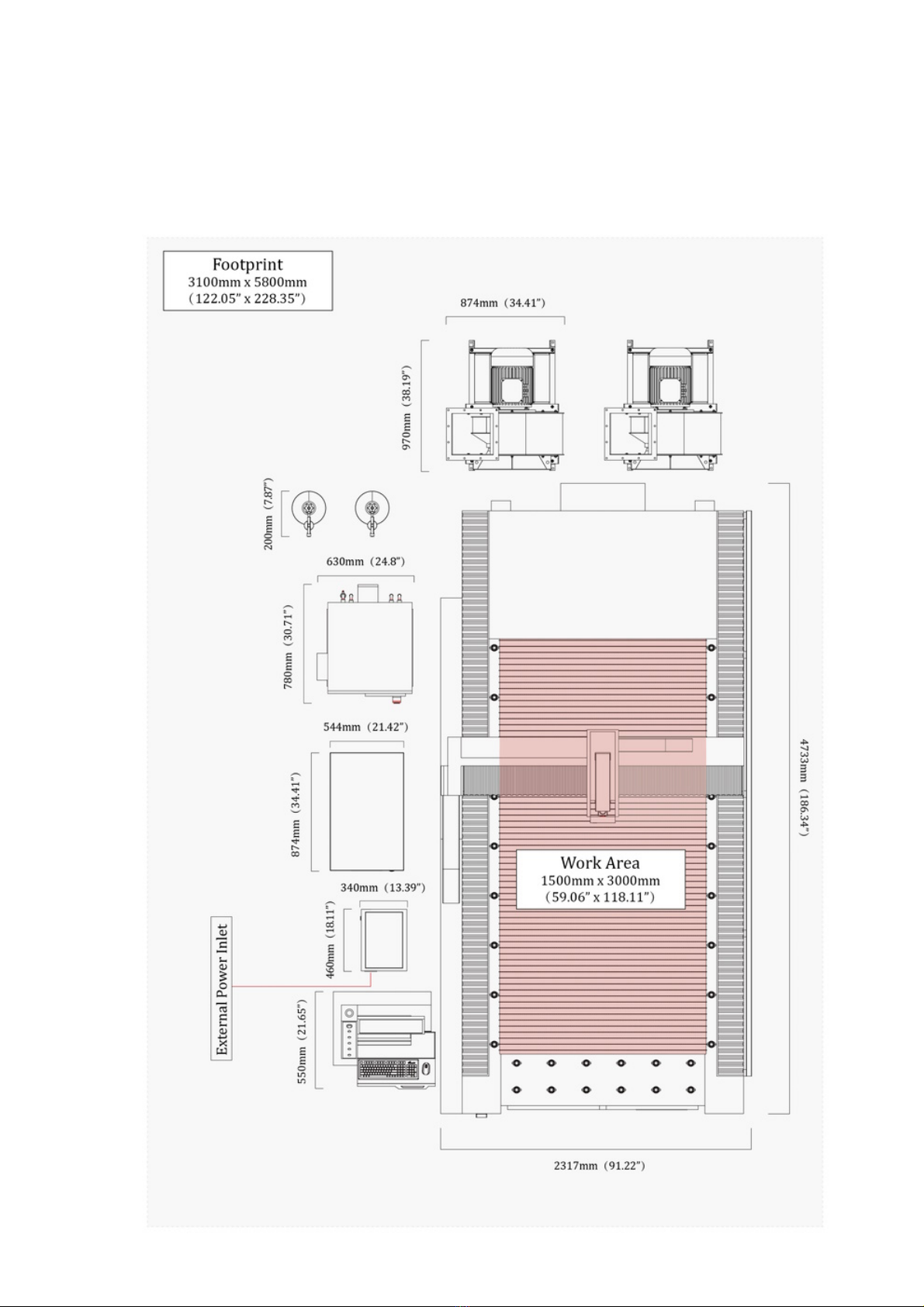

The weight of the machine is around 4500lbs, 2000kg. Precise leveling of the ground is not necessary,

but it should be reasonably level and sturdy enough to support the machine well.

The laser system comes with a 16ft, 5m power cord, prepare the electrical power interface in a

reachable position according to the transformer in the footprint.

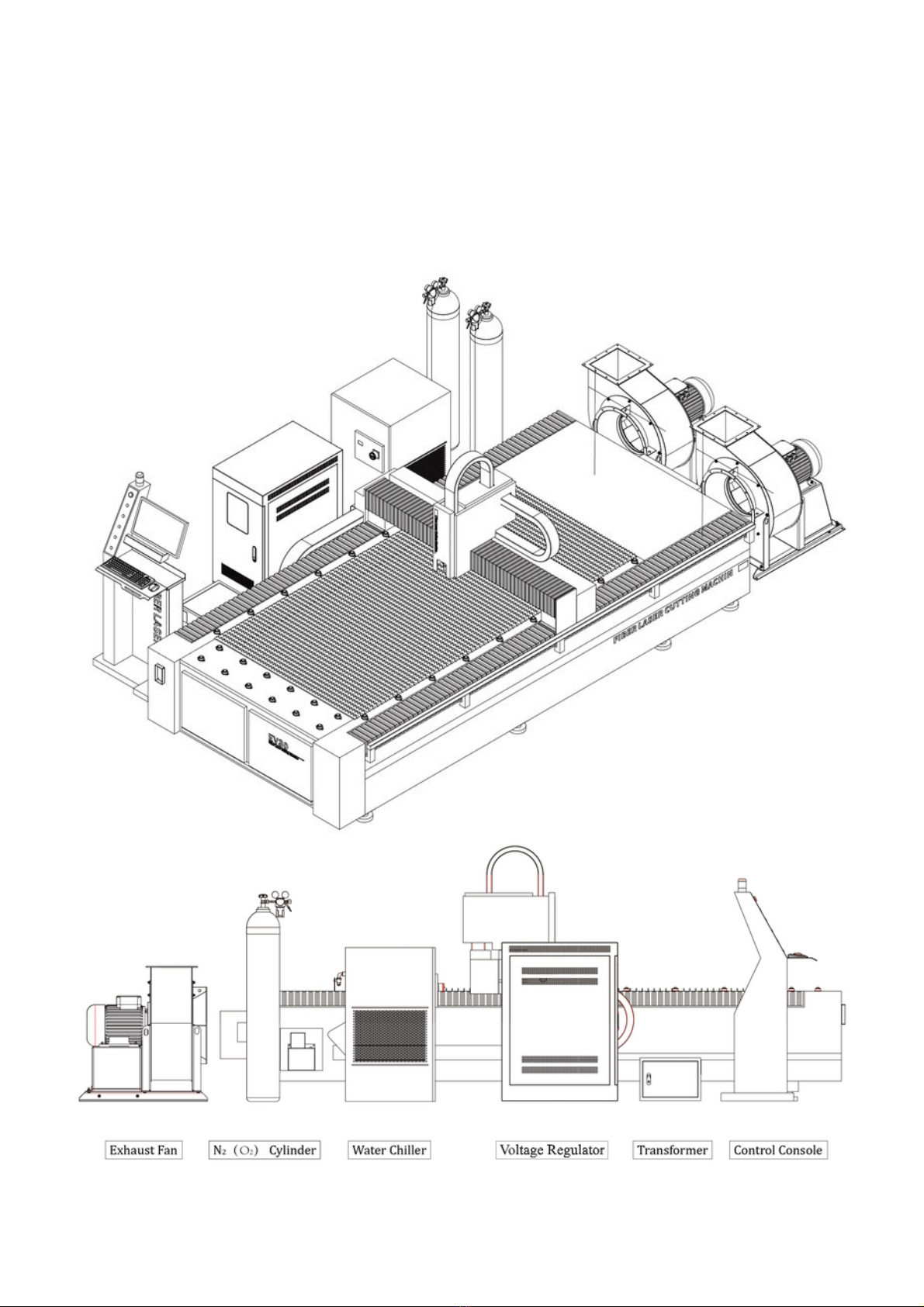

The assist gas system should be set according to the gas cylinder in the footprint.

The duct work should be set close to the exhaust(s) if there is such a system in your facility.

There should be enough space to load sheets onto the cutting bed from the front and the right side of

the machine.

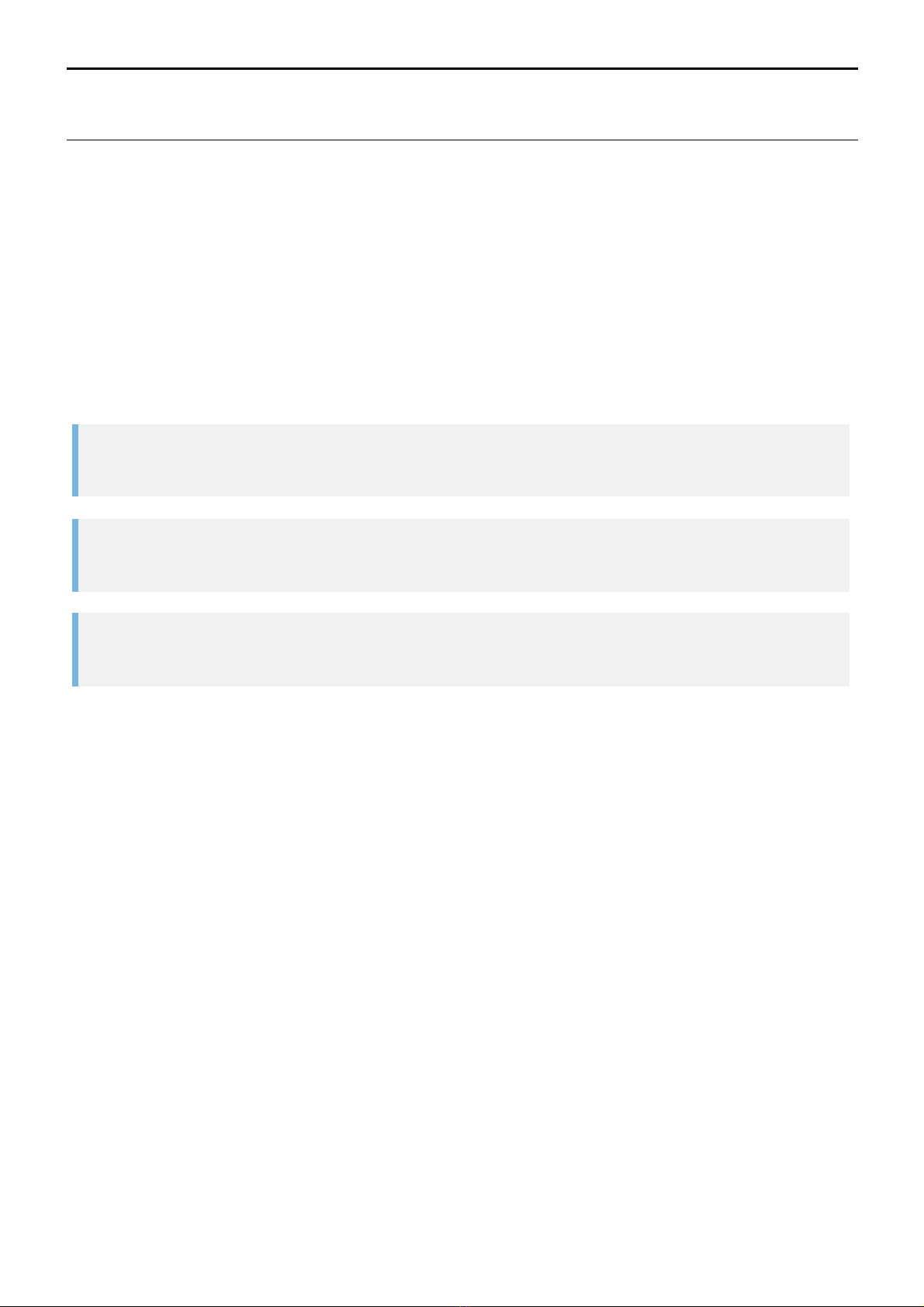

2. Electrical Power Requirements

The EV-30 laser system requires 3-phase 480-volt electrical power. The overall power consumption will

differ according to the laser configuration of your system.

Laser Configuration Overall Power Consumption

3 kW 40 kW

6 kW 80 kW

NOTE

It is recommended that a dedicated circuit be used if available, but it is not required.

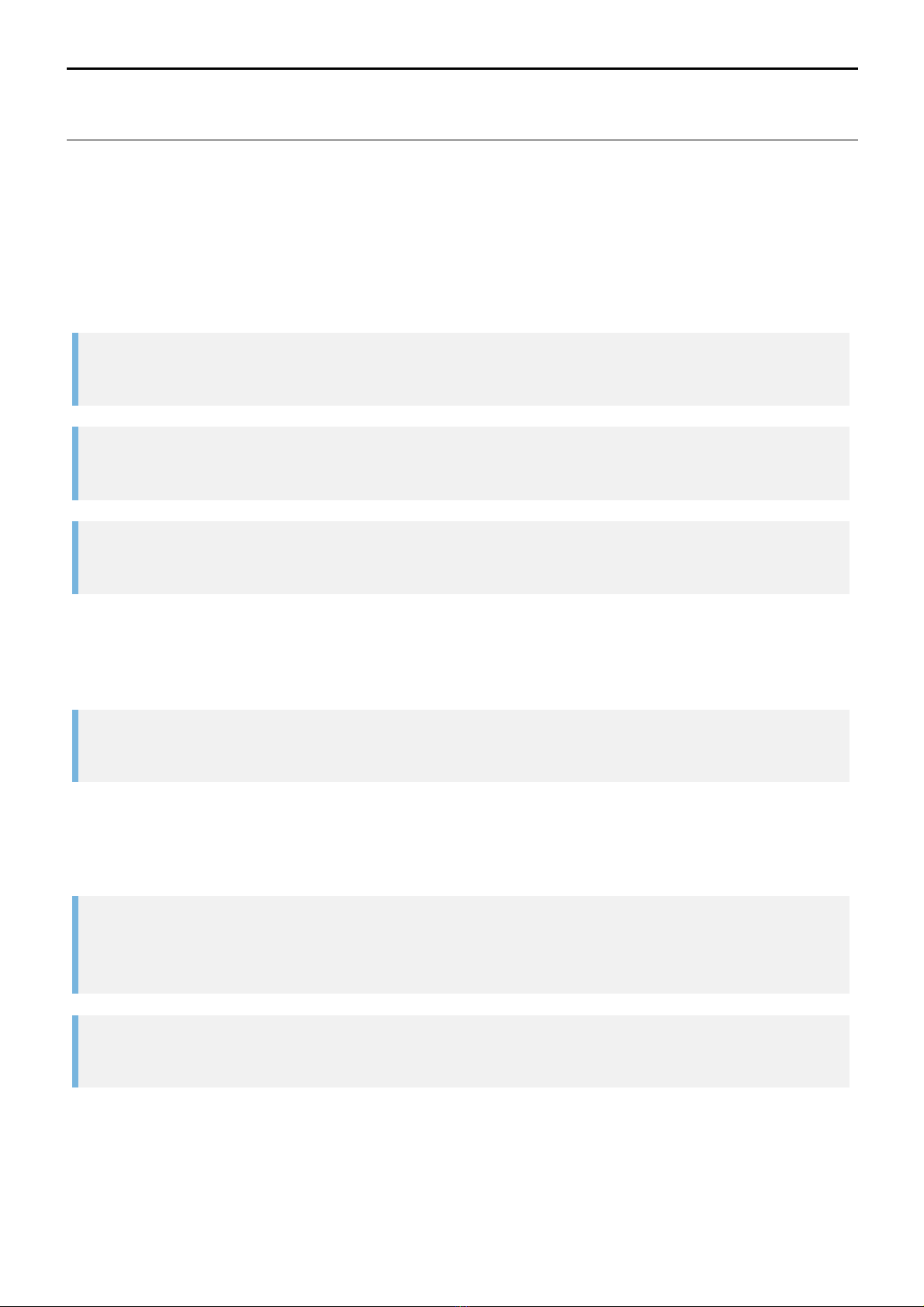

3. Cooling Requirements

Laser technology is such that the laser units generate a lot of excess heat and the units must be cooled

for proper operation. The EV-30 laser system comes with a chiller to do this job, which needs to be

filled up with appropriate water.

Water Type Water Consumption

Purified / Distilled 15-40 L (4-10.5 gal)

IMPORTANT

Other types of water may corrode the pipeline inside the fiber laser, and weaken the cooling

effects.

IMPORTANT

Add antifreeze to cooling water to protect the fiber laser from freezing if the ambient

temperature could be below 5°C (41°F). Otherwise, it may cause SEVERE DAMAGE to the core

components of the laser.