ASSEMBLY GUIDEASSEMBLY GUIDE

3

025G

025C

025B

025K

025D

025J

025G 025G

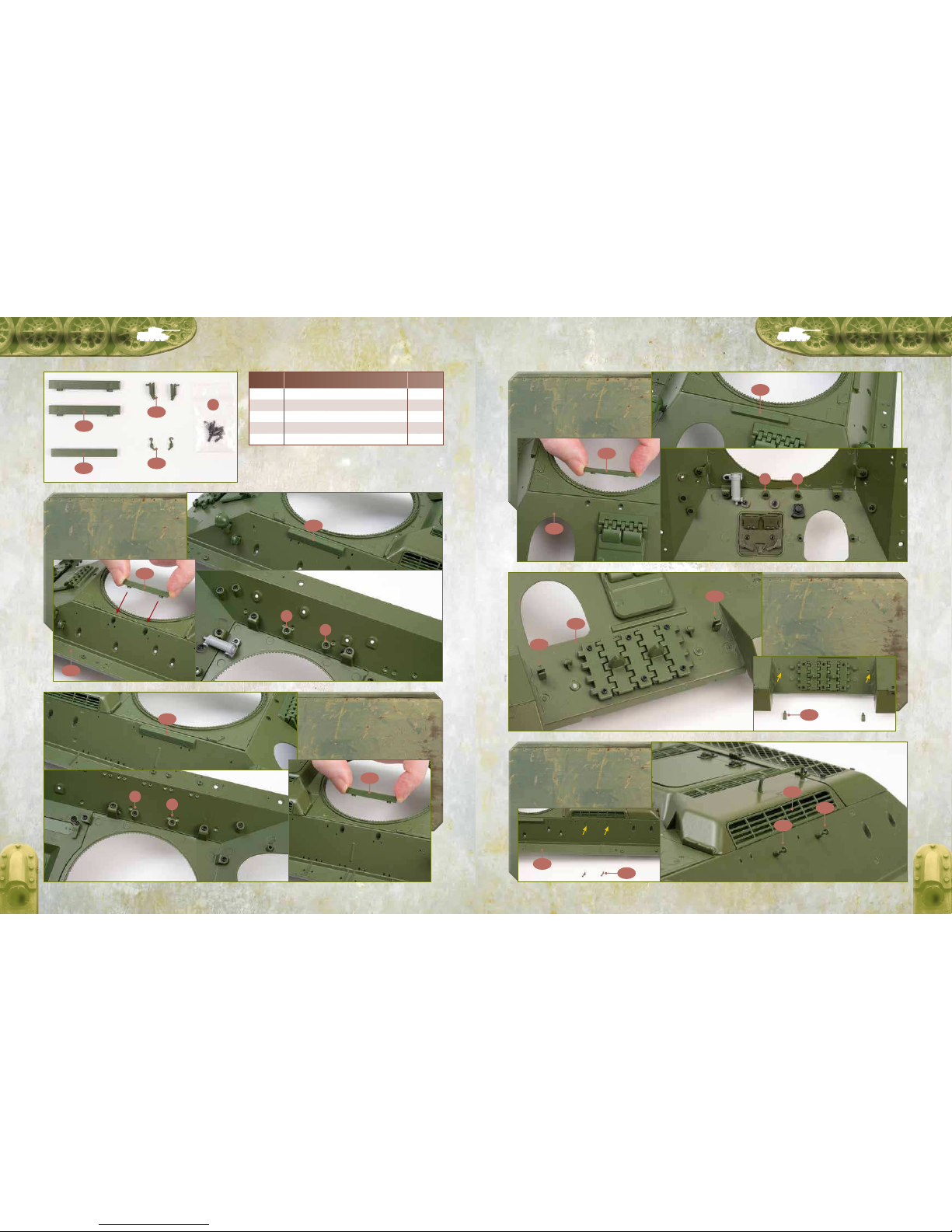

4Clip the hinge pins of the two

persicope inner covers (025G)

firmly into the hinge bases on

the driver’s hatch inner face (025F).

6Clip the hinge pins of the left

periscope cover (025C) into

the hinge base on the driver’s

hatch (025A) so that it covers the

left periscope. Repeat for the right

periscope cover (025D). Then clip the

driver’s hatch hinge (025B) over the

other side of the hinge base.

7Fit the driver’s hatch assembly

over the central aperture in the

front of the upper hull (012A)

and engage the two screw posts in

the underside of the hinge (025B)

with the holes above the aperture.

Turn the upper hull upside-down

and place the two spacers (washers)

(025K) over the protruding screw

posts, then fix with two HP screws.

8This is how the

driver’s hatch looks

when it is fitted.

NOTE: With the lock

handles (025H and 025I)

unfastened on the inside,

the hatch can be lifted up

and down.

5Push the driver’s hatch closing

handle (025J) into the two

holes in the driver’s hatch

inner face (025F) in the position

shown.

HP HP

025F

025F

025A

012A

025G

025J

025B

025C

025K

025D

025E

025H

025F

025E

025A

025G

1Fit the driver’s hatch left hook

handle (025H) and right hook

handle (025I) to the driver’s

hatch inner face (025F) in the

positions shown. Fix each handle

from behind with an HP screw.

3Fit the driver’s hatch inner face

(025F) over the driver’s hatch

(025A), ensuring that the screw

posts engage with each other inside

and that the persicopes protrude

through the two rectangular apertures.

Fix with two BP screws.

2Push the driver’s periscopes

(025E) into the two rectangular

apertures in the driver’s hatch

(025A). Ensure that the two ridges

between the periscopes fit over the

single off-set ridge between the two

holes – the persicopes will therefore

only fit correctly one way round.

BP HP

HP

BP

HP

BP

CODE

NUMBER COMPONENT NAME QUANTITY

025A Driver’s hatch 1

025B Driver’s hatch hinge 1

025C Left periscope cover 1

025D Right periscope cover 1

025E Driver’s periscopes 1

025F Driver’s hatch inner face 1

025G Persicope inner cover 2 * includes spares

025B

025A

025F

025F

025A

025H

025J

025I

025I

025E

025A

CODE

NUMBER COMPONENT NAME QUANTITY

025H Driver’s hatch left lock handle 1

025I Driver’s hatch right lock handle 1

025J Driver’s hatch closing handle 1

025K Spacer (washer) 2

BP 1.7 × 4mm screw 2+1*

HP 1.7 × 3 × 5mm screw 4+1*

2