International - ENG

February 2021

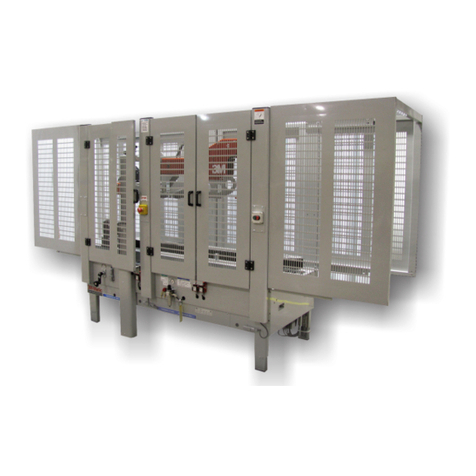

3M-Matic™8000a-I / 8000a3-I - Type 11700

Page vii

44-0009-2161-7 / ECO# 0078483

8000a-I / 8000a3-I Adjustable Case Sealer Page

Cover Page

Replacement Parts/Declaration of Conformity/Service Information . iii– vi

Table of Contents........................................vii– xi

Acronyms and Abbreviations ................................. xii

1. Introduction

1.1 ManufacturingSpecications/Description/IntendedUse ........... 1

1.2 HowtoReadandUsetheManual.............................. 2

1.2.1 ImportanceoftheManual .................................... 2

1.2.2 Manual Maintenance ........................................ 2

1.2.3 ConsultingtheManual....................................... 2

1.2.4 HowtoUpdatetheManualinCaseofModications................ 2

2. General Information

2.1 IdenticationData .......................................... 3

2.2 After-Sale Service .......................................... 3

2.3 Warranty / Contents......................................... 4

3. Safety

3.1 General Safety Information ................................... 5

3.2 Signal Words Explanation .................................... 5

3.3 Table of Warnings ....................................... 6 – 7

3.4 Operator’sQualicationsDenition ............................ 8

3.5 Number of Operators........................................ 8

3.6 SafeUseoftheMachineInstructions ........................... 8

3.7 Residual Hazards .......................................... 8

3.8 PreventOtherHazards—RecommendationsandMeasures ........ 8

3.9 Personal Safety Measures ................................... 8

3.10 Incorrect / Predictable Actions Not Allowed ....................... 8

3.11 Operator’s Required Skill Levels ............................... 9

3.12 Component Locations ...................................... 10

3.13 Table of Warnings and Replacement Labels ..................... 11

4. Technical Specications

4.1 Power Requirements ....................................... 12

4.2 Operating Rate ........................................... 12

4.3 Operating Conditions....................................... 12

4.4 MachineNoiseLevel ....................................... 13

4.5 Set-UpRecommendations .................................. 13

4.6 Tape.................................................... 13

4.7 TapeWidth............................................... 13

4.8 Tape Roll Diameter ........................................ 13

4.9 TapeApplicationLegLength—Standard ........................13

TapeApplicationLegLength—Optional

4.10 Box Board ............................................... 13

4.11 BoxWeightandSizeCapacities .......................... 13 – 14

4.12 MachineandPackagedMachineDimensions.....................15

Table of Contents — Manual 1:

8000a-I / 8000a3-I Adjustable Case Sealer

(For Taping Head information, see Manual 2 or 3: AccuGlide™3 Taping Heads, 2 Inch or 3 Inch)