CV3100 series and MINI series high performance general purpose inverter instruction manual

1-5

(3) Negative-torque load

The occasion that needs the load to be raised produces the negative torque usually,

the inverter would generate over current or over voltage fault, and so it would trip, in

case of this, a braking resistor shall be mounted.

(4) Mechanical resonance point of load device

In the certain output frequency range, the inverter is likely to meet the mechanical

resonance point of load device, if that, the jumping frequency must be set to avoid this

point.

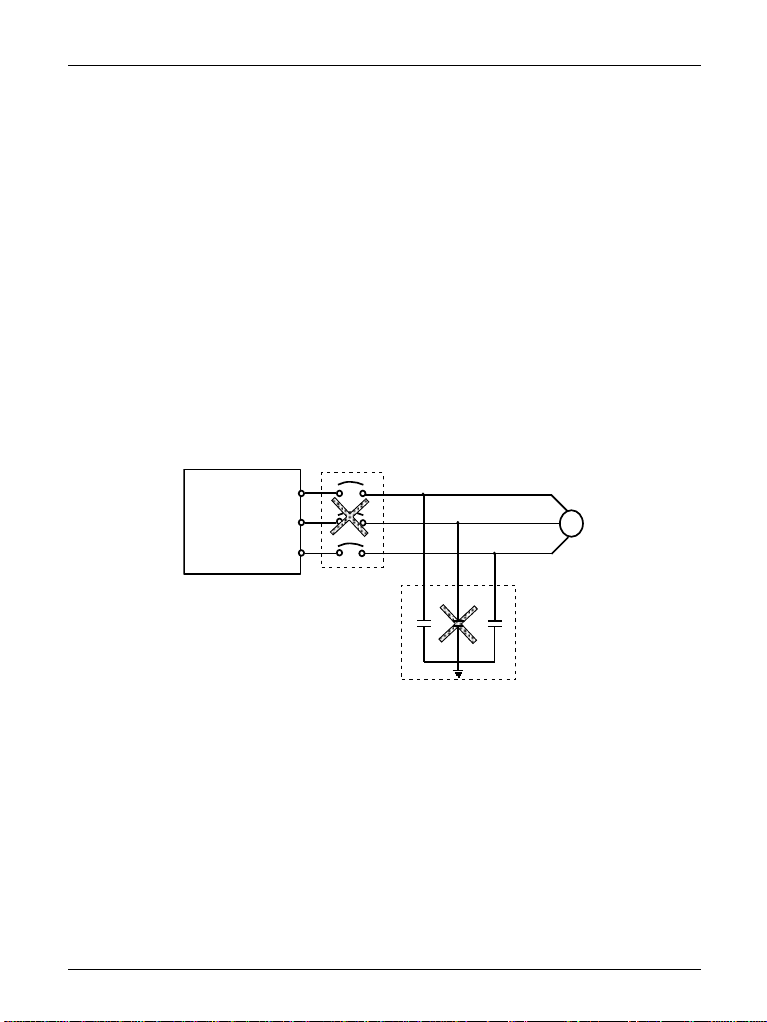

(5) Capacitor or pressure sensitive element that improves power factor

If there is a capacitor or varistor for lightning protection that improves power

factor mounted on the output side, they shall be removed, otherwise, the inverter

would trip for fault or the parts would be damaged, because output voltage of inverter

is the type of impulse wave. In addition, on the output side, it is suggested that air

switch and contactor would not be installed either, shown as diagram 1-3. (If the

switch unit has to be mounted on the side of output, the output current of inverter must

be zero when the switch operates.)

Diagram 1-3 Inverter output side never mounted with a capacitor

(6) Run at over 50Hz.

If the inverter has to run at over 50Hz, the applicable speed range of motor

bearing and mechanical equipment must be guaranteed in addition to considering the

vibration and noise of motor, and please inquire before inverter runs.

(7) Electronic heat protection value of motor

When a motor chosen is applicable, the inverter can provide the motor with heat

protection. If the motor doesn’t match with the rated capacity of inverter, the

protection value must be adjusted or other protection measures must be taken, to

guarantee the motor runs safely.