IF 1515 • 10/14 Copyright © 2014, Eaton’s Crouse-Hinds Business Page 2

FLOODLIGHT INSTALLATION

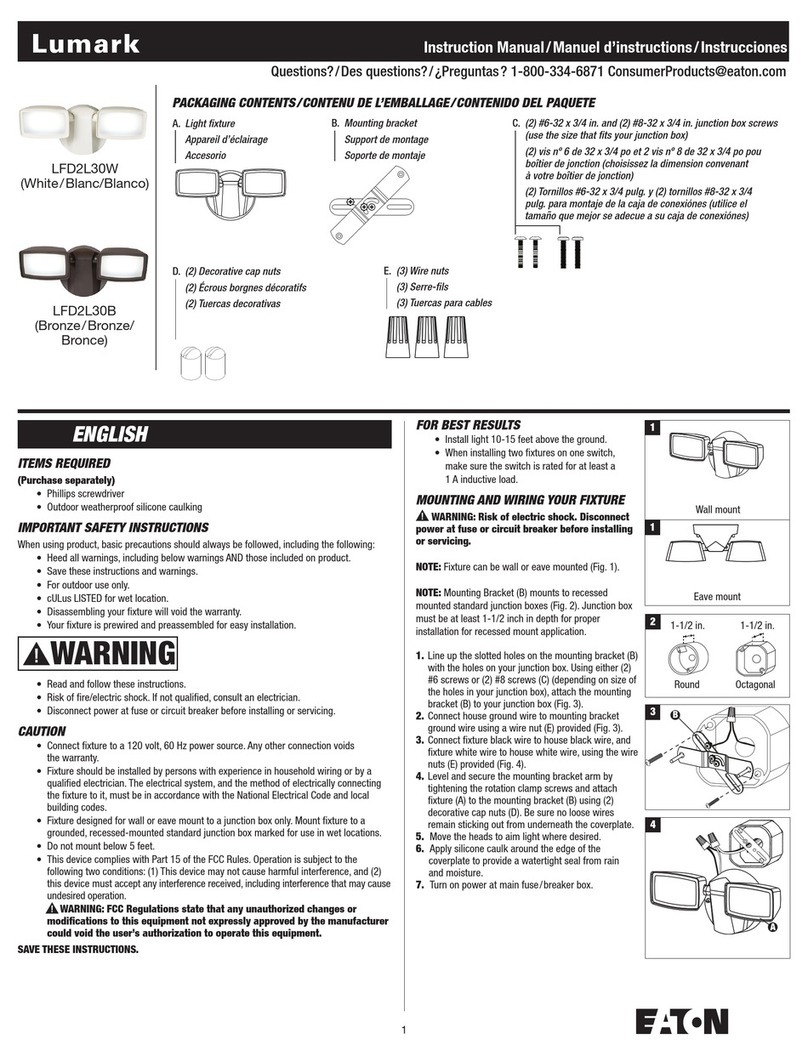

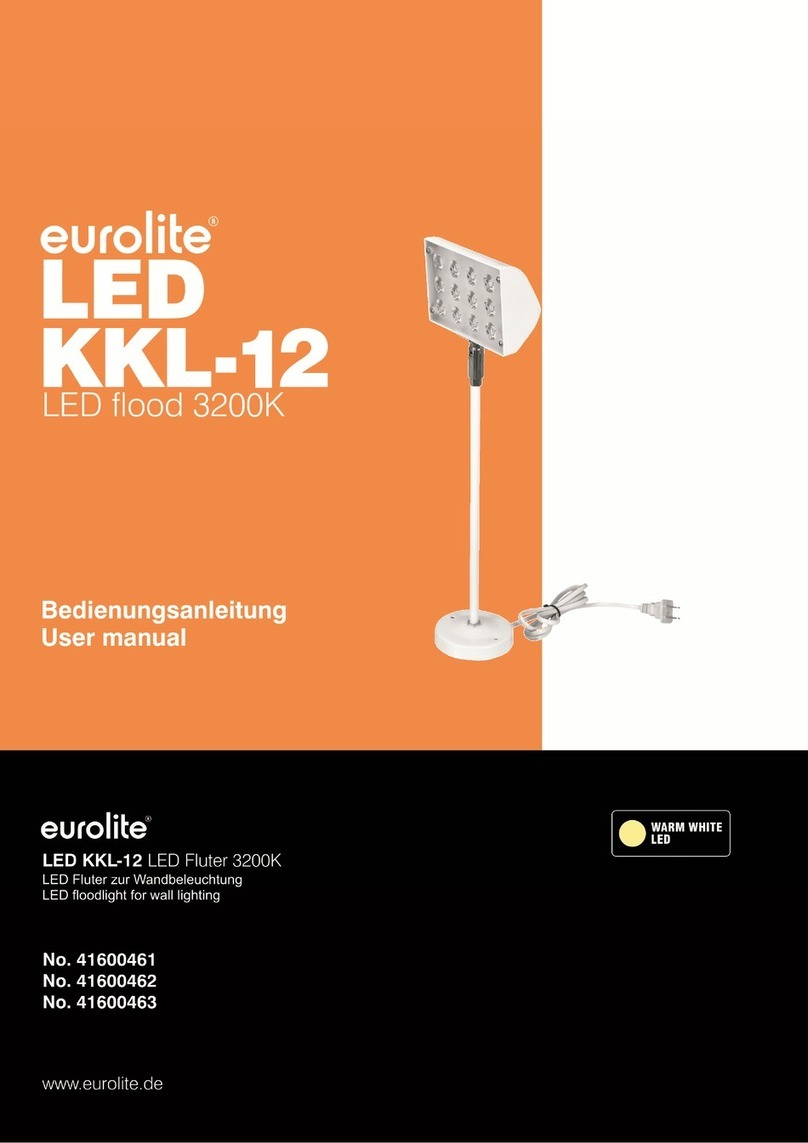

A) Yoke (Trunnion Mount)

1. Using trunnion arm as a template, mark and drill desired location on mounting

surface using only the mounting holes.

2. Secure trunnion arm to mounting surface using 1/2” bolts or lag screws

(provided by installer).

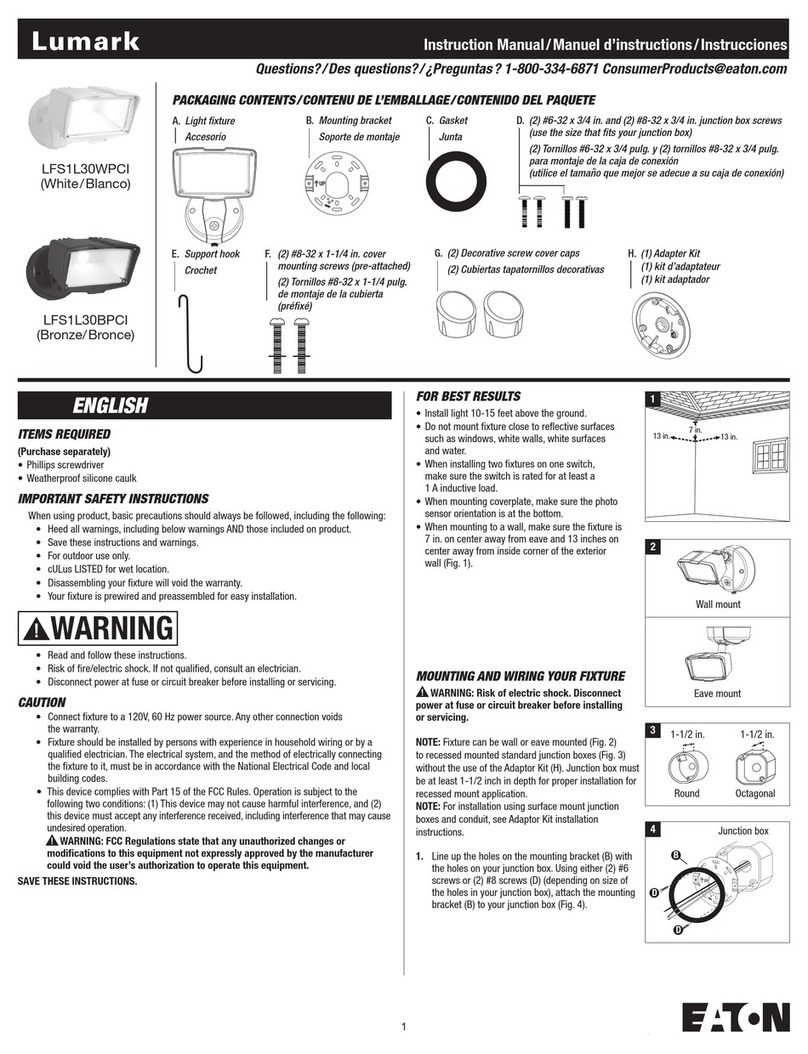

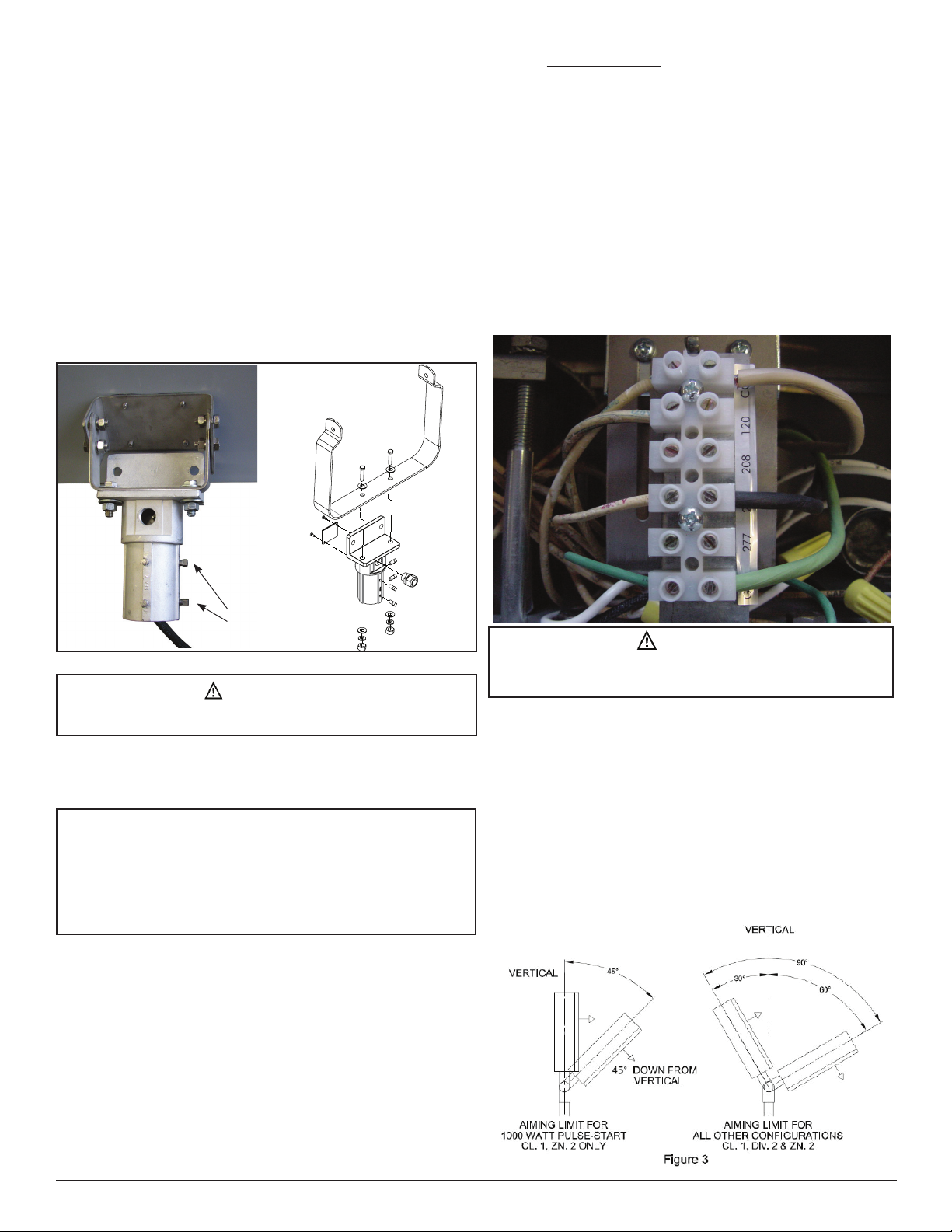

3. To make final vertical adjustment, loosen pivot bolts (2) on floodlight yoke and

position to desired vertical angle. Check to make sure the vertical angle is

within the aiming range shown (see Figure 3). Securely tighten both pivot bolts.

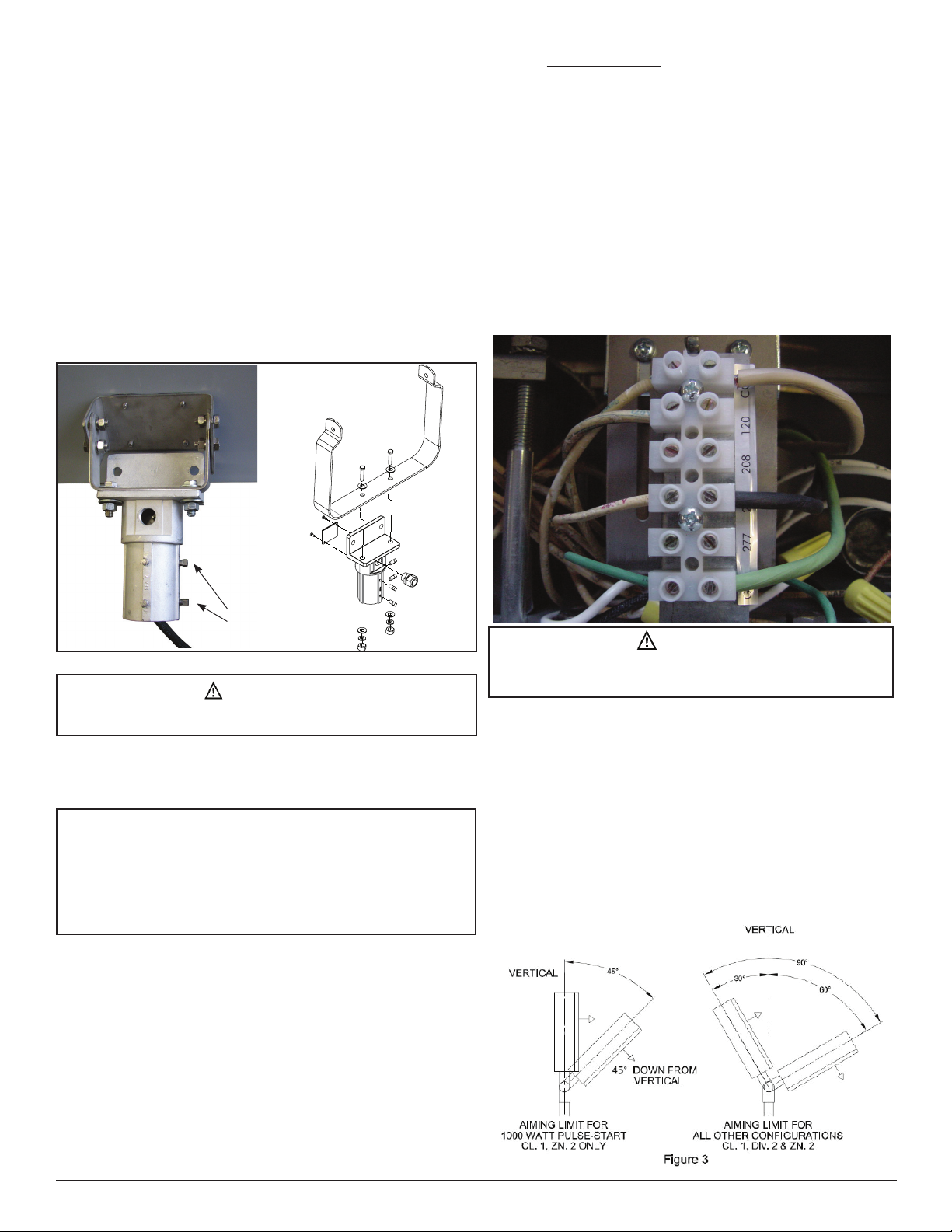

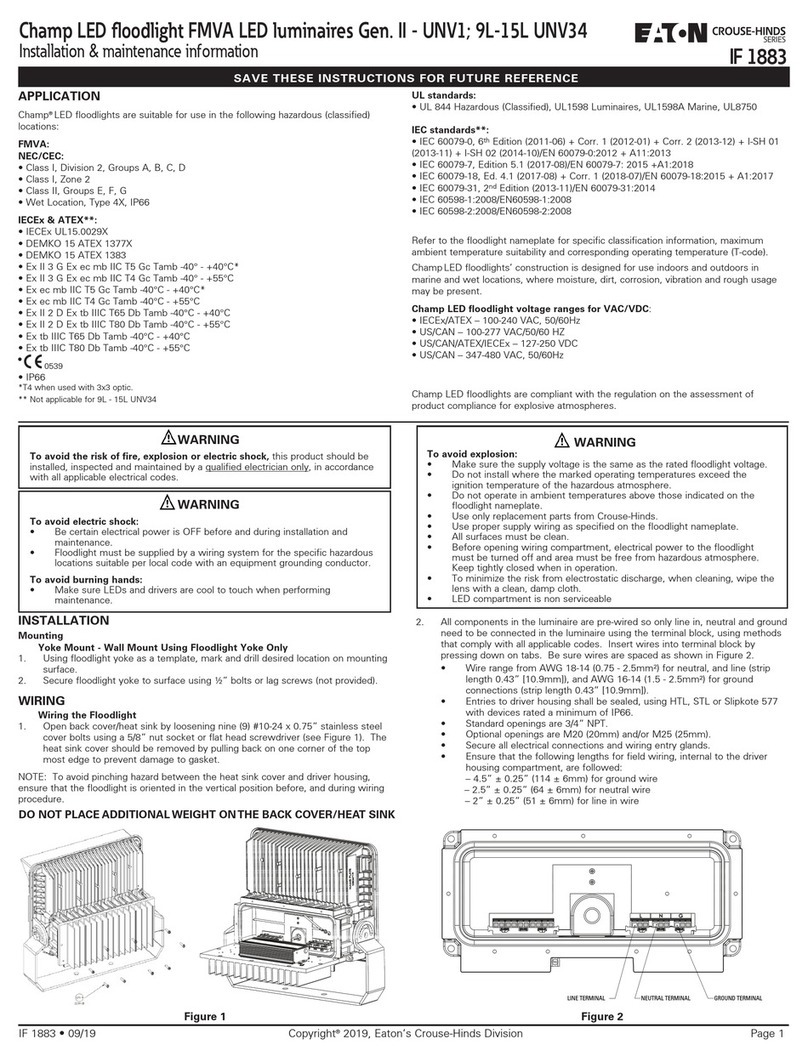

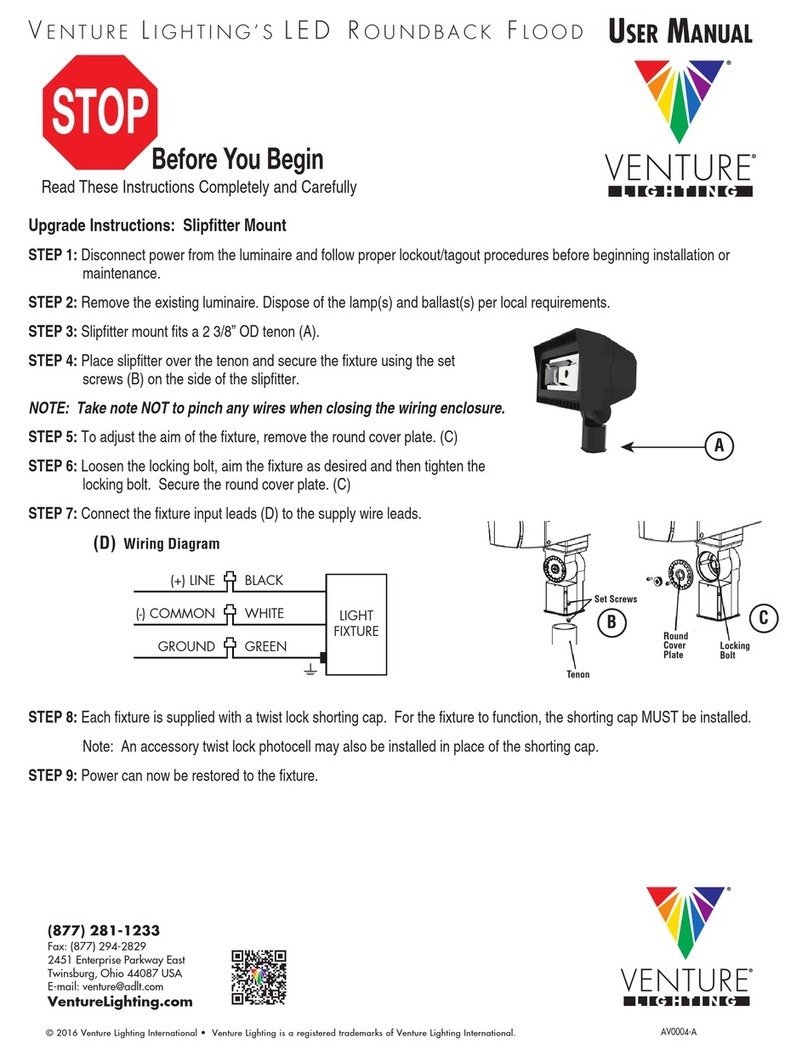

B) Pole Mount with SFA6 Slipfitter

1. Using the bolts, nuts, and lock washers provided, securely fasten the floodlight

yoke to the flange on the SFA6 slipfitter. Refer to Figure 2. Torque the bolts to

45 lbs.-ft.

NOTE: Angular positioning of the floodlight will be done later.

2. Place the SFA6 slipfitter adapter with the secured floodlight onto the 2” pole top

tenon.

3. Secure by tightening the slipfitter base bolts. Torque base bolts to 19 lbs.-ft.

WIRING

A) Pole and Yoke Mount – F2MV, FMV, FMV1000 Series Floodlights

and Champ®voyager nR Series Stainless Steel Floodlight

1. For yoke mount with SFA6 Slipfitter Adapter: Remove the access cover by

loosening the two (2) self-tapping screws. Set aside for reassembly later.

2. Using access opening, pull #16-3 type SO cord (or other extra hard usage

portable cord) supply wire from customer supplied wire chamber through pole.

Using the NCG7575 cable connector provided, position a minimum overall

length of 3 ft. cord for final connection to light fixture. Use a small amount

of HTL thread lubricant when installing cord connector and install according

to instructions supplied with connector. Securely tighten cord connector into

slipfitter.

3. Strip cord insulation jacket back 3 inches and strip each conductor 3/8”.

4. Secure the access cover as follows: For SFA6 slipfitter, secure cover by

tightening the two (2) self-tapping screws against SFA body. For SFA6 SS

slipfitter, attach access plate with four (4) screws and lock washers.

Proceed to B) Wiring the Floodlight.

B) Wiring the Floodlight

1. Loosen the twelve (12) captive floodlight cover screws on the door and

completely open the cover. Remove the four (4) screws that secure the

cover plate over the ballast housing. Be sure to retain the screws in a safe

place.

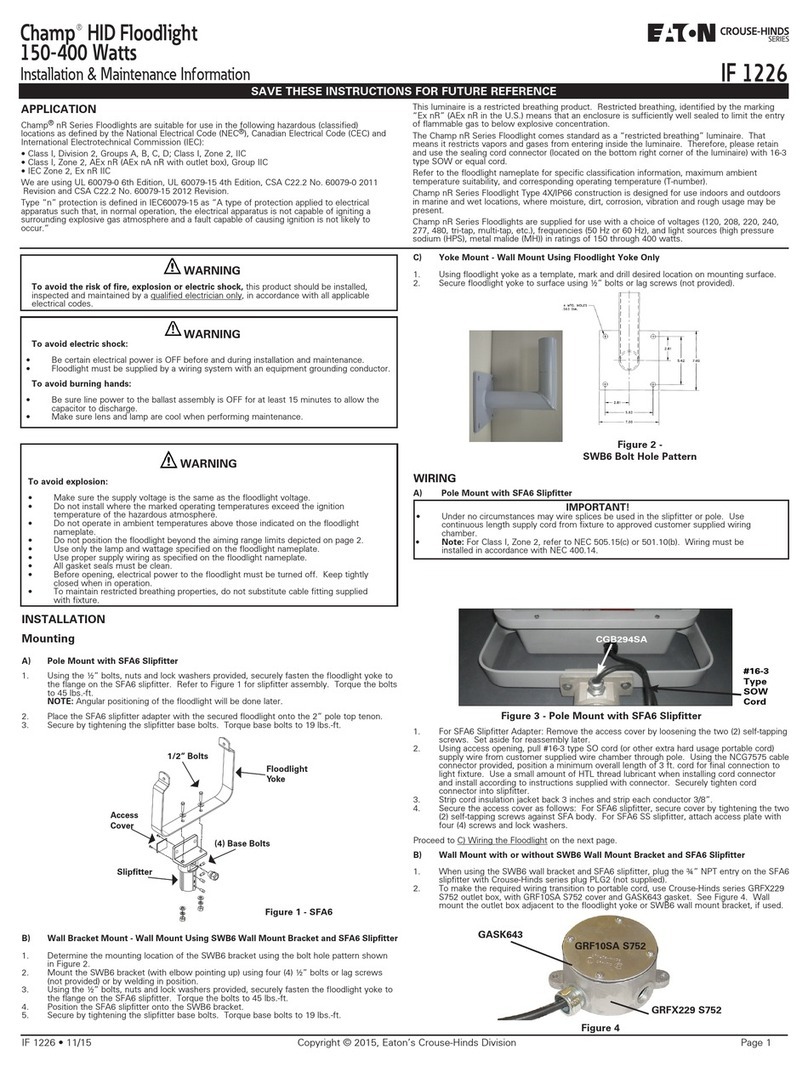

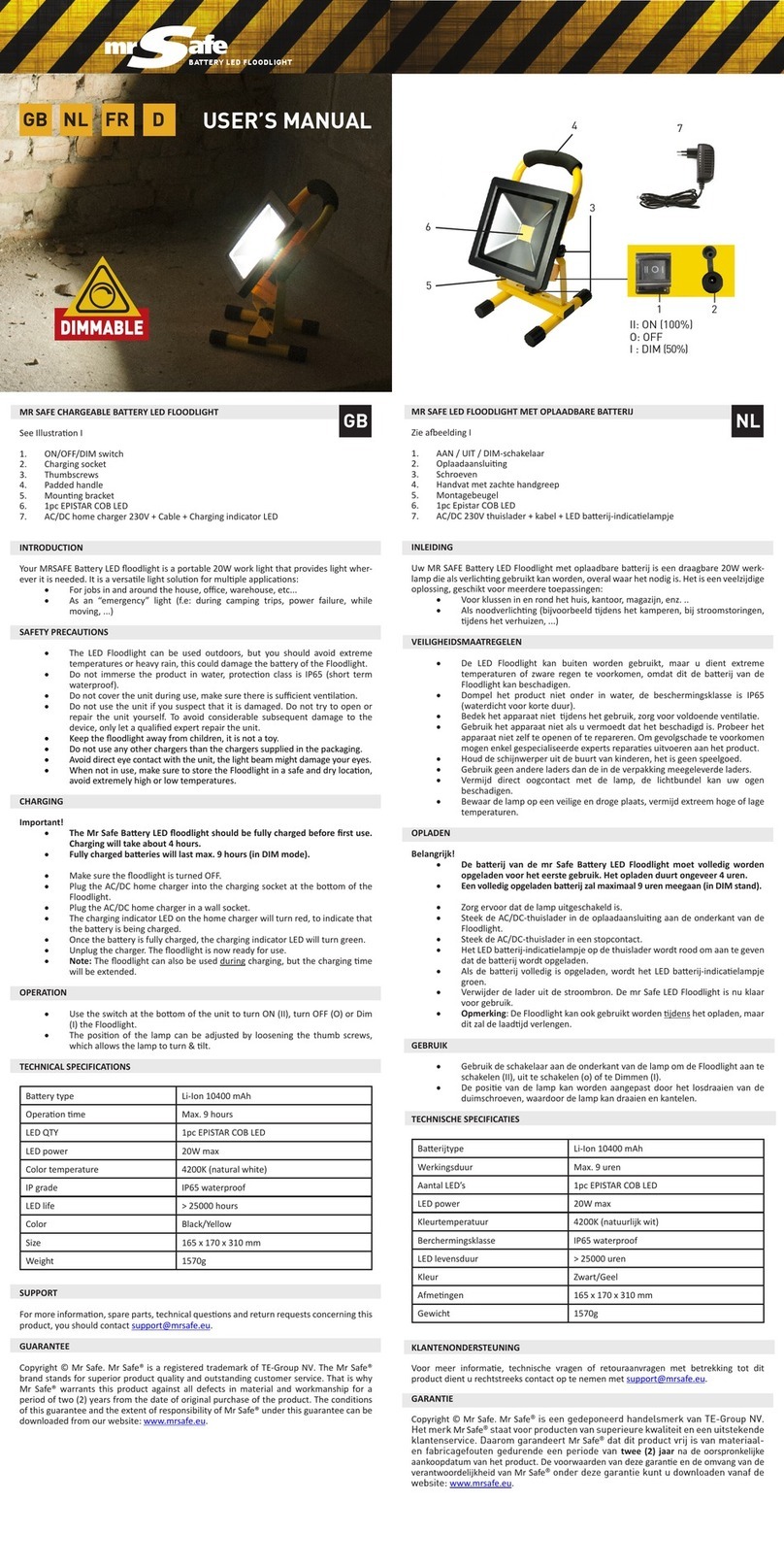

2. Ensure that line power is not connected to the SOW cord. Strip 3/8” of the

wires of the SOW cord for termination. Notice that all components in the

ballast assembly area are prewired. You will only need to wire line power to

the terminal block and ground wire.

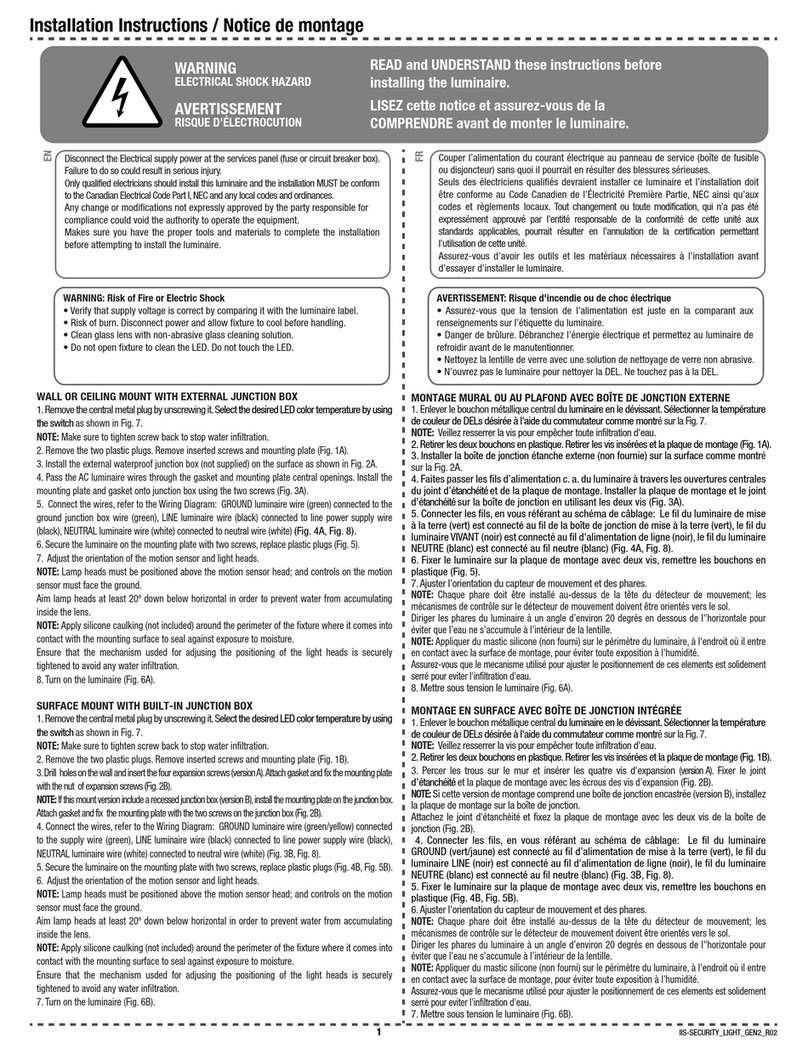

3. Loosen the screws on the terminal block for the appropriate line voltage,

ground (GND), and common (COM) connections. Run the SOW cord

through the sealing cord connector, which is the connector on the bottom

of the luminaire. Terminate the equipment grounding conductor (green) of

the SOW cord first, the common (usually white), and finally the line voltage

(usually black) to the marked terminal blocks.

4. Tighten the sealing cord connector around the SOW cord so that the cord is

held securely in place. Place the ballast assembly cover back over the ballast

assembly area and fasten in place with the four (4) screws.

5. Install the lamp as specified on the nameplate. See LAMP INSTALLATION

AND REPLACEMENT section.

6. Close floodlight cover door making sure that all wires are safely inside and

positioned away from the ballast area. Securely tighten all cover screws. For

proper gasket seal, torque the cover screws to 22 lbs.-in.

7. To make final vertical adjustment, loosen the two (2) pivot bolts on the

floodlight yoke to position floodlight at the desired angle (within the

acceptable aiming range limits). See Figure 3. Tighten the two (2) pivot bolts

to 45 lbs.-ft.

WARNING

To avoid decreased lamp and fixture life or overheating of fixture, do not

position fixture beyond aiming range limits.

WARNING

To avoid explosion: On ballasts with multiple supply voltage taps (MT, TT,

etc.), all unused leads must terminate at the terminal block or be capped with

closed end wire connectors.

Figure 2 - SFA6

Base

Bolts (4)

Under no circumstances may wire splices be used in the slipfitter or pole. Use

continuous length supply cord from fixture to approved customer supplied wiring

chamber.

Note: For Class I, Zone 2 refer to NEC 505.15(c) or for Class I, Division 2,

501.10(b). Wiring must be installed in accordance with NEC 400.14.

IMPORTANT!