LED Floodlight FMV Series

25L Industrial LED Floodlight

Installation & Maintenance Information

SAVE THESE INSTRUCTIONS FOR FUTURE REFERENCE

1711

APPLICATION

FMV LED Floodlights construction is designed for use indoors and outdoors in

marine and wet locations, where moisture, dirt, corrosion, vibration and rough

usage may be present.

• UL1598 Luminaires, UL1598A Marine, UL8750, UL844 Hazardous

(Classified), CSA C22.2 No. 137

• cUL

• Class I, Division 2, Groups A,B,C,D

• Class II, Division 1, Groups E,F,G

• Class III

• Wet Locations, NEMA 4X

• IP66

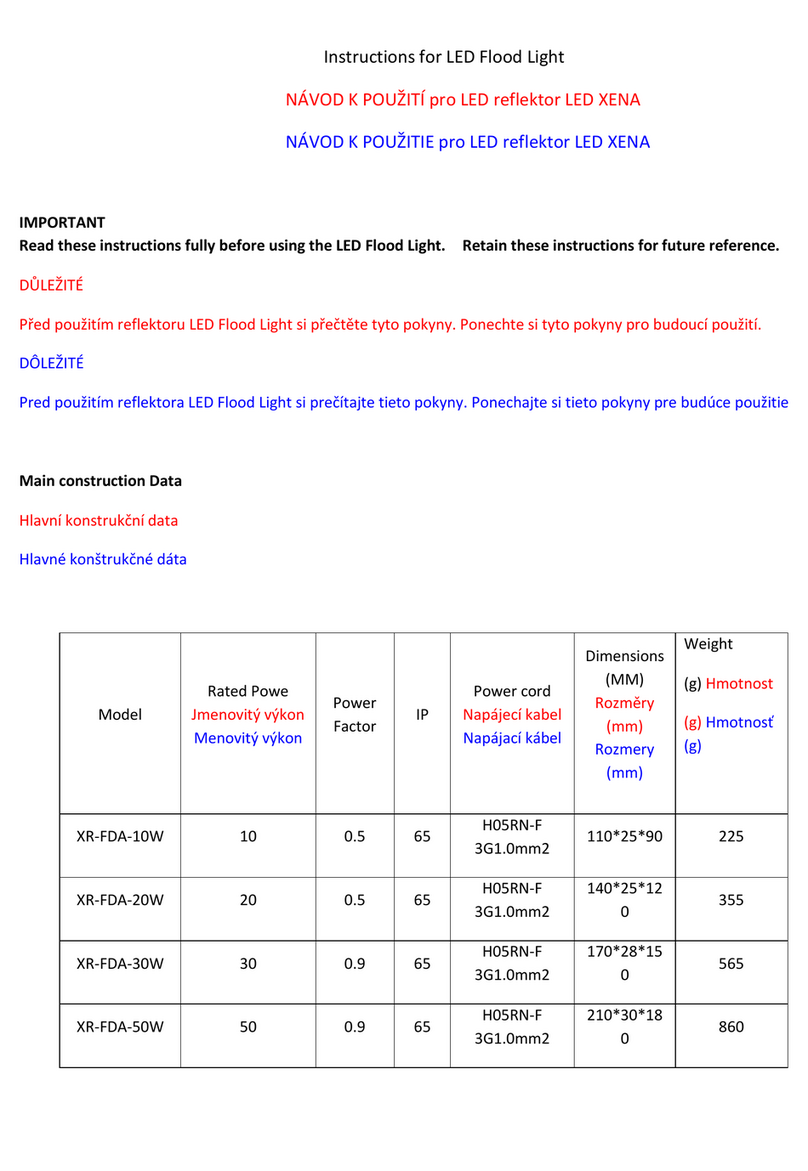

FMV LED Floodlights are supplied for use with a choice of voltages:

• 100VAC – 277VAC, 50/60Hz and 127VDC – 250VDC

• 277VAC - 480VAC, 50/60Hz

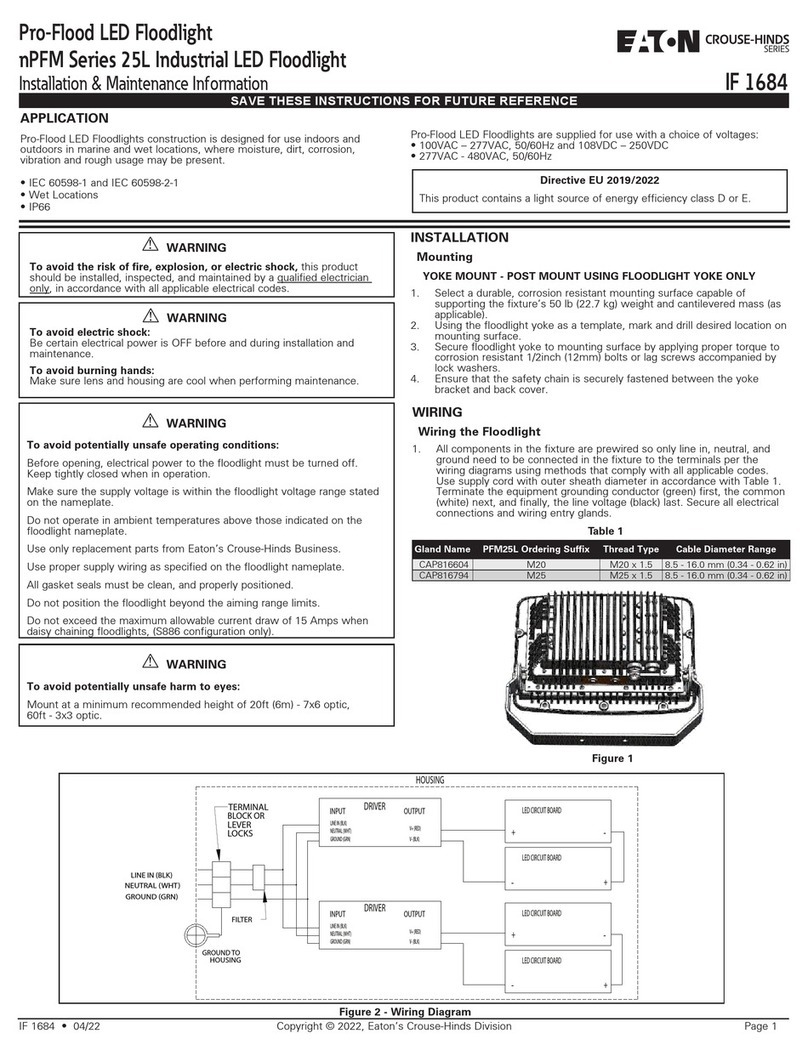

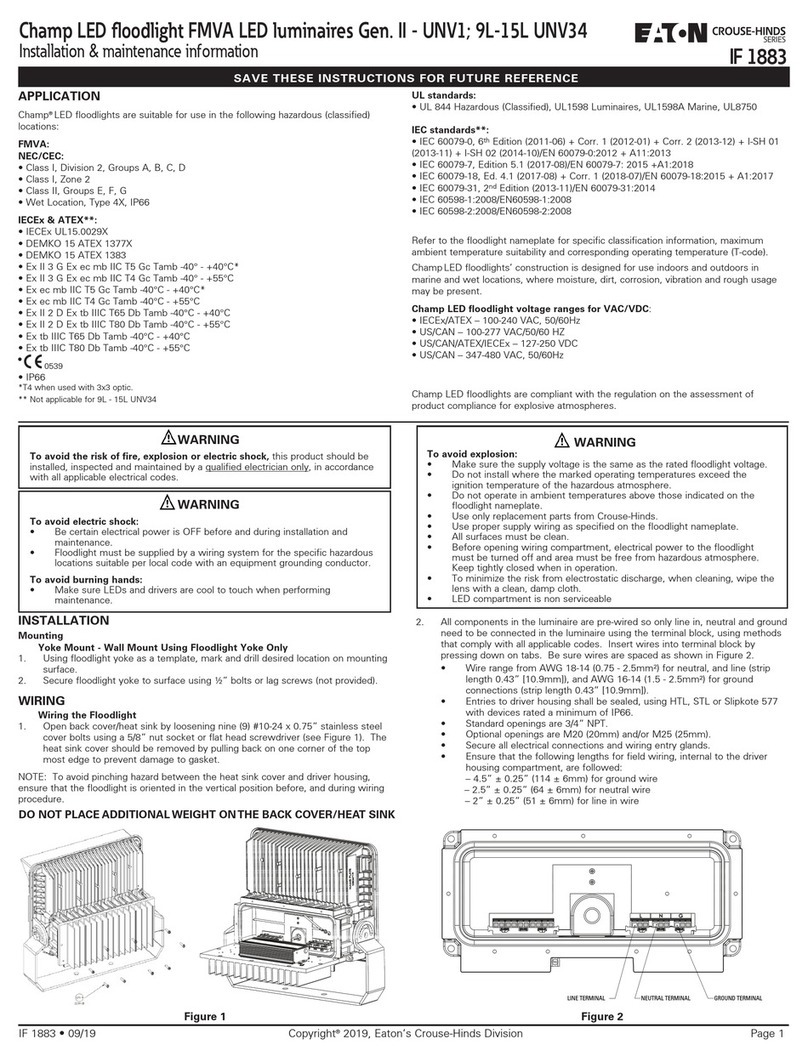

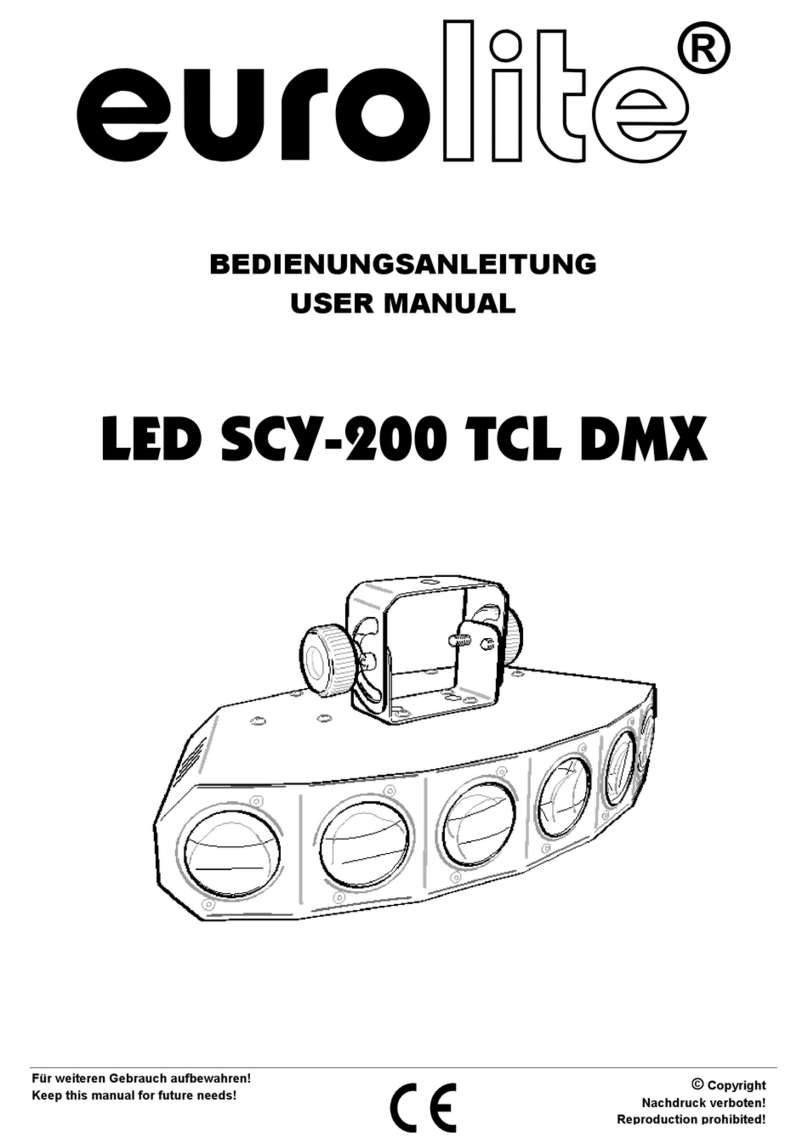

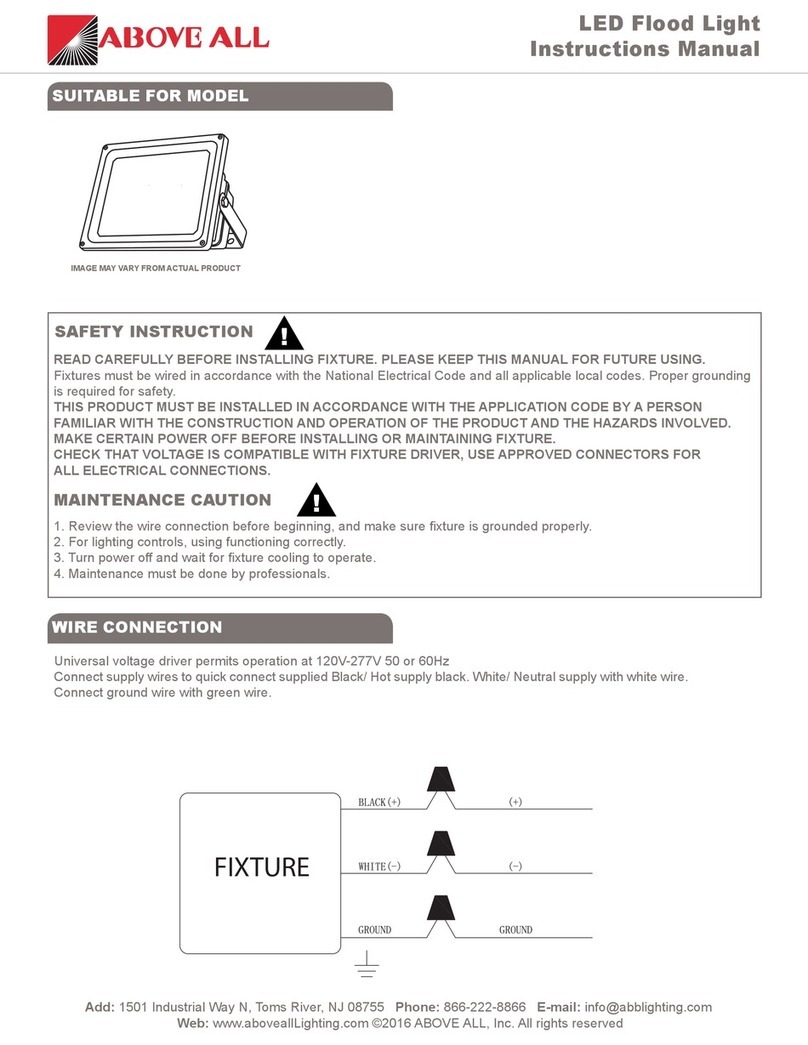

Figure 2 - Wiring Diagram

To avoid the risk of fire, explosion, or electric shock, this product

should be installed, inspected, and maintained by a qualified electrician

only, in accordance with all applicable electrical codes.

WARNING

To avoid electric shock:

Be certain electrical power is OFF before and during installation and

maintenance. Floodlight must be supplied by wiring system suitable for

Class I, Division 2 per NEC with an equipment grounding conductor.

To avoid burning hands:

Make sure lens and lamp are cool when performing maintenance.

WARNING

To avoid potentially unsafe operating conditions:

Make sure the supply voltage is within the floodlight voltage range

stated on the nameplate.

Do not operate in ambient temperatures above those indicated on the

floodlight nameplate.

Use only replacement parts from Crouse-Hinds.

Ensure supply cable and cable gland meet product ratings and conforms

with building and electrical codes.

Use proper supply wiring as specified on the floodlight nameplate.

All gasket seals must be clean.

Before opening, electrical power to the floodlight must be turned off.

Keep tightly closed when in operation.

Do not position the floodlight beyond the aiming range limits.

Do not exceed the maximum allowable current draw of 15 Amps when

daisy chaining floodlights.

WARNING

IF 1711 • 10/14 Copyright © 2014, Eaton’s Crouse-Hinds Business Page 1

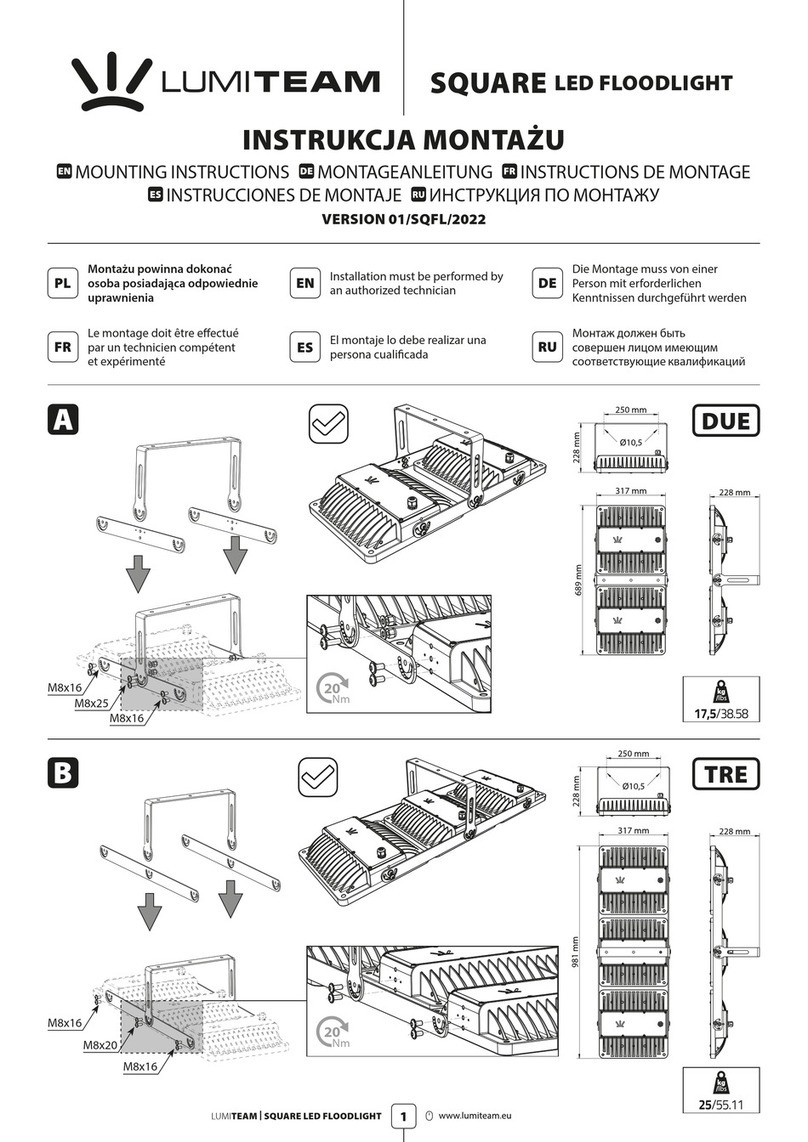

INSTALLATION

Mounting

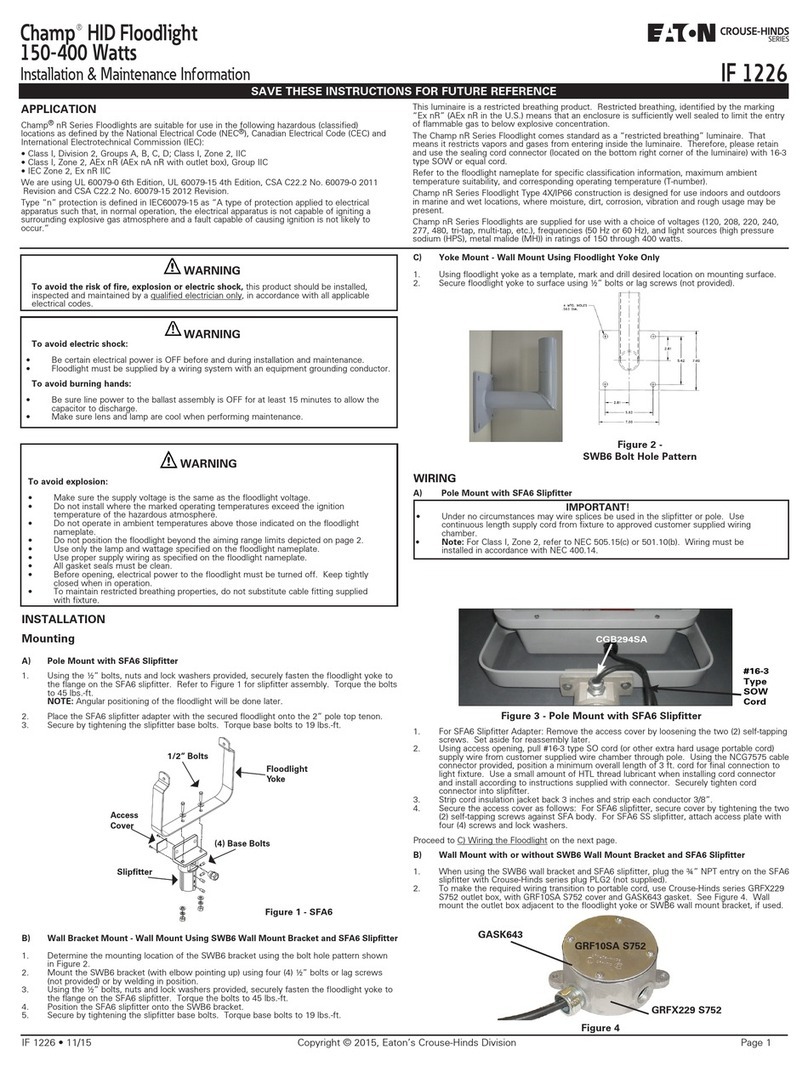

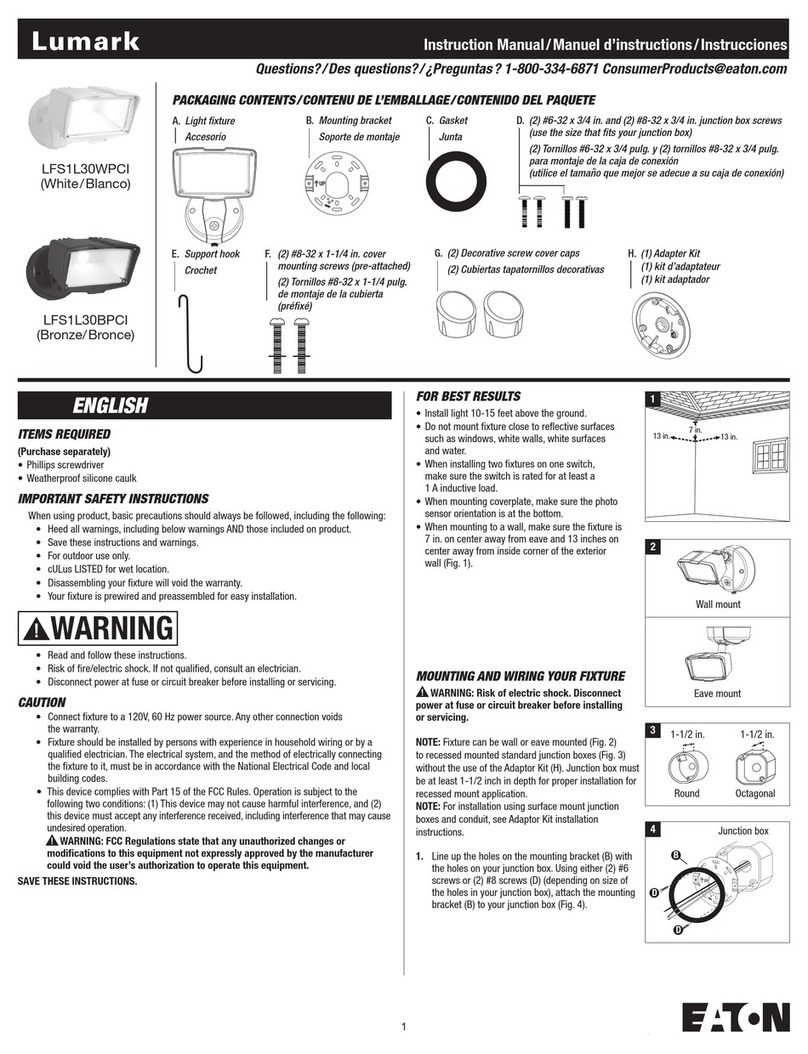

Yoke Mount - Post Mount Using Floodlight Yoke Only

1. Select a durable, corrosion resistant mounting surface capable of

supporting the fixture’s 50 lb (22.7 kg) weight and cantilevered mass (as

applicable).

2. Using the floodlight yoke as a template, mark and drill desired location on

mounting surface.

3. Secure floodlight yoke to mounting surface by applying proper torque

to corrosion resistant 1/2 in bolts or lag screws accompanied by lock

washers.

4. Ensure that the safety chain is securely fastened between the yoke

bracket and back cover.

WIRING

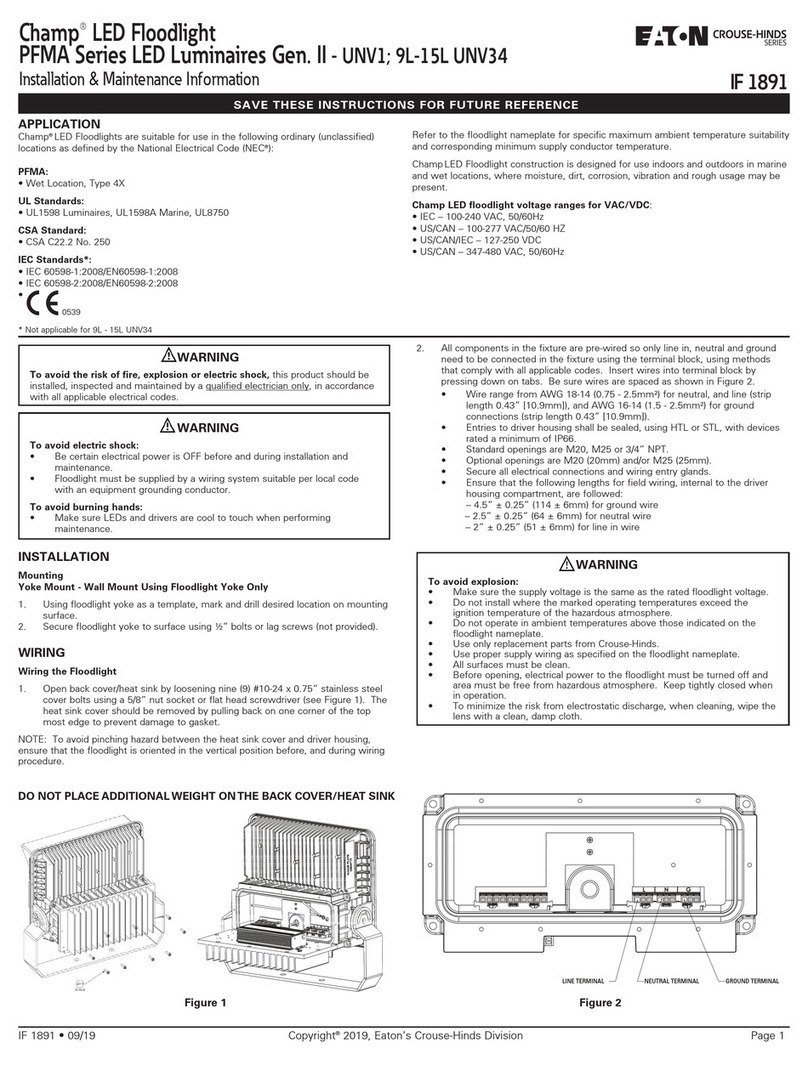

Wiring the Floodlight

1. Open back cover by loosening eight (8) 1/4 -20 x .625” stainless steel

cover screws. All components in the fixture are prewired so only line in,

neutral, and ground need to be connected in the fixture to the terminals

per the wiring diagrams using methods that comply with all applicable

codes. Terminate the equipment grounding conductor (green) first, the

common (white) next, and finally, the line voltage (black) last. Secure all

electrical connections. For DC voltage applications connect the positive

(+) lead to the white wire and negative (-) lead to the black wire.

DRIVER

INPUT OUTPUT

LINE IN (BLK)

NEUTRAL (WHT)

V+ (RED)

V- (BLK)

+-

DRIVER

INPUT OUTPUT

LINE IN (BLK)

NEUTRAL (WHT)

V+ (RED)

V- (BLK)

LED CIRCUIT BOARD

+-

NEUTRAL (WHT)

LINE IN (BLK)

GROUND (GREEN)

-+

LED CIRCUIT BOARD

LED CIRCUIT BOARD

+-

LED CIRCUIT BOARD

Figure 1

Entries shall be closed with

components that meet

enclosure ratings.