GENERAL INFORMATION EATON

2075

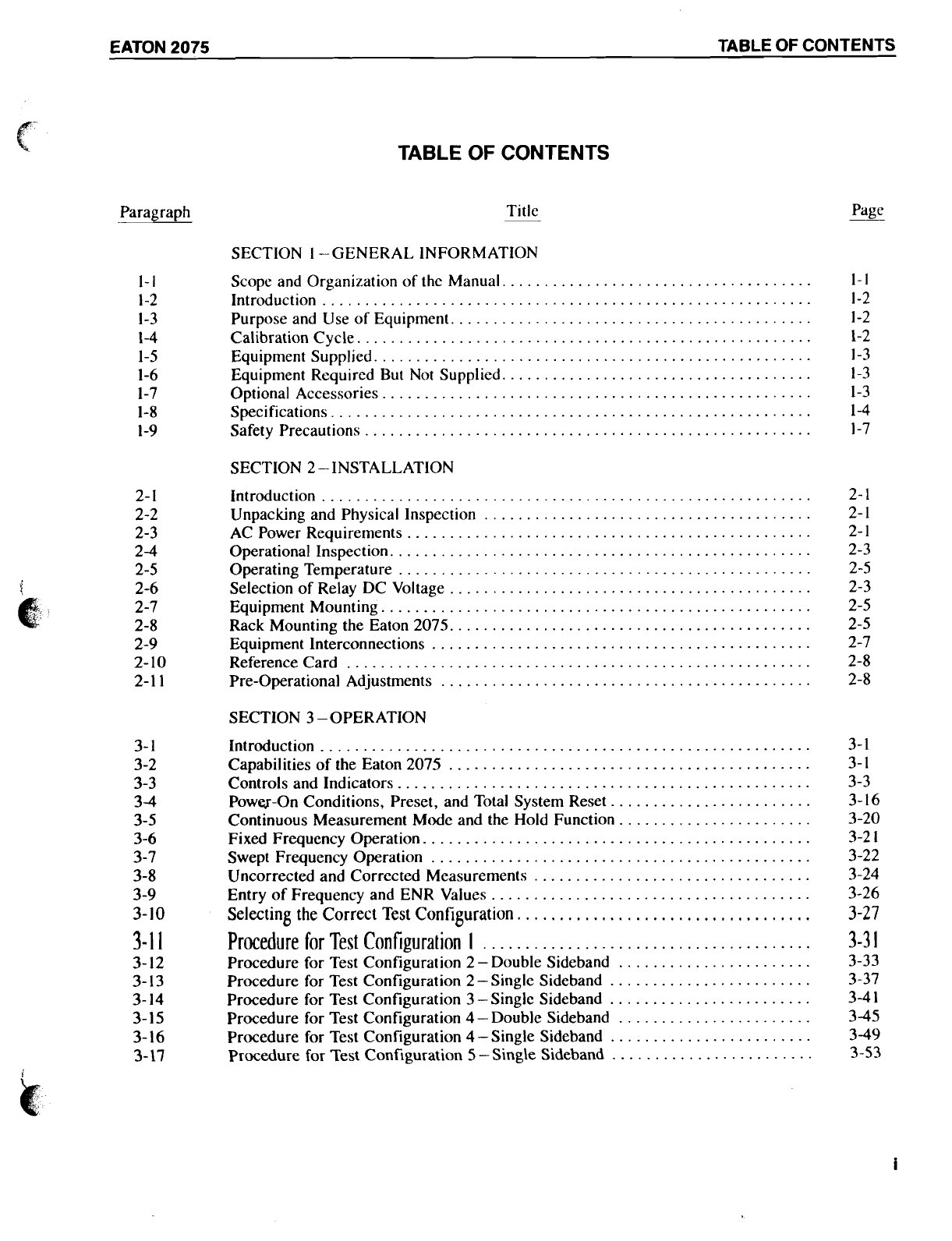

This manual has been organized to allow the new user

of the Eaton 2075 to quickly and easily begin test

operations. Read Section

1

to obtain a familiarity with

the test instrument.Follow the proceduresof Section 2

for installation.

The Eaton 2075 can be used in any of 6 test

configurations, depending on the desired test

application. Section

3

is organized to quickly bring the

user to the correct test configuration and its

procedure. Figure 3-1 and Table

3-1

may

be

studied to

obtain a familiarity with the controls and indicators.

Paragraph

3-10

and Table 3-4 guide the user in

selecting the correct test configuration. Paragraphs

3-

11 through 3-18 are the procedures to be used with

each configuration. Each procedure includes the

keystroke sequences necessary for each step. The

remaining pages of Section

3

cover, in greater detail,

specific subjects relevant to operation of the 2075.

Section4 coversoperationwhen the 2075 is controlled

by an external computer via a General Purpose

Interface Bus.

Section

5

includes information and procedures used to

verify that the 2075 is performing correctly.

1-2.

INTRODUCTION

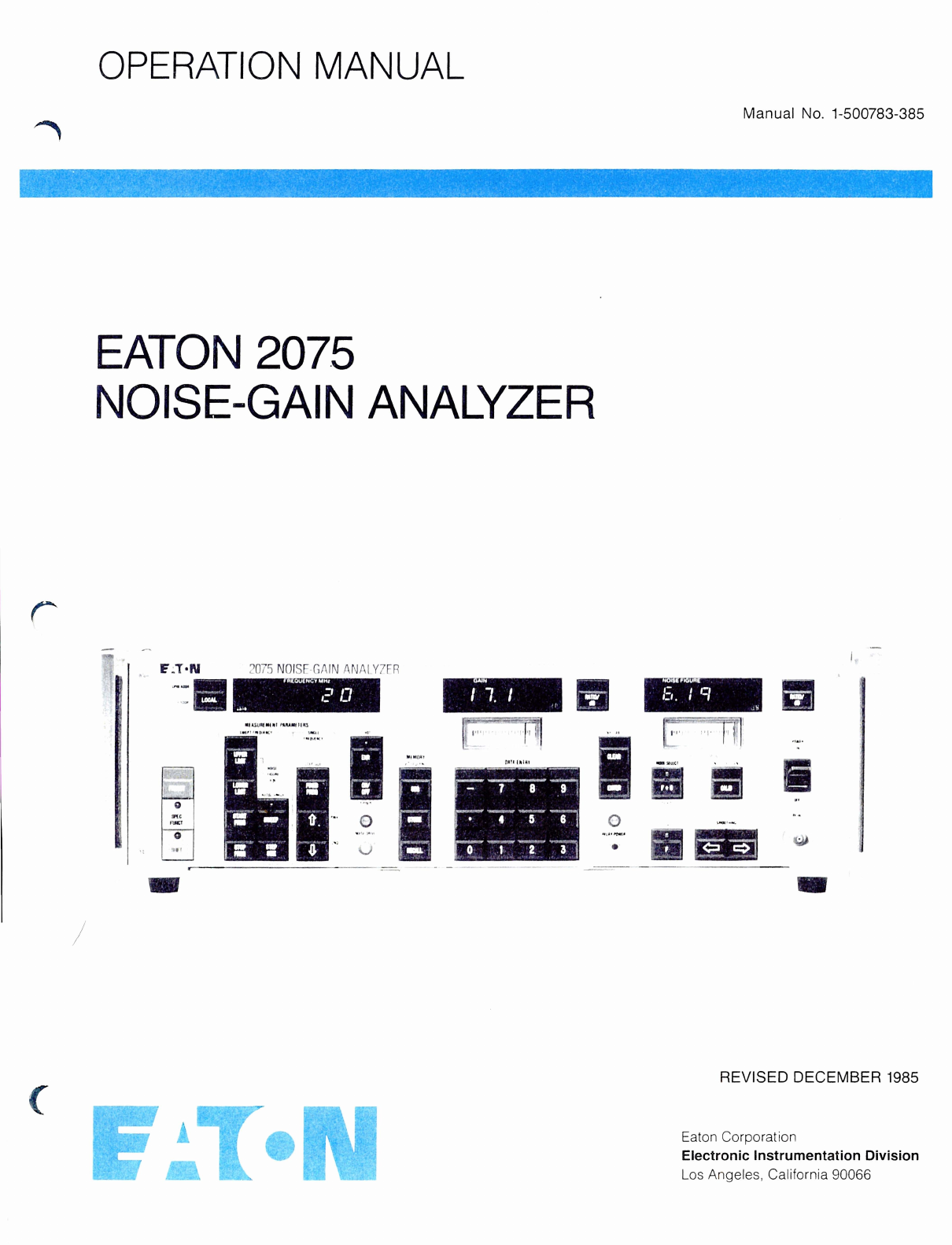

This section of the manual contains a general

description of the Eaton 2075 Noise-Gain Analyzer

including: purpose and function, equipment

requirements, available options, specifications, and

safety precautions.

1-3.

PURPOSE AND USE OF EQUIPMENT

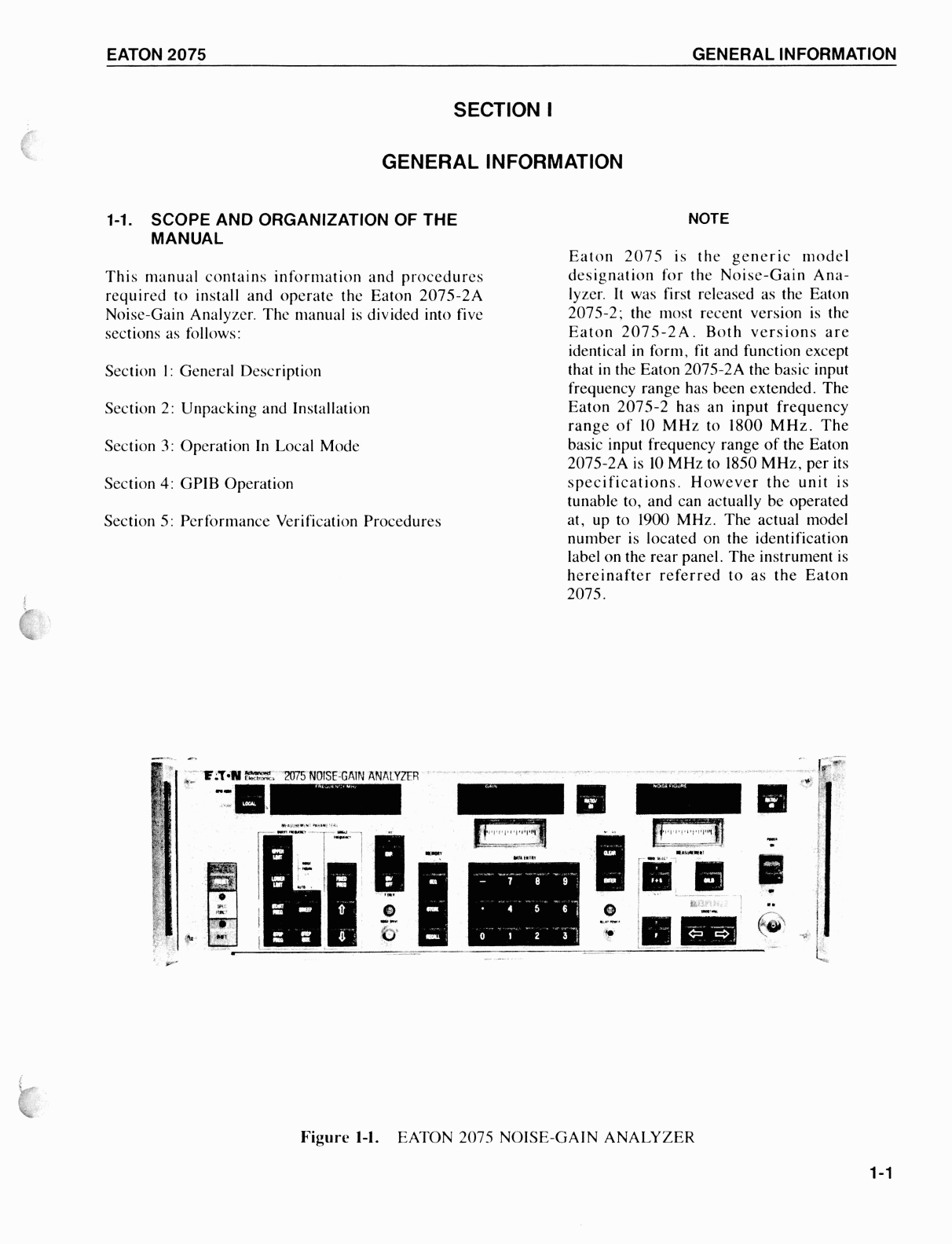

The 2075 Noise-Gain Analyzer is a programmable,

microprocessor-controlled instrument designed

specifically to make precise measurements of noise

and gain characteristics of RF devices. The analyzer

can be controlled in its local mode using its front panel

controls, or in the remote mode, by an external

controller via an IEEE-488 GPIB (General Purpose

Interface Bus).

The analyzer can make the following measurenlents:

e

Corrected Noise Figure and Gain

(F

+

G)*

Uncorrected Noise Figure

(F)

*

Corrected Effective Input Noise

Temperature and Gain (T,

+

G)

Effective Input Noise Temperature (T,)

Corrected Effective Operating Noise

Temperature and Gain (Top

+

G)

Effective Operating Noise Temperature (Top)

Noise Measure (includes Gain) (M)*

Y

Factor

Power

(Y)*

(PWR dB)*

Excess Noise Ratio (ENR)*

*Can be displayed in dB or as a dimensionless ratio

The specified input frequency range of the 2075

extendsfrom 10 MHz to 1850MHz. However, the unit

is actually tunable and operable to 1900 MHz. In its

simplest test configuration the analyzer will make

measurements of RF devices with output frequencies

in this range. More complex test configurations,

requiring one or two stages of external downconver-

sion, allow measurements of devices with output

frequenciesas high as 65.535 GHz. The 2075 has the

capability for controlling the local oscillator used in

the external downconversion process.

1-4.

CALIBRATIONCYCLE

At six month intervals the Performance Verification

Procedures in Section 5 of this manual should be

performed to ensure the continued optimum

performance of the 2075.

At one year intervals the instrument should be fully

calibrated using the alignment and adjustment

procedures from the maintenance manual. These

procedures should be performed by qualified

personnel experienced

in

calibration and servicing of

electronic instrumentation.

Scans by ArtekMedia © 2008