exhaust

outlet, andis forced through

the coolingsys-

tem, later to be discharged at the outlet in the ex-

haust tube provided for this purpose. Water enters

the cooling system through the holes in the watgr

by-pass cover above the anti-cavitation plate when

operating in REVERSE. (See

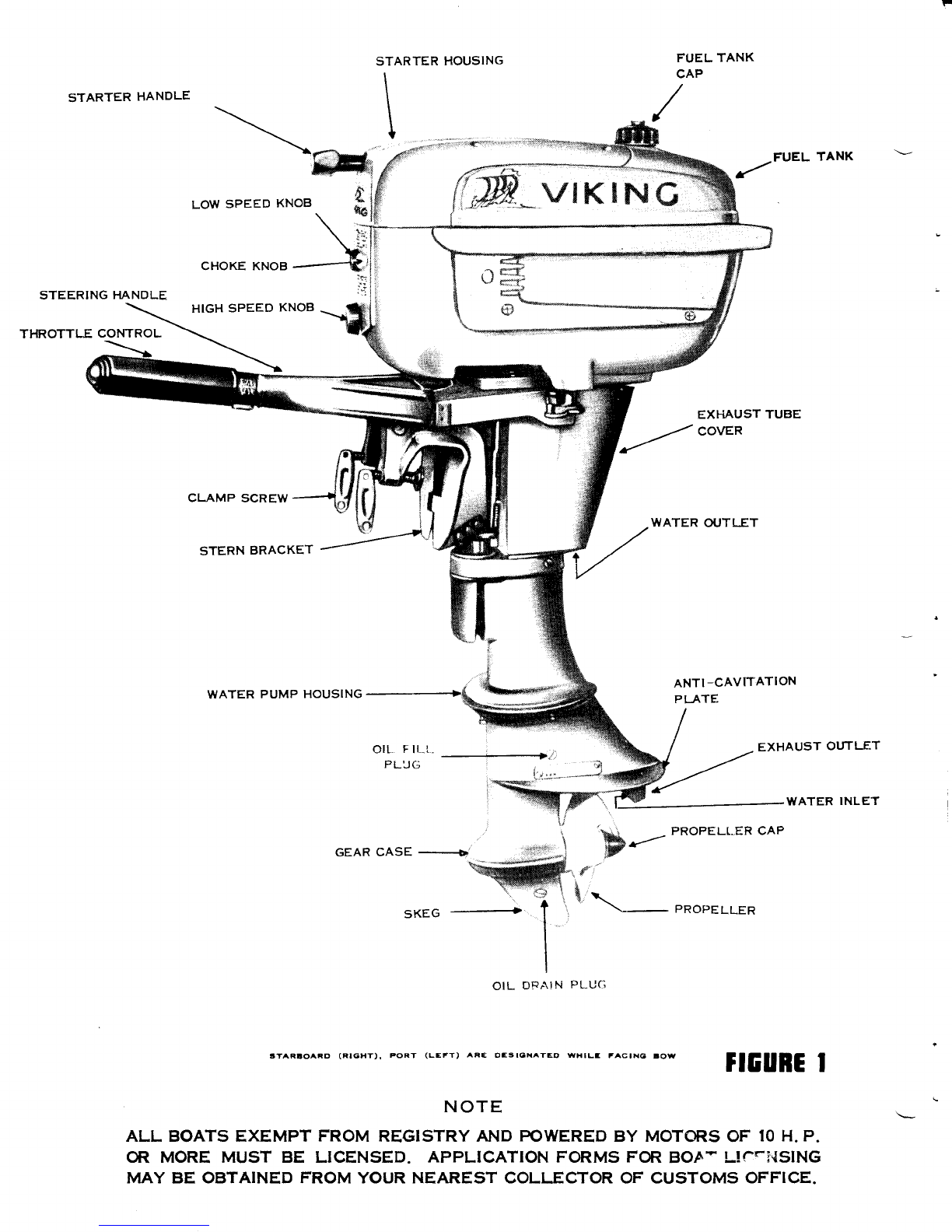

Figure 1 for locations

of cooling system parts.)

NOTE

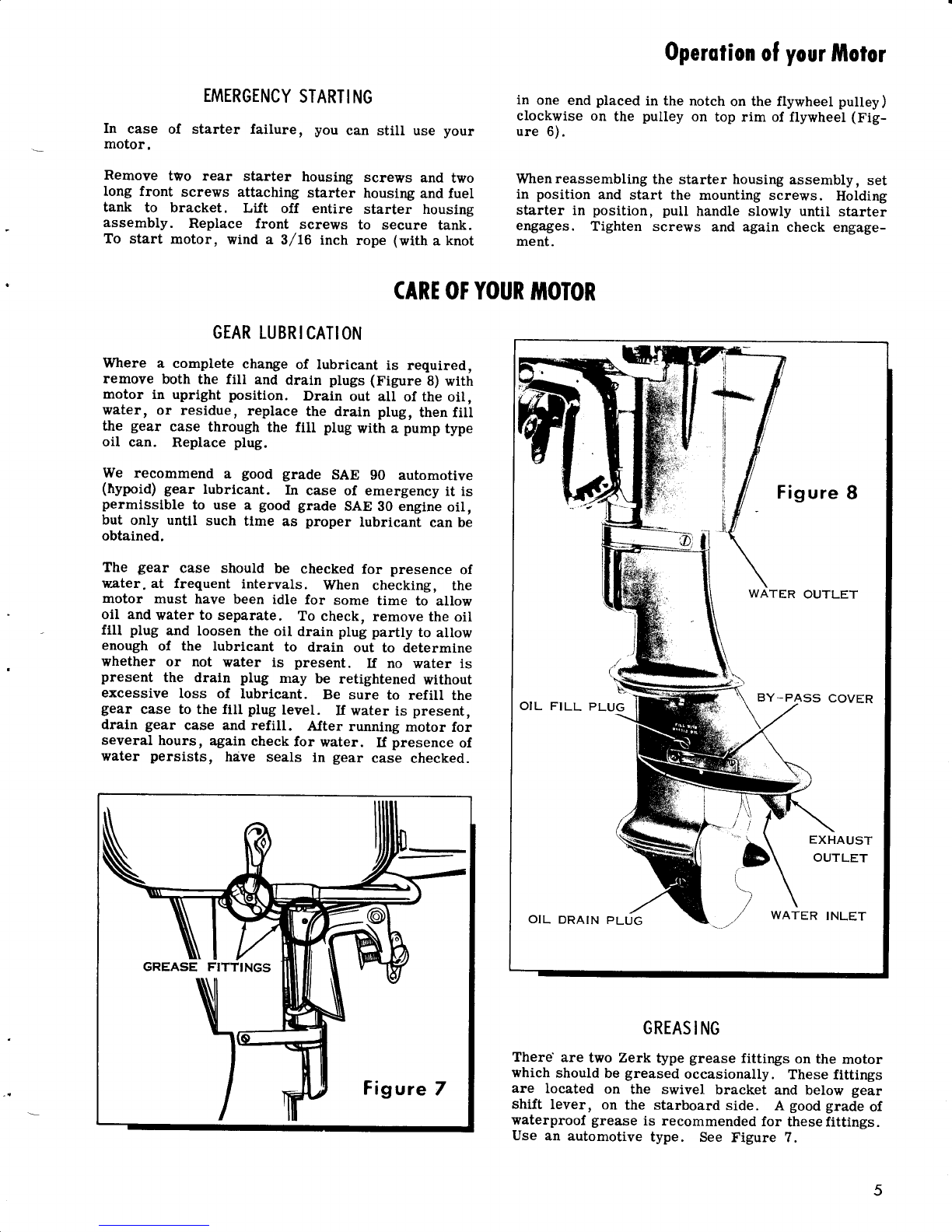

I1, while operating motor at full speed, it

should show signs of slowingdown, immedi-

ately check water drscharge at water outlet

(Figure B) located at rear of the motor di-

rectly below cylinder. In case no watei is

being discharged, immediately shut off the

motor and check water inlet (Figure 8) for

obstruction. If no obstruction is found, it

may indicate worn pump parts.

REMOVING

MOTOR

FROMBOAT

At end of run, with motor running in NEUTRAL,

plose fuel shut-off valve and permit motor torununtil

it stops, draining carburetor. Close air vent screw

in filler cap. The motor can then be carried with-

out fuel leakage. For safety, always drain fuel

tank before transporting motor. Also drain water

thoroughly as in "Care of Motor in CoId Weather. "

When removing motor from boat, Iift motor in a

straight upward position and hold this position for

a brlef period until aII water is drained from the

underwater exhaust tube and water cooling system.

Do not stand motor on top or carry with the top down

before draining water, as this may allow water to

enter the power head from underwater exhaust tube.

CARE

OFMOTOR

INCOLD

WEATHER

The motor will not freeze while in use, but when it

is idle, water in the cylinders or pump might lreeze

and damage the motor. Drain by setting the motor in

an upright position and pulling starter cord several

times with speed control grip in STOP position. If

the motor is to be stored during cold weather, be

sure that no water is left in the motor or it mav

freeze. (See "Preparation for Storage. ")

SALT

WATER

INSTRUCTIONS

A little time spent in caring for your motor whenused

in salt water will aid in not only keeping it in good

running order but help in retaining its finish and ap-

pearance. Tilt the motor out of the water when it is

not in use. At the end of the day or when not using

the motor for a period of time it is advisable to re-

move it from the boat and to flush it by running it in

a tank of fresh water. Wipe the motor dry and go

over all parts with an oily cloth. This should be

done as soon as possible after removing the motor

from the boat.

PREPARATION

FOR

STORAGE

No outboard motor should

be placed

in storage

with-

out considering

the necessaryprecautions. U motor

Coreol

yourlulolor

is operated in salt watet, flush by running in a tank

of fresh water. Drain and refill gear case with the

proper lubricant. See page 5.

Prior to storing the motor, run it for about one-half

(172) minute in choke position. Shut off motor with-

out pushing choke back to normal position. Purpose

of this operation is to flood the inner parts of tlie

powerhead with oil (oil in fuel mixture) while in

storage.

Drain all water from the cooling system. See "Care

of Motor in CoId Weather. "

Drain all fuel from fuel tank, gas.line and carbure-

tor.

Under no circumstances should the motor be stored

in an inverted position. It should be hung on a rack

similar to the manner in which it is mounted on the

boat. Store in a dry place. Wrap the motor in a

piece of canvas, old blanket. or heavy paper.

PUTTINGMOTOR

INUSEAFTERSTORAGI

Pull off spark plug Ieads and remove spark plugs.

If rubber spark plug hoods have been removed from

ignition leads, be sure to ground Ieads to some part

of motor to prevent possibility of spark. (THIS IS

IMPORTANT. ) Spin motor by pulling on starter cord

to remove excess oil from cylinders. Clean spark

plugs, check gap and replace. InstaII new plugs if

they are cracked, broken, or badly burned. Tighten

a-llscrews and nuts. Check adjustments such as tilt-

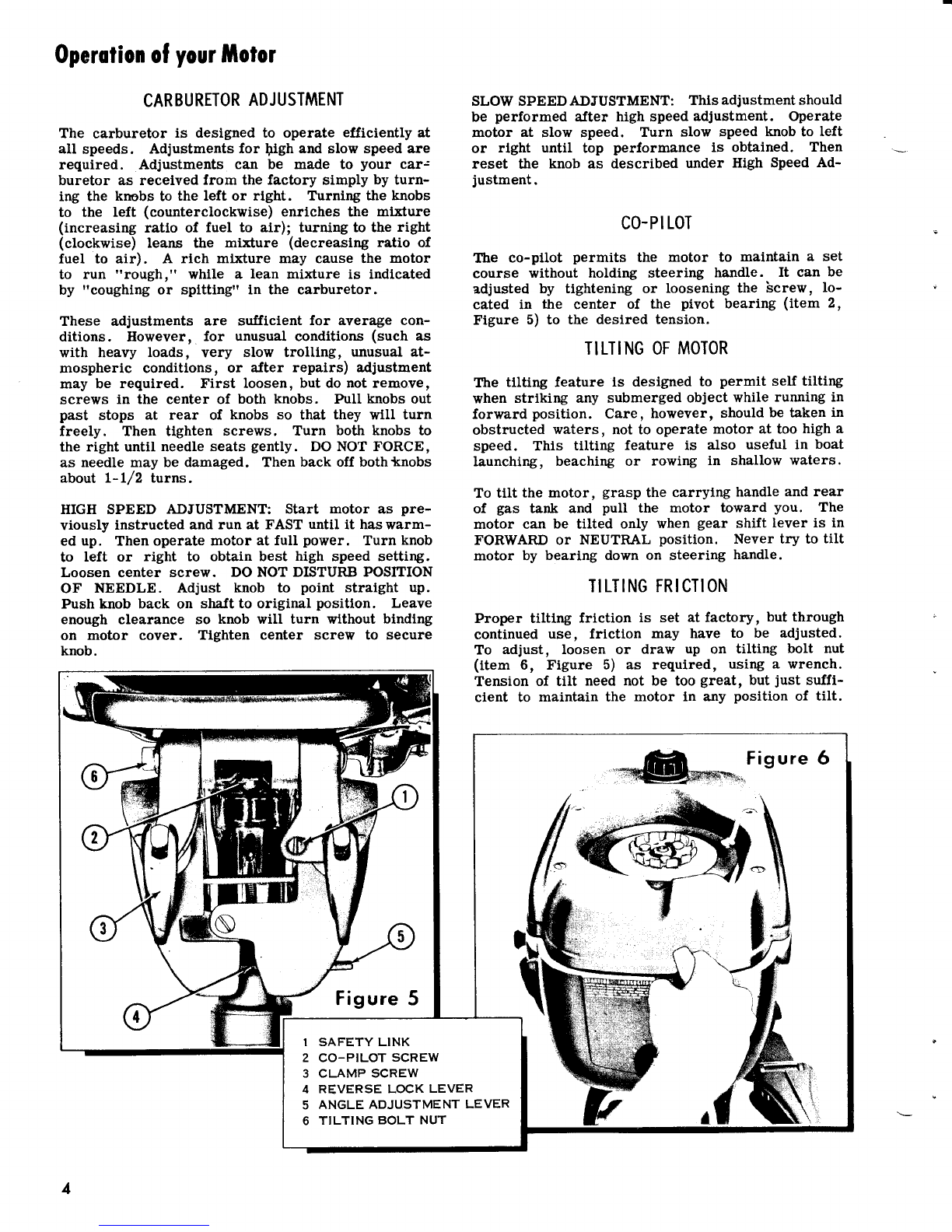

ing friction, co-pilot, and carburetor knob.

RUNNING

MOTOR

IN

TESTTANK

1. Do not run motor out of water.

2. Do not "break-in" motor in tank.

3. Remove water by-pass cover (small metal strip

on lower port side of upper pump housing, Figure B).

4. When running in tank be sure gear housing and

propeller are submerged.

5. Do not race motor in tank.

6. Use test propeller when testing motor in tank.

7. Cavitation (air pocket around propeller) may occur

when operating motor in tank with regular propeller.

Motor will then not perform properly or it may race

and be damaged as a result.

MOTORSTHAT

HAVI

BEIN

SUBMERGED

Precaution should be taken to prevent a motor going

overboard (see page 1). However, if a motor has

been submerged, it should be recovered as quickly

as possible.

Since the motor is temporarily out of working order,

do not attempt to operate it untii the following pro-

cedure has been used to restore it to service.