P51921 Rev 02

Effective: June 2007 Page 2

Questions? Call our Sensor Application Engineers at (800) 426-9184.

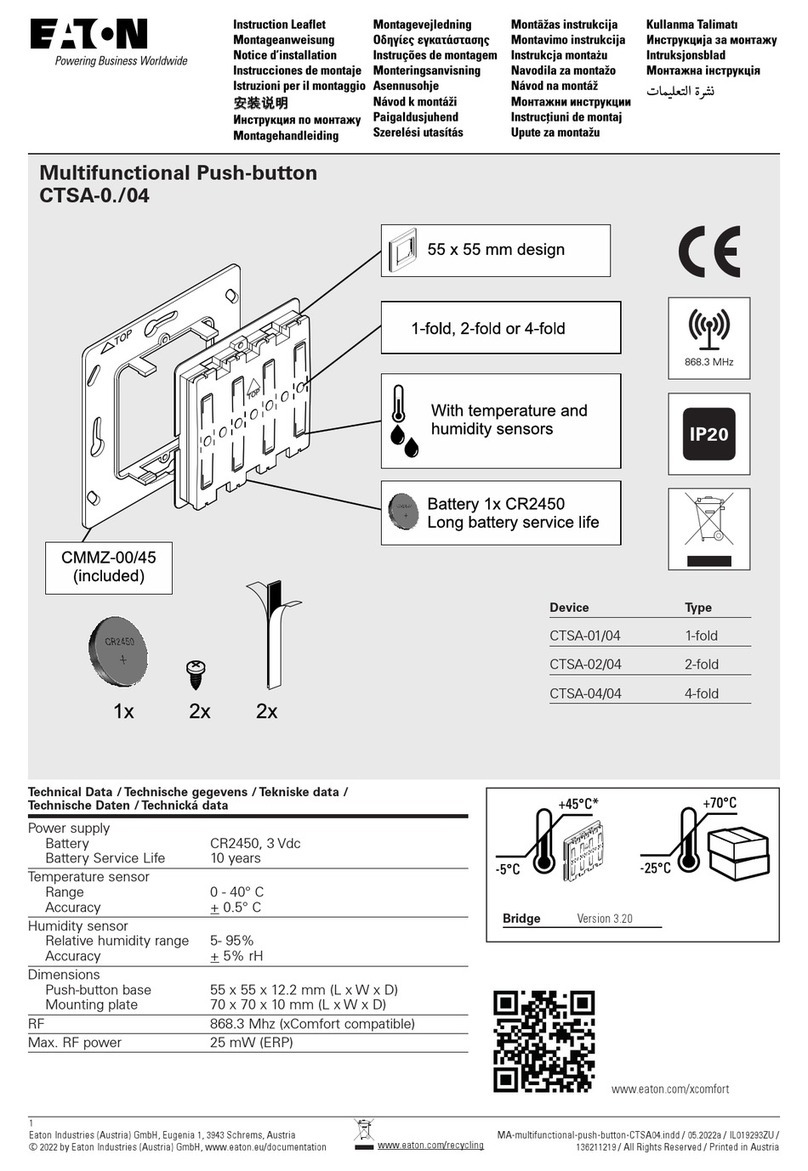

RANGES AND MAXIMUM AMPS

Housing Range

Maximum Amps

Continuous 6 sec. 1 sec.

Solid Core 1.5-175A 150A 400A 1,000A

Split Core 2-200A 150A 400A 1,000A

SWITCHING DELAY

Delay Type Low Range Mid Range High Range

On Delay 0.23 sec. max. 0.05 sec. max. 0.03 sec. max.

Off Delay 0.02 sec. max. 0.02 sec. max. 0.01 sec. max.

TROUBLESHOOTING

Problem Solution

Switch is

always tripped

The setpoint may be too low. Turn pot clock-wise to increase setpoint.

Switch may have been overloaded and contacts are burned out. Check the

output load, remembering to include inrush on inductive loads (coils, motors).

Switch will

not trip

The setpoint may be too high. Turn pot counter-clockwise to decrease

setpoint.

For split core models, the core contact area may be dirty. Open the sensor

and clean the contact area.

The monitored current may be below the minimum required. Loop the

monitored wire several times through the aperture until the “sensed” current

rises above the minimum. The sensed amps equals “actual amps” multiplied

by the “number of loops.” Count loops on the inside of the aperture.

Switch may have been overloaded and contacts are burned out. Check the

output load, remembering to include inrush on inductive loads (coils, motors).

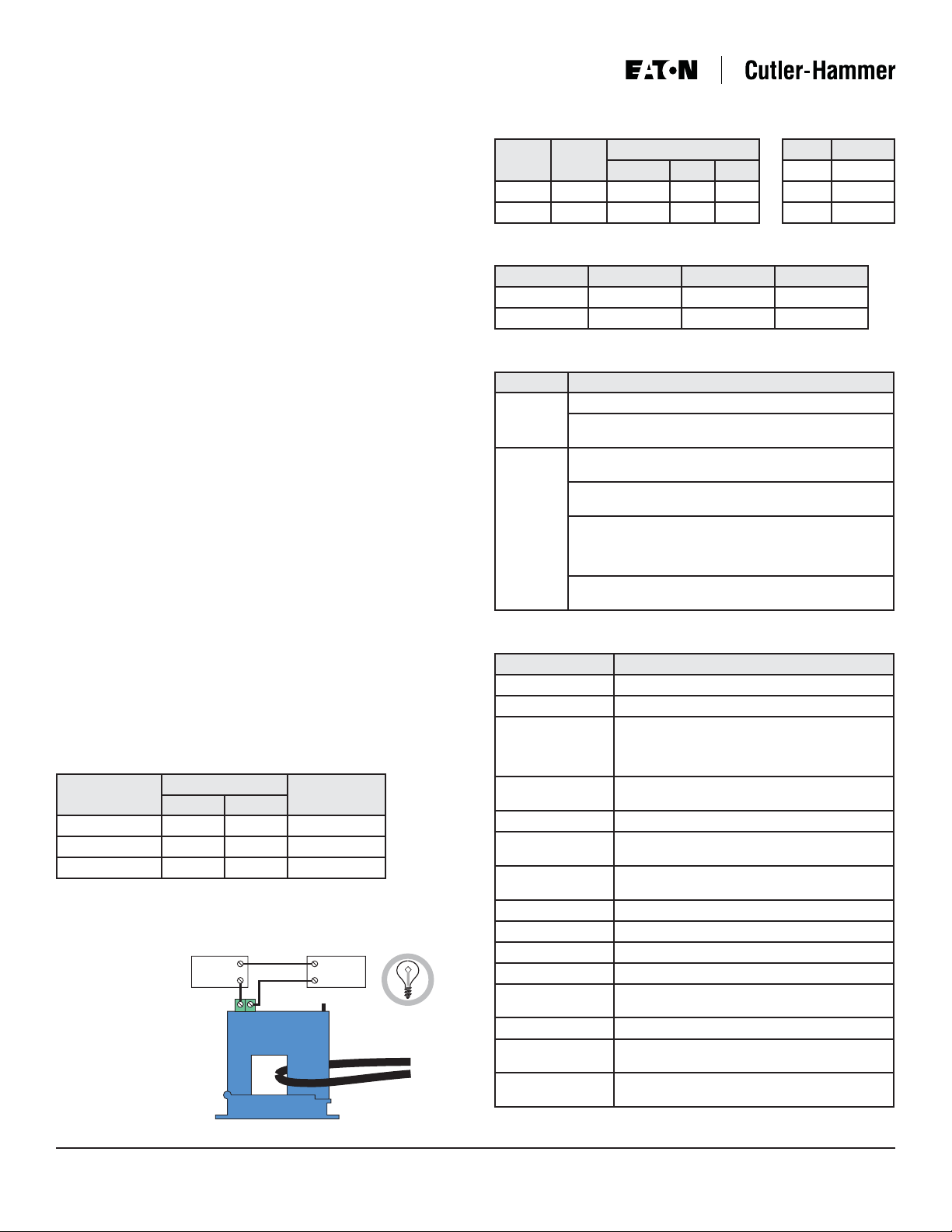

SPECIFICATIONS

Specification Value

Power Supply Self Powered–No Power Supply Needed

Output Magnetically Isolated Solid State Switch

Output Rating AC-Only Models: N.O./N.C. 1A @ 240V AC

AC/DC Models:

N.O. 0.15A @ 240V AC/DC

N.C. 0.20A @ 135V AC/DC

Off-State Leakage ECSTD402SC and ECSTD405SP Models: 2.5 mA

All Other Models: Negligible

Response Time Adjustable, 0.12 to 15 seconds

Setpoint Range Solid Core Models: 1.5-12, 12-55 and 50-175A

Split Core Models: 2-12, 12-55 and 50-200A

Setpoint Adjustment Solid Core Models: 15-Turn Potentiometer

Split Core Models: 4-Turn Potentiometer

Hysteresis Constant 5% of Setpoint

Overload See “Ranges and Maximum Amps” in Above Table

Isolation Voltage UL Listed to 1,270V AC, Tested to 5,000V AC

Frequency Range 50-100Hz

Sensing Aperture Solid Core Models: 0.75 in. (19mm) dia.

Split Core Models: 0.85 in. (21.7mm) sq.

Housing UL94 V0 Flammability Rated

Environmental Operating Temperature: -58 to +149° F (-50 to +65° C)

Humidity: 0-95% RH, Non-Condensing

Approvals UL and ULC Listed (Pending)

CE Certified (Pending)

394000109

SETPOINT ADJUSTMENT

The CurrentWatch™ ECSTD Series setpoint and time delay are adjusted

through two four-turn pots (on split-core models) and 15-turn pots (on

solid-core models). The unit comes from the factory with setpoint and

time delay set to the lowest level (fully counter-clockwise). Turning the

pots clockwise will increase their value. All pots have a slip-clutch to

prevent damage at either end of their rotation. To determine where the

adjustment is, turn the pot all the way counter-clockwise. This will return

it to the minimum setpoint.

Important Setpoint Adjustment Notes

• Output contacts are solid-state. Check output status by applying

the appropriate voltage to the contacts and reading the voltage

drop across the contacts. An Ohmmeter set on “continuity” will

give misleading results.

• It is recommended the setpoint be adjusted to allow for the usual

utility company voltage variations of 10 to 15 percent.

Typical Adjustment Steps

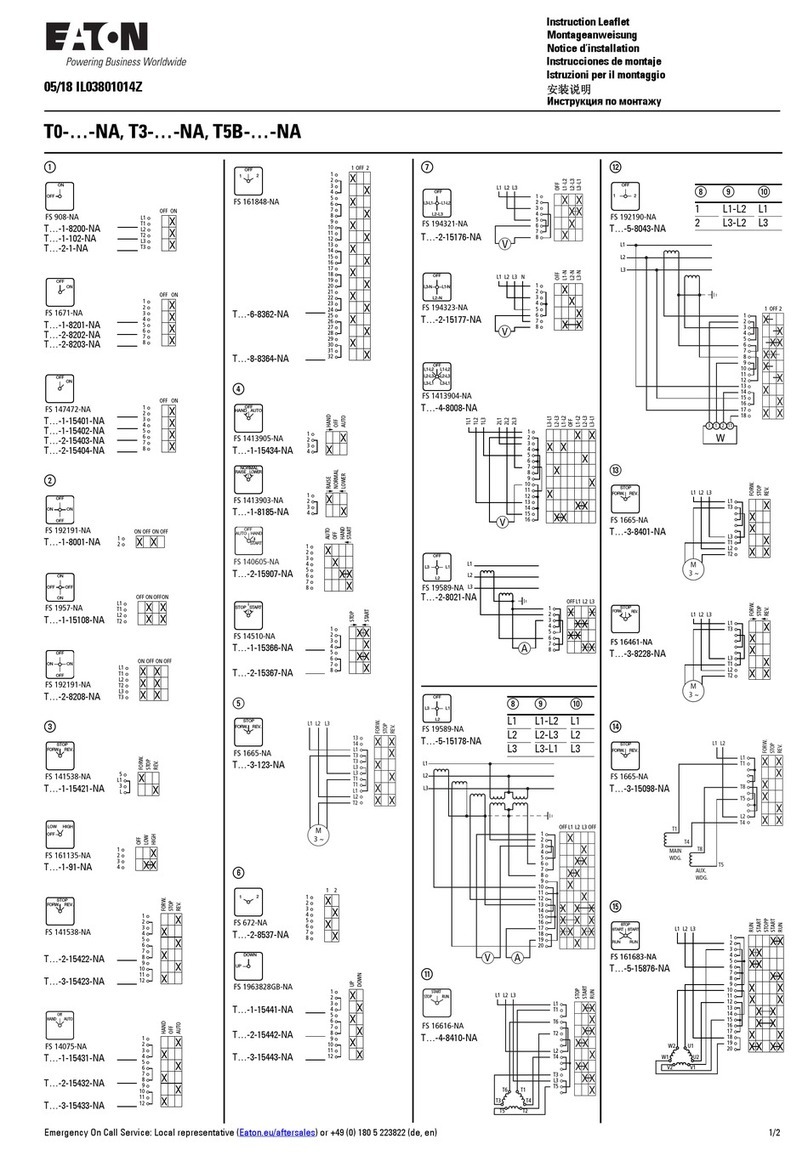

1. Identify expected Input Range and position jumper accordingly.

For LOW range, remove jumper entirely. For MID or HIGH range,

place jumper over proper two pins.

2. Turn the setpoint pot to the minimum value (four turns for split-core

models and fifteen turns for solid-core models).

3. Have normal operating current running through the switch. The

output should be tripped because the pot is at its minimum

setpoint. For units with LED, it should be flashing fast (two to three

times per second).

4. Turn the pot clockwise until the unit un-trips. This is indicated by

the slow flashing of the LED (once every two to three seconds), or

by the changing of the output switch status.

5. Now turn the pot counter-clockwise slowly until the unit trips again.

a. To set underload, turn the pot about 1/8 turn further counter-

clockwise

b. To set overload, turn the pot about 1/8 turn further clockwise

6. Adjust the time delay of the contact action in the same fashion.

Increase time delay by turning the pot clockwise. For split-core

models, each quarter-turn corresponds roughly to one second of

delay time. Expect ten turns for a 15 second delay.

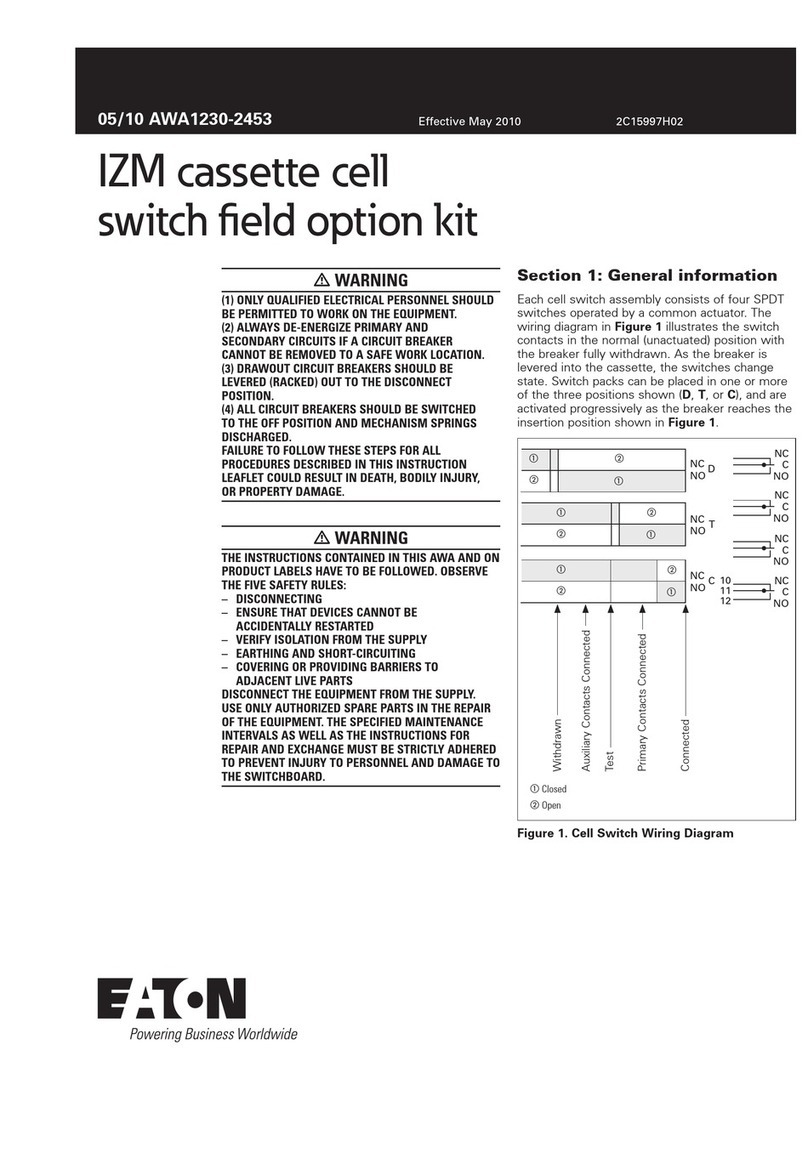

LED INDICATION / OUTPUT STATUS

Monitored Amps

Output Smart-LED

(If Present)N.O. N.C.

None or Minimum Open Closed Off

Below Trip Level Open Closed Slow (2 sec.)

Above Trip Level Closed Open Fast (0.5 sec.)

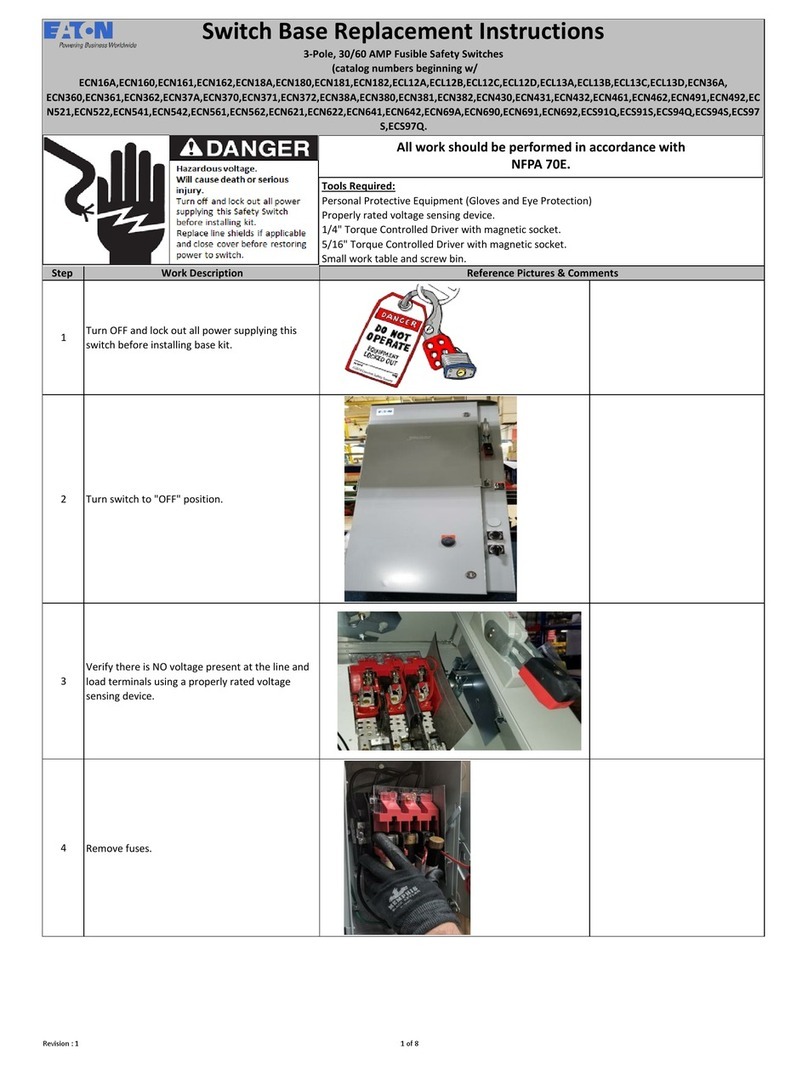

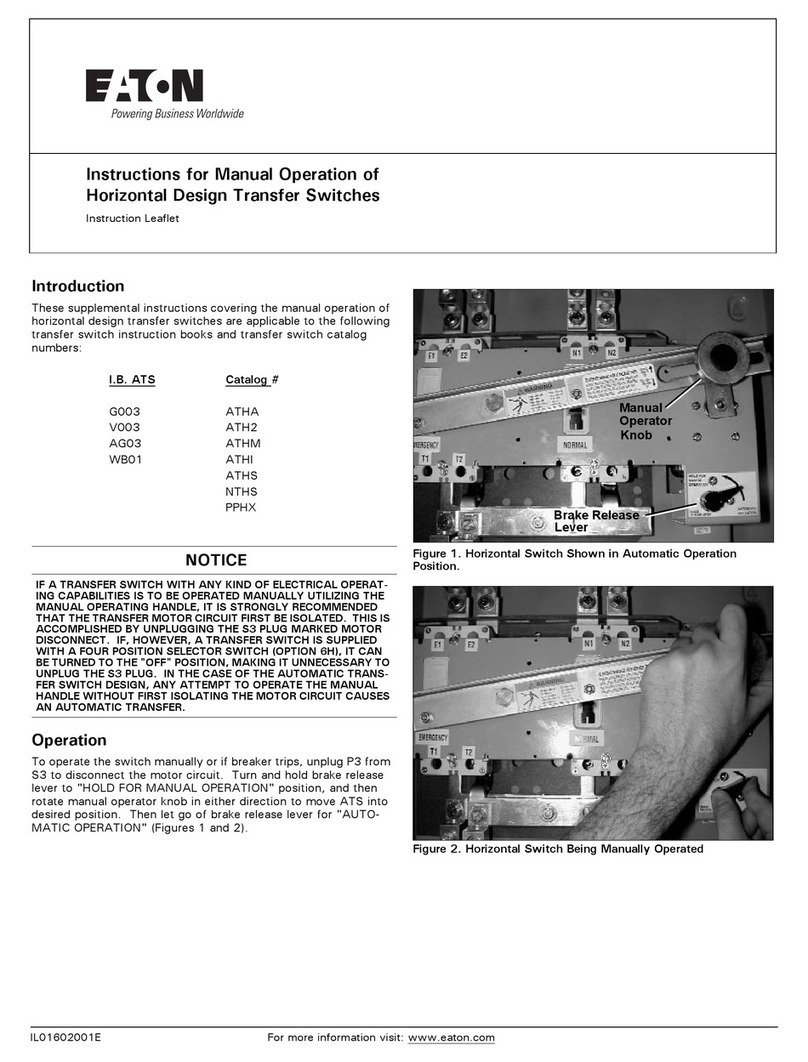

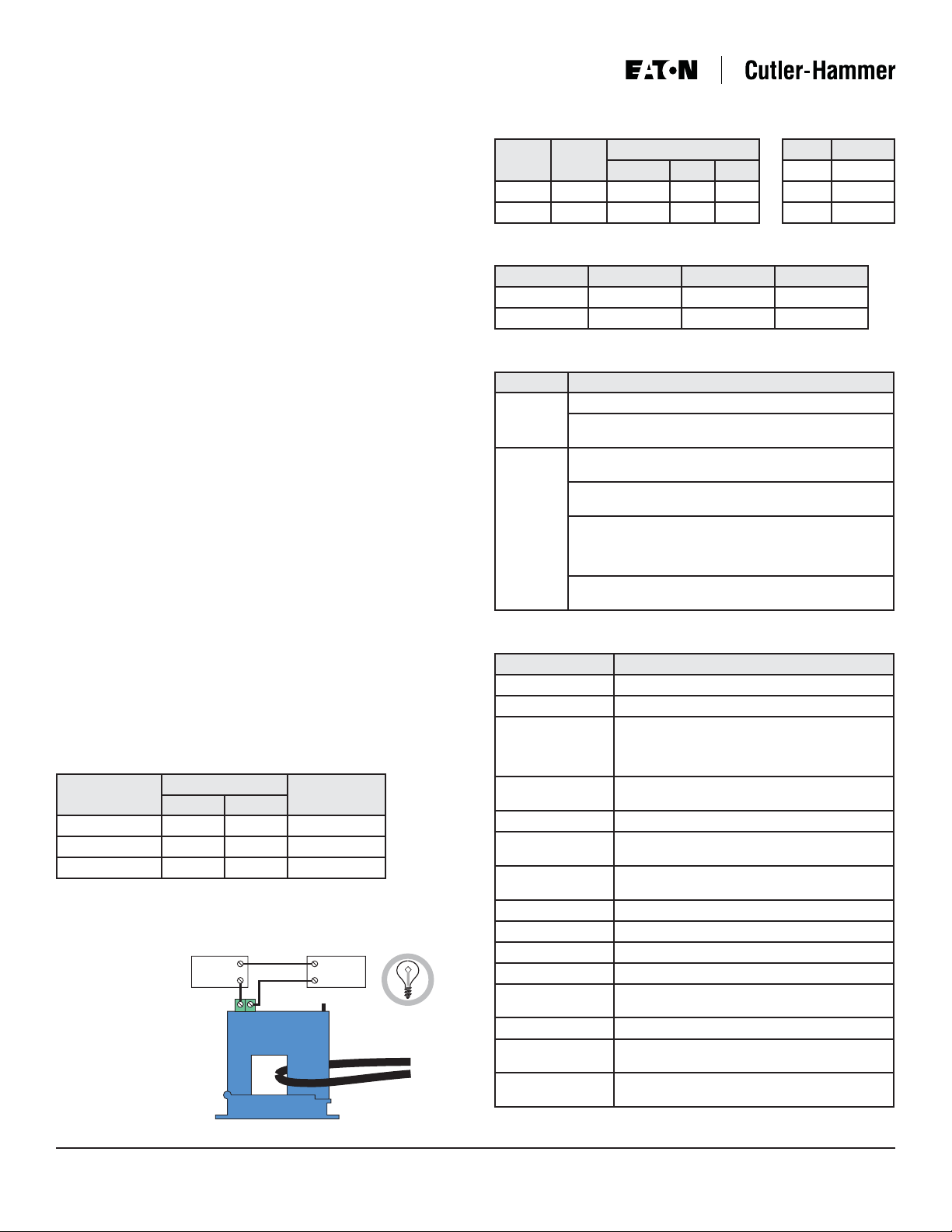

WIRING DIAGRAM

Connect control or monitoring wires to the sensor. Use up to 14 AWG

copper wire and tighten terminals to 5 inch-pounds torque. Be sure the

output load does not

exceed the solid state

output rating.

CAUTION! Incandescent

lamps can have “cold

filament inrush” current of

up to ten times their rated

amperage. Use caution

when switching lamps.

HYSTERESIS

Setting Hysteresis

Low <0.01A

Mid <0.1A

High <0.5A

AC or DC

Power

AC or DC

Load

Output Signal

To Monitored Load

Use caution when

switching lamps