SECTION 4 – OPERATION

4.1 DESCRIPTION

The RB10 Pumpset is designed to provide trouble-

free & safe operation in potentially explosive

environments provided it is operated in accordance

with the following recommendations.

1. Pump

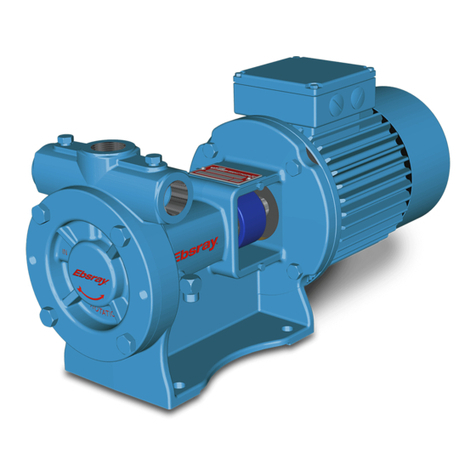

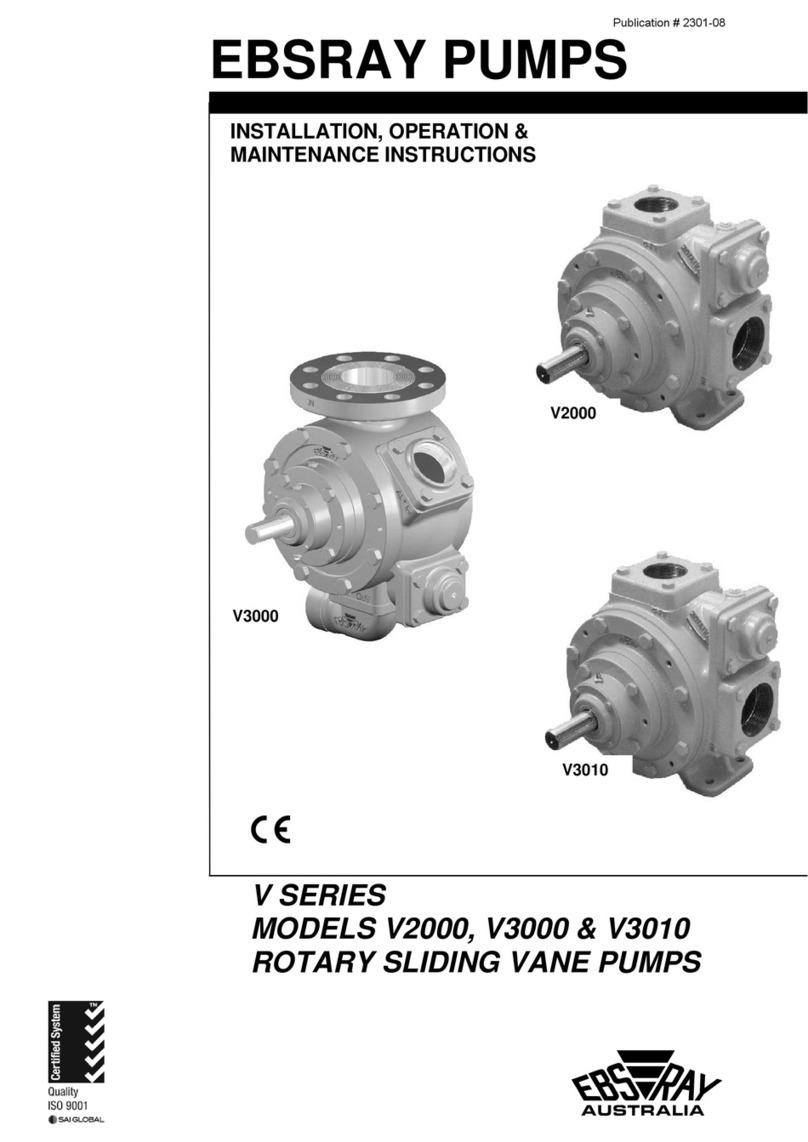

The Ebsray Model RB10 pump is a compact

Regenerative Turbine pump-motor unit, designed for

pumping LPG of Internationally accepted (ISO) quality

and specification.

The Pump meets the requirements of Australian,

European ATEX and other International Standards

and Codes for use in potentially explosive

atmospheres.

2. Motor

Standard RB10 pumpsets are available from Ebsray

using Direct Coupled 2,880 RPM (4kW or 5.5kW

50hz) or 3,500 RPM (5.5kW or 7.5kW 60hz) Electric

Motors. Ebsray can supply other options to suit

customer requirements. The RB10 pump can also be

driven by other means such as belt drive, diesel

engines etc. Ensure motor conformity with all

necessary Codes, Regulations, Standards, Directives

and site requirements.

3. Coupling

Non-Sparking design (e.g. “polygear” type) – sized to

suit duty. Supplied by Ebsray or customer supplied.

4.2 LUBRICATION

The Ball Bearings for RB10 pumps are grease

lubricated and 'sealed-for-life' design.

No 'in service' lubrication is required on EBSRAY's

RB10 Pumps.

For motor, refer to specific motor manufacturer's

recommendations.

4.3 PRE-STARTUP CHECKLIST

Refer to pre-start inspection checklist (Appendix B)

Do not run Pumpset dry.

Do not start Pump against

e. Severe internal damage

to the Pumpset will result, voiding Warranty.

closed Discharge Valv

4.4 STARTUP PROCEDURE

Fill in the ‘Pump Run Log’ provided in Appendix C

1 Ensure all conditions described in Pre-Startup.

2. pressure gauge. the

3. w to

4. nd statutory requirements

5. power (i.e. 'jog' motor) to verify

6

e

Checklist have been met.

Check reading on discharge

Record product vapour pressure in

commissioning section of the Pump Run Log.

Back-off Bypass Valve Adjusting Screw (scre

maximum 'out' position).

Verify all site conditions a

have been met.

Briefly activate

correct pump rotation. (Cast arrow on cover)

Start Pumpset.

If any aspect of the

pumpset or pumping

system does not function properly, immediately

turn the pump 'off' and rectify the problem befor

re-starting.

7. After startup, pump should immediately begin to

build differential pressure. If pump does not

prime immediately, switch off to determine reason

and rectify before re-starting.

8. After startup, initially ensure that liquid is flowing

through Bypass Valve. This should be detectable

by listening or feeling the Bypass Valve.

Screw 'in' the Bypass Valve Adjusting Screw until

the required system differential pressure is

achieved.

Record discharge pressure in the commissioning

section of the Pump Run Log.

9. Check that motor current is below FLA rating.

Record motor current readings in the

commissioning section of the Pump Run Log.

NOTE: During this procedure, or at any time,

motor current must not exceed FLA rating of

motor.

10. Stop pump, restart and check for consistent results.

11. Record discharge pressure and current readings in

the commissioning section of the Pump Run Log.

12. The Pumpset is now ready for normal operation.

13. After final Bypass Valve adjustment, tighten

adjusting screw locknut and seal for security.

14. The startup procedure is now complete.

15. Inspect Pumpset/pumping system frequently during

the first few hours of operation then periodically

thereafter (see Section 4.5 for frequency).

Record observations from these inspections in the

Pump Run Log.

4.5 PERIODIC INSPECTION

Periodic Inspection of the Pump, Pump System and

Ancillary Equipment is required to maintain safety,

conformity, operational functionality and reliability.

Ebsray recommends a maximum interval of three

months or 500 hours operation between routine

periodic maintenance inspections (More frequent

inspections may be necessary dependent upon

usage, site conditions, operation etc).

If any abnormal condition is discovered, cease

operation of pump immediately and take action to

rectify the problem. Record observations from these

inspections in Pump Run Log.

For safe operation, the following items should be

included in the routine periodic inspection:

a. Inspect the Pump for LPG leaks, vibration,

abnormal noises, signs of overheating,

discolouration, etc.

b. Inspect Coupling Assembly for signs of wear,

overheating, discolouration, etc.

c. Check Pump differential pressure

d. Check Motor Current.

e. Inspect motor for vibration, abnormal noises,

signs of overheating, discolouration, etc.

8