6

3.1.6 Bypass Valve

Bypass Valve (Ebsray Model RV18-VRS or CBS)

(Refer Appendix A - P & ID for details) is installed on

the pump discharge side and returns back-to-tank. It

may be mounted directly on the 'spare' discharge port or

in the discharge pipe (before any isolation valve). This

Bypass Valve is primarily for control of differential

pressure. (NOTE: Variation in tank vapour pressure has

a direct effect upon discharge pressure whilst constant

differential pressure is maintained).

If VRS option is used (Refer Appendix A - P & ID for

details), a critical function performed by this unique

Bypass Valve is its rapid vapour handling capability

during the pump start-up/priming cycle. (Also refer to

Ebsray RV18 Bypass Valve Brochure for details and

functionality.)

Ensure correct orientation i.e. flow is 'IN' from pump

discharge line and 'OUT' returns to tank.

NOTE: The Bypass Valve’s return-to-tank pipeline

MUST NOT have any restrictions which could

adversely affect or limit the vapour clearing

function during pump priming.

An Excess Flow Valve or other 'normally open' tank

valve is recommended/ preferred.

Flow of LPG during bypassing should return to Storage

Tank vapour space.

SECTION 4 – OPERATION

4.1 DESCRIPTION

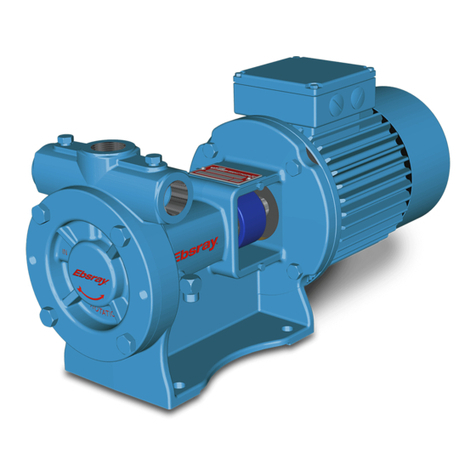

1. Pump

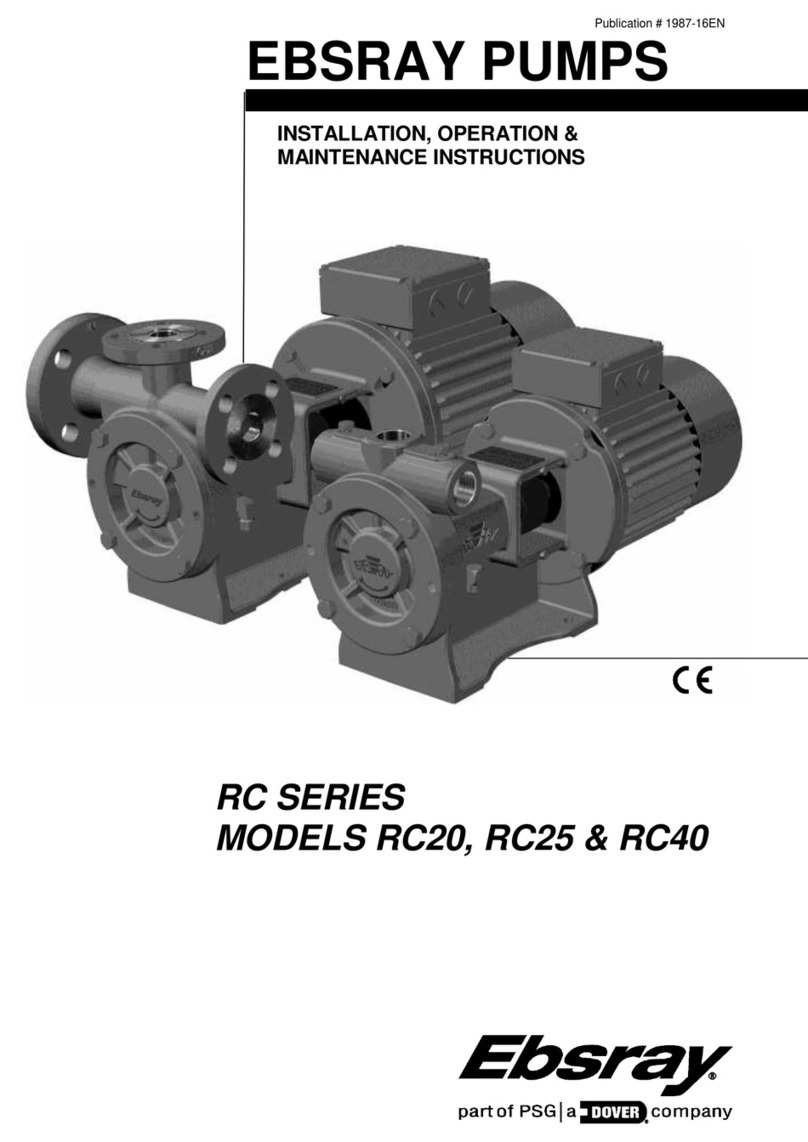

The Ebsray RC Series pumps are designed for ultra

quiet operation pumping LPG of Internationally

accepted (ISO) quality and specification.

The Pump meets the requirements of Australian,

European ATEX and other International Standards

and Codes for use in potentially explosive

atmospheres.

2. Motor

Certified explosion protected IEC frame 90 or 100 B5

Flange Mount 50Hz 2880 RPM or 60Hz 3500 RPM

electric motors fit directly onto RC Series pumps.

The RC20 uses 1.5 or 2.2kW and the RC25 uses 2.2

or 3.0kW Motors which can be either supplied by

EBSRAY or customer supplied. Motor must be wired

with a correctly sized IEC class 10A thermal overload

relay, and set to no more than the FLA of the motor.

Ensure motor conformity with all necessary Directives,

Standards, Codes, Regulations and site requirements.

3. Coupling

Non-Sparking design (e.g. “polygear” type) – sized to

suit duty. Supplied by Ebsray or customer supplied.

4.2 LUBRICATION

The Ball Bearings for the RC Series pumps are

grease lubricated and 'sealed-for-life' design.

No 'in service' lubrication is required on EBSRAY's

RC Series Pumps.

For motor, refer to specific motor manufacturer's

recommendations.

4.3 PRE-STARTUP CHECKLIST

Refer to pre-start inspection checklist (Appendix B)

Do not run Pumpset dry.

Do not start Pump against

e. Severe internal damage

to the Pumpset will result, voiding Warranty.

closed Discharge Valv

4.4 STARTUP PROCEDURE

Fill in the ‘Pump Run Log’ provided in Appendix C

.

2. pressure gauge. the

6 Start Pumpset.

1 Ensure all conditions described in Pre-Startup

Checklist have been met.

Check reading on discharge

Record product vapour pressure in

commissioning section of the Pump Run Log.

3. Back-off Bypass Valve Adjusting Screw (screw to

maximum 'out' position).

4. Verify all site conditions and statutory requirements

have been met.

5. Briefly activate power (i.e. 'jog' motor) to verify

correct pump rotation. (Cast arrow on cover)

If any aspect of the

pumpset or pumping

system does not function properly, immediately

turn the pump 'off' and rectify the problem before

re-starting.

7. After startup, pump should immediately begin to

build differential pressure. If pump does not

prime immediately, switch off to determine reason

and rectify before re-starting.

8. After startup, initially ensure that liquid is flowing

through Bypass Valve. This should be detectable

by listening or feeling the Bypass Valve.

Screw 'in' the Bypass Valve Adjusting Screw until

the required system differential pressure is

achieved.

Record discharge pressure in the commissioning

section of the Pump Run Log.

9. Check that motor current is below FLA rating.

Record motor current readings in the

commissioning section of the Pump Run Log.

NOTE: During this procedure, or at any time,

motor current must not exceed FLA rating of

motor.

10. Stop pump, restart and check for consistent results.

11. Record discharge pressure and current readings in

the commissioning section of the Pump Run Log.

12. The Pumpset is now ready for normal operation.

13. After final Bypass Valve adjustment, tighten

adjusting screw locknut and seal for security.

14. The startup procedure is now complete.

15. Inspect Pumpset/pumping system frequently during

the first few hours of operation then periodically

thereafter (see Section 4.5 for frequency).

Record observations from these inspections in the

Pump Run Log.