Eclipse AH-MA Series Guide

Other Eclipse Burner manuals

Eclipse

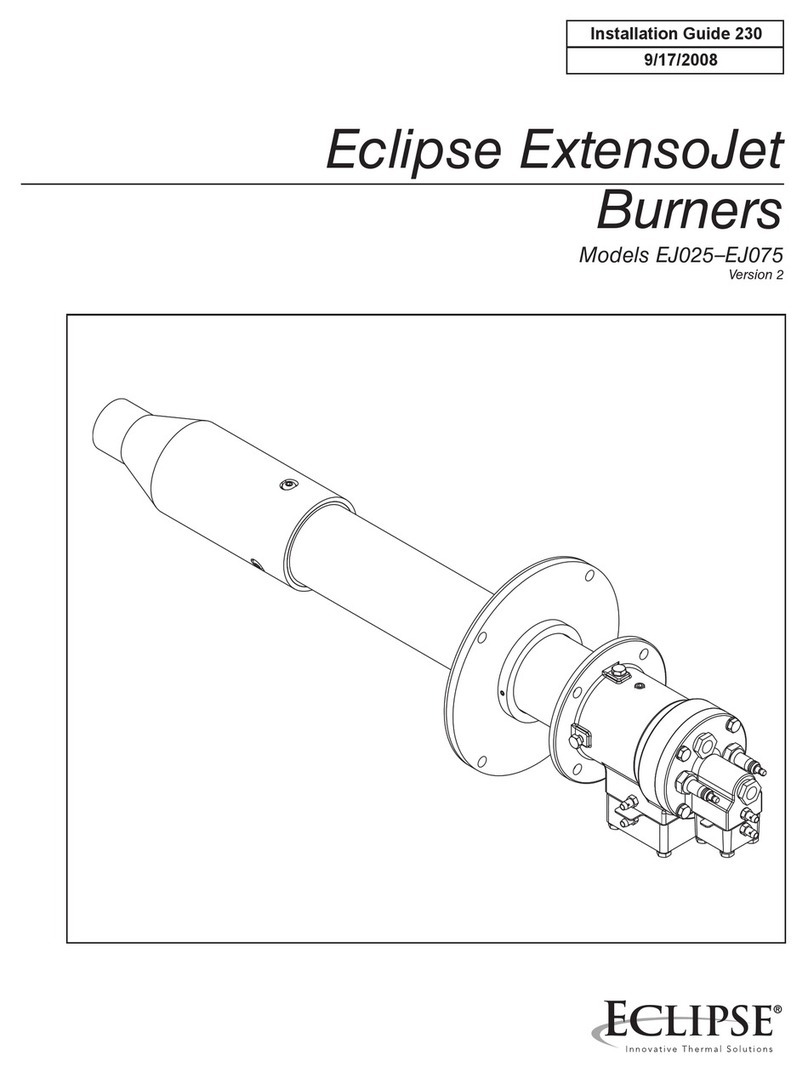

Eclipse ExtensoJet EJ025 User manual

Eclipse

Eclipse Immerso-Pak 100 IP Series Technical manual

Eclipse

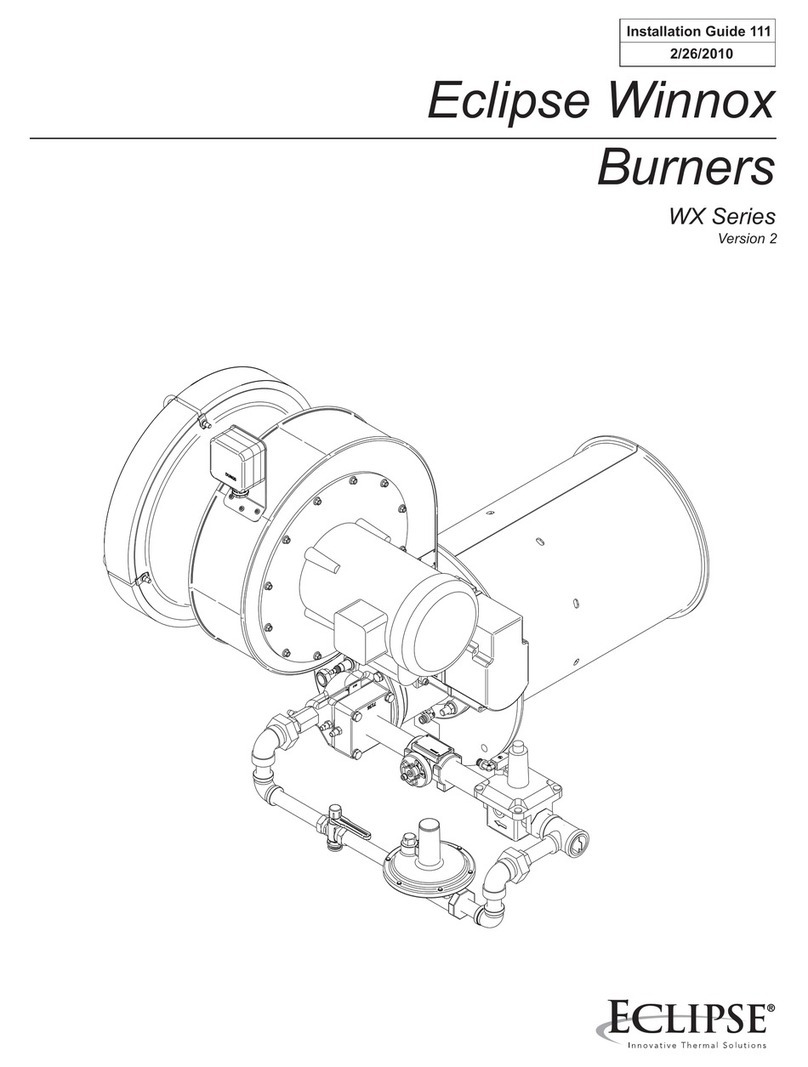

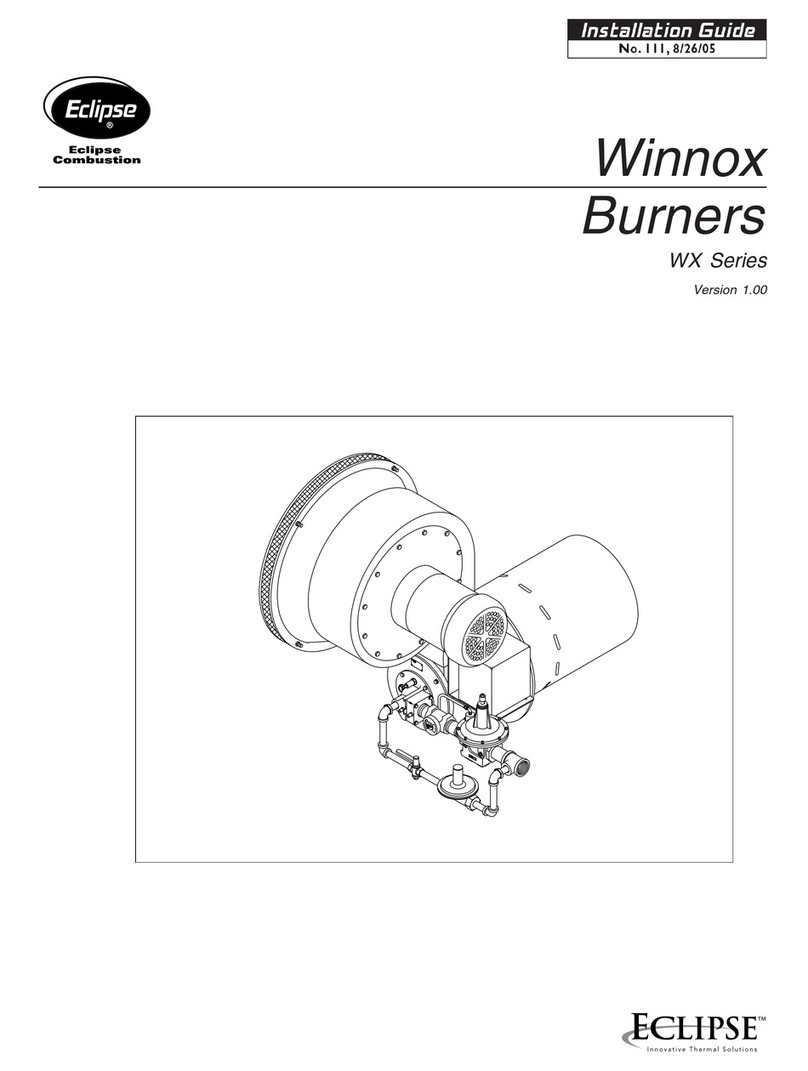

Eclipse Winnox WX Series User manual

Eclipse

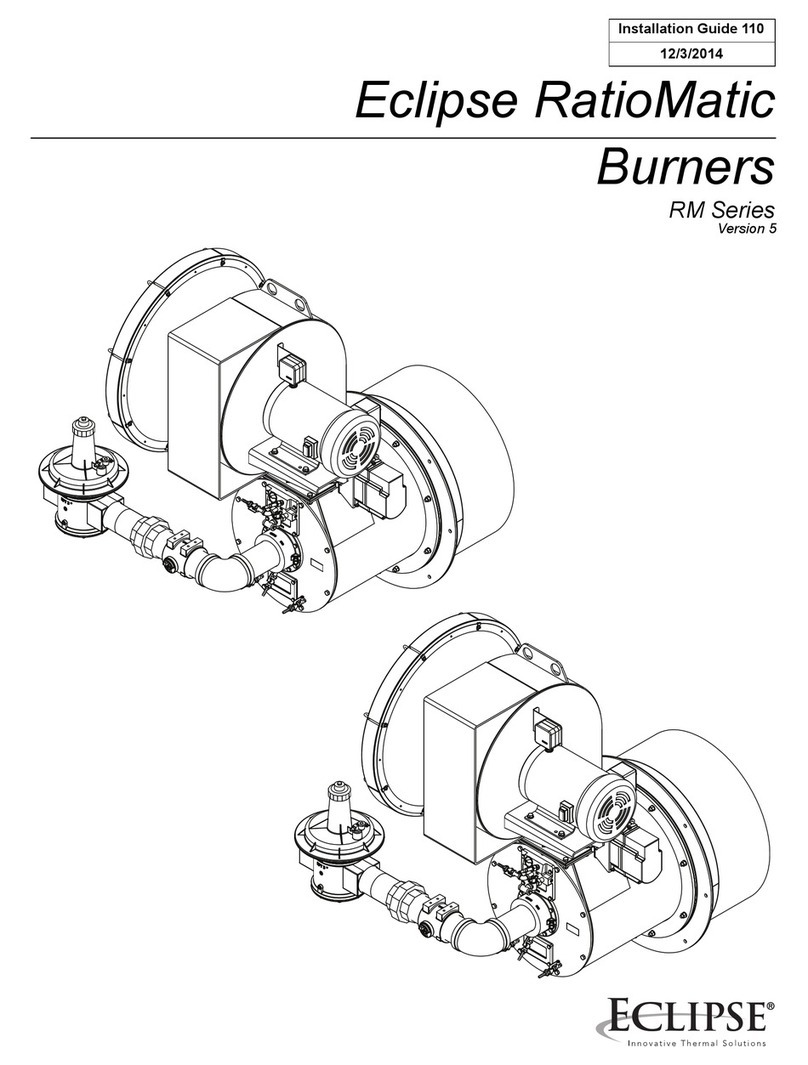

Eclipse RatioMatic RM Series User manual

Eclipse

Eclipse RA Series Guide

Eclipse

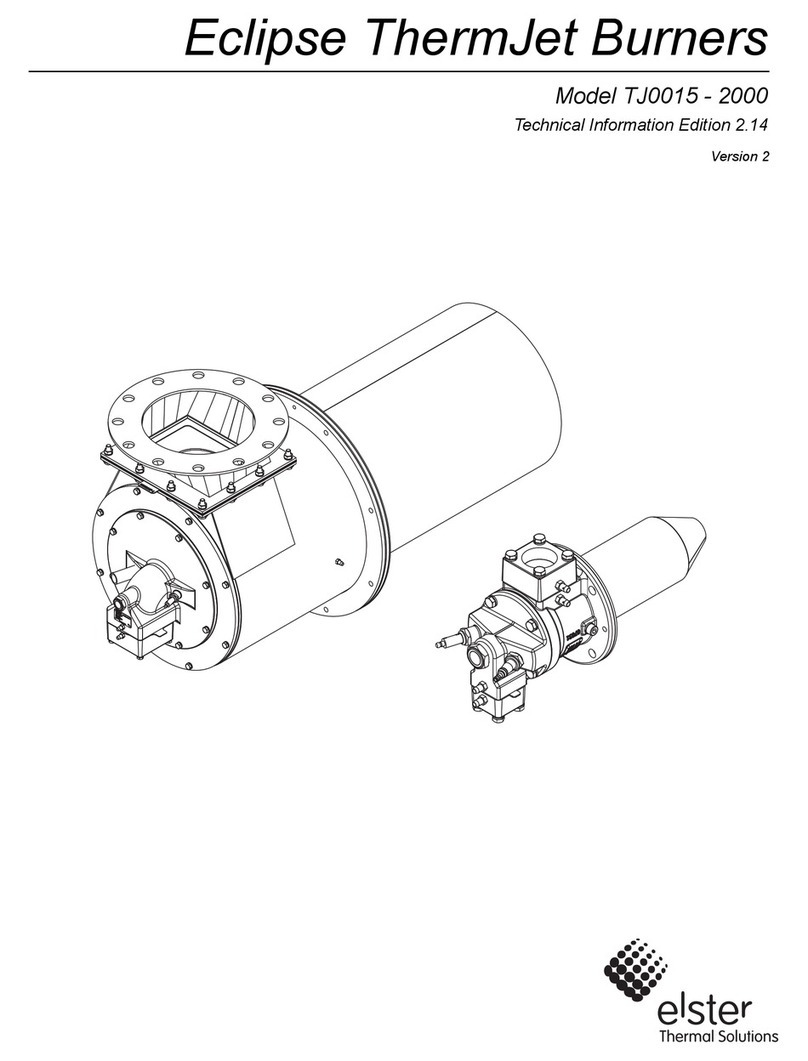

Eclipse ThermJet TJ0015 - 2000 Manual

Eclipse

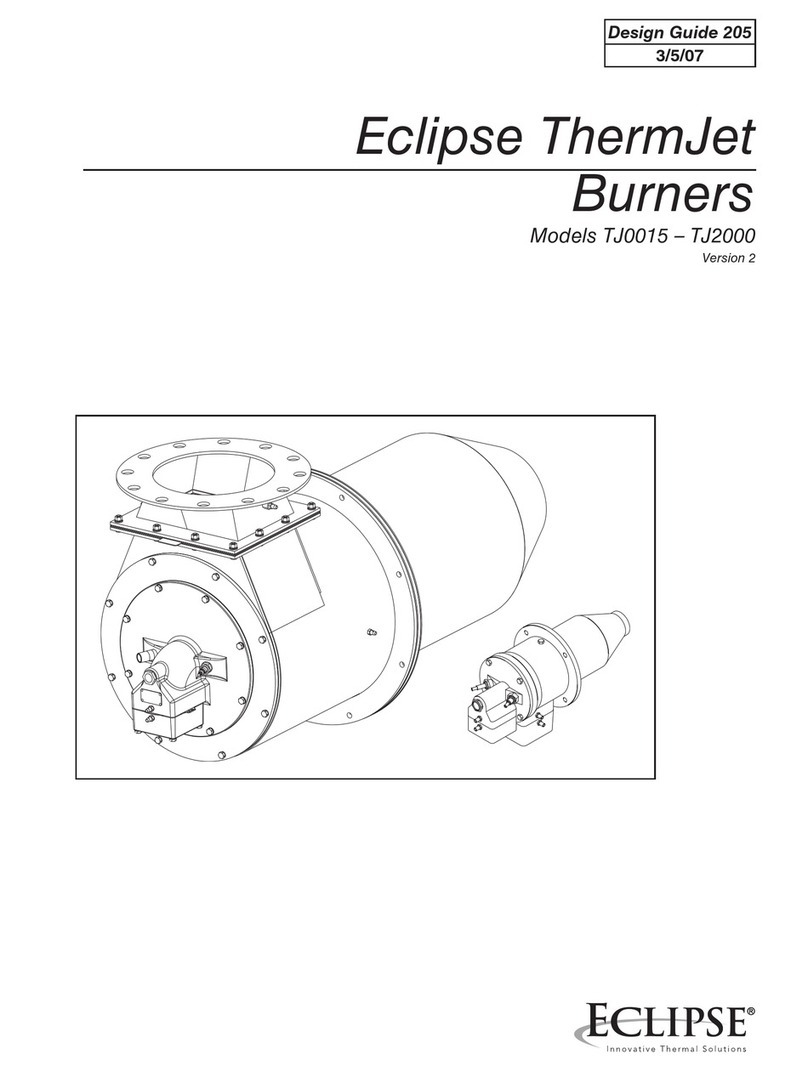

Eclipse ThermJet TJ0015 Guide

Eclipse

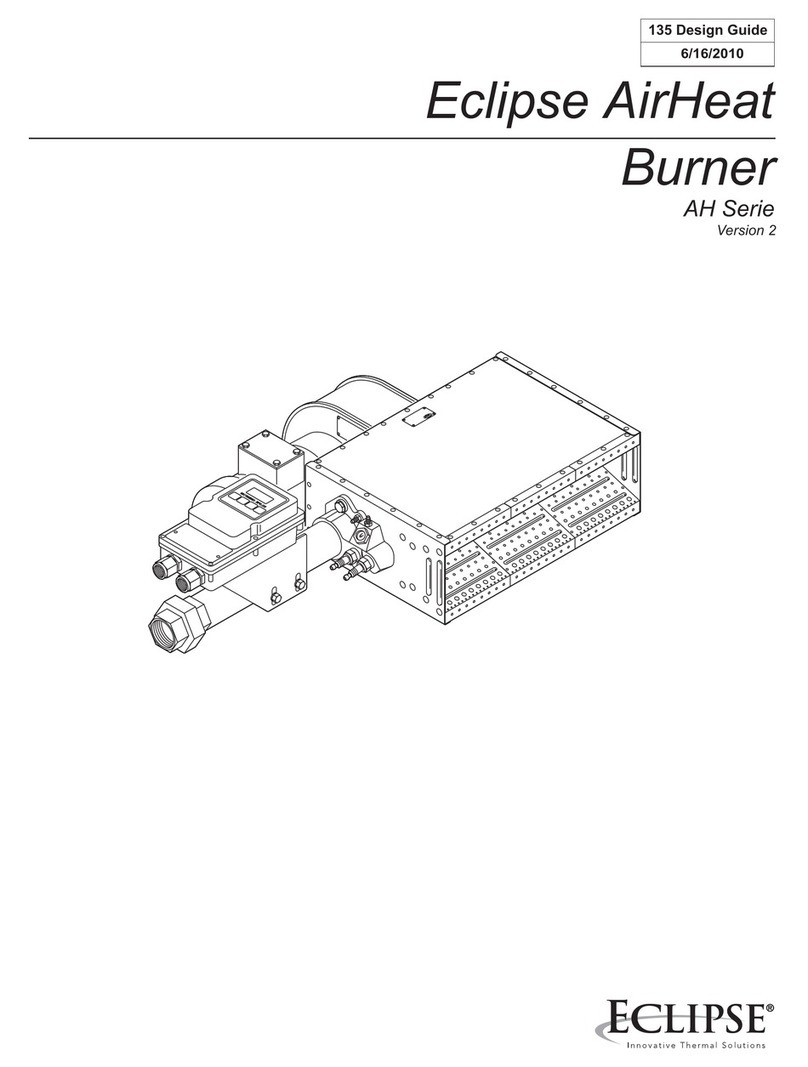

Eclipse AirHeat AH series Guide

Eclipse

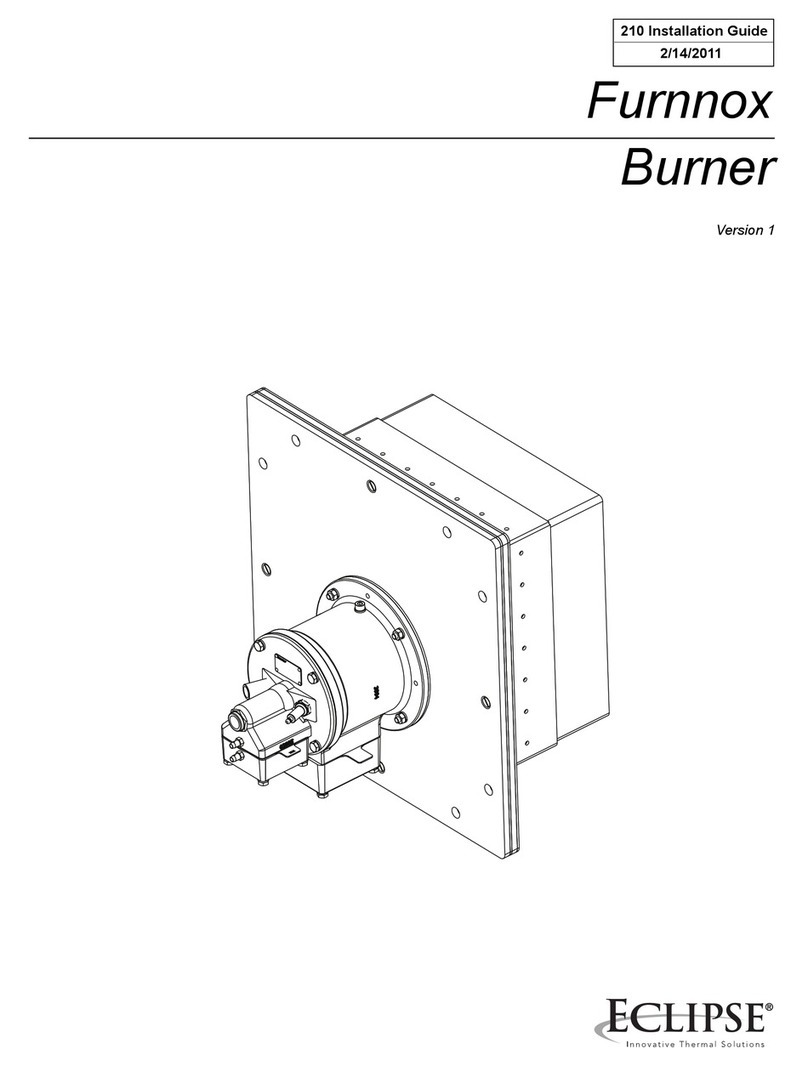

Eclipse Furnnox 210 Series User manual

Eclipse

Eclipse ThermJet TJSR Series Mounting instructions

Eclipse

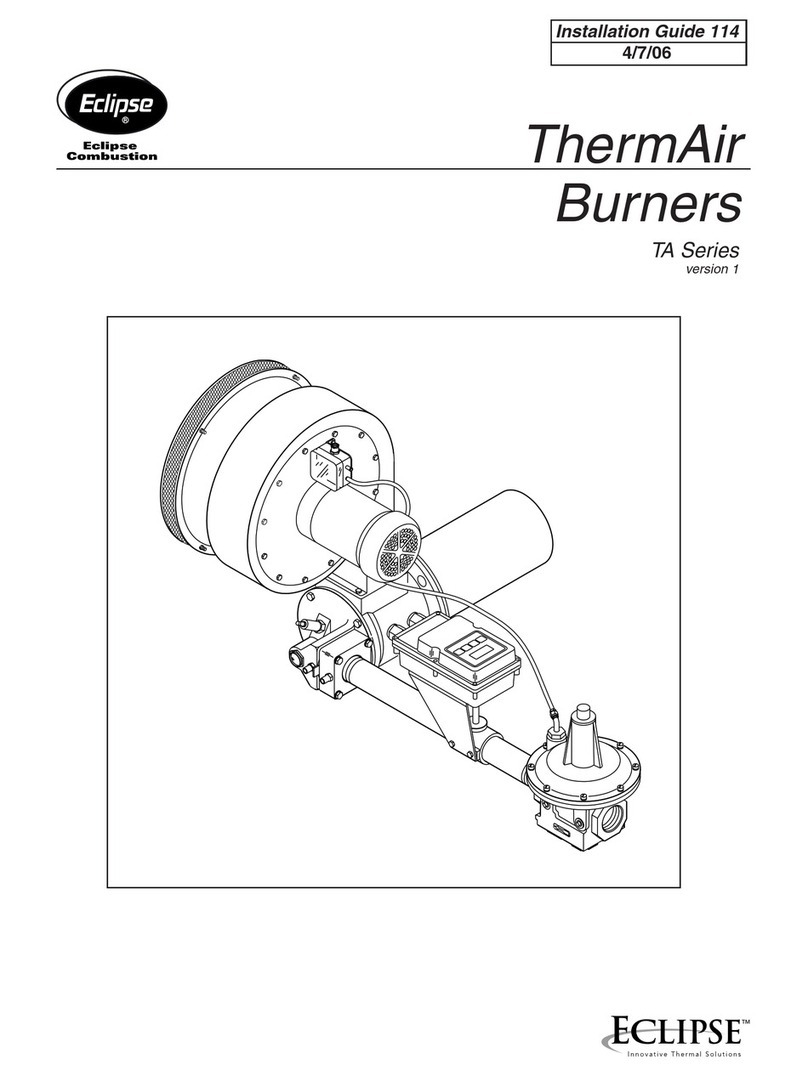

Eclipse TA Series User manual

Eclipse

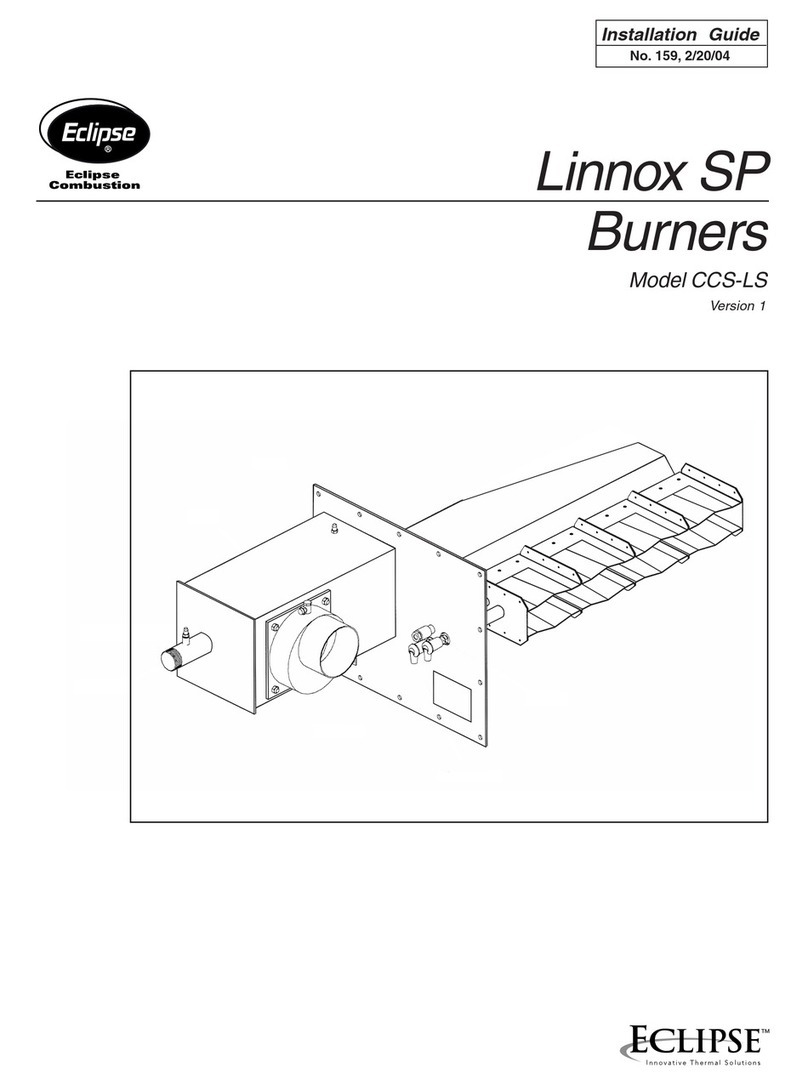

Eclipse Linnox SP CCS-LS User manual

Eclipse

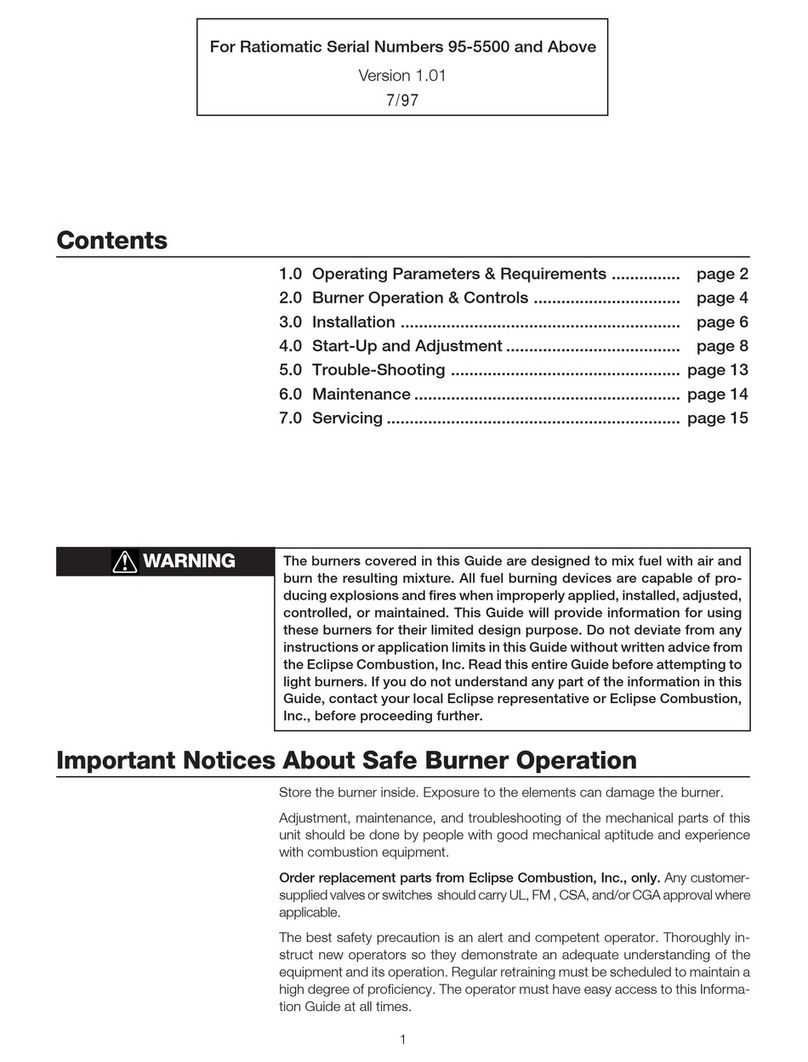

Eclipse RatioMatic 50 User manual

Eclipse

Eclipse RatioAir RA Series User manual

Eclipse

Eclipse TFB030 User manual

Eclipse

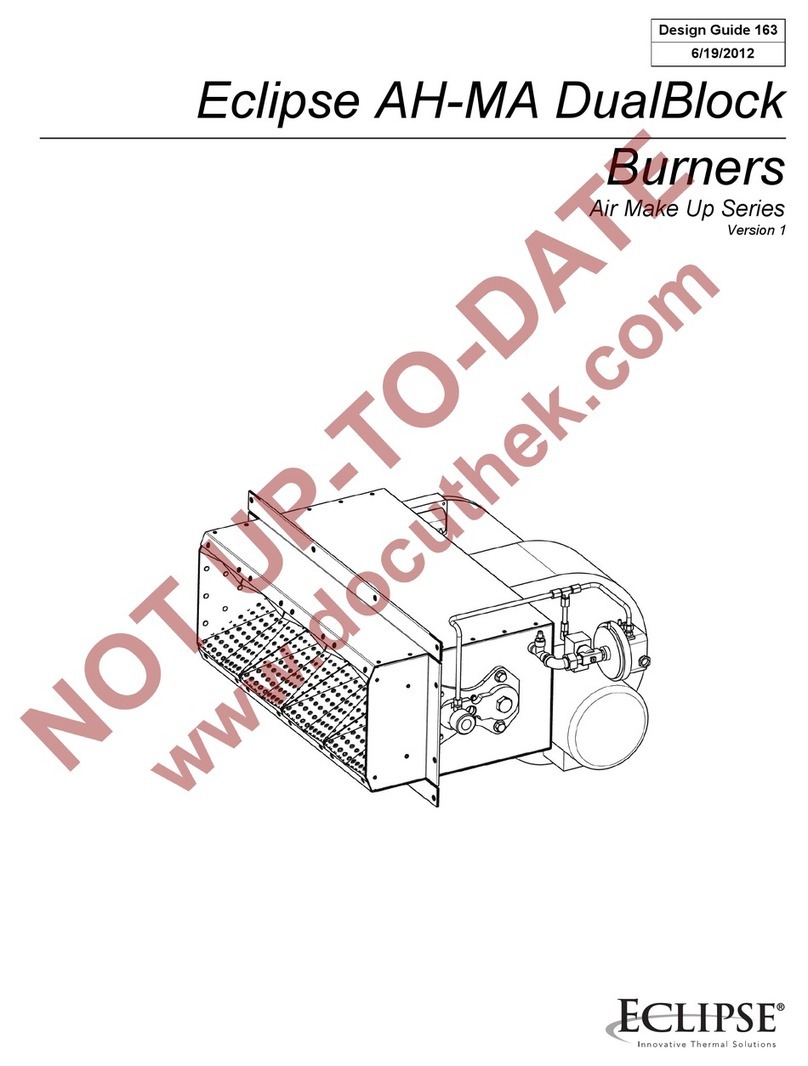

Eclipse AH-MA DualBlock Guide

Eclipse

Eclipse BrightFire 200 series User manual

Eclipse

Eclipse ThermJet TJSR Series Guide

Eclipse

Eclipse ThermJet TJSR0020 User manual

Eclipse

Eclipse WX Series User manual

Popular Burner manuals by other brands

baltur

baltur BT 250 DSG 4T manual

muenkel design

muenkel design round burner Operating and installation instructions

baltur

baltur BT 14 DSGW Instruction

artisan

artisan Art-SB1 Care & use manual

AESYS

AESYS TurboFire II Installation, operation and maintenance manual

Riello

Riello RG1RKD Installation, use and maintenance instructions