ecoclima EC/I-09QC User manual

Service manual

(INVERTER 50Hz R410A)

Split system:

EC(-W)/I-09QC(-B,-G,-W)

EC(-W)/I-12QC(-B,-G,-W)

EC(-W)/I-18QC(-B,-G,-W)

EC(-W)/I-24QC(-B,-G,-W)

2

CONTENTS

1.Range & Conditions.................................................................................................... 3

2. Control Specifications................................................................................................4

3. Exploded view.......................................................................................................... 14

4. Refrigerant Flow Diagram.......................................................................................18

5. Circuit Diagram.........................................................................................................19

6. Troubleshooting........................................................................................................21

7. Checking Electrical Components.......................................................................... 27

3

1.Range & Conditions

DB: Dry-bulb temperature

WB: Wet-bulb temperature

Rated Operating Conditions

Indoor Temperature

Outdoor Temperature

Cooling

27℃DB/19℃WB

35℃DB/24℃WB

Heating

20℃

7℃DB/6℃WB

Tubing Length (m)

3

Max. Operating Value

Indoor Temperature

Outdoor Temperature

Cooling

32℃DB/23℃WB

52℃DB

Heating

27℃

24℃DB/18℃WB

4

2. Control Specifications

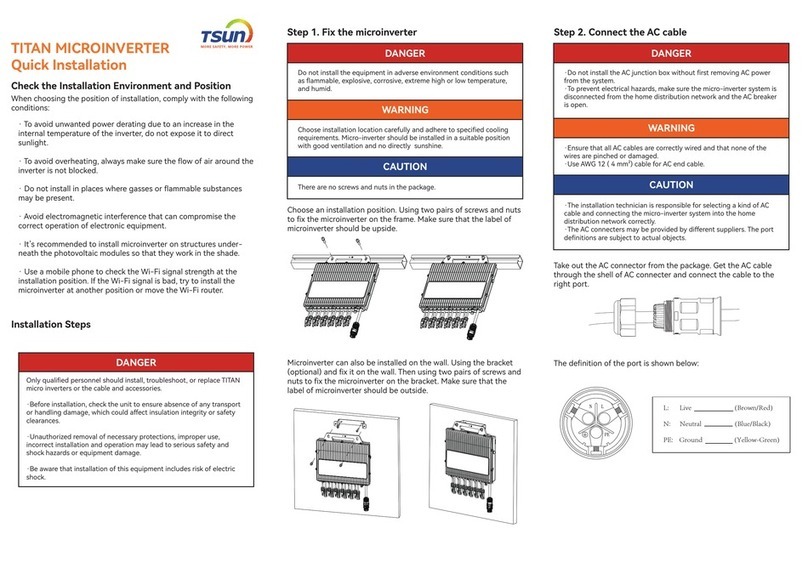

2.1 General introduction

The indoor fan motor uses PG;The compressor is 4 poles brushless motor which rotary

speed can be adjusted within 25-100rps.The outdoor controller has IPM transducer which

can control the compressor and PFC control circuit,and the power factor of complete unit

reaches up to more than 95%.

The aim of controlling:Temperature difference between indoor temperature and set

temperature. This unit has the following control:

2.1.1 Indoor fan motor controls(PG motor)

Fan speed:High,medium,low,gentle.

2.1.2 Outdoor fan motor (AC machine)

Fan speed:High,low.

2.1.3 Capacity control

Change the capacity of cooling and heating through changing the rotate speed of

compressor. The transducer can convert the voltage AC220V into volts d.c. and control the

power supply condition of compressor by IPM module.

2.1.4 Over current protection

Outdoor controller examines input current and the compressor begins to run after accepting

the order from indoor unit. When the current value exceeds the prescribed value, the

outdoor controller will decrease the rotate speed of compressor, in that case, compressor

can run at the speed by the order from indoor unit within the range of the current value does

not exceed the prescribed value.

2.1.5 High-loaded prevention(freeze-prevention)

Indoor heat exchanger examines the condensation temperature of refrigerant when the unit

is in heating operation.(evaporate temperature of refrigerant when cooling and heating).If

the temperature exceeds the prescribed value,(or lower than the prescribed value),then

decrease the rotary speed of compressor to make compressor runs at the speed within the

prescribed temperature range in order to keep high pressure from excessive rising.(Or

keeping indoor heat exchanger from freezing.)

2.1.6 Blades control

Users can realize tridimensional airflow through controlling vertical blades.

Control the position of blades automatically according to operating condition. Press“vertical

airflow ”button to set the position of vertical blades freely. Electric control will store the

position of blades when the current is switched on.

2.1.7 Power-failure automatic reset

2.2 Panel display

2.2.1. See Q model for the details of panel display.

5

2.2.2 Emergency Run button: The unit will be turned off when pressing this button when the

unit is in operation;

The unit will be turned on and operates in Smart mode after pressing this button when the

unit is in off status.

2.2.3 Press any key when the unit is in operation, the buzzer will give a buzz sound ; When

the unit is in off status, press the button of “on/off”, “air refresh” or “smart”, the unit will be

turned on with a buzz sound.

2.2.4 Please see the operating instructions for the usage of remote controller.

2.3 Blades Control

The blades range for vertical blades is from1-5 point position. Press “vertical airflow” button,

the blades will swing according to “1-2-3-4-5-swing-1-… “.But sometimes the blades can not

be controlled because the unit is in protect function.

2.3.1 Cooling, Dehumidification and Air refresh function:

The blades will swing circularly within the range of 1-4.

In cooling and dehumidification operation, louver blades can change the position

automatically to prevent from dripping.

2.3.2 Heating:

The blades will swing circularly within the range of 2-5.

During the course of heating beginning or defrosting(namely when the unit is in the pause

condition),the blades are in fixed position to avoid blowing cold airflow because of the too

low temperature of indoor evaporator. Only when the temperature of evaporator is higher

than 32℃,will the unit enter normal control.

2.4 Cooling

2.4.1 Indoor blower control:

The fan speed can be set as high, medium, low and auto level.

If changed to auto level, the indoor blower will choose the fan speed according to room

temperature and set temperature.

2.4.2 Cooling capacity control:

Calculating the difference value between the temperature detected by indoor pipe

temperature sensor and the prescribed indoor pipe value temperature to determine the

correction of frequency command signal, correct the frequency command signal currently

existing. When the indoor pipe temperature is lower than the prescribed indoor pipe value

temperature, the unit will decreases the rotary speed of compressor.

2.4.3 Freeze-prevention control:

Pipe coil sensor detects the temperature of indoor heat exchanger. If the temperature is

lower than the prescribed value, then the unit decreases the rotary speed of compressor to

keep the indoor heat exchanger from freezing. If the temperature exceeds the lower limit

6

value, then please stop decreasing frequency; If the temperature exceeds the upper limit

value, then the unit will exists freeze-prevention protection. If the temperature is lower than

certain prescribed value, the unit will stop.

2.4.4 Over current-prevention control

If the value of input current detected by outdoor current sensor is higher than the prescribed

value, the rotary speed of compressor will be decreased and controlled in order to keep the

current value not higher than the upper limit value;compressor will come to normal

operation when the current value drops to the lower limit value;If current value is higher than

the upper limit value, compressor will stop.

2.4.5 Cooling overload working

In cooling operation, if the temperature of outdoor heat exchanger is too high, the speed of

compressor will be adjusted to a lower gear automatically ,and sometimes compressor may

be stopped.

2.4.6 Sleep control(soft operation)

Press“sleep” button on remote controller,the unit will control rotary speed of compressor

and indoor fan motor and enters sleep operation:

Rotary speed of fan motor:medium level or low level

Rotary speed of compressor:decrease

The set temperature will increase 1℃automatically after running for 1 hour; After running for

about 1 hour, the set temperature will increase 1℃ ;After running for another 1 hour, the set

temperature will go on increasing 1℃. The temperature will not increase when the set

temperature is higher than the prescribed value. The temperature will not exceeds the

prescribed value when lower than the prescribed value.

2.4.7 The highest rotary speed of compressor controlled by wind rate grade

To determine the highest rotary speed of compressor according to indoor and outdoor

temperature.

2.4.8 Outdoor Motor Control

The speed of outdoor motor is decided in low or higher according to the outdoor

surroundings temperature and the indoor pipe temperature.

2.4.9 Dry Mildew Proofing Operation

Indoor fan motor will go on running for a period of time after the unit is turned off

to dry surplus moisture remain in unit.

2.4.10 Compressor frequency control

A Frequency range of compressor is 25-100Hz。

B Original frequency of compressor:Set by original indoor temperature and surroundings

temperature.

C Running frequency of compressor is controlled by artificial intelligence.

7

2.5 Heating

2.5.1 Indoor fan motor control

Fan speed:High,medium,low,auto.

If choosing “Auto” mode, then indoor fan motor chooses fan speed according to indoor

temperature and the set temperature.

2.5.2 Cool-airflow-prevention while heating

Avoid cool airflow:At the beginning of heating mode, if the temperature of indoor pipe coil is

lower than the prescribed value, and compressor stops or running time less than the

prescribed time (If exceeding the prescribed time,the unit will exist

cool-airflow-prevention.),the unit is in cool-airflow-prevention condition, then louver blades

can not swing and indoor fan motor stops. The PAUSE indicator lights during

cool-airflow-prevention period.

2.5.3 Heating capacity control

Calculating the difference value between the temperature detected by indoor pipe

temperature sensor and the prescribed indoor pipe value temperature to determine the

correction of frequency command signal, correct the frequency command signal currently

existing. When the indoor pipe temperature is higher than the prescribed indoor pipe value

temperature, the unit will decreases the rotary speed of compressor.

2.5.4 High-loaded control

Indoor pipe coil temperature sensor examines evaporator temperature, if temperature

exceeds the prescribed value, the frequency does not increase; if temperature exceeds

upper limit value, the rotary speed of compressor will be gradually decreased to avoid too

high heat load;if temperature is lower than the prescribed value, the frequency does not

decrease; if temperature is lower than lower limit value, unit will exist high-loaded control

and enters normal operation.

2.5.5 Over current control

If the value of input current detected by outdoor current sensor is higher than the prescribed

value, the rotary speed of compressor will be decreased and controlled in order to keep the

current value not higher than the upper limit value;compressor will come to normal

operation when the current value drops to the lower limit value;If current value is higher than

the prescribed value, compressor stops.

2.5.6 Defrosting control

2.5.6.1 Defrosting test

When machine is in heating mode, it controls defrosting through defrosting sensor (Te)

detecting the frost level of heat exchanger.

2.5.6.1.1The first conditions of entering defrosting:

2.5.6.1.1.1 The prerequisite of defrosting: heating compressor is running for 10 minutes and

45 minutes in total ( general defrosting)/ 90 minutes 【(low temperature defrosting:outer

environmental temperature is under -6℃】;

8

2.5.6.1.1.2 Sufficient conditions of entering defrosting as below:

2.5.6.1.1.2.1 Not to enter defrosting if outer environmental temperature is above 15℃;

2.5.6.1.1.2.2 Enter defrosting if outer environmental temperature is under -6℃and

defrosting temperature is less or equal to -15℃for 5 minutes;

2.5.6.1.1.2.3 Enter defrosting if outer environmental temperature is between 【5℃-15℃】

and defrosting temperature is less or equal to -6℃for 5 minutes;

2.5.6.1.1.2.4 Enter defrosting if outer environmental temperature is between 【-6℃-5℃】

and defrosting temperature is less or equal to TeS for 5 minutes.

TeS=C*outer environmental temperature-A A=8 Outer environmental temperature<0℃

C=0.8 outer environmental temperature >=0℃C=0.6

2.5.6.1.2The second conditions of entering defrosting:

Compressor runs for 3 hours, but not to enter defrosting and temperature of condenser pipe

is less -2℃for 3 minutes

2.5.6.2 Defrosting operation

Stop compressor first and turn off 4-way valve relay and outdoor fan motor;Turn on

compressor again. Outdoor fan stops while defrosting.

2.5.6.3 Existing defrosting

Defrosting operation will change into heating operation when meeting any of the following

condition:

1)Outdoor heat exchange is higher than the prescribed value.

2)Outdoor heat exchange is higher than the prescribed value for a consecutive period of

time.

3)Time of defrosting is longer than the longest time of prescribed time.

2.5.6.3 Defrosting note:

2.5.6.3.1 Machine will not stop when the compressor frequency doesn’t go up to 80Hz,

switched to non-heating mode after entering defrosting.

2.5.6.3.2 Sensor error code will not be shown in the display of indoor during defrosting even

if the sensor has problems, but the error code will be shown 3 minute after the compressor

starts to run when the machine is restarted after defrosting exits, or the compressor will

open or close according to the environmental temperature.

2.5.6.3.3 The outdoor unit will not detect the temperature of indoor sensor during

defrosting.(The outdoor unit always detects the inner environmental temperature, but the

detected result is no use for outdoor unit.)

2.5.6.3.4 The conditions of ending defrosting must be detected 2 minutes after the

compressor starts to run.

2.5.6.3.5 Compressor running time record will not be refreshed if the machine is not

switched to non-heating mode, even if the machine is turned off.

2.5.7 Blowing surplus energy function

When turning off compressor, indoor fan motor chooses low speed operation( gentle/stop)

9

according to temperature of indoor pipe coil to make the best of surplus energy of indoor

pipe coil.

2.5.8 Temperature control for compressor vent

Vent temperature sensor detects the temperature of refrigerant air exhausted from

compressor and control rotary speed of compressor(same as cooling and heating)to ensure

high efficient operation of system.

2.5.9 Sleep control(soft operation)

Press“sleep” button on remote controller,the unit will control rotary speed of compressor

and indoor fan motor and enters sleep operation:

Rotary speed of fan motor:medium level or lower lever

Rotary speed of compressor:decrease

The set temperature will decrease 1℃automatically after running for 1 hour; After running

for another 1 hour, the set temperature will go on decreasing 1℃. But the set temperature

displayed on LED will remain unchanged.

2.5.10 Outdoor fan motor control(except defrosting)

The speed of outdoor motor is decided in low or higher according to the outdoor

surroundings temperature and the indoor pipe temperature.

2.5.11 compressor frequency control

A Frequency range of compressor is 25-100Hz。

B Original frequency of compressor:Set by original indoor temperature and surroundings

temperature.

C Running frequency of compressor is controlled by artificial intelligence.

2.6 “Smart”function

The unit will judge the operation mode automatically after receiving the SMART signal.

2.6.1 Original set temperature:Choosing indoor temperature according to set temperature.

2.6.2 Original mode :Choosing original mode according to outdoor temperature and

indoor temperature. There are three modes are available: cooling, heating, fan sweep

Fan sweep mode:High level,louver blades swing automatically and can be adjustable.

In“Smart”mode, all additional function is available. Indoor fan speed is set as automatic and

louver swing automatically. Outdoor rotary speed is controlled according to the

corresponding mode, and users can adjust position of louver and temperature.

Unit will judge next working mode after finishing operation of a kind of mode. If in fan sweep

mode, unit will enter mode to judge program every per minute until enter cooling or heating

mode.

2.6.3 Judge mode again:Choosing cooling(heating/fan sweep) mode according to indoor,

outdoor temperature and the set temperature.

10

2.7 Dehumidification

2.7.1 When indoor temperature is higher than a certain temperature value, and higher

than(set temperature),unit operates in cooling mode and outdoor fan speed is the same

with the speed in cooling operation;or unit operates in dehumidifying operation according to

indoor temperature and outdoor fan motor is at low speed level.

When indoor temperature is higher than the upper limit value, compressor operates by a

certain prescribed frequency.

When indoor temperature is between upper limit temperature and lower limit temperature,

compressor operates by a prescribed frequency.

When indoor temperature is lower than lower limit temperature, compressor stops.

2.7.2 Fan motor runs at low speed level.

2.7.3 Freeze-prevention control: same as cooling mode.

2.7.4 Dry Mildew Proofing Operation: same as cooling mode.

2.8 Other functions

2.8.1 Timelag protection function for compressor

In order to protect compressor(expect for defrost mode),there will be a 3-minute delay to

restart when compressor stops from working condition. And there is still 3 minute delay

when the compressor is firstly started.

2.8.2 Automatic restart

This function refers to:When the electricity comes again after power failure, the unit is

required to get back to the condition before power failure automatically. The mode, set

temperature, air refresh, sleep, lock for the safety of children, humidification and air

ventilation all keep in the same condition before power failure.

This function can be set or cancelled through EEPROM device on electric board or the

installation of peripheral circuit.

2.8.3 Independent air refresh function

Press “air refresh”button on remote controller when the unit is in off status, the unit is in Fan

Sweep mode. Press this button again, this function can be cancelled.

2.8.4.Timing on/off

1. Turn on the air conditioner on timer: The air conditioner will starts operation at the set

time.“time on”function is only effective for once in 24 hours. If user turns on the air condition

by pressing on/off button on the remote controller before the set time, then” timing on”

function will be cancelled. If user select “timing on” when the air conditioner is in on status,

the air conditioner will stop immediately and restart automatically at set time.

2. Timing off: The air conditioner will exit running at set time. ” timing off” function is only

effective for once in 24 hours. If user turns off the air condition by pressing on/off button on

11

the remote controller before the set time, then” timing on” function will be cancelled. If user

selects “timing off” when the air conditioner is in off status, the air conditioner will run

immediately and stop automatically at set time.

3. Program timing control:Air conditioner is turned on/off automatically at set time every

day. if user turn off the air conditioner by pressing off button before the set time, then the

“timing off” function will be cancelled but the “timing on” function is still effective;If user turns

off the air conditioner by pressing on the emergency button before the set time, then the

program timing control will be cancelled. If user turn on the air conditioner by pressing on the

on button on the remote controller before the set time, then timing on function will be

cancelled but the timing off function is still effective; if the user turn of the air conditioner by

pressing on emergency button before set time, then the program timing control will be

cancelled.

2.8.5 Induction function(of remote controller)

The remote controller sends the room temperature signal to air conditioner once time in

every 3 minutes, and the unit will run according the signal. To detect the room temperature,

remote controller must be placed in the area where the signal of remote control can be

received. If the signal from remote control can not be received in 5 minutes, the air

conditioner will operate according to the temperature which detected by indoor temperature

sensor.

12

2.9 Failure indication

A.Failure indication for outdoor unit:

The red light will flash when there is any failure happened.Otherwise, no red light is on.

The green light will be on when outdoor unit is with electricity.

B.Failure indication for indoor unit:

1.PG motor failure---F0

2.Indoor temperature sensor failure---F1

3.Outdoor temperature sensor failure---F2(The red light on outdoor PCB will flash twice)

4.Indoor pipe coil temperature sensor failure---F3

5.Outdoor pipe coil temperature sensor failure---F4(The red light on outdoor PCB will flash

one time)

6.Exhausting temperature sensor failure---F5(The red light on outdoor PCB will flash 4

times)

7.Indoor communications can not be accepted---F6(The red light on outdoor PCB will flash 6

times)

8.Outdoor unit and IPDU communications failure---F8(The red light on outdoor PCB will

flash 14 times)

9.IPM module protection---F9(The red light on outdoor PCB will flash 7 times)

10.Indoor EEPROM on PCB failure---FD

11.Outdoor EEPROM on PCB failure---FE(The red light on outdoor PCB will flash 5 time)

12.Compressor overhead protection----E0(The red light on outdoor PCB will flash 11 times)

13.IPM over current protection---E3(The red light on outdoor PCB will flash 12 times)

14.IPDU current sensor (no or failure)---E3(The red light on outdoor PCB will flash 12 times)

15.IPDU position circuit failure ---E6(The red light on outdoor PCB will flash 19 times)

16.Compressor speed up abnormally---E7(The red light on outdoor PCB will flash 18 times)

17.Compressor is stemmed ---E7(The red light on outdoor PCB will flash 15 times)

18.Compressor desynchronizing while running---E7(The red light on outdoor PCB will flash

17 times)

19.Compressor failure ---E8(The red light on outdoor PCB will flash 16 or 20 times)

20.Board temperature too high---E9(The red light on outdoor PCB will flash 13 times)

C.Failure indication for indoor unit::

1. Protection for compressor exhausting temperature----P1(The red light on outdoor PCB

will flash 25 times)

2.Defrosting----P3

3.Heating overload----P4(The red light on outdoor PCB will flash 27 times)

4.Freeze-prevention----P5(The red light on outdoor PCB will flash 28 times)

5.Cooling overload----P6(The red light on outdoor PCB will flash 26 times)

13

2.10 UVC function and specifications

Press the UVC bottom on remote controller to start or stop UVC sterilize function.

Note:Read the maintenance instructions before opening the device.

1.This appliance contains a UVC lamp.

2.Unintended use of the appliance or damage to the housing may result in the escape of

dangerous UVC radiation. UVC radiation may, even in small doses, cause harm to the eyes

and skin.

3.Appliances that are obviously damaged must not be operated. Prior to cleaning or other

maintenance, the appliance must be disconnected from the supply mains.

4.If applicable, precautions to be taken when replacing UVC emitters and starters;

5.Disconnect the power supply before replacing the UVC lamp;

6.Doors and access panels with a UV radiation hazard symbol may have UVC spectral

irradiance greater than 1,7 W/ cm2 and are equipped with an interlock switch to disconnect

UVC lamp power for safety. Don't go beyond;

7.It is recommended to disconnect the power supply before opening doors and access

panels with UV hazard symbols for user maintenance.

8.UVC barriers with UV radiation hazard symbols should not be removed;

9.For appliances fitted with UVC lamps, provide information on replacement of UVC lamps,

including model number and/or part number;

10.In the case of field installation, a factory-designated UVC sterilization lamp system

approved for use in this product shall be specified in the operating instructions by a

particular model;

11.Do not operate THE UVC lamp outside the device

14

3. Exploded view

3.1 Exploded view for indoor unit

15

NO.

Materails Description

NO.

Materails Description

1

Front panel subassembly

22

electric heating tube

2

Front panel

23

Positive and negative ion generate

3

Air filter

24

Sensor bracket

4

Medium frame subassembly

25

Electric control board

5

Screw cover

26

Spring

6

Evaporator subassembly

27

Display box

7

pressure plate

28

Display P.C.B assembly

8

Bearing

29

WIFI subassembly

9

Bottom frame subassembly

30

Electric control box board(metal)

10

Stepping motor

31

Cover of electirc control box

11

Blade

32

Transformer

12

Wall-Mounting frame

33

Terminal board

13

Pipe pressure plate

34

Wire pressure plate

14

Drainage pipe subassembly

35

Electirc control box

15

Stepping motor

36

P.C.B assembly

16

Crossflow fan

37

Electric control box(metal shell)

17

Motor Bracket (bottom)

38

Power line

18

Fan motor

39

Room temperature sensor

19

Motor Bracket(top)

40

Pipe temperature sensor

20

Motor cover

41

Negative ion generator

21

Negative ion generator

NOTE:Actual product may be different from above graphics,please refer to

actual products.

16

3.2 Exploded view for outdoor unit

17

NOTE:Actual product may be different from above graphics,please refer to

actual products.

NO.

Enlish description

1

front net cover

2

front plate subassembly

3

propeller fan

4

fan motor

5

motor bracket subassembly

6

bottom plate subassembly

7

Metal support

8

partition board

9

Top cover assembly

10

condenser subassembly

11

rear net cover

12

Sensor holder

13

capillary subassembly

14

outdoor electric control subassembly

15

Platen

16

Terminal seat

17

Electrical inseallation board

Electrical inseallation board

18

reactor

19

electric cover subassembly

20

Valve mounting plate

21

Lateral plate assembly

22

cut-off valve 3/8

cut-off valve 1/4

23

four-way valve subassembly

24

compressor

18

4. Refrigerant Flow Diagram

Thermal insulating of refrigerant pipeline

To prevent heat loss and condensed water from dropping on the floor, the wide and narrow tube of

air conditioner should be wrapped with thermal insulating materials. For using capillary tube, and the

tubes are in low temperature, the thickness of thermal insulating materials shall be more than 8mm.

19

5. Circuit Diagram

5.1 Electrical wiring diagram for indoor unit

To avoid electrical shock hazard, be sure to disconnect power before

checking, servicing and/or cleaning any electrical parts.

Warning

20

5.2 Electrical wiring diagram for outdoor unit

To avoid electrical shock hazard, be sure to disconnect power

before checking, servicing and/or cleaning any electrical parts.

Warning

This manual suits for next models

15

Table of contents

Popular Inverter manuals by other brands

Hyundai power products

Hyundai power products 1500 quick start guide

Xylem

Xylem CentriPro AQUAVAR CPC4 FD Series Supplement manual

Sungrow

Sungrow SG36KRL-M Quick installation guide

Vacon

Vacon FI9 user manual

Beghelli

Beghelli NOVA NV-6KW Installation and operation manual

Velleman Instruments

Velleman Instruments PCG10 Reference manual