Ecoflo Coco Filter EC7 Series User manual

- Polyethylene

Installation Guide –CAN/USA

This guide contains the information required to install an Ecoflo®Coco Polyethylene and Ecoflo®Coco Polyethylene

Pack option. The installation must be performed by a duly trained installer. A list of installers can be provided by

contacting our customer service at 1 800 632-6356.

Table of contents

1. Technical datasheet: polyethylene EcofloCoco Filter

2. Description of system components

3. Location of the components and specific instructions

4. Determination of the effluent discharge mode

5. Description of the polyethylene EcofloCoco Filter components

6. Installation sequence

7. Transportation and handling

1. Technical data sheet

Component materials

•Shell: polyethylene

•Cover, main access, secondary access, central support, tipping bucket, distribution plates: polyethylene

•Filtering medium: Coconut husk fragment-based compound

1.1 Technical datasheets of models 2.8, 3.4 and 4.1 including the PACK option

Table 1 Technical Data Sheet 2.8 model

* Refer to the drawings on Figure 1.

** The weights indicated are approximate (non-contractual) and provided for handling and lifting purposes only.

NOTE: Refer to the dosage volume chart for the Ecoflo®Coco Filter model.

Model

Ecoflo®Coco Filter 2.8

Ecoflo®Coco Filter 2.8

PACK option

Hydraulic capacity

500 US gal/d

(1,900 L/d)

500 US gal/d

(1,900 L/d)

Actual volume of the primary/septic tank

N/A

750 US gal

(3,000 L)

Effluent filter in the primary/septic tank

N/A

Polylok PL-122

Mode of discharge

Gravity

Pumped

Gravity

Pumped

Type of bottom

Watertight

Watertight

Watertight

Watertight

Length (A)*

10'3" (3,120 mm)

10'3" (3,120 mm)

Width (B)*

4'2" (1,280 mm)

7'9" (2,360 mm)

Height (C)*

5'10" (1,770 mm)

5'10" (1,770 mm)

Inlet invert height (D)*

4'1" (1,230 mm)

4'4" (1,285 mm)

Inlet invert height (E)*

1'9" (540 mm)

1'7" (485 mm)

Outlet invert height (Fg and Fp)*

1¾" (44 mm)

3'9" (1,140 mm)

1¾" (44 mm)

3'9" (1,140 mm)

Weight** (including internal components

and filtering medium)

1,210 lb

(550 kg)

1,235 lb

(560 kg)

1,650 lb

(4.1 kg)

1,670 lb

(760 kg)

Factory-set dosage volume

---

25 US gal. (95 L)

---

25 US gal. (95 L)

Maximum dosage volume

---

160 US gal. (605 L)

---

160 US gal. (605 L)

Retention volume (between the bottom of

the containment tank and the bottom of

the filtering medium)

---

255 US gal. (965 L)

---

255 US gal. (965 L)

Table 2 Technical Data Sheet 3.4 model

Table 3 Technical Data Sheet 4.1 model

* Refer to the drawings on Figure 1.

** The weights indicated are approximate (non-contractual) and provided for handling and lifting purposes only.

NOTE: Refer to the dosage volume chart for the Ecoflo®Coco Filter model.

1.2 Technical datasheets of models 5.7 and 7.3

Model

Ecoflo®Coco Filter 3.4

Ecoflo®Coco Filter 3.4

PACK option

Hydraulic capacity

600 US gal/d

(2,200 L/d)

600 US gal/d

(2,200 L/d)

Actual volume of the primary/septic tank

N/A

1,000 US gal

(3,875 L)

Effluent filter in the primary/septic tank

N/A

Polylok PL-122

Mode of discharge

Gravity

Pumped

Gravity

Pumped

Type of bottom

Watertight

Watertight

Watertight

Watertight

Length (A)*

11'8" (3,550 mm)

11'8" (3,550 mm)

Width (B)*

4'2" (1,280 mm)

7'9" (2,360 mm)

Height (C)*

5'10" (1,770 mm)

5'10" (1,770 mm)

Inlet invert height (D)*

4'1" (1,230 mm)

4'4" (1,285 mm)

Inlet invert height (E)*

1'9" (540 mm)

1'7" (485 mm)

Outlet invert height (Fg and Fp)*

44 mm (1¾")

1,140 mm (3'9")

44 mm (1¾")

1,140 mm (3'9")

Weight** (including internal components

and filtering medium)

1,320 lb

(600 kg)

1,340 lb

(610 kg)

1,850 lb

(840 kg)

1,870 lb

(850 kg)

Factory-set dosage volume

---

30 US gal. (115 L)

---

30 US gal. (115 L)

Maximum dosage volume

---

180 US gal (680 L)

---

180 US gal (680 L)

Retention volume (between the bottom of

the containment tank and the bottom of

the filtering medium)

---

1,135 L

(300 US gal.)

---

1,135 L

(300 US gal.)

Model

Ecoflo®Coco Filter 4.1

Ecoflo®Coco Filter 4.1

PACK option

Hydraulic capacity

750 US gal/d

(2,870 L/d)

750 US gal/d

(2,870 L/d)

Actual volume of the primary/septic tank

N/A

1,250 US gal

(4,750 L)

Effluent filter in the primary/septic tank

N/A

Polylok PL-122

Mode of discharge

Gravity

Pumped

Gravity

Pumped

Type of bottom

Watertight

Watertight

Watertight

Watertight

Length (A)*

13'4" (4,050 mm)

13'4" (4,050 mm)

Width (B)*

4'2" (1,280 mm)

8'2" (2,485 mm)

Height (C)*

5'10" (1,770 mm)

5'10" (1,770 mm)

Inlet invert height (D)*

4'1" (1,230 mm)

4'4" (1,285 mm)

Inlet invert height (E)*

1'9" (540 mm)

1'7" (485 mm)

Outlet invert height (Fg and Fp)*

1¾" (44 mm)

3'9" (1,140 mm)

1¾" (44 mm)

3'9" (1,140 mm)

Weight** (including internal components

and filtering medium)

1,430 lb (650 kg)

1,450 lb (660 kg)

2,070 lb (940 kg)

2,090 lb (950 kg)

Factory-set dosage volume

---

35 US gal. (135 L)

---

35 US gal. (135 L)

Maximum dosage volume

---

200 US gal (755 L)

---

200 US gal (755 L)

Retention volume (between the bottom of

the containment tank and the bottom of

the filtering medium)

---

350 US gal. (1,325 L)

---

350 US gal.

(1,325 L)

Table 4 Technical Data Sheet 5.7 & 7.3 DV models

** Refer to the drawings on Figure 2.

** The weights indicated are approximate (non-contractual) and provided for handling and lifting purposes only.

NOTE: Refer to the dosage volume chart for the Ecoflo®Coco Filter model.

Model

Ecoflo®Coco Filter 5.7 DV

Ecoflo®Coco Filter 7.3 DV

Hydraulic capacity

1,050 US gal/d

(4,000 L/d)

1,350 US gal/d

(5,100 L/d)

Mode of discharge

Gravity

Pumped

Gravity

Pumped

Type of bottom

Watertight

Watertight

Watertight

Watertight

Length (A)*

11'1" (3,380 mm)

13'7" (4,130 mm)

Width (B)*

6'7" (2,000 mm)

6'7" (2,000 mm)

Height (C)*

6'1" (1,840 mm)

6'1" (1,840 mm)

Inlet invert height (D)*

4'2" (1,260 mm)

4'2" (1,260 mm)

Inlet invert height (E)*

1'11" (580 mm)

1'11" (580 mm)

Outlet invert height (Fg and Fp)*

3" (76 mm)

4'1" (1,240 mm)

3" (76 mm)

4'1" (1,240 mm)

Weight** (including internal components

and filtering medium)

2,620 lb

(1,190 kg)

2,640 lb

(1,200 kg)

3,100 lb

(1,405 kg)

3,120 lb

(1,415 kg)

Factory-set dosage volume

---

20 US gal. (75 L)

---

20 US gal. (75 L)

Maximum dosage volume

---

230 US gal.

(870 L)

---

295 US gal.

(1,115 L)

Retention volume (between the bottom of

the containment tank and the bottom of

the filtering medium)

---

375 US gal.

(1,420 L)

---

500 US gal.

(1,900 L)

2. Description of system components

2.1 Septic/Primary tank

The size and configuration of the septic/primary tank shall be in accordance with the NSF listing (as applicable) or

State or local requirements. Septic/Primary tank allows the clarification of wastewater by letting suspended solids

settle to the bottom and retaining floating matter to avoid clogging the secondary or advanced secondary treatment

system. Primary treatment can be done using a septic tank that meets local regulation.

Some Ecoflo Coco Filters housed into polyethylene tank are available into a monobloc configuration (PACK unit)

that combines both, the septic/primary tank and the Ecoflo Coco Filter. Consult technical datasheets and respective

installation guides for more information on this Ecoflo Coco Filter configuration.

Premier Tech Aqua provides a complete line of high-performance polyethylene septic tanks ranging from 600 US gal

to 1530 US gal. that are all certified with Standard CSA-B66-16 and equipped with an effluent filter meeting this

same standard. Premier Tech Aqua also offers a full line of septic tank accessories such as extensions (PSR-060

and PSR-140) single- or double-walled covers (LID-240S and LID-240D) as well as adaptors for accessing concrete

septic tanks (TAD-240). For more information on these products, consult the Peripherals section on

ptzone.premiertechaqua.com

.

You may decide to keep an existing septic tank, in which case, it will need to be carefully inspected to make sure

that it is in good condition. If the tank is not equipped with an effluent filter, an effluent filter will need to be installed

in a tank located immediately downstream of the septic tank. Premier Tech Aqua sells such a tank equipped with a

PL-122 effluent filter (TLF-240P).

The effluent filter extends the life of any treatment system by keeping solids in the septic tank. The effluent filter is

especially important if the household is equipped with a sewage pump or any other appliance that is liable to

increase the suspended solids content in the wastewater and, thereby, jeopardize the operation of the system and

affect its performance. In situations where an effluent pump is required as part of the septic system, an effluent filter

will also prevent solids from reaching said pump. We do not recommend the use of a garbage disposal unit. If a

garbage disposal is used, you must follow the state & local code for tank and absorption field sizing.

Effluent filters to be used with the Ecoflo®Coco Filter shall have a minimal flow area of 9 in² and filter particles 1/16”

and larger. While many different brands of effluent filters meet those specifications, Premier Tech Aqua highly

recommends the use of the effluent filter PL-122 from Polylok or equivalent.

2.2 Ecoflo®Coco Filter

Once the wastewater has passed through the septic/primary tank, it then flows towards the Ecoflo® Coco Filter.

Inside the biofilter, a central tipping bucket equally scatters the wastewater on both sides of the biofilter. Both sides

are equipped with specially designed plates which evenly distribute the wastewater on top of the filtering media.

The wastewater then trickles through a filtering medium composed of coconut husk fragments. The organic matter

contained in the wastewater is then decomposed by the microorganism attached to the media via an optimized

water/air (oxygen) mass transfer process.

To ensure effective treatment, there must be enough oxygen present in

the system to feed the microorganisms in the filtering media. Air enters

the system through vents located on the main access cover. Depending

on the model used, the pumping station and/or central support allows air

to naturally circulate between the surface and base of the filtering media.

Air circulates throughout the system by way of convection from the

residence’s vent (or a standalone vent) through the feed pipe to the septic

tank.

The operating principle of the Ecoflo®Coco Filter allows the system to be

used continuously or intermittently without requiring any special

precautions or having any impact on the effectiveness of the treatment.

In most cases, no specific action by owner is required to start the system.

Air flow diagram

(polyethylene shell)

Usually the Ecoflo®Coco Filter model and number of units are determined based on the number of bedrooms in the

residence or the total daily volume of domestic wastewater generated per day for other type of building. The

selection of the model also depends (without limitation) on the available surface area, the topography of the lot,

depth of seasonal high groundwater table, as well as the type, permeability and depth of the natural soil on site.

There are many different models of Ecoflo®Coco Filters and each model has different characteristics. Unit can be

housed either in concrete, polyethylene or fiberglass reservoirs. The following table presents the different Ecoflo®

Coco Filter models available according to the surface area of the filtering medium and treatment capacity. All of

these models are certified compliant with Standard NSF/ANSI 40.

2.2.1 Product nomenclature

There are several Ecoflo®Coco Filter models available that have different characteristics which are identified by the

model number.

EC7 Models Series:

Therefore, the EC7-500-P-P model refers to an Ecoflo®Coco Filter that can treat 500 US gallons per day, housed

into a watertight bottom polyethylene shell with an integrated pump for effluent discharge.

EC5 Model Series:

Therefore, the ECP-370-P model refers to an Ecoflo®Coco Filter that can treat 370 US gallons per day, housed into

a watertight bottom polyethylene shell with an integrated pump for effluent discharge.

2.3 Influent pumping station (if required)

When wastewater cannot be conveyed by gravity between the primary treatment

system and the Ecoflo®Coco Filter, a pumping/lifting station is then required. Like

for the septic/primary tank, the size and configuration of the pump tank shall be

based on design flow and occupancy and as to meet State or Local requirements.

The pumping station must be watertight. Premier Tech Aqua offers different pumping

station models to meet your needs (PSA-240 and PSA-240H).

Premier Tech Aqua recommends a dose between 8 to 10 US gallons (30 to 40 litres)

of wastewater every pump dosing cycle. Refer to the Peripherals section on

ptzone.premiertechaqua.com

for further information regarding the pumping stations.

Pump tank must have adequate venting to avoid buildup of harmful gases, air lock

and corrosion. This can be accomplished using a separate vent pipe on the pump

chamber or septic tank, by using a vented lid, or by connecting to the main building

vent stacks.

2.4 Discharge pump (when applicable)

As presented in table above, some Ecoflo®Coco Filter models housed into either concrete or polyethylene shells

come into a closed bottom configuration including a discharge pump vault. It allows to pump the final treated

effluent towards the site specific final dispersal method. The dosing can be accomplished either on demand (pump

to gravity, pressure dosed) or timed dosing.

The integrated pump vault includes a pump, a float tree on which, an ON/OFF float, and alarm float are attached

and an alarm box.

Each of the models listed below offer a certain built-in capacity for dosing and storage in case of emergency. In

case of emergency, water can be accumulated for a limited period of time in the filter bed without adversely affect

the performance of the system. These are presented on products respective technical data sheets.

Table 5 Dosing and Emergency Storage Capacity

PSA-240 pumping station

2.5 Flow divider

When an installation consists either of two Ecoflo®Coco Filter units which cannot be fed by gravity or of 3 or more

Ecoflo®Coco Filter units, a special attention shall be given to even flow distribution between the units.

Premier Tech Aqua offers several pressurized flow dividers. For more information on Premier Tech Aqua’s

pressurized flow divider, consult the Peripherals Section at

ptzone.premiertechaqua.com

.

2.6 Final dispersal

The final dispersal system must be designed in accordance with Premier Tech Aqua guidelines and/or State or Local

regulations.

3. Location of components and specific instructions

3.1 Components of a residential septic installation: separate septic/primary tank and Ecoflo®model

Ecoflo Coco Filter Unit Size

Maximum Volume available for

Dosing

Emergency Storage Capacity

(total - above alarm float)

2.8

160 US Gal

(600 L)

545 US Gal

(2,050 L)

3.4

180 US Gal

(680 L)

610 US Gal

(2,300 L)

4.1

200 US Gal

(750 L)

760 US Gal

(2,850 L)

5.7

230 US Gal

(870 L)

925 US Gal

(3,500 L)

7.3

295 US Gal

(1,110 L)

1,300 US Gal

(4,900 L)

Septic/primary

tank with

effluent filter

Ecoflo®

Coco Filter

View of an Ecoflo®Coco Filter

treatment system (gravity discharge)

View of an Ecoflo®Coco Filter

treatment system

(with pump)

Septic/primary

tank with

effluent filter

Ecoflo®

Coco Filter

3.2 Components of a residential septic installation: one-piece configuration –PACK option

3.3 Minimum distances to be maintained

The wastewater treatment system must be installed in a place:

•Where there is no motorized vehicle traffic;

•In an area that is not likely to be flooded and where it will not be submerged (depending on the situation, a drain

may be required around the septic tank to prevent installation of the septic tank in ground water).

•That is accessible at all times for maintenance, inspection and emptying;

•That complies with the distances in the following table:

Table 6 Minimum distances to be maintained in accordance with Premier Tech Aqua specifications

Reference point

Polyethylene Ecoflo® Coco Filter

Bottom of a talus, surplus backfill (A)

13’ (4 m)

Parking area (B)

13’ (4 m)

Vehicle or object weighting more than 500 lb (C)

13’ (4 m)

Retaining Wall (D)

13’ (4 m)

Finished landscaping vs base of Ecoflo lid (E)

2” (50 mm)

Seasonal High Groundwater Table (SHGT) vs. base of Ecoflo unit (Fp)

(See Figure 3)

2.8, 3.4, 4.1 Unit max 2’ (60 cm) from the bottom of

the unit

5.7 and 7.3 do not install in saturated soil

Distances may be higher to comply with local regulation

Ecoflo®Coco Filter with

PACK option combining

primary tank

Ecoflo®Coco Filter with

PACK option combining

primary tank

View of an Ecoflo®Coco Filter –PACK option

treatment system (with pump)

View of an Ecoflo®Coco Filter –PACK option

treatment system (gravity discharge)

Figure 1 Seasonal High Groundwater (SHGT) levels to respect for Ecoflo®installation

3.4 Installation conditions

3.4.1 Septic/Primary tank

It must be installed in compliance with the following instructions:

•Both openings must be extended to the soil surface through watertight and insulated chimneys and equipped

with watertight covers (keep clearance distance with final grade of minimum 2”).

•Tank backfilling must not exceed 18" (45 cm) in the case of the Ecoflo Coco filter PACK unit .

•The installation must be 100% watertight and receive only domestic wastewater (no roof water, surface water

or discharge from footing drains).

•The septic/primary tank must be placed where it is not at risk of being flooded or submerged (depending on the

situation, it may be necessary to provide for drainage around the septic/primary tank to prevent groundwater

from reaching a level that would pose a flooding risk with a surrounding berm or with drainage).

•The manufacturer’s specifications.

3.4.2 Polyethylene Ecoflo®Coco Filter

The Ecoflo®Coco Filter must be installed in compliance with the following recommendations and it is important to

notify all stakeholders (installer, landscaper, owner, snow removal company, etc.) of them to prevent any damage

to the system and system components.

•NEVER obstruct access to the covers of your septic installation. NEVER cover (with mulch, soil, fixed structure,

etc) or bury the lid of an Ecoflo®Coco Filter.

•The lid of the Ecoflo Coco Filter must be at least 2" (50 mm) above the surface of final landscaping grade.

•Ensure an upslope interceptor drain or water diversion berm is installed to direct surface and/or ground water

away from the Ecoflo module and soil absorption system;

•For models 2.8, 3.4 and 4.1, a maximum totalising 3 extensions may be installed on the polyethylene unit and

on each access to the primary/septic tank (when present). Theses extensions must be provided by PTA: a STR-

060 extension for the main access and a PSR-060 extension for the accesses to the primary tank (total of 3).

•NEVER connect a drain pipe, roof gutter, sump pump or air conditioner drain to your septic installation.

•NEVER discharge content or water from a water softener, spa or pool backwash into your septic system

•NEVER discharge wastewater from a recreational vehicle (tent trailer, house trailer, etc.) into your septic system

•NEVER install extensions over the access of a polyethylene Ecoflo®Coco Filter (models 5.7 and 7.3).

By respecting these guidelines, you contribute to the proper operation of your wastewater treatment system. Failure

to abide by these guidelines may void the warranty, at Premier Tech’s discretion.

4. Determination of the effluent discharge mode

IMPORTANT!THIS STEP IS KEY TO ANY SEPTIC INSTALLATION.

The polyethylene Ecoflo®Coco Filter offers a variety of disposal/dispersal methods of treated effluent depending

on local regulations).

Here are a few methods suggested by Premier Tech Aqua (but not limited to). The effluent of the Ecoflo®Coco Filter

may be discharged into (as applicable):

•Subsurface dispersal such like, but not limited to: absorption bed/pad or trenches, at-grade bed, drip dispersal,

or any type of gravelless system, etc.;

•Surface discharge as applicable when conditions and regulations permit it.

Ecoflo Coco Filter treated effluent can be discharged either by gravity or pumped to the final dispersal,

discharge method or a disinfection process.

4.1 Subsurface dispersal

4.1.1 Site and soil assessment

Site assessment and soil conditions are critical to determine the appropriate type of treated effluent discharge. An

accurate assessment of the soil's hydraulic conductivity is essential in planning any septic installation. This

assessment should be performed in accordance with local regulations. Adequate sizing of the soil absorption system

relies on the determination of the soil's infiltration capacity and will ensure adequate infiltration of the treated effluent

into the soil at all times. The soil's infiltration capacity is often expressed as a percolation rate (average time in

minutes that is required for water to drop one centimetre in the soil), which can be determined by a qualified

individual through a field permeability test, a laboratory soil particle-size analysis, or any other method approved by

local regulations. Soil permeability and analysis is most important within the horizon intended to be the point of

application of the treated effluent.

Site and soil assessment must be conducted by competent and duly authorized person as per local regulation.

4.1.2 Required effective soil depth or vertical separation to limiting layer

The vertical separation between the infiltration area to seasonal high groundwater table, impermeable layer or

bedrock must comply with applicable local requirements. Premier Tech Aqua recommends that the minimal vertical

distance between the clean crushed stone (treated effluent distribution zone) and the limiting layer (groundwater,

bedrock or impervious layer) be at least of 12".

Always consider the following recommendations when designing and installing the subsurface dispersal area:

•When referring to groundwater, the Seasonal High Groundwater Level (SHGL) must be taken into account;

•The profile of final grade must be such that runoff water flows away from the septic system;

•The shape of the soil absorption system may vary according to site conditions;

•Various means can be used to promote infiltration in low permeability soils. Contact your local distributor or

Premier Tech Aqua for suggestions.

4.2 Surface discharge

Depending on local regulations and jurisdictions, the effluent of the Ecoflo®Coco Filter could be surface discharged

into a watercourse, stream or dry swale. Requirements for such applications vary from one jurisdiction to another,

but it will most likely require disinfection. When required the Ecoflo® Coco Filter can be combined with Premier Tech

Aqua’s disinfection unit (DiUV) or other UV disinfection system to reduce the fecal coliforms concentration below

200 UFC/100 ml. For more information on PTA's DiUV, please consult

ptzone.premiertechaqua.com.

The DiUV can either be integrated in the pump vault located inside the Ecoflo®Coco Filter unit or installed separately

in another containment vessel. The following table lists the technical specifications of the Premier Tech Aqua DiUV.

The outlet pipe through which the effluent is discharged into the watercourse must be located at all times below the

surface of the receiving water.

Side view of the gravity discharge into a watercourse

Ensure that the profile of final grade is such that runoff water flows away from the septic system.

5. Description of the polyethylene Ecoflo®Coco Filter components

5.1 Exploded view of models 2.8, 3.4 and 4.1

5.2 Exploded view of models 2.8, 3.4 and 4.1 –PACK option

Component

Material

Description

1

1

2

2

3

4

5-6

7

8

9

10

5.3 Exploded views of models 5.7 and 7.3 DV models

Component

Material

Descprition

1

4

3

2

2

4

5-6

7

8

9

10

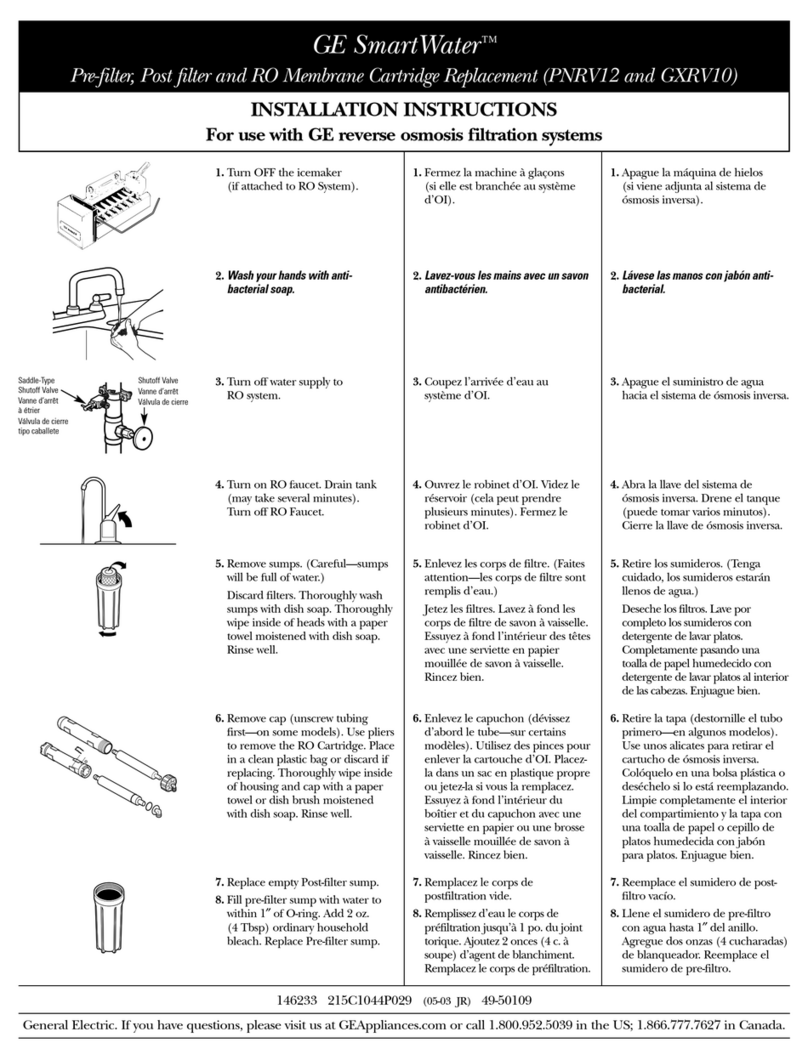

6. Installation sequence

Important: The installer is responsible for taking the necessary safety measures at all steps of the installation. This

includes the use of hardhats, gloves, boots, safety glasses, masks, etc.

During a typical installation, the components are installed in the following sequence:

1- Septic/Primary tank

2- Polyethylene Ecoflo®Coco Filter

3- Water inlet and discharge pipe connections

6.1 Excavation, base and installation of the Ecoflo®Coco Filter

Excavate a sufficiently large area to free up approximately 30 cm (1') around the Ecoflo®Coco Filter stand alone or

PACK unit. Depending on soil conditions, it may be necessary to add a 150 mm (6") layer of 20 mm Ø (0–¾") clean

stone that is free of organic matter or a layer of 20 mm Ø (¾") clean stone that does not contain fillers. The layer of

clean stone must be wrapped in engineering fabric (geotextile). Place the shell down on the surface of the soil and

verify that the installation elevation is adequate. There is no extension available for polyethylene Ecoflo®Coco Filter

models 5.7 and 7.3. However, it is possible to add a 6" (150 mm) riser for models 2.8, 3.7 and 4.1. Verify that the

shell is level and rests fully on the levelled and compacted base.

6.1.1 Systems with gravity discharge

NOTE: if you want to modify a pump unit into gravity unit, refer to the next section

Ecoflo®Coco Filter models 5.7 and 7.3

In the case of the Ecoflo®Coco Filter 5.7 and 7.3 with gravity discharge, remove the protective red cap and use a

watertight and flexible outlet adaptor to connect the effluent discharge pipe. Make sure that the maximum seasonal

high ground water level is never higher than the base of the shell.

Connect the pipe of the Ecoflo®Coco Filter while making sure to maintain a constant downslope over the entire

length of the pipe toward the dispersal area or final discharge. Note that the soil under the pipes must be adequately

compacted.

Ecoflo®Coco Filter models 2.8, 3.4 and 4.1

For the Ecoflo®Coco Filter 2.8, 3.4 and 4.1 with gravity discharge, remove the

protective cap and use a watertight and flexible outlet adaptor to connect the

effluent discharge pipe. Make sure that the maximum seasonal high ground water

level is never higher than the base of the shell.

If you need to use the outlet oriented on the same side of the water inlet, remove

the protective red cap and knock out the gravity outlet. If a yellow warning sticker

is on the red cap, you must drill the green tank skin with a 3-½ inch hole saw. Also,

make sure to cap the original gravity outlet on the other side of the biofilter.

Connect the pipe of the Ecoflo®Coco Filter while making sure to maintain a constant downslope over the entire

length of the pipe toward the dispersal area or final discharge. Note that the soil under the pipes must be adequately

compacted.

6.1.1B Modify a pumping unit into a gravity unit

Ecoflo®Coco Filter models 2.8, 3.4, 4.1, 5.7 and 7.3

To modify a pumped Ecoflo®Coco Filter 2.8, 3.4, 4.1, 5.7 and 7.3 into a gravity discharge biofilter, remove the

protective red cap, punch the baffle in the outlet fitting and use a watertight and flexible outlet adaptor to connect

the effluent discharge pipe. Make sure that the maximum water table level is never higher than the base of the shell.

If you need to use the outlet oriented the same side then the water inlet, remove the protective red cap and knock

out the gravity outlet. If a yellow warning sticker is on the red cap, you must drill the green tank skin with a 3-½ inch

hole saw. Also, make sure to cap the original gravity outlet on the other side of the biofilter.

Original gravity

outlet

Gravity outlet

Outlet adaptor

Tank adaptor

Outlet Pump

pipe

Connect the pipe of the Ecoflo®Coco Filter while making sure to maintain a constant downslope over the entire

length of the pipe toward the dispersal area. Note that the soil under the pipes must be adequately compacted.

Ecoflo®Coco Filter models 2.8, 3.4 and 4.1

If you need to knock out the gravity outlet, make sure to knock out the fitting and drill the green tank skin with a 3-

½ inch hole saw.

6.1.2 Systems with pumped discharge

Ecoflo®Coco Filter models 5.7 and 7.3

Install the screwed adaptors provided in the component box (placed in the main access at the time of delivery of

the shell) for the pumped discharge outlet. The component box contains the 1" (25 mm) and 1.5" (38 mm) outlet

adaptors as selected by the installer.

Ecoflo®Coco Filter models 2.8, 3.4 and 4.1

Unscrew the cap and screw on the appropriate outlet adaptor from the component box.

6.2 Anchoring

6.2.1 Anchoring kit (models 2.8, 3.4 and 4.1) for Ecoflo®stand alone

When a single riser is installed on models 2.8, 3.4 and 4.1, the biofilter (stand alone) must be anchored with the

geotextile provided to this effect before the final backfilling such as to maximize the stability of the unit.

Spread out the geotextile as illustrated in the following figures and make sure it overextends by 20" (500 mm) on

each side. Next, use the 6 ties provided to solidify the installation at the pultrusions. Add backfill material on top of

the geotextile to keep it in place.

6.2.2 Anchoring of model 5.7 and 7.3 - Installation of the extension pipes and membranes

To ensure that the shell does not move in the soil, install the six (6) extension

pipes onto the ends of the pipes in the shell. On each side of the shell, place a

section of membrane over the three extension pipes. Adequately spread out

and level the backfill material under and above the membranes.

6.3 Initial backfill of the shell

Backfill around the shell up to 8" (200 mm) below

the invert of the feed pipe. To backfill around the

shell, begin with the two longest sides and end with

the extremities. Note that the backfill material must

be laid down rather than pushed (do not compact

the backfill material using the power shovel).

The backfill material must be sandy and free of

rocks or stones.

ATTENTION: Make sure that no backfill material enters the shell during the backfilling operation.

6.4 Assembly of components on the site of installation

Pumped

effluent pipe

Gravity

effluent pipe

Inlet pipe

200 mm

(8")

6.4.1 Models 5.7 and 7.3

•Unscrew and remove the packaging material from both accesses.

•Remove the main and secondary accesses. The main access assembly

includes the cover and the insulating panel. To remove the cover,

unscrew the four lag screws in the corners.

•Remove the box and internal components located on the distribution

plates.

•Glue the elbow assembly onto the water inlet pipe. Line up the

alignment marks to properly position the elbow assembly.

Once in place, the inlet pipe must be centred with the tipping

bucket. The elbow assembly can be found in the component

box, placed in the main access at the time of delivery of the

shell.

ATTENTION: Do not invert the direction of the elbow to avoid

decentring the water inlet pipe.

•Set the tipping bucket on the central support by inserting the two (2) blocking notches into the central

support’s anchor holes and fold back the opposite end to maintain the tipping bucket in place. Verify the

installation of the tipping bucket by activating it from left to right. It must not block along its course.

•Verify that:

–The plates are firmly in place;

–The top of media is well leveled

–The float shaft and the pump are firmly in place (models equipped with a pump);

–The tipping bucket operates correctly on either side.

Blocking notches

Anchor holes

Lid

Insulating board

Main access

Secondary

access

•Screw both accesses in place using the lag screws provided and place

the insulating panels and covers on both accesses. Close the cover of

the main access using the four (4) lag screws and close the cover of the

secondary access using the two (2) quarter turns. The secondary

access’s cover and insulating panel are in the component box (placed

in the main access at the time of delivery of the shell).

6.4.2 Models 2.8, 3.4 and 4.1 (stand alone and PACK option)

Primary tank for the PACK option

Assembling the riser on the primary tank:

•Clean the rim of the primary tank’s access (where 4 holes have been

punched to allow for the installation of the lag screws).

•Install the watertight gasket on this rim.

•Place the extension on the access by aligning the holes on the base

of the extension with the holes on the primary tank.

•Insert the plastic washers in the four (4) lag screws provided with the

extension and screw the lag screws into the holes to secure the

extension in place.

Ecoflo Coco Filter

Remove the access lid by turning the two ¼ turn locks. Remove the insulating panel.

Using the 3/8” screws provided and a 9/16” socket driver (not provided), loosely fasten

the riser through the hole above the pumping vault (1). Center the riser on the Ecoflo by

running your hand alongside the riser’s outer rim and repositioning it if necessary.

Using the drill bit provided, pre-drill a hole on the opposite side and loosely fasten the

riser to the Ecoflo biofilter (2). Drill a new hole only when the previous screw is

positioned. Do not drill all holes at once. Alternating sides and following the order

shown, loosely fasten all 10 bolts. Evenly secure and compress the gasket by

progressively tightening each bolt at least twice.

Drill a new hole only after the previous screw has been inserted

into place. Once all screws are in their respective positions,

tighten them further, but not completely. This will ensure that

the gasket is evenly compressed into place. At this stage, the

D-shaped gasket is about 30% compressed. The best practice

is to alternate screws and sides instead of going from one

screw to the next.

Completely tighten

each screw by

going over it one

last time.

By securing the riser in multiple tightening sequences, you evenly

compress the gasket and ensure maximum watertightness.

This manual suits for next models

8

Table of contents

Other Ecoflo Water Filtration System manuals