Ecoflo CLIVUS MULTRUM LOW PROFILE User manual

CLIVUS MULTRUM

LOW PROFILE

INSTALLATION & OPERATION MANUAL

IMCM-203-2023.04.18

©Ecoo Wastewater Management Pty Ltd

TABLE OF CONTENTS

ITEMS REQUIRED (NOT INCLUDED) 1

TOOLS REQUIRED 1

SCHEMATICS 2

INSTALLATION 3

STEP 1: POSITION THE PEDESTAL 3

STEP 2: POSITION THE WASTE CHUTE 3

STEP 3: INSTALL THE WASTE CHUTE 5

EXTRA LENGTH FOR UNDER-FLOOR AREAS 6

STEP 4: INSTALL THE WHEELS 7

STEP 5: INSTALL THE MIXER 7

STEP 6: INSTALL THE CHAMBER 8

STEP 7: CONNECT THE VENT PIPE AND FAN 9

OPTIONAL EXTRAS 9

STEP 8: CONNECT THE FLEXIBLE VENT PIPE AND LIQUID DRAIN HOSE 10

POWERING YOUR FAN 11

LEACHATE DRAIN 12

COMPOSTING ACCELERATORS 13

MAINTENANCE 14

ROTATION OF CHAMBERS 15

TROUBLESHOOTING 16

PRODUCT & COMPONENT WARRANTY 18

MAINTENANCE SCHEDULE 19

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 1

ITEMS REQUIRED (NOT INCLUDED)

Please check the packing slip to ensure everything has been delivered. If anything is missing, please

notify Ecoo within 72 hrs of receipt.

You will need the following items to complete your installation.

Vent items

• Wall brackets to x the vent pipe to the building

• A length of 100mm DWV vent pipe to connect to the air exhaust (length depends on specic

installation)

• Dektite if DWV vent pipe will penetrate the roof

Leachate drain items (please check with your local authority)

• Ø100mm Agricultural pipe

• 1.5m x 0.5m Synthetic or Hessian geotextile mat

• 50mm PVC pipe to connect the hose to the agricultural pipe

• 0.30m³ 20mm Aggregate

A vent kit and drain kit are available to purchase separately from Ecoo.

TOOLS REQUIRED

PVC

CEMENT

SILICONE

Marker Tape Measure Shovel Hand Saw

JigsawPlumb BobPVC CementCaulk Gun

Power Drill Philips Drill Bit Masonry and Brad

Point Drill Bits Hole Saw

Drill Bit

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 2

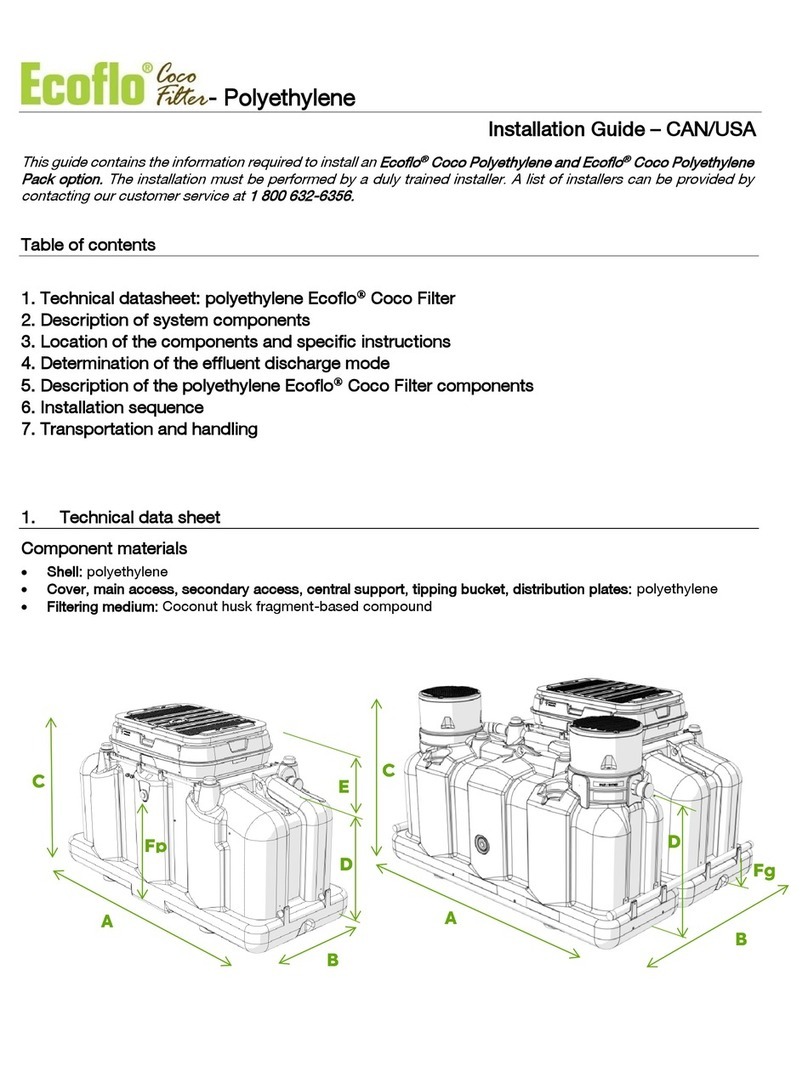

Pedestal

Chute

Min. 500mm

Fan in housing

Y Juntion

L.I.T Reducer

Vent pipe

Brackets*

100mm DWV pipe*

45° bend

Dektite*

600mm

600mm

Vent cowl

Camlock fittings

Excess liquid drain hose

T-piece*

(3 way hose connector)

Leachate drain*

Out-of-service

chamber

In-service

chamber

Pedestal

Chute

Min. 500mm

Fan in housing

L.I.T Reducer

Vent pipe

Brackets*

100mm Sewer pipe*

45° bend

Dektite*

600mm

600mm

Vent cowl

Camlock fittings

Excess liquid drain hose

Leachate drain*

In-service

chamber Out-of-service

chamber

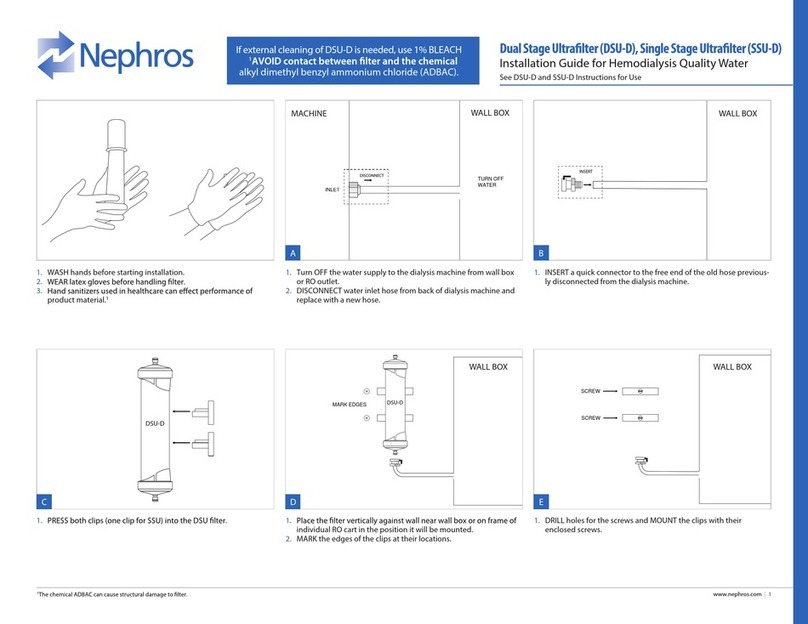

SCHEMATICS

If you are planning

to excavate an area

under the house for

the compost chambers,

please ensure the area

is well-drained and any

retaining walls are built

to the satisfaction of

the local authority.

Optional Vent

Installation

Optional Installation An optional extra connection

kit is available to purchase

separately from Ecoo.

* Not included in package.

A separate vent kit and drain

kit are available to purchase

from Ecoo.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 3

INSTALLATION

STEP 1: POSITION THE PEDESTAL

Locate the approximate area where you want the pedestal to go before cutting the hole.

The usual position for pedestals is centered between side walls.

NOTE: Due to the pedestals being man made, the distance to the center may vary from 245-255mm.

Please check before cutting the hole.

STEP 2: POSITION THE WASTE CHUTE

A 240mm hole must be cut in the toilet room oor to accommodate the waste chute.

2

1

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 4

Go to the underoor area and look for the hole you have drilled.

Check to see if there is a oor joist, water pipe or electrical wiring under the area you

are going to cut.

If there is a joist in the way, either reposition the waste hole OR install trimmer joists to

each end of the cut joist, and x all connections with galvanized framing anchors with 4

nails each leg (refer to diagram below).

View from under oor

4

3

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 5

STEP 3: INSTALL THE WASTE CHUTE

First ensure the pad or ground level on which the ‘In-service’ chamber will reside is at its nal level

beneath the toilet room.

Insert the chute into the hole

Mark position

1

5

3

6

4

2

Note: Remove lid

before measuring.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 6

EXTRA LENGTH FOR UNDER-FLOOR AREAS

If the underoor height exceeds 900mm, you will require additional lengths of chute, xed together with

small stainless steel self-tapping screws below the ange of the additional waste chute.

As the chute joints are tapered, the top waste chute must be inserted through the toilet room oor rst

with additional waste chutes added from below.

900mm

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 7

The compost mixer comes pre-assembled and installed in each chamber.

RingGear

Cog

Mixer Key

Mixer Rake

Crank handle for rotating the ring gear.

Simply place the hook in the eyelet and

turn clockwise.

STEP 4: INSTALL THE WHEELS

Attach wheels onto axle.

STEP 5: INSTALL THE MIXER

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 8

STEP 6: INSTALL THE CHAMBER

1. A brush seal is supplied for the

‘In-service’ lid and acts as a seal to

prevent any odor emitting from the

chamber. Remove the adhesive cover

and place the brush seal on the inside

surface of the lid as shown below.

2. Add 50mm depth of bulking agent

to the chamber to create a bed.

3. Slide the chamber lid (with hole) up

onto the waste chute from underneath.

5. Rotate the lid to lock the catch

plates onto the pins.

4. Place the chamber underneath the

lid and lower it onto the chamber.

6. Lock the toggle latches as shown

below.

Place brush seal on insi

de surfaceof

chute extrusion as shown.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 9

STEP 7: CONNECT THE VENT PIPE AND FAN

The fan is IP68 rated so will not be effected by moisture.

Do not glue the fan

housing to the DWV

ttings.

It is recommended that

the fan runs 24 hours

a day to continuously

circulate air through

the compost heap.

Air is drawn down the

toilet pedestal through

the compost chamber

and out the vent pipe.

100mm DWV vent kit:

• ø100mm DWV Pipes

• ø100mm DWV Slip Joiners

• ø100mm Stand Off Brackets

• Dektite

Extra chamber connection kit:

• Y junction

• Flexible vent pipe

• Pipe connectors

• Male camlock

• Sullage hose

• T-piece

Pedestal

Chute

Min. 500mm

Fan in housing

Y Juntion

L.I.T Reducer

Vent pipe

Brackets*

100mm DWV pipe*

45° bend

Dektite*

600mm

600mm

Vent cowl

Camlock fittings

Excess liquid drain hose

T-piece*

(3 way hose connector)

Leachate drain*

Out-of-service

chamber

In-service

chamber

Pedestal

Chute

Min. 500mm

Fan in housing

L.I.T Reducer

Vent pipe

Brackets*

100mm Sewer pipe*

45° bend

Dektite*

600mm

600mm

Vent cowl

Camlock fittings

Excess liquid drain hose

Leachate drain*

In-service

chamber Out-of-service

chamber

Optional Installation

OPTIONAL EXTRAS

These optional kits are available to purchase separately from Ecoo Wastewater Management.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 10

STEP 8: CONNECT THE FLEXIBLE VENT PIPE AND LIQUID DRAIN HOSE

Connect the exible vent pipe (black) and liquid drain hose (purple) to the chambers.

1

2

Air vent outlet (See image 1)

Screw the threaded 50mm MI connector

into here. Then insert the slotted pipe

connector into the MI connector.

Liquid drain outlet (See image 2)

MI Connector Slotted Pipe

Connector

Flexible Vent Pipe

Female

Camlock

Nipple Male Barbed

Camlock

Liquid Drain Hose

Dip the ends of

the vent pipe into

hot water for easier

insertion of the

pipe connectors.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 11

1 2

43

POWERING YOUR FAN

Mains Power

A 120 /12 volt regulated transformer is included to run the fan from mains power. The positive wire

the transformer is marked with a white line. The fan has anti-polarity protection and would not run if

connected incorrectly.

Connect the fans to the transformer as follows:

solar Power

Refer to separate installation manual for the solar panel.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 12

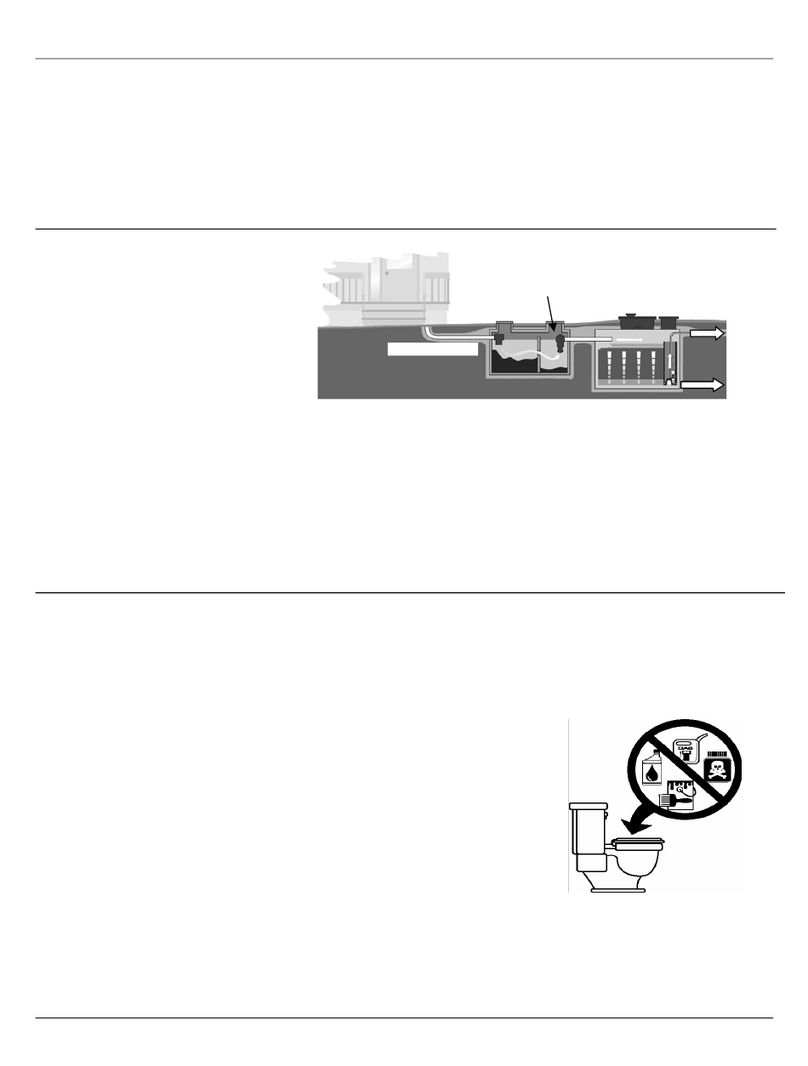

LEACHATE DRAIN

A leachate drain kit (not including gravel) is available to purchase separately from Ecoo Wastewater

Management.

Alternatively, if your council allows, you may wish to construct your own leachate drain. The liquid drain

hose should run into either a 50mm PVC pipe (drilled to allow liquid to escape) OR a length of socked

slotted Ag pipe, buried in an absorption trench as shown in the diagram below.

150mm

230mm

500mm

1200mm

Socked slotted pipe

230 min

150 min

500 min

Leachate drain

Gravel

Geofabric layer

300 min

150 min

450 min

20mm Gravel

ø100mm Agi Drain

Geofabric layer

agi Drain

Trench arch Drain

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 13

COMPOSTING ACCELERATORS

Whilst Clivus Multrum users report successful composting without the use of any additives, we strongly

recommend the use of the following items in order to optimize composting, particularly when the toilet

is in permanent use by more than two people.

Bulking agenT

This should be added on a regular basis, preferably a handful after each

solid use. Alternatively, if this is not possible, add the equivalent of this

on a daily or weekly basis. The bulking agent can be added through the

pedestal.

We do NOT recommend the use of:

• Sawdust as it creates an anaerobic condition within the chamber.

• Cypress, cedar or eucalyptus wood shavings due to their antimicrobial

properties.

• Sugar cane mulch as it makes using the mixer difcult.

liquiD enzyMes

A 125ml bottle of enzyme concentrate is supplied with the toilet. Please

refer to the label for instructions and spray into the waste chute. A spray

ask is provided. Any staining of the pedestal can also be removed with

the spray.

MicroBes

This should be used each time a chamber is changed to kick start the

process in the new chamber.

Shop consumables:

ecoo.com.au/products/consumables

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 14

MAINTENANCE

Daily or weekly

• Clean restroom and toilet xtures using only biodegradable cleaners (enzymes)

• Add 1 cup of bulking agent to toilet after every solid use

MonThly

• Inspect the ‘In-service’ chamber, depends on usage, prepare another ‘In-service’ chamber for use

once the chamber becomes full (refer to Rotation of Chambers, page 15).

• Check vent pipe and remove any foreign matter.

• Check the fan is operating

• Check that system is draining correctly

6 MonThs

• Remove and clean fan

It is important to observe safety procedures when dealing with fresh

human waste.

Please ensure you wear protective clothing (gloves and old clothes).

Do not attempt to move the chambers on your own.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 15

ROTATION OF CHAMBERS

your firsT roTaTion of The chaMBers:

The Clivus Multrum composting toilet chambers will need to be changed on a regular basis. A sufcient

number of chambers must be purchased to allow the ‘Out-of-service’ chamber a minimum 6 months to

compost; depending on climate, from the time they are disconnected from the waste chute.

Prepare a new ‘In-service’ chamber for use (refer to Step 6: Install the Chamber, page 8).

Pour a small bucket of bulking agent (clean mulch) down the pedestal to cover up the waste pile before

removing the full chamber.

exTra chaMBer/s:

The ‘Out of Service’ chamber should be put in a warm position with the vent cap attached to the

threaded MI connector and the dust plug attached to the liquid drain camlock.

reMoval of coMPosT:

The pile should have reduced in size to approximately 20% of its original size and contain a maximum

of 75% moisture. This ‘humus’ must then be disposed of as per the local health department regulations.

This normally means digging the humus into the soil and covering with at least 100mm of soil.

reTurning achaMBer To service:

1. Ensure all hose and vent connections are clear.

2. Prepare the ‘In-service’ chamber for use (refer to Step 6: Install the Chamber, page 8).

If the ‘Out-of-service’ chamber is to be placed away from the Main Vent assembly, you will need to dig a

small second trench 200 x 200 x 200mm to allow residual liquid to exit the chamber. Connect the second

liquid drain hose from the chamber to the trench.

MI Connector Pipe

Connector Vent Cap

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 16

TROUBLESHOOTING

Clivus Multrum toilets have proven themselves to be one of the easiest systems to manage. However,

being a natural process, reliant on a number of factors beyond our control, it can occasionally need

some help to maintain an appropriate balance.

The ‘in-service’ chaMBer is filling Too quickly:

This may be caused by a number of factors:

THE TEMPERATURE IS TOO LOW

for effective composting.

INSUFFICIENT AIR FLOW

This can be caused by a broken fan or the chamber being too full. Check the fan is operating and the

level of the pile is not too high. This problem could also be caused by a blocked insect screen in the

vent cowl.

THE PILE BEING TOO WET

This could be the result of the outlet of the liquid chamber being blocked and causing the upper

chamber to ood. Check the drain hose is not blocked and ush with a hose if necessary. You may need

to change chambers if the blockage is in the chamber and thoroughly ush out the contents of the

liquid chamber.

ANTIBIOTICS AND DISINFECTANTS WILL SLOW DOWN OR STOP THE PROCESS

Restart the composting by reintroducing microorganisms. In many of these situations Nature Flush

Enzymes will help solve inefcient composting by breaking down the solids and thereby speeding up

decomposition.

The ‘ouT-of-service’ chaMBer is coMPosTing Too slowly:

This may happen due to one or more of the problems described above. At this point the most effective

course of action is to aerate the pile by turning it over with the Compost Mixer. You could also add

500ml of Nature Flush Enzymes from a domestic spray bottle as you turn the material and add a

quantity of Nature Quick Microbes.

You should consider locating the chamber where it has a greater exposure to direct sun light. However,

if you nd the pile is drying out too quickly put the chamber in a shadier position.

If you nd none of the above measures are effective, it means the local climatic conditions are less

than ideal. This can happen in cold or humid conditions and you will need to purchase an additional

chamber in order to provide an extended composting period.

If you need to change your ‘In-service’ chamber and the ‘Out-of-service’ chamber is not yet composted,

dispose of the waste as normal and order an extra chamber from Ecoo.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 17

Find more Troubleshooting and FAQ information online at

ecoo.com.au/FAQ

or email us at

info@ecoo.com.au

The oDour froM The ‘ouT-of-service’ chaMBer is unPleasanT:

If the ‘Out-of-service’ chamber is not connected to the vent pipe it may smell immediately after it has

been taken ‘Out-of-service’. Odours can be greatly reduced or eliminated by covering the top of the

pile with straw or dry grass clippings. You may wish to do this before disconnecting the chamber.

The oDour froM The ‘in-service’ chaMBer is unPleasanT:

If this is not caused by a failed fan, or blockage in the vent pipe, liquid drain hose or tting, please see

the “‘In-service’ chamber is lling too quickly” section for how to resolve this problem.

The Power has faileD resulTing in ToileT rooM oDours:

Cover the pedestal with cling lm until the power is restored. If you are connected to mains power

consider installing an Uninterrupted Power Supply (UPS), available at Ecoo. The UPS will cut in with

power from a 7Ah battery when there is a loss of mains power.

Helpful hints from our customers:

• Paint the Vent Stack black to produce an upward air ow.

• Add a wind assisted turbo vent to the Vent Stack.

©Ecoo Wastewater Management Pty LtdIMCM-203-2023.04.18 Page 18

PRODUCT & COMPONENT WARRANTY

Ecoo will furnish new parts to a customer whose toilet fails within the allotted warranty period for

the particular component, provided that our inspection shows such failure is due to defective material

or workmanship. Any part supplied is warranted for the balance of the original warranty period. The

warranty period for a part begins from the date the original product was dispatched (plus 10 working

days for transportation).

warranTy PerioD:

Any electrical component including solar 1 year

Any rotomoulded component 10 years

Any porcelain/polymarble component 4/5 years

Toilet seats 1 year

Any other component 1 year

This warranTy Does noT cover:

• Damage resulting from neglect, abuse, accident or alteration; or damage caused by re, ood, acts

of god or other causality.

• Damage resulting from failure of the purchaser to follow normal installation and operating

procedures outlined in the manual or in any other printed instructions supplied with the system.

• Labour and service charges incurred in the removal and replacement of any parts found defective

under this warranty.

Items subject to a dispute, where photographic evidence is inconclusive, must be sent prepaid to

Ecoo. The cost will be reimbursed by Ecoo should the claim be found valid.

In addition to the above, Ecoo will only replace a fan that fails during the warranty period under the

following conditions:

• The fan has only ever been connected and powered by either a 12 volt transformer plugged into

mains power or a solar system supplied by Ecoo. Connecting your fan directly to a power source

other than one supplied or specied by Ecoo may result in damage to the fan and void the

warranty.

• The fan and transformer must not be modied/altered in any way.

• The faulty fan is returned to Ecoo for inspection, if required.

Providing the above conditions have been met replacement fans are shipped the same or following day

free of charge by regular post.

Table of contents

Other Ecoflo Water Filtration System manuals