Ecolibrium Solar EcoX User manual

EcoX Gen2 Installation Guide, Rev 1.11

Installation Guide

Gen2

EcoX Gen2 Installation Guide, Rev 1.11 i

Table of Contents

EcoX Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . ii

Installer Responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Warnings & Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

General Application Notes . . . . . . . . . . . . . . . . . . . . . . . . iii

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

EcoX Components . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview of Components . . . . . . . . . . . . . . . . . . . . . . . . 3

Layout Array on Rooftop . . . . . . . . . . . . . . . . . . . . . . . . . 4

Prepare the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The Basics of Wire Management . . . . . . . . . . . . . . . . . . . . . 7

Install Attachments to Roof . . . . . . . . . . . . . . . . . . . . . . . . 8

Install the Junction Box Bracket . . . . . . . . . . . . . . . . . . . . . 10

Install the Clamp Assemblies . . . . . . . . . . . . . . . . . . . . . . 11

Level and Align the Clamp Assemblies on Southern Row . . . . . . . . . . . . 12

Install Skirts on Downhill Row . . . . . . . . . . . . . . . . . . . . . . 14

Install Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Level the Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Grounding and Bonding (overview) . . . . . . . . . . . . . . . . . . . . 22

Appendix A: How to Replace the Clamp Assembly with a Coupling . . . . . . . A-1

Appendix B: Thermal Expansion . . . . . . . . . . . . . . . . . . . . . B-1

Appendix C: Service and Maintenance. . . . . . . . . . . . . . . . . . . C-1

Appendix D: Modules Evaluated as part of EcoX UL 2703 Certification . . . . . . D-1

Appendix E: Power Accessory Bracket Installation . . . . . . . . . . . . . . E-1

Appendix F: Installing Skirt-Less Clamp Assemblies . . . . . . . . . . . . . . F-1

Appendix G: Installing EcoX on a Membrane Roof . . . . . . . . . . . . . . G-1

Installer Responsibility

The installer is solely responsible to:

lComply with all applicable building and electrical

codes

lMeet municipal, utility and inspector requirements

lEnsure installation methods and procedures meet

all applicable OSHA safety standards

lConfirm all building structural members and

related connections can withstand all forces

resulting from the EcoX installation

lMaintain waterproof integrity of all existing roofing

materials

lVerify all design criteria are correct and appropriate

for the application and specific site

lFollow all manufacturer's specifications,

recommendations and manuals

lCheck that only Ecolibrium Solar approved

materials are utilized during EcoX installation

lGuarantee array installation is completed by

qualified and competent personnel

lVerify all equipment and materials are appropriate

for application and site conditions

lEstablish that anchoring devices, including lag

screws, have adequate pullout strength and shear

capacities as installed

lDetermine that PV module is approved for use with

EcoX and is capable of withstanding the project

specific conditions.

Warnings & Safety

Both electrical and roofing knowledge is required to

correctly and safely install a solar photovoltaic

system. Only qualified and certified installation

professionals should install EcoX. Failure to follow

the methods and procedures outlined in this guide

may result in injury and/or damage to property.

Carefully read this guide before starting any work.

Store a copy of this guide on the job site at all times

and contact Ecolibrium Solar with any installation

questions related to EcoX.

Please note the following warnings when installing

EcoX:

lEcoX Bonding Clip may have sharp edges

lEcoX components fit together tightly and could

cause pinch injuries

lEcoX components may be hot to the touch if left in

the sun.

Please follow the safety requirements below when

installing EcoX:

lAlways keep children and unauthorized people

away from work areas

lAlways wear required OSHA approved Personal

Protective Equipment (PPE)

lAlways use insulated tools when working with or

near electrical systems

lAlways provide OSHA approved fall protection for

all installation personnel

lNever wear jewelry during mechanical and

electrical installation work

lNever work in rain, snow or extremely windy

conditions

lNever leave a module unsupported or unsecured

on the roof

lNever install broken photovoltaic modules

lNever use photovoltaic modules as a work surface

ii

Introduction

EcoX is an innovative, simple, and easy to install

flush-mount solar racking system. By eliminating the

mounting rail, EcoX offers a flexible system layout and

streamlines the installation process. EcoX utilizes

aluminum components with stainless steel hardware,

ensuring the system will withstand harsh installation

environments. With EcoX, the racking and modules

work together as a system, creating an

interconnected, continuously bonded structure.

This install guide outlines the overall installation

process, and details the steps involved. Ecolibrium

support staff are available to answer questions or

offer support. Feel free to contact us, and thank you

for installing EcoX!

EcoX Gen2 Installation Guide, Rev 1.11

iii

Module Types: EcoX is certified to be installed with standard framed 60 cell

modules according to the approved module list.

Mechanical Loading: EcoX is certified to UL2703 for mechanical loading.

Tested modules are listed in Appendix D. Span requirements for a given

jobsite can be determined using the EcoX Estimator design tool:

Fire Testing: EcoX is certified to UL2703/1703 Fire Resistance Standard with

the following requirements:

lInstructions in this guide must be followed.

lThe EcoX system must be mounted over a fire resistant roof covering rated

for the application.

lModules may be installed in landscape or portrait

lThe EcoX fire rating is valid with or without a skirt.

lAll height settings of EcoX product are valid, up to highest setting

(corresponds to 4 ¼” from roof surface to lower edge of module frame).

For pitches greater than 2:12 (9.46 degrees):

lEcoX is certified to Class A with Type 1 and 2 modules.

lJunction box must be mounted away from the roof downhill edge.

For pitches less than 2:12 (9.46 degrees), aka “flat“ or “low-slope“ roofs:

lEcoX is certified to Class A with Type 1 modules.

lJunction box can be mounted at any location.

Grounding and Bonding: EcoX is certified to UL2703 for grounding and

bonding. The grounding and bonding test evaluates EcoX as a system with

approved modules. When installed per the requirements outlined in this

installation guide, EcoX with approved modules are rated as a system to

create a continuous bonded structure.

Installation Requirements: This install guide officially documents the

components used and proper methods for an EcoX installation. Bonding

elements are incorporated into EcoX components. As the system is built on

the roof, components and modules are bonded together. Specific steps to

ensure a bonded system are described through the installation guide. It is the

installer's responsibility to ensure that the system is safely and properly

installed, and that the system is bonded back to a final ground point. There

are no specific array size limitations due to the flexible and expandable design

of EcoX.

UL2703 System Documentation: To document the UL2703 system rating, a

label is factory-applied to the end of each skirt. For skirt-less configuration, a

label is factory-applied to the side of the End Clamp assembly. Below is an

example of the label:

http://ecox-estimator.ecolibriumsolar.com

EcoX General Application Notes

System Design and Span Requirements: EcoX is designed to flush-mount

photovoltaic modules on pitched roofs as described in this guide. The span

between attachment locations depends on the module, the site conditions,

and the system layout.

Site Specific System Design: The EcoX Estimator is a powerful system design

tool. The user inputs all site conditions and can layout multiple roof surfaces.

The EcoX Estimator outputs a site specific design package with engineering

specs and bill of materials.

Visit the EcoX Estimator at to

layout your array and instantly obtain attachment spacing, bill of materials,

and engineering analysis.

Roof Type: EcoX is designed to mount photovoltaic modules to a range of roof

surfaces, including :

Asphalt or composite shingles

Concrete or clay tiles (see Addendum )

Membrane roof

Metal roofs are permitted as long as the method of bonding and grounding

the metal roof is approved by AHJ. Contact Ecolibrium Solar if your project’s

roof surface type is metal, or not listed above.

Wind Zone: EcoX is designed to mount photovoltaic modules on pitched roof

surfaces in areas with extreme wind conditions. Please contact Ecolibrium

Solar if your project's wind speed exceeds the zone allowable in the EcoX

Estimator.

Roof Height: EcoX is designed to mount photovoltaic modules on pitched roof

surfaces with a mean roof height up to 60 feet. Please contact Ecolibrium

Solar if your project's mean roof height exceeds 60 feet.

Roof Pitch: EcoX is designed to mount photovoltaic modules on roof surfaces

between 0 and 90 degrees from horizontal.

Roof Zones: EcoX is designed to mount photovoltaic modules on pitched roof

surfaces in all roof zones with attachment spacing as prescribed in the EcoX

Estimator.

Roof Orientation: Throughout this manual, “downhill” is used to reference

the direction of the lower or leading edge of the array, and “uphill” is used to

reference the direction of the trailing or back edge of the array.

EcoX Certifications

Approved Modules: This racking system may be used to ground and/or

mount a PV module complying with UL 1703 only when the specific module

has been evaluated for grounding and/or mounting in compliance with the

included instructions. Specific modules included in EcoX certifications are

documented in Appendix D at the end of this install guide.

http://ecox-estimator.ecolibriumsolar.com

l

l

l

EcoX Gen2 Installation Guide, Rev 1.11

EcoX Gen2 Installation Guide, Rev 1.11 iv

Revision History - Install Guide

Revision

Description of Changes

Date

1.0

Initial Release

2015-July

1.1

Updated UL 2703 Specifications

2015-August

1.2

Updated UL 2703 Specifications

2015-September

1.3

Updated for LA County Requirements

2015-October

1.4

Updated for 32mm Modules and Uphill

Bonding Clip

2016-January

1.5

Updated bonding lug instruction

2016-March

1.6

Updated for membrane roof and additional

approved modules

2016-December

1.7

Updated Appendix D with additional UL

2703 qualified modules

2017-September

1.8

Updated Appendix D

2017-October

1.9

Added Modules to Appendix D

2017-November

1.10

Added Modules to Appendix D

2018-January

1.11

Added Modules to Appendix D

2018-April

Dovetail

Engagement

(mates to Base)

Dovetail

Engagement

(mates to Skirt)

Glider

Strut Nut

Serrated

Strut Bolt

Bonding Clip

(not visible)

Lower Clamp

(tongue supports

downhill edge

of Module)

Upper Clamp

EcoX Components

Attachment Kit

Coupling Assembly

Clamp Assembly

Skirts (optional item) Skirts are used on the

first downhill row to

enhance the

appearance along the

edge of the array.

Dovetail Engagement

positions height of

and locks Skirt to

Clamp Assemblies and

Couplings.

Factory cut to length

to match specific

Modules.

Available in three

configurations (height

variances) to fit the

most common

Module sizes.

l

l

l

See Appendix G for

skirt-less installation

details.

The Clamp Assembly is

mounted to the Base of

the Attachment Kit.

Dovetail Engagement

to Base for height and

uphill/downhill

adjustments.

Upper and Lower

Clamp secures edges

of Modules

Upper and Lower

Clamp engage Skirt on

Skirt row.

Strut Bolt and Strut

Nut secure Clamp

Assembly to Base and

Modules to Clamp

Assembly.

Factory installed Bond

Clip bonds Skirt to

Attachment Kit on

south row, and Module

to Attachment Kit on

subsequent rows.

l

l

l

l

l

The Attachment Kit is

secured to the roof and

supports the array via

the Clamp Assembly.

Its features include:

Grooves along sides of

Base are Dovetail

Engagements which

provide adjustability

of the Clamp

Assembly in height

and uphill-downhill

directions.

Base is attached via a

single Lag Screw.

Lag Screw includes a

factory pre-installed

Sealing Washer.

l

l

l

Torque Spec: 14 ft-lbs

Couplings connect up to

four Modules together.

Couplings include

indicator marks to set

a 1/2" gap between

Modules.

On the first downhill

row, Couplings secure

adjacent Skirts at their

joints.

Factory installed Bond

Clips (two per

Coupling) bond

Modules left and right.

l

l

l

Torque Spec: 14 ft-lbs

Flashing

Torque Spec: 14 ft-lbs

Base

Dovetail

Engagements

(mates to Glider)

5/16" Lag Screw

with Sealing

Washer

Dovetail

Engagement

(mates to Skirt)

Serrated

Hex Bolts

Bonding Clip

(not visible)

Bonding Clip

(not visible)

Lower Clamp

(tongue supports

downhill edge

of Modules)

Upper Clamp

Alignment Indicators

Dovetail Engagement

(mates to Clamp

Assemblies and

Couplings)

1 of 31

EcoX Gen2 Installation Guide, Rev 1.11

EcoX Components (cont.)

Power Accessory Bracket Junction Box BracketRow to Row Bonding Clip

End CouplingEnd Clamp End Coupling connects

two modules left to

right.

End Couplings include

indicator marks to set

a ½” gap between

Modules.

Factory installed

Bonding Clips (two per

End Coupling) bond

modules left to right.

l

l

Torque Spec: 14 ft-lbs

The End Clamp is

mounted to the base on

the downhill row, and

may be used in place of

the Skirt for a Skirt-Free

installation.

Dovetail Engagement

to base for height and

uphill/downhill

adjustment.

Upper End Clamp

secures module.

Integrated bonding

clip bonds module to

clamp and Attachment

Kit.

l

l

l

Torque Spec: 14 ft-lbs

Power Accessory Bracket mounts a micro-inverter or

power optimizer to the Module.

lThe serrated teeth ensure a secure connection to the

module.

lThe Power Accessory Bracket bonds the micro inverter or

power optimizer to the Module.

Torque Spec: 14 ft-lbs

The Junction Box Bracket mounts to the Base, and acts as a

support for a Junction Box.

lCan be installed to any base.

lCan be installed before or after modules are installed.

Torque Spec: 10 ft-lbs

The Row to Row Bonding Clip bonds each row of modules

to the next.

lBonding Clip is added to the uphill side of one clamp per

row.

lFor systems using the skirt, Bonding Clip bonds skirt to

first row of Modules.

Glider

Strut Nut

(partially

visible)

Serrated

Strut Bolt

Serrated

Hex Bolt

Upper

End

Coupling

Lower End

Coupling

Upper

End

Clamp Bonding Clip

(not visible)

Bonding Clip

(not visible)

Bonding Clip

(not visible)

2 of 31

EcoX Gen2 Installation Guide, Rev 1.11

The EcoX installation

begins at the downhill

edge of the roof and

progresses uphill.

Installation is sequential

and requires minimal

hand tools.

Installation steps:

1. Layout Array on

rooftop.

2. Install Attachment

Kits to rooftop.

3. Install the Junction

Box Bracket.

4. Install Clamp

Assemblies on

downhill row.

5. Install the Skirts.

6. Install Couplings to

Skirts.

7. Install Modules

8. Install Clamps and

Couplings on uphill

side of Modules.

9. Level the row of

Modules.

10. Repeat Module

install on

subsequent rows.

11. Install additional

Bonding Clips at one

end of each row to

complete row to

row bonding.

Required Tools:

Tape Measure

Chalk Line

Hammer

Drill with 3/16" Bit

Flat Roofing Bar

Impact Driver

1/2" Socket

String Line

Torque Wrench

Chalk

l

l

l

l

l

l

l

l

l

l

Overview of Components

Note: Rooftop and shingles not shown for clarity

Attachment Kit

Clamp

Coupling

Coupling

Skirt

Adjoining

Skirts

Modules

(transparent for

visual clarity)

3 of 31

EcoX Gen2 Installation Guide, Rev 1.11

1. Layout Array on Rooftop

Using chalk, layout the

footprint of the array on

the rooftop. Look for

any obstructions on the

rooftop that could

prevent a complete and

proper installation of

the array.

1. Starting from the

downhill edge,

place a mark 2-1/2"

up from the bottom

edge of the downhill

course of shingles.

2. Using the Module

dimensions include

the following:

Left/right include a

1/2" gap between

Modules.

Uphill/downhill

includes a

3/4" gap between

Modules.

The following page

continues this layout

and illustrates a finished

rooftop layout.

l

l

Knowing where the

Modules intersect

will identify potential

interferences between

Attachments and

Couplers.

Most AHJ’s require a

roof setback per

their local fire code

requirements. Make

sure that the required

setback is observed

when marking the

footprint of the array.

1a. Mark the Four Corners of Array

Mark Module

Intersections

Mark Footprint

of Array Modules

Mark 2-1/2" up

from bottom edge

of downhill course

2-1/2"

3/4"

Gap

3/4"

Gap

1/2" Gap 1/2" Gap

Module

Width

Module

Width

4 of 31

EcoX Gen2 Installation Guide, Rev 1.11

1. Snap left/right chalk

lines.

2. Mark the

attachment

locations by locating

the structural

members of the

roof. Refer to the

EcoX Calculator for

maximum allowable

span and cantilever.

Ensure that

attachment

locations meet and do

not exceed, the EcoX

design specifications on

allowable spans and

cantilever distances.

When marking the

attachment

locations, make the

downhill leg of the mark

long enough to be

visible from the downhill

edge of the Flashing

when the Flashing is in

its installed position.

This mark will accelerate

the Flashing installation

by quick alignment of

the Flashing to the mark.

1b. Snapping Chalk Lines and Marking Attachment Locations

Corners

of Array

Make these

marks

extra long

downhill.

See

Roof Structural Members Attachment Locations

1. Layout Array on Rooftop (cont.)

Cantilever Span

5 of 31

EcoX Gen2 Installation Guide, Rev 1.11

What follows is

basic information on

wiring an EcoX array.

Warning: All wiring

must be done in

compliance with NEC

and AHJ requirements.

The maximum OCP

rating is 20A when

using an Enphase micro-

inverter for grounding.

It is advisable to

prepare Modules on the

ground before moving

them to the rooftop.

This can be done as

penetrations are

installed.

1. Finalize the junction

box location and

string diagram as

soon as the array

design is marked on

the roof and

confirmed.

2. Once the EcoX bases

are installed use the

Junction Box Bracket

to mount the

junction box.

3. Use the EcoX Power

Accessory Bracket to

mount micro-

inverters or power

optimizers to the

modules.

4. Prepare modules on

the ground for easy

wiring on the roof.

2a. Wire Management: Position Leads, install Clips

2. Prepare the Modules - Before moving them to rooftop

Position and attach

Microinverters

or Optimizers.

Remove their provided

identification stickers

and place them on

the array map.

Use a marker and label

each unit for easy

to identification.

Use wire management

Clips to arrange wiring

and keep away from

roof top, and/or

interfering with

Clamps or Couplings.

Use the EcoX Power Accessory Bracket

to attach Microinverters or Optimizers.

See Appendix E for installation details.

Arrange leads for

easy access.

Use a string map

to determine the

direction that

+ and leads will

face for each row.

–

6 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Image shows an

example wire layout to

illustrate typical wire

management.

3a. Suggested Routing and use of Clips

3. The Basics on Wire Management

Positive

Home Run

Negative

Home Run

7 of 31

EcoX Gen2 Installation Guide, Rev 1.11

4a. Proper positioning of Flashing to Shingles

1a 1a Apply a horseshoe

shaped generous bead

of caulking on the roof

surface or the bottom of

the Flashing with the

opening downhill. Start

and end the bead near

the Flashing’s downhill

edge.

Use roof compliant

sealant.

When correctly

positioned the Flashing

will prevent water

damage to roof from

water seepage and/or

freeze/thaw cycles.

Best practice is to

position the Flashing

mounting hole 2-1/2"

up from the bottom

edge of the shingle

course. This places the

Flashing downhill edge

flush with the edge of

the shingle course its

mounted on.

It is acceptable to shift a

Flashing uphill on its

shingle course and to

trim the uphill shingle to

clear the Base.

Positioned Incorrectly Positioned Correctly Acceptable

(when necessary)

Position

2-1/2"

4. Install Attachments to Roof

4b. Drill 3/16" pilot hole 4c. Apply Caulk to Flashing

At the attachment

locations drill a 3/16"

piolt hole at a sufficient

depth to fully secure the

Lag Screw and Flashing

to roof.

Prior to installing

Flashing, apply caulk

in hole as an added

sealant against moisture.

Seal any holes that

missed a rafter.

Horseshoe

shaped

Caulking

Bottom

Side of

Flashing

Attachment

Location

Drill 3/16"

Pilot Hole

Corner of Array

Flashing is

aligned with

downhill edge

of Shingle

Incorrect: Do not allow

Flashing to extend

below the downhill

edge of Shingle

Incorrect: Do not leave

a gap between Shingles

not completely covered

by Flashing

Gap between Shingles

completely covered

by Flashing

Remove nails

as needed for

clearance

Trim notch in

shingle to

clear Base

Base

Downhill

8 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Be sure to orient the

Base as shown with its

offset mounting hole

directed uphill. On the

Skirt row the Base can

be rotated 180 degrees

which helps hide the

Base behind the Skirt

(see examples below).

Install the Base using

the Lag Screw with its

pre-installed Sealing

Washer. Drive the Lag

Screw into the roof

structure securing the

Base and Flashing to the

roof top. Torque to

14 ft-lbs to ensure seal.

Torque to: 14 ft-lbs

If necessary, clearance

trim the up-course

Shingles to clear the

Base.

Line up the Flashing’s

mounting hole to pre-

drilled pilot hole and

square the Flashing to

the Shingles.

The bottom or

downslope edge of

the Flashing must not

extend beyond the

course of Shingles that

it’s attached to.

4d. Place Flashing

4. Install Attachments onto Roof (cont.)

Slide Flashing

under uphill course

of Shingles

Use Flat Roofing Bar

to lift uphill Shingles

Align with Pilot

Hole/Chalk Line

Lag Screw with

Sealing Washer

If needed,

Notch shingles

to clear Base

Base

4e. Attach Base

Base can be rotated 360 degrees to

allow adjustability of Clamp position.

Rotates around its offset mounting hole.

Skirt row Base Position

It’s recommended to rotate the Base so its

offset mounting hole is downhill.

This helps hide the Base behind the Skirt.

Standard Base Position

Offset mounting hole

is uphill.

Base Positioning - Skirt Row vs other Rows

9 of 31

EcoX Gen2 Installation Guide, Rev 1.11

5. Install the Junction Box Bracket

5a. Attach Bracket to Base with Self Drilling Screws

Base

Bracket

Bracket can be flipped

for height adjustment

Flanges

pointed

upward

Bracket

Universal Mounting Slots

#14 x 1" Self Drilling Screw

(3-places)

Base

Elevation of Bracket

to Base can be

anywhere within

this range

Junction Box

The Junction Box can be secured to

the Bracket with Self Drilling Screws

or by utilizing the Universal

Mounting Slots along with

appropriate attaching hardware.

The Junction Box

Bracket is attached to

the Base with Self

Drilling Screws.

Select one of the

previously installed

Bases in a location

suitable for mounting

the Junction Box and

install the Bracket as

shown.

Torque to: 10 ft-lbs

10 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Height settings are

made by utilizing the

5-position dovetailed

engagements of the

Glider-to-Base. The

image to the left shows

three of these positions.

1" range of travel is

possible in 1/4"

increments. This equates

to 1/8" variation from

Glider to adjacent Glider

to adjustment and

compensate for irregular

or undulating roof tops.

Start by setting the

Glider on the end-of-

row Clamp Assemblies

to their middle position

and then adjust other

Clamps along the row as

needed to level the row.

6. Install the Clamp Assemblies (if installing Skirt-Less version skip to Appendix G)

6a. How to Clamp Assembly Height via the GliderSet the

Highest Position Middle Position

(start here)

Lowest Position

Dovetailed

Engagements

change elevation

in 1/4" increments

Glider

Align Highest

setting Mark

of Glider to

top of Base

Align Middle

setting Mark

of Glider to

top of Base

Align Lowest

setting Mark

of Glider to

top of Base

1" range of adjustment (1/4" increments)

between High & Low positions

Clamp

Assembly

(includes Glider)

Base

6b. Install the Clamp Assemblies

Glider

Align north edge

of Glider with marks

(shown in red)

provided on Base

Lowest

Setting Marks:

Middle

Highest

Glider

Note: For clarity the Upper and Lower

Clamps are shown transparent.

Base

Base

Alignment

Marks

Base

Clamp

Assembly

Align Dovetail

Engagements and

Slide onto Base

Long “Tongue”

of Lower Clamp

points uphill

Two vacant

slots at Top

Two vacant

slots at

Bottom

Start in

Middle

Position

11 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Use an impact driver to

tighten the Strut Bolt

and engage the Strut

Nut channels with the

two flanges of the Base.

Leave the Clamp open

to accept the Module.

The Leaf Spring provides

pressure to keep the

Strut Nut engaged and

in-position while the

installation continues.

Further tightening will

be done as the Modules

are installed.

Do not over tighten

the Clamps on the

Skirt row. They need to

be open enough to

accept the Skirts. All

non-Skirt row Clamps

will be tightened as they

are installed.

6c. Engage Strut Nut with Base

Strut

Bolt

Strut

Nut

Note: For Skirt row Clamp installation only.

Flanges

Leaf

Spring

Channels

6. Install Clamp Assemblies (cont.)

A String Line is used to

level and align Clamp

Assemblies on the first

downhill row only.

The body of the Glider

includes one “String

Groove” specifically

designed to assist with

this process.

Run and secure the

String Line between the

two outermost left/right

Clamp Assemblies. Place

String on the top String

Grooves, pulling it taught

and securing its ends.

7. Level and Align Clamp Assemblies on Southern Row

7a. Run a E-W String Line

String

Groove

Align outermost

left/right Gliders

with Marks on

Bases

Base rotated; its offset

mounting hole is downhill

to accommodate Skirt

Run String on

uphill side of

Clamp Assembly

Position String

on top groove

of the two

outermost left/right

Clamp Assemblies

12 of 31

EcoX Gen2 Installation Guide, Rev 1.11

7. Level and Align Clamp Assemblies (cont.)

7b. Level and Align to String Line

Left

Clamp Assembly

Right

Clamp Assembly

String Line

String

Line

Problem:

Top Groove

not aligned

with String Line

Solution:

Raise Glider one Dovetail Engagement (1/4")

to align Top Groove of Glider with String

Base

String

Groove

(Top

Groove)

Uphill/Downhill Adjustments

Height Adjustments

String

Line

Gap

Problem:

Gap too large

between String

Line and Glider

Solution:

sliding Glider

Toward String

leaving a gap

of 1/16" or less

Reduce gap by

String

Line

13 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Align the left/right

position of the Skirt

with the outer edge of

the array. Torque

Clamps to 14 ft-lbs.

Check to ensure north

side of Clamp is

positioned to accept

Module.

Torque to: 14 ft-lbs

8. Install Skirts on Downhill Row

8a. Skirt to Lower Clamp Positioning

Skirt must

be installed

in upper

position

8b. Install the First Skirt

Module

40 & 50mm Skirt Position

High Position Skirts are held in place

by the Clamps and

joined (end-to-end) by

Couplings.

Three Skirt types are

available fitting the

most common Module

frame thickness (see

table). The Skirt type is

stamped on the inside

face of Skirt.

Skirts must be installed

in the correct dovetail

engagement (Skirt-to-

Clamp) to match the

Module in use. Once

installed, the Skirt sets

the Upper Clamp

position matching it to

the Module thickness.

Metric Inches

(approx)

33mm 1-5/16

35mm

32mm

1-3/8

1-1/2

40mm

50mm

2

1-5/8

55mm

1-11/16

Module Thickness Skirt must

be installed

in lowest

position

Skirt

Module

Lower

Clamp

Upper

Clamp

32, 33, 35 & 45mm Skirt Position

Low Position

Align and mate

the appropriate

engagements

Tighten Strut Bolts enough

to hold Skirt in position -

leave Clamps open to accept

Modules

Align this edge

with outside

edge of Module

32, 33, 35 & 45mm Skirt Position

14 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Left/Right positioning of

the Couplings is flexible.

Couplings can be

adjusted “off-center” of

the Skirt joint as needed

to work around an

Attachment or other

roof obstacle.

If Coupling must be

moved off-center, utilize

its alignment indicators

as guides and offset the

Coupling no less than

the 1" minimum

allowable overlap.

Do not offset the

Coupling less than

the minimum allowable

1" overlap. Doing so will

cut the electrical bond

of the array and reduce

structural integrity.

8. Install Skirts on Downhill Row (cont.)

8c. Install Coupling and adjacent Skirt

8d. Left/Right Positioning of Coupling

Just as with the Clamps,

the Skirts must be

installed in the correct

dovetail engagement to

match the specific

Module thickness.

The Lower Clamp

provides two height

positions. The upper

position is used on 40 &

50mm Modules while

the lower position is

used on 32, 33, 35 &

45mm Modules.

Torque to: 14 ft-lbs

40 & 50mm use upper position (shown)

32, 33, 35 & 45mm use lower position

Coupling centered over Skirt Joint is ideal Position Obstacle: Attachment requires Coupling to be offset

from center. Offset is acceptable but within limits

4. Butt Skirt up

against previously

installed Skirt 3. Slide next-in-line

Skirt into Coupling

Upper

Position

Skirt Lower Position

Coupling

Upper

Clamp

1. Slide Coupling onto

previously installed Skirt

5. Tighten second Bolt.

Torque both Bolts to

14 ft-lbs.

2. Tighten one Bolt enough to hold Coupling in

place. This leaves it open to accept next Skirt.

Attachment

presents

an obstacle

Alignment

Indicators

Skirt Joint Skirt Joint

Offset CouplingCentered Coupling

1" Minimum allowable Overlap

(Skirt joint to edge of Coupling)

Skirt 2Skirt 2 Skirt 1Skirt 1

15 of 31

EcoX Gen2 Installation Guide, Rev 1.11

Table of contents

Popular Solar Panel manuals by other brands

ECO-WORTHY

ECO-WORTHY 12 manual

COMFORTPOOL

COMFORTPOOL CP-80022 Installation & operation manual

Horizont

Horizont 14536 instruction manual

Amerisolar

Amerisolar AS-6P18 installation manual

CNPV

CNPV CNPV-PS-M-S0010-IEC Installation instruction

Owens Corning

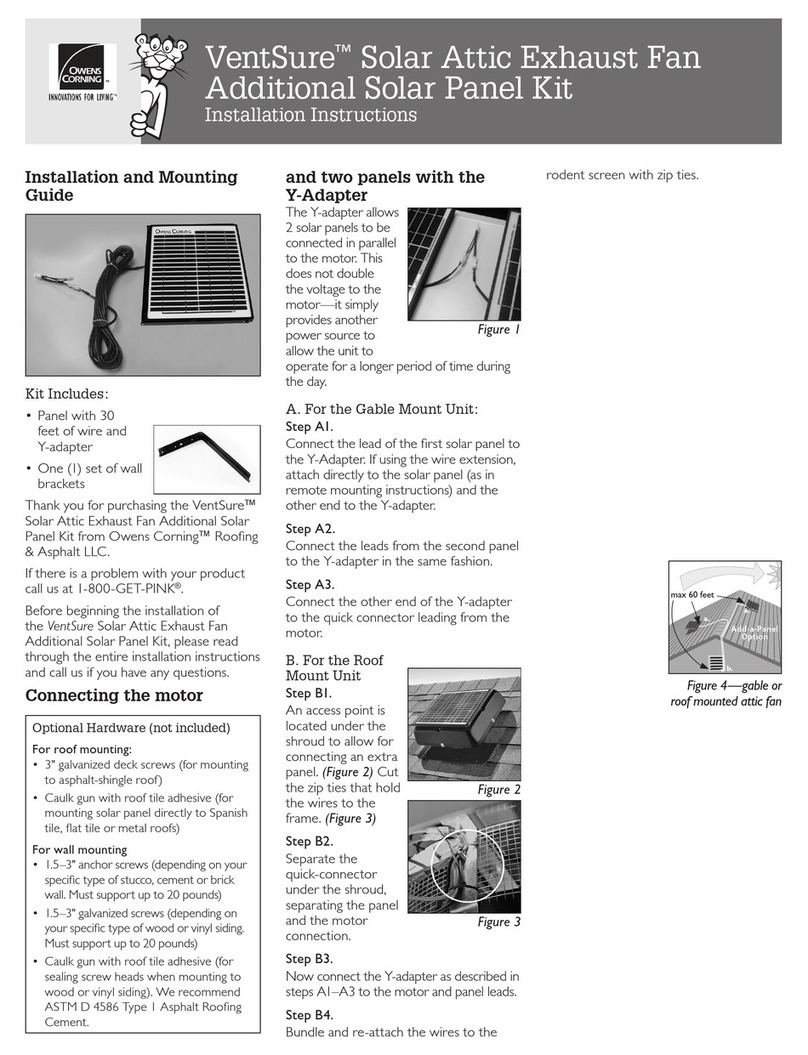

Owens Corning VentSure Solar Attic Exhaust Fan Additional Solar Panel... installation instructions

Improvements

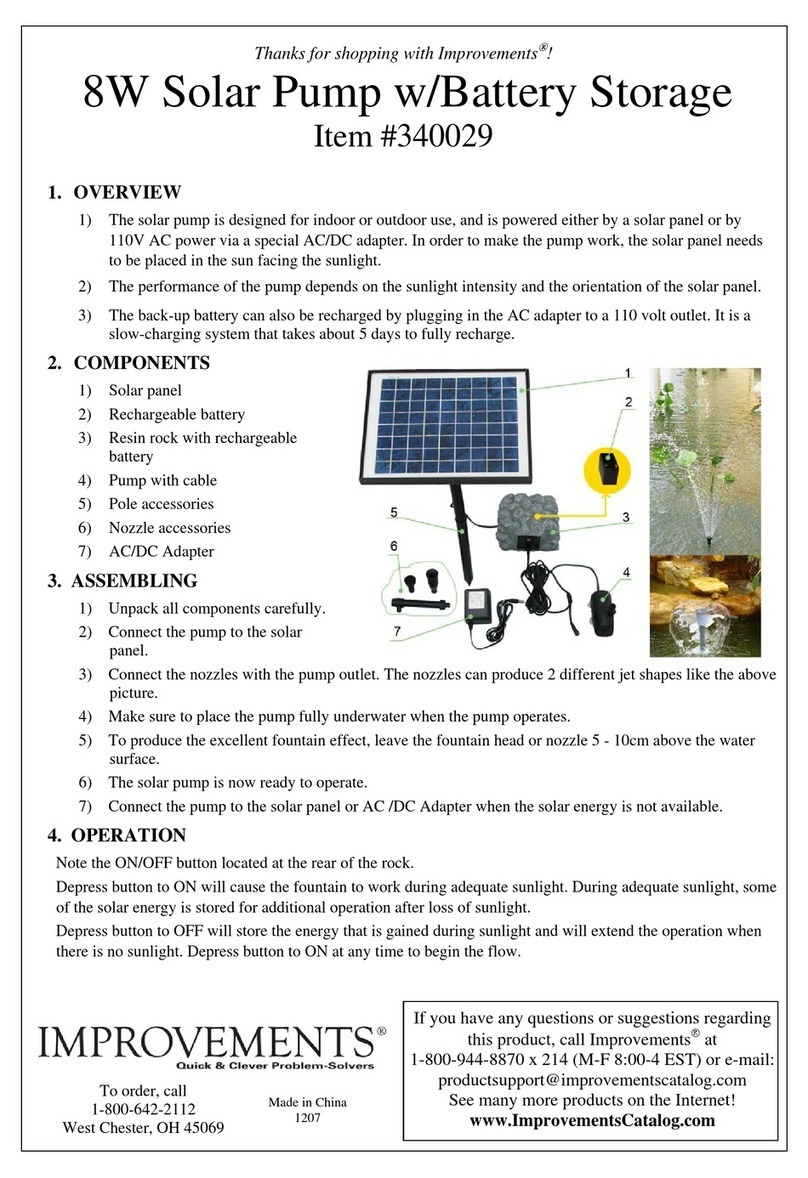

Improvements 340029 quick guide

SUNFLOWER

SUNFLOWER SFB-AL Series installation manual

Photonic Universe

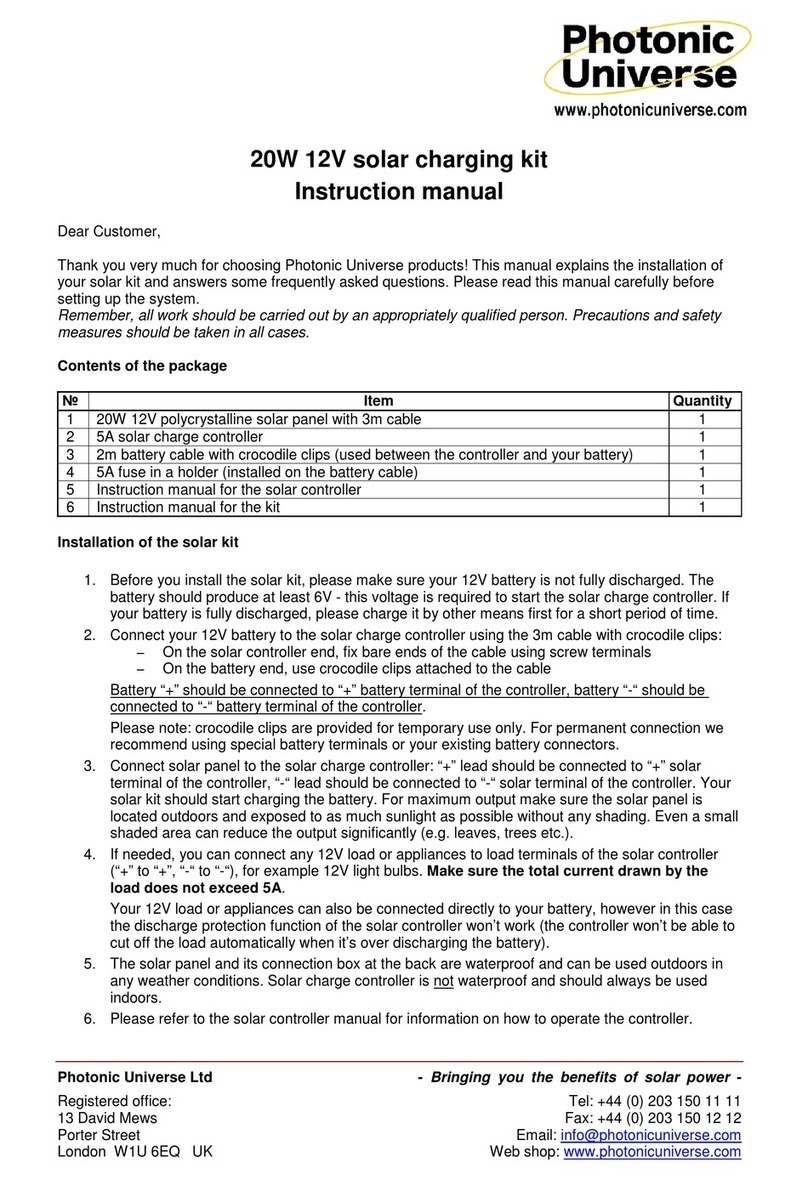

Photonic Universe BST-20P-12VKIT instruction manual

Chromasun

Chromasun High?Temperature Thermal Collector System installation manual

XtremepowerUS

XtremepowerUS 90100 Owner's manual and safety instructions

Sunman

Sunman eArc installation manual