ECS Warmair 135 User manual

Operation Manual

For Model 135 Warming Units

Cincinnati Sub-Zero Products, LLC 12011 Mosteller Road Cincinnati, Ohio 45241, U.S.A.

www.cszmedical.com

WarmAir®, FilteredFloand Warming Tube™are Registered Trademarks of

Cincinnati Sub-Zero Products, LLC

Copyright 2018, Cincinnati Sub-Zero Products, LLC, All rights reserved.

Part No. 57128

57128 Rev. Q

ECN M1801-5437

WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 2 of 17

How to get Technical Help

How to Contact Manufacturer (for Customer Service, Order Placement, or Technical Support):

Cincinnati Sub-Zero Products, LLC Telephone 1-800-989-7373

12011 Mosteller Road (U.S) 24hr Clinical Support 1-513-460-2038

Cincinnati, OH 45241 Med Tech Support 1-888-437-5608

United States of America Fax 1-513-772-9119

Website www.cszmedical.com

Before You Call for Service...

To help us better serve you, please have the serial number of your WarmAir135 unit ready when you call for parts or

service. The serial number is located on the back plate of the WarmAir135 unit.

In-Warranty Repair and Parts

WarmAir135 units are covered by a one-year warranty. To return defective parts or units, obtain a Returned Materials

Authorization (RMA) number from our Medical Technical Service department. A WarmAirModel 135 shipping carton

will be sent to you, if needed. Extended Warranty Available.

Receiving Inspection

After unpacking the WarmAir135 unit, inspect the system for concealed damage. Retain all packing material and

carefully record or photograph any damage. Notify the carrier at once and ask for an inspection (in writing). Failure to do

this within 15 days may result in loss of claim. Do not return the equipment to Cincinnati Sub-Zero. Call our Medical

Technical Service department for further instructions.

Important Safety Information

Refer to this manual for instructions and caregiver information. Read and understand all precautionary

information before using, prescribing, or servicing the WarmAir135 unit. See the Operation and Technical

Manual for details on how to perform maintenance.

WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 3 of 17

Table of Contents

How to get Technical Help.............................................................................................................2

How to Contact Manufacturer (for Customer Service, Order Placement, or Technical Support): .........2

Before You Call for Service................................................................................................................2

In-Warranty Repair and Parts ..........................................................................................................2

Important Safety Information .......................................................................................................2

Table of Contents...........................................................................................................................3

Symbols...........................................................................................................................................4

Section 1: Safety Precautions .......................................................................................................5

General Description of the WarmAir®135........................................................................................5

Indications for Use...........................................................................................................................5

Contraindications ............................................................................................................................5

Warnings.........................................................................................................................................6

Precautions .....................................................................................................................................7

Read Before Servicing Equipment ....................................................................................................7

Section 2: Specifications ...............................................................................................................8

Physical...........................................................................................................................................8

Electrical .........................................................................................................................................8

Temperature Control System ...........................................................................................................8

Safety System ..................................................................................................................................9

Service Life......................................................................................................................................9

Approvals........................................................................................................................................9

For Use with Patient-Applied Parts ................................................................................................12

Shipping and Storage Conditions....................................................................................................12

Section 3: Operating Instructions...............................................................................................13

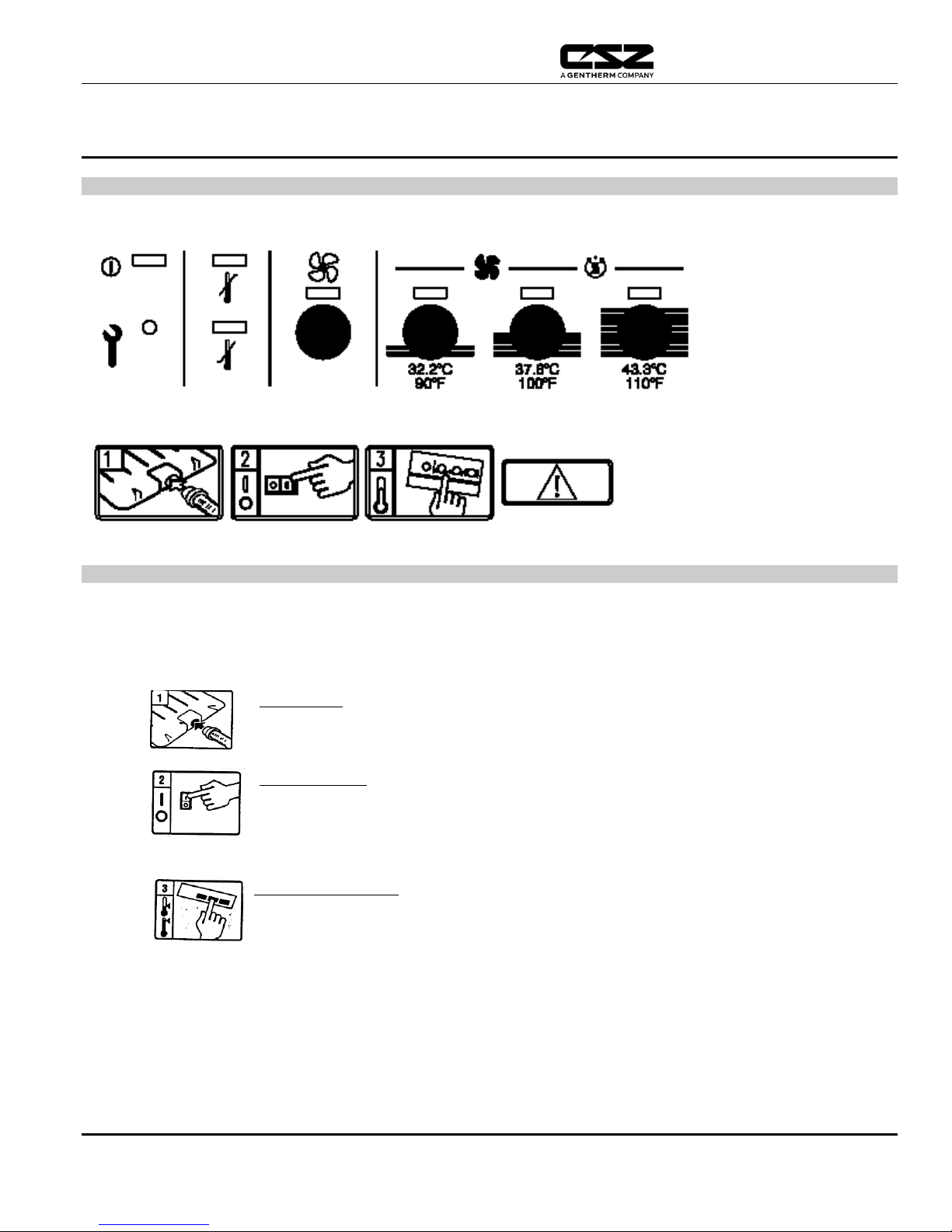

Control Panel and Operation Label.................................................................................................13

Operation Fundamentals................................................................................................................13

Selecting Temperature and Using the Control Panel........................................................................14

Mounting the WarmAirUnit .........................................................................................................16

Section 4: Preventive Maintenance ............................................................................................17

Cleaning the Unit ...........................................................................................................................17

Hour Meter....................................................................................................................................17

Worldwide Order Placement ......................................................................................................17

Illustrations

Control Panel and Operation Label.................................................................................................................................13

WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 4 of 17

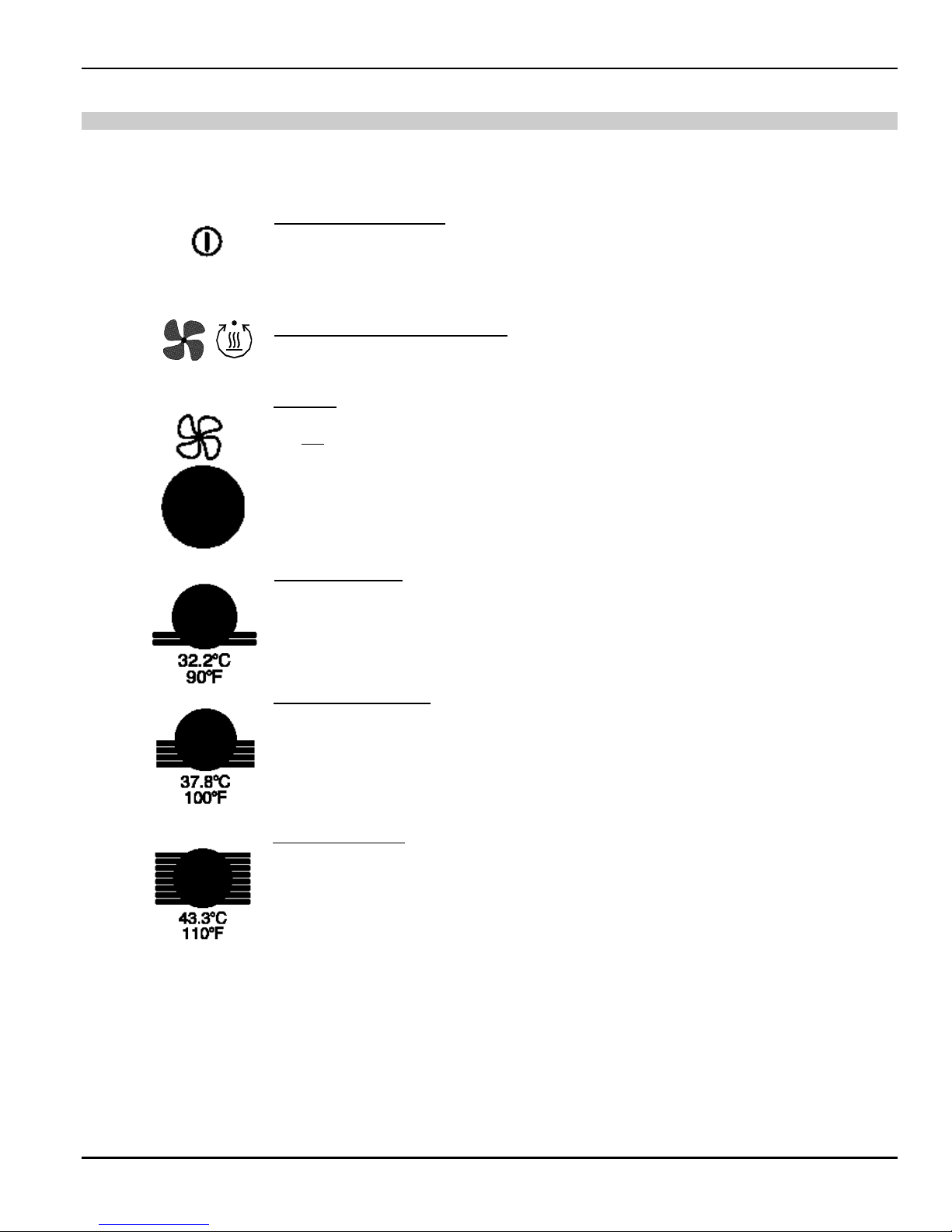

Symbols

Voltage, Alternating Current

Potential Equalization Connection (Grounding)

Protective Earth (Ground)

Type BF Equipment (per IEC-601-1)

(Patient Applied)

Consult instructions for use and/or manual before operating

Over-Temperature Safety Limit

Under-Temperature Safety Limit

Hour Meter

Power On/Off Indicator

Fan Only Selection

Temperature Selection Switches

Low setting: 32.2°C

Medium setting: 37.8°C

High setting: 43.3°C

Separate collection for electrical and Electronic equipment. Dispose of the

WarmAir unit per hospital protocol.

CAUTION! Hose Nozzle MUST be connected to a compatible Forced Air

Blanket or thermal injury may occur.

WARNING: To prevent tipping when mounting the Model 135 unit to an IV

pole, clamp the unit no higher than 44 inches (112 cm) on an IV pole with a

minimum 24 inch (61 cm) diameter base. Failure to heed these restrictions

may result in IV pole instability, catheter site trauma, and patient/user

injury. Note: For instructions on use of the symbols, refer to the “Operating

Instructions” section

Insert Hose

<44”

<112cm

>24”>61cm

Safety Precautions WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 5 of 17

Section 1: Safety Precautions

Cincinnati Sub-Zero Products, LLC, reserves the right to make changes to the device, which may not be reflected in this

manual.

General Description of the WarmAir®135

The WarmAir®135 unit is a small and compact warming unit designed to supply air at temperatures of ambient, 32.2°C,

37.8°C or 43.3°C to a patient-applied air-distribution device. The settings are termed “Fan Only”, “Low”, “Medium” and

“High”, respectively.

Indications for Use

The WarmAir®135 patient warming system is intended to prevent hypothermia and/or reduce cold discomfort before,

during, and after surgical procedures. The thermal regulating system is used to raise a patient’s temperature and/or

maintain a desired patient temperature through convective heat transfer from the controller to a warm-air-heated

blanket. The single-patient use blankets transfer the thermal energy to adult, pediatric or neonate patients to

obtain/maintain normal body temperature. It is intended for use by appropriately trained healthcare professionals in

clinical environments.

Contraindications

High temperature settings to be used with close patient observation when treating patients with the following conditions:

Significant peripheral vascular disease, occlusive or diabetic in nature.

Low cardiac output.

Marginal cutaneous perfusion.

Do not apply heat to lower extremities during arterial cross-clamping. Thermal injury may occur if heat is applied to

ischemic limbs.

Safety Precautions WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 6 of 17

Warnings

A Licensed Healthcare Practitioner's order is required for setting temperature and use of equipment.

At least every 20 minutes, or as directed by a Licensed Healthcare Practitioner, check the patient's

temperature and skin condition of areas in contact with the disposable blanket. Pediatric and

temperature-sensitive patients should be checked more frequently. Notify the Licensed Healthcare

Practitioner promptly of any change in order to avoid serious injury.

Patient temperature depends on ambient temperature and additional sheets or blankets. Reduce or

discontinue therapy when therapeutic goal is reached or if vital signs instability occurs. Thermal

injury may result. Notify Licensed Healthcare Practitioner immediately of vital signs instability.

Do not use the WarmAir135 unit distal to arterial cross clamping. Thermal injury may result.

Do not use the WarmAir135 unit along with High Frequency surgical instruments or endocardial

catheters. Electrical shock, thermal injury or electromagnetic interference may result.

Notify the Licensed Healthcare Practitioner promptly if any of the following occur:

If the patient's temperature is not responding properly,

If the patient's temperature does not reach the prescribed temperature in the prescribed time, or

If there is a change in the prescribed temperature range. Failure to inform the Licensed Healthcare

Practitioner of the deviation may result in injury to the patient.

The warming of transdermal medications (patches) can increase drug delivery, resulting in possible

injury to the patient.

Do not use the WarmAirModel 135 unit with any blanket or warming cover other than CSZ

FilteredFloBlankets or the Warming Tube. Thermal injury may result.

Do not attempt to warm patient without a blanket, i.e. with the hose only. Thermal injury may result.

Unapproved modifications may cause patient/caregiver injury and/or equipment damage.

Do not continue therapy if either the Over-Temperature or Under-Temperature warning light activates

or the audible alarm sounds. Do not continue therapy if power cannot be maintained to the unit.

Thermal injury may result. Turn the unit off and remove from service.

Do not initiate therapy unless the WarmAir135 unit is securely mounted or injury may result.

Always unplug the unit before accessing internal components during service. Failure to unplug the

unit could result in electric shock.

Do not by-pass ground lug. Electrical Hazards may result.

The use of materials of good thermal conductivity, such as water, gel and similar substances, with the

WarmAir135 unit not switched on, can decrease the body temperature of a patient.

Thermal injury may occur if heating therapy is applied to ischemic limbs.

Do not use the WarmAir135 unit in the presence of flammable anesthetics. Risk of explosion may

result.

The WarmAir135 unit disposables (FilteredFloBlankets, Warming Tube) are not sterile and are

intended for single patient use only. DO NOT sterilize or reprocess these disposables. Thermal injury

and/or cross-contamination may result.

Do not allow the hose to contact the patient. Thermal injury may result.

Do not return the WarmAir135 unit to service without the filter present. Thermal injury may

result.

Do not use the WarmAir135 unit without the designated filter in place. Thermal injury or airborne

contamination may result.

Electrical shock hazard. To avoid risk of electrical shock, disconnect power before servicing.

To avoid the risk of electric shock, this equipment must only be connected to a supply mains with

protective earth.

Safety Precautions WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 7 of 17

Read Before Servicing Equipment

The repair, calibration and servicing of the WarmAir135 unit must be performed by qualified Medical Equipment Service

Technicians, Certified Biomedical Electronics Technicians, or Certified Clinical Engineers familiar with good repair

practices for servicing medical devices in accordance with the instructions contained in the Operation and Technical

manual. Improper repair can result in patient or user injury and damage to the WarmAir135 unit. Do not hipot unit.

Improper repair may also void the warranty. Reference the Operation & Technical manual for Troubleshooting

instructions.

Precautions

CAUTION: Federal law (U.S.A.) restricts this device to sale by or on the order of a Licensed Healthcare

Practitioner.

Read all instructions provided with CSZ FilteredFloBlankets or the Warming Tubeprior to use.

The surface of the WarmAir135 unit and CSZ FilteredFloBlanket or Warming Tubeshould be

checked for freedom from mechanical damage prior to each application.

The WarmAir135 unit is not intended for use in ambient temperatures above 30°C. Maximum contact

surface temperature, during normal operation, is 48°C.

Do not hipot or dielectric test the WarmAir135 unit. Only apply the rated voltage to the unit.

Subjecting the unit to voltages other than the rated voltage may cause damage to the unit. These tests

are done only by CSZ.

Power interruption will cause the WarmAir135 unit to shut down, resulting in no therapy to the

patient. Follow instructions listed under the “Operation Fundamentals” section of this manual to

resume therapy.

All temperature settings represent temperatures at the end of the hose outlet, not blanket surface

temperature.

Medical electrical equipment needs special precautions regarding EMC and needs to be installed and

put into service according to the EMC table information provided in this manual.

Portable and mobile RF communications equipment can affect medical electrical equipment

Other cables and accessories may affect EMC performance

Avoid stacking or locating close to other equipment according to the EMC tables.

If a means is needed in retaining a patient either on or under a CSZ FilteredFloBlanket or the Warming

Tube, the means should not block the fluid pathways of the WarmAir135 unit.

Specifications WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 8 of 17

Section 2: Specifications

Physical

Dimensions: 22.2 cm x 22.2 cm x 34.3 cm

Hose Outlet: 1.8m flexible hose

Weight: 6.1 kg

Filtration: 0.2 microns, High Efficiency

Construction: Impact-resistant plastic case with aluminum sub-structure. None of the WarmAirSystem components

are made with natural rubber latex.

Electrical

WarmAir135 unit is available in 100V, 110-120V or 220-240V:

100V, 50/60 Hz and 110-120V, 50/60Hz units:

1200 VA

15 Amp Circuit Breaker

15' (4.6m) Power Cord (14/3 SJT with Hospital-Grade plug)

220-240V, 50/60Hz units:

1200 VA

7 Amp Circuit Breaker

15’ (4.6m) Harmonized Power Cord (H05VV-F 3x1.5mm² cord

with CEE 7/7 plug)

220-240V, 50/60Hz units:

1200VA

13 Amp Circuit Breaker

15’ (4.6m) British Standard Power Cord (HO5VVF3G1.5mm

Molded-on BS1363 fused male plug)

For all units:

Under 300 A earth leakage current

Ground resistance 0.2or less

Mains Supply Isolation: Two-Pole Mains Switch

Temperature Control System

Control System: Microprocessor and thermistor-based.

Temperature Settings as

measured at the hose outlet of

the device:

No Heat (ambient temperature)

32.2°C +4.0°C/ -2.0°C

37.8°C +4.0°C/ -2.0°C

43.3°C +4.0°C/ -2.0°C

Operating Environment:

Temperature: 15°C to 30°C (59°F to 86°F)

Relative Humidity: 20% - 60%

Maximum Contact Surface Temperature (during normal operation): 48°C

Time to reach 37°C from 23±2°C: Approximately 3 minutes

Specifications WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 9 of 17

Safety System

Maximum Temperature Setting:

43.3°C +4.0°C

Independent Primary

Over-Temperature Limit:

52.0°C ± 3.0°C as measured at the hose outlet

of the device (i.e. where the hose connects to

the blanket).

Audible and visible alarms.

Heater and blower shutdown.

Note: Based on testing, the maximum

contact surface temperature of the

blanket, when the primary over-

temperature limit activates is 45°C ±

3.0°C.

Independent Secondary Over-Temperature

Limit:

64°C or less as measured at the hose outlet of

the device (i.e. where the hose connects to the

blanket).

Power shutdown.

Note: Based on testing, the maximum

contact surface temperature of the

blanket, when the secondary over-

temperature limit activates is 45°C ±

3.0°C.

Independent Under-Temperature Limit:

29.4°C or less as measured at the hose outlet

of the device (i.e. where the hose connects to

the blanket).

Audible and visible alarms.

Heater and blower shutdown.

(Heat settings only).

Open/Shorted Sensor Safety:

Audible and visible alarms.

Service Life

The expected service life / lifetime of the WarmAir135 unit is seven (7) years from the date of manufacture provided

the product is not subject to misuse, negligence, accident or abuse and under the conditions that the device is properly

used as intended, and serviced and maintained according to the Operation / Technical Manual provided with the device.

Approvals

Electrical

MODEL 135, MEDICAL ELECTRICAL

EQUIPMENT IN ACCORDANCE WITH UL60601-

1, IEC60601-1 AND ASTM F2196-02.

ALSO CLASSIFIED WITH RESPECT TO

ELECTRICAL SHOCK, FIRE AND MECHANICAL

HAZARDS ONLY IN ACCORDANCE WITH CSA

22.2 NO. 601.1

16HV

Specifications WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 10 of 17

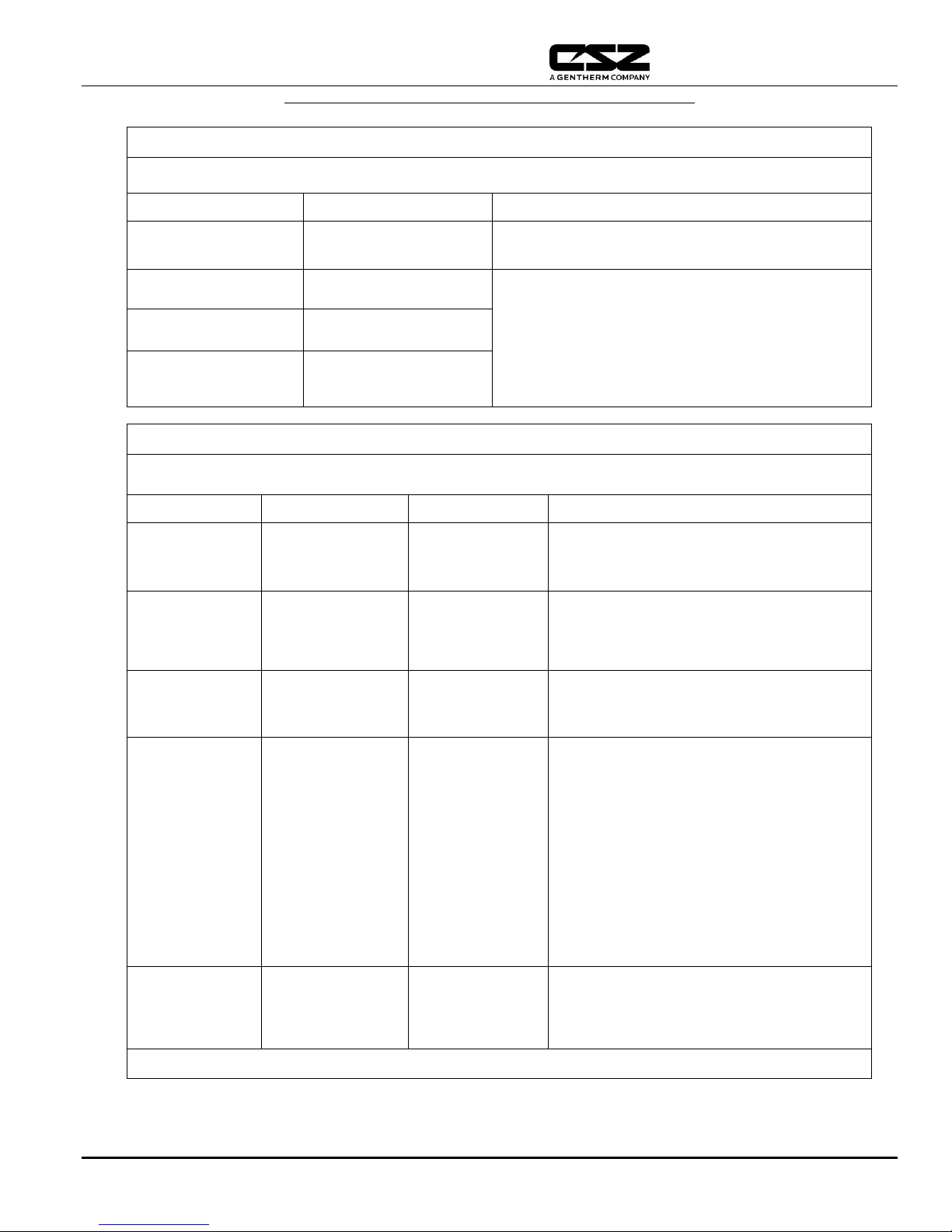

EMC COMPATIBILITY TABLES ACCORDING TO IEC 60601-1-2

Guidance and manufacturer’s declaration – electromagnetic emissions

The WarmAir, Model 135 is intended for use in the electromagnetic environment specified below. The customer or the user of this unit

should assure that it is used in such an environment.

Emissions tests

Compliance

Electromagnetic environment –guidance

RF emissions

CISPR 11

Group 1

The WarmAir, Model 135 uses RF energy only for its internal function.

Therefore, its RF emissions are very low and are not likely to cause

any interference in nearby electronic equipment.

RF emissions

CISPR 11

Class A

The WarmAir, Model 135 is suitable for use in all establishments

other than domestic and those directly connected to the public low-

voltage power supply network that supplies buildings used for

domestic purposes.

Fluctuations and Flicker emissions testing is not required or 120 or

100 Volt units

Harmonic emissions

IEC 61000-3-2

Class A

Voltage fluctuations/

flicker emissions

IEC 61000-3-3

Complies

Guidance and Manufacturer’s Declaration – electromagnetic immunity

The WarmAir, Model 135 is intended for use in the electromagnetic environment specified below. The customer or the user of the WarmAir,

Model 135 should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic environment - guidance

Electrostatic

discharge (ESD)

IEC 61000-4-2

±6 kV contact

±8 kV air

±6 kV contact

±8 kV air

Floors should be wood, concrete or ceramic tile. If floors

are covered with synthetic material, the relative humidity

should be at least 30%.

Electrical fast

transient/burst

IEC 61000-4-4

±2 kV for power supply

lines

±1 kV for input/output

lines

±2 kV for power supply

lines

±1 kV for input/output

lines

Mains power quality should be that of a typical commercial

or hospital environment.

Surge

IEC 61000-4-5

±1 kV differential mode

±2 kV common mode

±1 kV differential mode

±2 kV common mode

Mains power quality should be that of a typical commercial

or hospital environment.

Voltage dips, short

interruptions and

voltage variations on

power supply input

lines

IEC 61000-4-11

<5% UT

(>95% dip in UT)

for 0,5 cycle

40% UT

(60% dip in UT)

for 5 cycles

70% UT

(30% dip in UT)

for 25 cycles

<5% UT

(>95% dip in UT)

for 5 s

<5% UT

(>95% dip in UT)

for 0.5 cycle

40% UT

(60% dip in UT)

for 5 cycles

70% UT

(30% dip in UT)

for 25 cycles

<5% UT

(>95% dip in UT)

for 5 s

Mains power quality should be that of a typical commercial

or hospital environment. If the user of the WarmAir, Model

135 requires continued operation during power mains

interruptions, it is recommended that the WarmAir, Model

135 be powered from an uninterruptible power supply or

a battery.

Power frequency

(50/60 Hz) magnetic

field

IEC 61000-4-8

3 A/m

3 A/m

Power frequency magnetic fields should be at levels

characteristic of a typical location in a typical commercial

or hospital environment.

Note: UT is the a. c. mains voltage priorto application of the test level.

Specifications WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 11 of 17

Guidance and manufacturer’s declaration – electromagnetic immunity

The WarmAir, Model 135 is intended for use in the electromagnetic environment specified below. The customer or the user of the WarmAir,

Model 135 should assure that it is used in such an environment.

Immunity test

IEC 60601 test level

Compliance level

Electromagnetic environment - guidance

Conducted RF

IEC 61000-4-6

Radiated RF

IEC 61000-4-3

3 Vrms

150 kHz to 80 MHz

3 V/m

80 MHz to 2,5 GHz

3 Vrms

3 V/m

Portable and mobile RF communications equipment

should be used no closer to any part of the WarmAir,

Model 135, including cables, than the recommended

separation distance calculated from the equation

applicable to the frequency of the transmitter.

Recommended separation distance

d = 1,2√P

d = 1,2√P 80 MHz to 800 MHz

d = 2,3√P 800 MHz to 2,5 GHz

where Pis the maximum output power rating of the

transmitter in watts (W) according to the transmitter

manufacturer and dis the recommended separation

distance in meters (m).

Field strengths from fixed RF transmitters, as determined

by an electromagnetic site survey, ashould be less than the

compliance level in each frequency range. b

Interference may occur in the vicinity of equipment

marked with the following symbol:

NOTE 1: At 80 MHz and 800 MHz, the higher frequency range applies.

NOTE 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection from

structures, objects and people.

aField strengths from fixed transmitters, such as base stations for radio (cellular/cordless) telephones and land mobile radios, amateur

radio, AM and FM radio broadcast and TV broadcast cannot be predicated theoretically with accuracy. To assess the electromagnetic

environment due to fixed RF transmitters, an electromagnetic site survey should be considered. If the measure field strength in the

location in which the WarmAir, Model 135 is used exceeds the applicable RF compliance level above, the WarmAir, Model 135 should

be observed to verify normal operation. If abnormal performance is observed, additional measures may be necessary, such as re-

orienting or relocating the WarmAir, Model 135.

bOver the frequency range 150 kHz to 80 MHz, field strengths should be less than 3 V/m.

Specifications WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 12 of 17

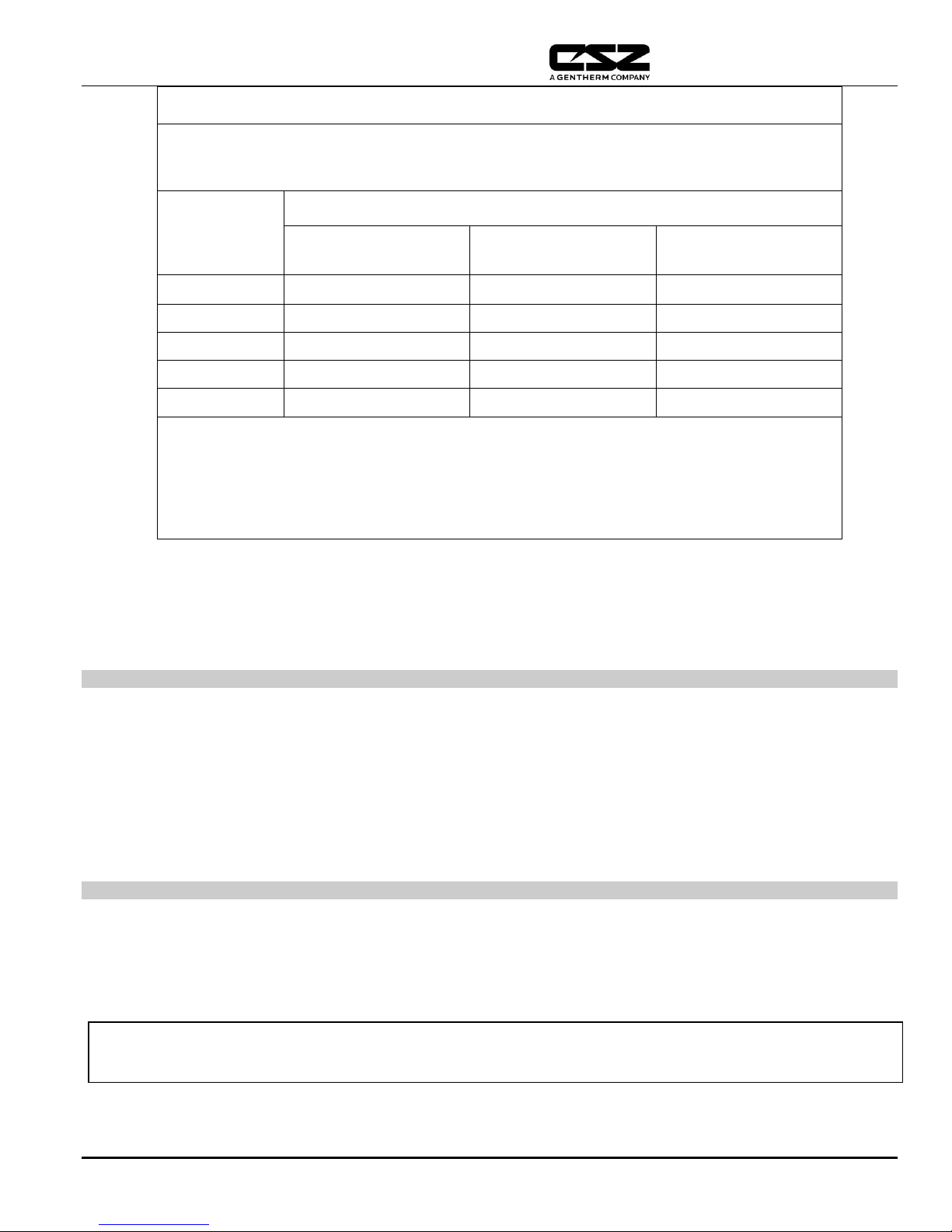

Recommended separation distances between portable and mobile RF communications

equipment and the WarmAir, Model 135

The WarmAir, Model 135 is intended for use in an electromagnetic environment in which radiated RF disturbances are

controlled. The customer or the user of the WarmAir, Model 135 can help prevent electromagnetic interference by maintaining a

minimum distance between portable and mobile RF communications equipment (transmitters) and the WarmAir, Model 135 as

recommended below, according to the maximum output power of the communications equipment.

Rated maximum

output power of

transmitter

W

Separation distance according to frequency of transmitter

m

150 kHz to 80 MHz

d = 1,2√P

80 MHz to 800 MHz

d = 1,2√P

800 MHz to 2,5 GHz

d = 2,3√P

0,01

0,12

0,12

0,23

0,1

0,38

0,38

0,73

1

1,2

1,2

2,3

10

3,8

3,8

7,3

100

12

12

23

For transmitters rated at a maximum output power not listed above, the recommended separation distance din meters (m) can

be estimated using the equation applicable to the frequency of the transmitter, where Pis the maximum output power rating of

the transmitter in watts (W) according to the transmitter manufacturer.

Note 1: At 80 MHz and 800 MHz, the separation distance for the higher frequency range applies.

Note 2: These guidelines may not apply in all situations. Electromagnetic propagation is affected by absorption and reflection

from structures, objects and people.

Supplemental certification or EMC information available on request.

For Use with Patient-Applied Parts

FilteredFloBlankets and Warming Tube

All CSZ disposables are:

1. Made from non-woven polypropylene or polyethylene.

2. Manufactured to meet the flammability standards of the Flammable Fabrics Acts and NFPA 99 for Health Care

Facilities.

3. Transparent to X-ray and imaging systems.

4. For single-patient use only.

5. Not sterile unless otherwise indicated on product.

Note: Do not sterilize or reprocess CSZ disposables.

Shipping and Storage Conditions

The WarmAir135 unit can be transported through normal shipping methods via ground, air, or water when packaged in its

original packaging material. During transportation and storage, packaging should not be exposed to conditions that

fall out of the ranges below:

1.1.1 Temperature: -40C to 50C (–40F to 122F)

1.1.2 Humidity: 5% to 95%

WarmAir accessories and additional technical information is available in the Operation &

Technical Manual

Operating Instructions WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 13 of 17

Section 3: Operating Instructions

Control Panel and Operation Label

The control panel and operation label for the WarmAir135 unit are located on the top of the unit.

Operation Fundamentals

The lower portion of the control panel gives a brief description of operating the WarmAirSystem. Read all instructions

and safety precautions included with the FilteredFloBlanket or Warming Tube.

For all WarmAirSystems

Insert hose. Insert the free end of the flexible hose into the air inlet port of the

FilteredFloBlanket or Warming Tube. Make sure the hose is pushed in

beyond the raised areas on the fitting.

Power Unit On. Using the rocker switch on the side of the unit, depress the “I”

side to activate power to the unit. Depressing the “O” side deactivates power.

Note: The blower and heater will not activate until a temperature setting has

been selected.

Select Temperature. Activate the desired temperature setting using the four

touch-sensitive buttons, applying the following instructions.

Cincinnati Sub-Zero Products, LLC Page 14 of 17

Selecting Temperature and Using the Control Panel

The control panel is located on top of the unit and is composed of four pressure sensitive touch switches, each having a

LED display. The external features on the control panel of the WarmAirunit are described as follows:

Power On/Off Indicator.This LED light will indicate that the unit is on. A

temperature selection can now be made. Power is toggled at the rocker switch on

the side of the unit.

Temperature Selection Switches.Four temperature selection switches on the

control panel allow the caregiver to select a temperature setting for the patient.

Fan Only Depressing this switch will activate the unit to draw in ambient room

temperature air and deliver it to the patient via the disposable blanket. The heater

will not be activated. The temperature delivered to the patient will depend on the

current room temperature during operation of the unit. (Air temperature delivered

may be up to three degrees higher than the ambient temperature due to heat from

the blower motor.) The LED will be activated to indicate that the unit is in the

ambient temperature mode.

Low Temperature. Depressing this switch will activate the unit to draw in room

air, heat the air to 32.2°C +4.0°C/ -2.0°C and deliver it to the patient via the

disposable blanket. The LED will be activated to indicate that the unit is in the low

temperature mode.

Medium Temperature. Depressing this switch will activate the unit to draw in

room air, heat the air to 37.8°C +4.0°C/ -2.0°C and deliver it to the patient via the

disposable blanket. The LED will be activated to indicate that the unit is in the

medium temperature mode.

High Temperature. Depressing this switch will activate the unit to draw in room

air, heat the air to 43.3°C +4.0°C/-2.0°C and deliver it to the patient via the

disposable blanket. The LED will be activated to indicate that the unit is in the high

temperature mode. The high temperature setting is to be used with close

patient observation.

Cincinnati Sub-Zero Products, LLC Page 15 of 17

CAUTION!

High temperature setting to be used with close patient observation when treating patients

with the following conditions:

a. Significant peripheral vascular disease, occlusive or diabetic in nature.

b. Low cardiac output.

c. Do not apply to ischemic limbs, e.g., during arterial cross-clamping.

CAUTION!

Do not attempt to warm patient with hose only. Operating the WarmAir135 unit without a

blanket may result in patient injury.

CAUTION!

High temperature setting to be used with close patient observation. Reduce air temperature

or discontinue therapy when the therapeutic goal is reached or if vital signs instability

occurs.

Over-Temperature Safety Limit. This LED indicator light will indicate an over-

temperature condition (an audible alarm will also sound). Immediately

discontinue use and remove from service if activated.

Under Temperature Safety Limit. This LED indicator light will indicate an under-

temperature condition (an audible alarm will also sound). Immeidately

discontinue use and remove from service if activated.

Hour Meter. This LED indicator will alert the caregiver that 500 hours of

service has transpired and the unit is due for its regular preventative

maintenance, including changing the filter.

!

!

!

!

Cincinnati Sub-Zero Products, LLC Page 16 of 17

Mounting the WarmAirUnit

The WarmAir135 unit must be mounted securely before it is used. There are three ways to mount the unit:

1. IV Pole Clamp The unit may hook onto a secure, vertical IV pole of no less than 2.2 cm and no more than

2.86 cm in diameter.

2. Mounting The unit may hook onto a secure bed rail or footboard up to 3.8 cm

Bracket thick.

3. Anti-slip Feet The unit may be placed on a table or stand near the patient. Do not place the unit in bed with

the patient.

WARNING!

To prevent tipping when mounting the Model 135 unit to an IV

pole, do not clamp the unit higher than 112 cm on an IV pole with a

minimum 61 cm diameter base. When hooking the unit on a rail,

make sure the unit cannot tip to a point where it may fall off the

rail.

When placing the unit on a table or stand near a patient, make sure

the unit is not located in an area where it can be knocked off by

caregivers or passing traffic.

Failure to heed these restrictions may result in IV pole instability,

catheter site trauma, and patient or user injury.

!

Preventive Maintenance WarmAirModel 135 Manual

Cincinnati Sub-Zero Products, LLC Page 17 of 17

Section 4: Preventive Maintenance

Cleaning the Unit

For cleaning and disinfecting always use conventional hospital-approved, topical equipment cleaners, and disinfectants.

Thoroughly wipe down device with a damp cloth to remove any residue from cleaning solutions. Ensure that all

inaccessible cracks and crevices on the WarmAir are reached during cleaning.

Hour Meter

The WarmAir135 unit is equipped with a built-in timer that will activate the "Hour Meter" light after 500 hours of use.

This is an indication that routine maintenance is required. See Operation & Technical Manual for instructions. Instructions

on replacing the WarmAir135 air filter are also located in the Operation & Technical Manual.

WarmAir135 unit has approval in accordance with IEC 80601-2-35. These standards are based on contact surface

temperature of the blanket being 48°C or less. Temperatures referenced at the hose outlet do not represent

contact surface temperatures of the blanket due to temperature loss through the hose and dispersion through the

blanket.

Worldwide Order Placement

United States and Canada Telephone 1-800-989-7373

(U.S.) 24hr Clinical Support 1-513-460-3028

Healthlink Europe Fax 1-513-772-9119

De Tweeling 20-22 Med Tech Support 1-888-437-5608

5215 MC’s Hertogenbosch

The Netherlands

CAUTION!

Disconnect from power when cleaning the Warming Unit. Allow

to air dry thoroughly. Do not use dripping wet cloth or otherwise

allow water to seep into electrical areas of the WarmAir135

unit.

!

Cincinnati Sub-Zero Products, LLC

12011 Mosteller Road

Cincinnati, OH 45241

Telephone: 1-800-989-7373 Fax: (513)772-9119

Table of contents

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual