eDAQ PowerChrom 280 User manual

ii PowerChrom

This document was, as far as possible, accurate at

the time of printing. Changes may have been made

to the software and hardware it describes since

then, though: eDAQ Pty Ltd reserves the right to alter

specifications as required. Late-breaking information

may be supplied separately. Latest information and

information and software updates can be obtained

from our web site.

Trademarks of

eDAQ

e-corder

and PowerChrom are registered trademarks

of eDAQ Pty Ltd. Specific model names of data

recording units, such as

e-corder

201, and

PowerChrom 280, are trademarks of eDAQ Pty Ltd.

Other Trademarks

Mac OS, and Macintosh, are registered trademarks

of Apple Computer, Inc. Windows 98, Windows

Me, Windows 2000, and Windows XP are

trademarks of Microsoft Corporation.

PostScript, and Acrobat are registered trademarks of

Adobe Systems, Incorporated.

All other trademarks are the properties of their

respective owners.

Document Number: U-ER280-1003

Copyright © October 2003

eDAQ Pty Ltd

6 Doig Avenue

Denistone East, NSW 2112

AUSTRALIA

http://www.eDAQ.com

email: [email protected]

All rights reserved. No part of this document may be

reproduced by any means without the prior written

permission of eDAQ Pty Ltd.

PowerChrom iii

Contents

1 Overview

1

How to Use this Manual 2

Checking the System 2

Computer Requirements 2

Other Hardware 3

The Software 3

The Hardware 3

The Front Panel 4

The Back Panel 5

2 Setting Up

9

Self-Test 10

Connecting to the Computer 10

External Equipment 11

How Does it Work? 13

Detector Inputs 15

Analog Output 15

Injection Signal Input 16

Digital Outputs 16

Recording Unit Accuracy 17

Sampling Operation 18

A Glossary

19

B Troubleshooting

23

USB Issues 23

Problems 24

C Specifications

27

Index

31

License & Warranty

33

iv PowerChrom

PowerChrom 1

CHAPTER ONE

1

Overview

The PowerChrom system comprises a PowerChrom 280 hardware unit

and PowerChrom software, and is designed to record, display, and

analyze experimental chromatographic data.

Your PowerChrom hardware unit has considerable computing power of

its own and performs many tasks that are necessary during data

acquisition. Data is transferred via a USB interface to a Windows or

Macintosh computer.

This chapter provides an overview of the PowerChrom system.

2 PowerChrom

How to Use this Manual

This manual describes how to connect and begin using your

PowerChrom recording unit.

Specifications are included in the appendixes, but only an authorized

eDAQ representative should attempt repairs. User modification of the

recording unit voids your warranty.

The

PowerChrom Software Manual

provides detailed information for

acquiring, storing, and analyzing data.

Checking the System

Before using the PowerChrom hardware check that:

• all items in the accompanying packing list are present; and that

• there are no obvious signs of damage that might have occurred

during transit.

If anything is missing, or seems to be damaged, contact your eDAQ

representative immediately.

Computer Requirements

Windows

• Pentium processor or better

• 32 MB available RAM

• 20 MB free hard disk space

• USB 2.0, or 1.1

• Windows 98, Me, 2000, XP or later (Windows 95 and NT do

not support USB)

• 800 x 600, 256 color display or better.

Chapter 1 — Overview 3

Macintosh

• PowerPC, G3, G4 or later processor

• 32 MB available RAM

• 20 MB free hard disk space

• USB 2.0 or 1.1

• Mac OS 8.6 or later.

Other Hardware

You should have at least a basic chromatography system: a column,

pump, injector, and detector. The PowerChrom system is designed to

replace integrators or chart recorders. It can support one or two

detectors for a single column, for example a UV-visible and refractive

index detector. Autoinjectors, autosamplers, and fraction collectors (if

available) can be triggered by contact closure or TTL signals from the

PowerChrom unit.

The Software

PowerChrom software is provided with each PowerChrom unit. The

PowerChrom software provides facilities for real-time recording,

integration, and reporting of chromatograms. See the

PowerChrom

Software Manua

l for further details and installation instructions.

You must install the software on your computer to use the PowerChrom

unit.

The Hardware

Please familiarize yourself with the external features of your recording

unit before connecting it to a power source. The rest of this chapter

discusses the different features, connectors, and indicators of the

PowerChrom unit.

4 PowerChrom

The Front Panel

The front panel of your PowerChrom 280 unit, Figure 1–1, has three

indicators that show the various states of the system.

The Power indicator is a blue light which shows when the recording unit

is on. If this indicator does not light when the unit is switched on, check

that power is turned on at the wall socket and the mains cord is

plugged in correctly. Also check that the power socket is working by

connecting another appliance.

PowerChrom

PowerChrom

Power

Status

Start

280

Power, Status, and

Start (inject) indicators

Status

Indicator Meaning

Off Idle and not yet initialised by the PowerChrom soft-

ware.

Green,

constant

Idle, initialized, and waiting for a command from

the PowerChrom software.

Yellow,

constant

Communicating with the computer.

Yellow,

flashing

Signal sampling is occurring. May show green

between yellow flashes.

Red,

flashing

An internal fault has been detected during the

power-up test. The unit must be turned off, then on

again to re-set it. If the red flashes recur then con-

tact your eDAQ distributor.

Figure 1–1

The front panel

Table 1–1

Status indicator states.

Chapter 1 — Overview 5

The Status indicator flashes different patterns and colors depending on

the state of the recording unit, Table 1–1.

The Start (Inject) Signal indicator will glow yellow when the inject signal

is received.

The Back Panel

The back panel of the PowerChrom unit, Figure 1–2, provides the

sockets to connect the recording unit to the computer and to the power

outlet. It also provides a single connector which can deal with all the

signals necessary to connect to external equipment for recording.

The USB Port

The PowerChrom unit connects to your computer using a USB (Universal

Serial Bus) port. PowerChrom works with USB 2.0 or 1.1 compliant

computers. USB requires Windows 98, Me, 2000, XP or later, or a

Macintosh running Mac OS 8.6 or later.

You can safely turn on and off, or disconnect or reconnect, a USB

connected device while the computer remains on. However you should

not disconnect the PowerChrom unit while the PowerChrom software is

running.

RS 485

Made in Australia by eDAQ Pty Ltd.

No user serviceable parts inside.

Refer servicing to qualified service personnel.

14

2015 10

15

COM COM COM

TRIG CH1 CH2 DAC CTL1 CTL2 CTL3 CTL4

Rated Voltage: 90 - 250 V AC

50/60 Hz 25 VA

Power

switch

Serial Port Power requirements

Power

socket

Instrument Connection Port USB Port

Remove links for contact closure

Install links for TTL

Figure 1–2

The back panel

6 PowerChrom

Serial Port

The serial port is for factory diagnostic use only. It should NOT be

connected to your computer.

Power Connections

The power switch is used to turn the unit on and off. The 3-pin IEC

power socket is used to connect your recording unit to a 3-pin earthed

(grounded) power cable. Do not use 2-pin (unearthed) power sockets or

adaptors. The PowerChrom unit is a universal input switching power

supply can be used with AC supplies of 90 – 250 V at frequencies of

50 or 60 Hz.

The Instrument Connection Port

All the connections that the PowerChrom recording unit uses for signal

measurement and control are made through the single 20 pin

Instrument Connection port, Figure 1–3, on the back panel, which

provides:

• inputs for two analog signal inputs, differential or single–ended

(CH1 and CH2);

• one analog output (DAC);

• an input for a digital inject signal input (TRIG); and

• four digital control outputs (CTL1, CTL2, CTL3, and CTL4) to

control external equipment (either contact closures or TTL levels,

configured by links).

A plug-in terminal block adaptor, Figure 2–2, page 12, is provided for

easy connection of bare wires. Refer to Chapter 2 for details of

connecting equipment.

Detector Inputs

The PowerChrom unit has two independent detector input channels that

are used to record external analog signals from attached detectors.

Each input can be set up as differential (with the difference between the

positive and negative inputs recorded), or single-ended (with the

negative input referenced to ground).

▲

WARNING!

Failure to ensure

adequate earthing of the

PowerChrom unit results

in unsafe operation. Two

pin (unearthed) power

outlets, or adaptors, must

NOT be used.

Chapter 1 — Overview 7

The detector inputs used to record signals from ±10 V to the microvolt

range without the need for additional external amplification. Each

analog input has an independently programmable gain amplifier. Note

that applying more than ±15 V to the detector inputs could possibly

damage the circuitry. The detector inputs are marked ‘CH1’ and ‘CH2’

and their ground connections are marked ‘COM’ (common).

Injection Signal (Trigger) Input

A contact closure from the injector is often used to mark sample

injection time. The contact closure must be longer than 10 ms to be

registered. The Inject Signal, or Trigger, indicator (the lowest one on the

front panel), will glow yellow when contact closure occurs. The

PowerChrom Software Manual

covers its practical use in normal

recording. The inject signal connections are marked ‘Trig’ (for Trigger).

Analog Output

The PowerChrom unit can generate a controlled voltage (0 – 10 V,

controlled from the PowerChrom software) through the analog output

pins, marked ‘DAC’ (for digital-to-analog convertor).

1234

TTL

COM COM COM

TRIG CH1 CH2 DAC CTL1 CTL2 CTL3 CTL4

TTL TTL TTL

Digital output 4

Digital output 1

Digital output 2

Digital output 3

+

Analog output

Inject signal input –

+

–

+

–

+

–

+

–

+

–

GND

+

–

GND

+

GND

Detector 1 input

Detector 2 input

Digital output 1, TTL/Contact Select

Digital output 2, TTL/Contact Select

Digital output 3, TTL/Contact Select

Digital output 4, TTL/Contact Select

Remove links for

contact closure

GND

GND

Figure 1–3

The pin assignments for

the Instrument

Connection Port, and the

link configurations.

8 PowerChrom

Digital Output Controls

The Instrument Connection Port also provides four independent digital

output controls. These outputs can be used to control external devices

using the PowerChrom software (via Method tables). The digital outputs

can provide logic levels (5 V TTL) or contact closures (depending on the

link settings) and are therefore suitable for use with a wide range of

external devices. PowerChrom software can be used to set:

• a contact closure to be open or closed;

• a logic voltage to be high or low; or

• pulse a logic voltage from one state to the other for a brief time

(from 16 to 32 ms, depending on internal timing).

Technical details of the digital input and output connectors are given

later in this manual: please refer to the descriptions before attempting to

connect equipment to them. The digital output connections (positive and

negative) are marked ‘CTL1’ to ‘CTL4’ (for control).

More information on the use of the digital outputs is given in the

PowerChrom Software Manual

.

Links

A set of four links are present at the right of the Instrument Connection

Port, Figure 1–3, one for each of CTL1, CTL2, CTL3 and CTL4. When

the links are present the Digital Output Controls, page 8, are

configured as TTL. Remove the links using tweezers, or by levering them

out with a small screwdriver, to configure the Digital Outputs as contact

closures.

PowerChrom 9

CHAPTER TWO

2

Setting Up

This chapter describes how to connect your recording unit to a

Windows or Macintosh computer, using the USB interface, and to

chromatography equipment. Technical details of the PowerChrom 280

unit are also described.

Please note that there are no user serviceable parts inside the

PowerChrom 280 unit. Do not use this document as a service manual:

that user modification of the PowerChrom unit will void your rights

under warranty.

10 PowerChrom

Self-Test

Check that the PowerChrom hardware unit is working properly, before

you first connect it to your computer:

1. Connect the PowerChrom unit to a power outlet using the power

cable that came with your unit. Turn the power on at the wall.

2. Turn on the power switch located on the rear of the unit.

3. Observe the three indicators on the front panel, Figure 1–1,

page 4:

• The Power indicator should glow blue while the recording unit

is on (see Table 1–1, page 4). If the Power indicator does not

glow blue, then either there is a problem with the power source,

power cable or PowerChrom unit itself. Check the connections.

Make sure the wall socket is switched on.

• The Status indicator should flash yellow, and then stay green. If

an error is detected during the self-test, the Status indicator will

flash red, indicating that the problem is one that prevents the

PowerChrom unit communicating with the computer. Turn

everything off, and then after at least five seconds turn the

PowerChrom back on again. This should clear a temporary

problem. If the PowerChrom does not seem to be getting power,

or the Status indicator flashes red even after restarting, contact

your PowerChrom representative as soon as possible.

• The trigger indicator should flash yellow and then stay off.

If the PowerChrom unit has successfully performed its internal self-test, it

can be safely connected to your computer. The PowerChrom unit also

performs this self-test every time it is switched on, regardless of whether

it is connected to a computer.

Connecting to the Computer

Use the USB cable supplied with your PowerChrom to connect the USB

port on its back panel to the USB port on the computer, or to an active

USB hub connected to the computer. USB ports and cables should be

marked with a trident-like icon, , (or the letters ‘USB’). If the

connection is to a USB card installed in the computer, there might not

be any icons on the card.

▲

WARNING!

Failure to ensure

adequate earthing of the

PowerChrom unit results

in unsafe operation. Two

pin (unearthed) power

outlets, or adaptors, must

NOT be used.

Chapter 2 — Setting Up 11

External Equipment

All the connections that the PowerChrom recording unit uses for signal

measurement and control are made through the single 20-pin Instrument

Connection port on the back panel, Figure 1–2, page 5. The recording

unit is shipped with a plug-in terminal block adaptor, Figure 2–2, that

provides connections to all available inputs and outputs. The terminal

block adaptor is designed to accept the bared ends of wires, or bare

metal connectors, and it is then plugged into the Instrument Connection

port. Refer to the labelling on the back panel of the recording unit, and

Figure 1–3, page 7 when connecting your own equipment cables.

The terminals most frequently used are the detector inputs and injector

signal.

If you have a suitable autoinjector then it can be connected to the

injector signal input (‘TRIG’) of the PowerChrom unit. The resulting

signal is used by the PowerChrom software to mark the injection time

for a run. A contact closure longer than 10 ms will be registered as an

injection event. The polarity of this connection is not critical unless the

equipment’s injector supplies a voltage level, in which case the positive

output of the injector should be connected to the + TRIG input. The

maximum voltage input should be ≤ 6 V.

The detector inputs (‘CH1’ and ‘CH2’) of the recording unit record the

signals from the chromatography detectors. Both differential (+ and –)

Computer

PowerChrom unit

USB icon

USB cable

Figure 2–1

Connecting PowerChrom

to a computer.

▲WARNING!

Using cables that are

wired incorrectly can

cause internal damage to

the recording unit. Such

damage is not covered

under warranty.

12 PowerChrom

The terminal block adaptor

plugs into the Instrument

Connection port

CH1

Positive

signal Negative signal

or ground

Cable shield (do not

connect at other end)

+ COM – + COM –

CH2 CH1

Positive

signal Negative signal

or ground

+ COM – + COM –

CH2

To detector To detector

Shielded connection Unshielded connection, or when the

shield is connected at the detector

Terminal block adaptor

Instrument Connection port

Figure 2–3

Detector connection to

terminal block adaptor.

Figure 2–2

The terminal block

adaptor

Chapter 2 — Setting Up 13

or single-sided (+ and COM or ground) outputs from the detectors can

be used. It is often worth using the + and – terminals even with a single-

ended detector signal as this may give a better quality signal. Some

detectors may make use of all three (+, –, and COM) sockets.

In general, for best results, use a twisted-pair cable, with a braided

shield. The shield can be connected to a COM pin of the PowerChrom

unit, Figure 2–3, or to a ground connection on the detector, but not to

both!

If your detector provides signal outputs at different levels (for example a

10 mV ‘integrator’ output, and a 1 V ‘recorder’ output) use the larger

output (in this example the 1 V recorder output would be used). The

larger signal will usually exhibit a better signal to noise ratio. You can

adjust the input sensitivity of the PowerChrom hardware unit to match

the output of your detectors, see the Input Amplifier section in the

PowerChrom Software Manual.

If an incorrect polarity connection is made the signal will be inverted

(that is, the peaks will be pointing downwards instead of upwards).

How Does it Work?

The PowerChrom unit contains its own microprocessor, memory, and

specialized analog amplifiers for signal conditioning. The block

diagram in Figure 2–4 shows its basic elements.

All sampling, output, and communications is controlled by an internal

PowerPC 403 microprocessor running at 60 MHz. The microprocessor

has access to 4 megabytes of RAM for data storage and buffering prior

to transmission to the computer. The recording unit uses USB (Universal

Serial Bus) to transfer recorded data to the computer, and for the

computer to control the PowerChrom unit.

The PowerChrom unit has two input channels, with separate amplifiers,

used to record analog signals (more detail is given on page 18). The

outputs of these amplifiers are multiplexed to a precision 16-bit analog-

to-digital convertor. This ADC samples at rate of 10 kHz. The

PowerChrom software maximum recording rate is 100 Hz, the extra

capacity of the ADC is used to average individual samples to produce

higher resolution data, see Sampling Operation, page 18. The CPU

14 PowerChrom

assembles groups of data points into ‘packets’ and then transmits them

via the USB connection to the computer, where the PowerChrom

program receives, records, and displays the data.

A 16-bit DAC (digital-to-analog convertor) is used to control the analog

output of the recording unit available through the Instrument Connection

port, Figure 1–3, page 7. The DAC produces waveforms under

software control that are fed through an attenuation network to produce

different full-scale ranges. The signal is then buffered by an amplifier to

give it the capability to drive external loads.

The injection signal input is coupled to the recording unit via an optical

switch providing high voltage isolation, Figure 2–6.

Back

Panel

16-bit ADC

Clock

30 MHz

Injection signal

50/60Hz

Interrupt

Multiplexer

2 Programmable

Gain Amplifiers

16-bit DAC

Range

Control

+1

Instrument Interface

USB Port IEC Mains Input

Switching

Power

Supply

Links to set

Contact Closure

or TTL

System

Glue Chip

PPC403 CPU

Anti-alias filters

Instrument Connection Port

DRAM Flash

ROM

USB

Controller

Figure 2–4

Block diagram of the

PowerChrom 280 unit.

Chapter 2 — Setting Up 15

The four digital output connections of the Instrument Connection port

provide a means to control external devices. The digital output signals

can be configured as either TTL signal levels or contact closures, by

installing or removing a set of links, Figure 1–3, page 7. These digital

outputs can be used to signal external devices such as autosamplers,

fraction collectors, or autoinjectors. More detail on these controls is

provided on page 16.

The recording unit uses a universal input switching power supply.

Detector Inputs

Each of the PowerChrom unit’s analog input differential amplifiers have

independently computer-controlled gain from ×1 (10 V range setting) to

×5000 (2 mV range setting). Applying more than ±30 V to the detector

inputs could damage the circuitry.

Each input is fitted with a 900 Hz second order Bessel anti-aliasing low-

pass filter which eliminates high frequency interference. Input

impedance is 1 MΩ.

The operation of the input amplifiers is illustrated by the block diagram

in Figure 2–5.

Using differential analog inputs for the detectors gives the system

greater immunity to external electrical interference, when used in

conjunction with a suitable cable. The best type of detector cable would

be a twisted pair with a braided shield, as shown in Figure 2–5. The

shield should be connected to the detector’s analog ground, or to the

COM pin of CH1 or CH2, but not to both.

Analog Output

The analog output provides a computer–controlled variable output (0 –

10 V, at up to 10 mA) that can be used to control peripheral devices.

The analog voltage output is accessed via the DAC pins in the

Instrument Connection port (DAC + and COM), Figure 1–3, page 7.

The voltage is controlled using the PowerChrom software Method

tables, see the PowerChrom Software Manual for more information.

16 PowerChrom

Injection Signal Input

The injection signal input uses a solid-state relay input to recognize

external relay closures. A closure of 10 ms or more results in the

registering of the injection signal with the PowerChrom program. The

input can also be connected to a logic or voltage level output of

another instrument provided the device can sink several milliamperes of

current. The equivalent circuit of the injector signal input (TRIG) is

shown in Figure 2–6.

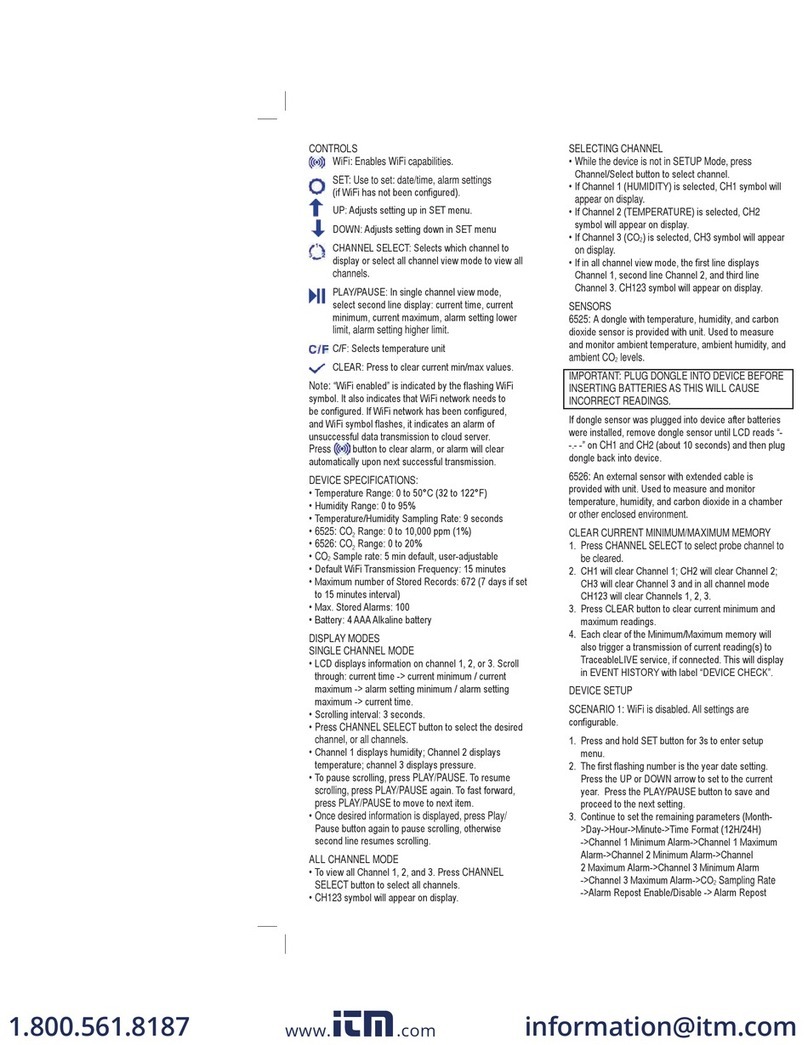

Digital Outputs

There are four digital control outputs (marked CTL1, CTL2, CTL3, and

CTL4), each of which provide a logic level or contact closure

depending on the presence, or absence, of the corresponding links to

Gain

control

900 Hz low-

pass filter

Channel control bus

Detector

To

multiplexer

Grounding

and input

selection

Gain

control

Instrument

amplifier

+

–

+

–

GND

Shielded

cable

Do NOT ground the

shield at both ends!

1 MΩ

COM

+5V

820 R

Internal circuitry

Injection

signal input

Injection signal input

(contact closure)

+5 V

820 Ω

Internal circuitry

TRIG +

TRIG –

Figure 2–5

Block/schematic

diagram of the input

amplifier circuitry.

Figure 2–6

The equivalent circuit of

the injection signal input.

Table of contents

Popular Data Logger manuals by other brands

Vaisala

Vaisala HUMICAP HMT140 user guide

INTEGRA Merering

INTEGRA Merering AMBUS Link Mounting and operating instructions

Capetti Elettronica

Capetti Elettronica WineCap WSD12T-IIDR user manual

T&D

T&D RTR502B user manual

Sensitech

Sensitech Sentry 500 Instructions for use

MadgeTech

MadgeTech X Series Product user guide