INTEGRA Merering AMBUS Link Service manual

Mounting and operating instructions

AMBUS®Link

The intelligent M-Bus data central for configuration, operation and monitoring of M-Bus

installations as a total system. The integrated web server offers a modern administration

of consumption data.

Table of contents

1Safety 2

1.1 Intended use 2

1.2 Notes on safety instructions and symbols 2

1.3 Safety instructions and precautionary measures 3

1.4 About the operation manual 3

2Product description 4

2.1 Areas of application 4

2.2 Device design 4

2.3 Power supply 5

2.4 Interfaces 6

2.5 Memory card 7

3Scope of delivery and accessories 7

4Mounting 8

5Installation 9

5.1 Connection scheme 10

5.2 M-Bus network (field level) 11

6Commissioning 17

6.1 Switchig on the AMBUS®Link 17

6.2 Operation via AMBUS®Link 18

6.3 Operation via web server 20

6.4 Configuration meter via web server 24

6.5 Creating usage units via web server 29

6.6 Configuring a reporting date reading via web server 32

6.7 Driver configuration via web server 34

6.8 Configuring a logger via web server 37

6.9 Data management via web server 45

6.10 System integration via web server 47

7Maintenance and repair 51

8Malfunctions and error messages 52

9Decommissioning, disassembly and disposal 55

9.1 Decommissioning 55

9.2 Disassembly 55

9.3 Disposal 56

10 Technical data 56

10.1 Dimensions 58

11 Appendix 59

11.1 CE declaration of conformity 59

11.2 Export file type csv standard 60

11.3 Export file type csv FULL-DB 65

VD 9-925 e 02.2017

AMBUS® Link 2

1 Safety

1.1 Intended use

The device AMBUS®Link is exclusively intended for the configuration, operation and

monitoring of M-Bus installations as a total system.

Any improper or inappropriate use might result in a state in which the operational safety

of the device cannot be guaranteed anymore. The manufacturer waives any liability for

resulting damages of persons and materials.

1.2 Notes on safety instructions and symbols

The devices have been designed to fulfil modern safety requirements. They have been

tested and delivered in a condition that ensures safe operation. However, improper or

non-intended use of the device may result in it becoming dangerous. Please always pay

attention to the safety instructions in this manual which are accompanied by the following

symbols:

WARNING

WARNING

indicates an action or measure which, if performed incorrectly,

can potentially cause life-threatening injuries and lead to a high safety risk.

ATTENTION

CAUTION indicates an action or measure which, if performed incorrectly,

can cause minor to medium severe injuries.

NOTE

NOTE indicates a dangerous situation which might lead to material damage,

if not prevented.

COMMENT

COMMENT provides helpful tips and recommendations as well as infor-

mation for efficient and trouble-free operation.

AMBUS® Link 3

1.3 Safety instructions and precautionary measures

The manufacturer takes over no responsibility if the following safety instructions and pre-

cautionary measures are disregarded:

1. Changes to the device, which are implemented without prior written approval of

the manufacturer, lead to the immediate termination of product liability and warran-

ty.

2. Installation, operation, maintenance, repair and decommissioning of this device

must only be performed by specialists authorised by the manufacturer, operator or

owner of the device. The specialist needs to read and understand the entire instal-

lation and operation manual and is obliged to follow these instructions.

3. Control the supply voltage and information given on the type plate, before the de-

vice is installed.

4. Check all connections, settings and technical specifications of any available pe-

ripheral devices.

5. Open the housing or parts of the housing, which contain electrical or electronic

components, only if the electric energy is turned off.

6. Touch no electronic components (ESD sensitivity).

7. Expose the system concerning the mechanical load (pressure, temperature, IP

protection etc.) maximally to the specified classification.

8. For works concerning mechanical components of the system, the pressure in the

pipe system has to be released or the temperature of the medium needs to be

brought to values harmless for humans.

9. No information stated here or anywhere else releases planners, engineers, fitters

and operators from their personal careful and comprehensive evaluation of the re-

spective system configuration in terms of functionality and operational safety.

10.The local working and safety standards and statutes need to be met.

1.4 About the operation manual

The manufacturer reserves the right to change the technical details without prior notice.

The newest information and versions of this operation manual are available at your local

subsidiary or representation as well as on the website.

WARNING

Any liability is waived if the instructions and procedures

in this manual are

not followed!

NOTE

This installation instruction is intended for qualified personnel and contains

thus no basic working steps. Before putting AMBUS® Link or the system into

operation, the installation and operation manual needs to be read and un-

derstood completely.

Keep this manual for later reference!

AMBUS® Link 4

2 Product description

We congratulate you for purchasing this high-quality M-Bus data central.

The device AMBUS®Link makes the configuration, operation and monitoring of M-Bus

installations as a total system easier. The integrated web server serves for easy provision

of your consumption data on any terminal devices or subordinate control systems.

2.1 Areas of application

AMBUS®Link is designed for technical building management and also for building ser-

vices and can be used as follows:

Data concentrator

As central function of your consumption data for analysis and documentation purposes of

all flow and energy meters. For easy administration the integrated web server supports

on all web-enabled terminal devices the user in recording, presentation and provision of

consumption data for utility cost billing or monitoring.

System integration component

With the versatile interfaces AMBUS®Link has to offer you can integrate your consump-

tion data in the simplest way in subordinate building control systems.

2.2 Device design

AMBUS®Link is intended for control cabinet installation. The device design is defined as

follows:

Optical signals/lights

LED reading and LED scanning

Operating elements

oEnter button

oFunction button

AMBUS® Link 5

Protection covers

Mounting rail protection

Mounting rail guide

Status logger, operating status

M-Bus slaves

IP address

Subnet mask

Default gateway

Firmware version

2.3 Power supply

For using the product outside a control cabinet the power supply can be realised as fol-

lows.

External

Manufacturer recommendations

Switching power supply UNO POWER

•Output voltage 24 VDC

•Output power 4.2 A

•Capacity 100 W

Dimensions W x H x D 55×90×84 mm

AMBUS® Link 6

2.4 Interfaces

The data central consists of a TCP/IP interface with integrated data logger and combines

the function of an M-Bus data logger and an M-Bus reading software. Thus the following

software and hardware interfaces are implemented.

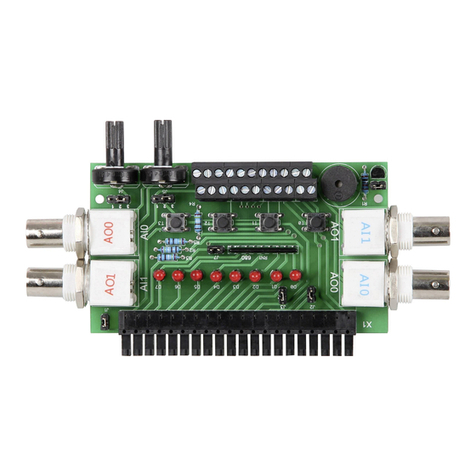

2.4.1. Connections

RJ45 LAN connection

Micro SD card slot

USB type A

USB type B

Terminal connection 1-15

Pulse inputs terminals 1-8

Power supply terminals 9-10

AMBUS® Link 7

2.4.2. Protocols

Communication protocols

•Ethernet/LAN/WLAN

•BACnet/IP

•FTP/sFTP

•HTTP

•JSON

•CSV

•POP3

Options retrofittable via external

router

•LTE

•UMTS/HSPA

•GPRS/EDGE

2.5 Memory card

The medium stores all system-specific parameters and contains parts of the operating

system. It is a requirement for operating the AMBUS®Link.

Micro SD

microSDHC card Transcend Premium 400x

•Storage capacity 32 GB

•Class 10

•Reading (max.) 60 MB/s

•Writing (max.) 25 MB/s

3 Scope of delivery and accessories

The scope of delivery is described on the delivery note and the content is displayed on

the packaging. Please check all components and delivered parts immediately after re-

ceiving the product. Transport damages need to be reported immediately!

1x

AMBUS®Link

1x

microSDHC card

1x

brief instruction

3x

protective covers

AMBUS® Link 8

4 Mounting

ATTENTION

Material damage caused by neglected ambient conditions

Danger of malfunction or damage!

•Assuring accessibility for installation, operation and maintenance

•Protected, dry surroundings

•Avoid exposure to heat/sun

•Keep a safe distance to sources of electrical noise

Control cabinet mounting

1. Place recesses of the device at the top

edge of the mounting rail

2. Press lightly on the AMBUS®Link

3. AMBUS®Link snaps onto the mounting

rail

AMBUS

®Link is firmly connected to the mount-

ing rail

Control cabinet removal

1. Remove the piston

2. Lift AMBUS®Link up from the mounting

rail

AMBUS

®Link is separated from the mounting

rail

AMBUS® Link 9

5 Installation

Carefully read the following calls for action and warning information to assure a trouble-

free commissioning.

WARNING

Burns and paralysis resulting in death when touching or grabbing energised system parts.

Life hazard due to electrical shock!

•Perform installation and maintenance work only when the system is

off power

•Work on and with voltage shall only be performed by authorised spe-

cialists under consideration of applicable regulations

•Apply voltage only to the terminals intended

•Safeguarding by external protection elements to assure a safe

switch-off in case of an error

•Install a labelled disconnector (fuse) at an accessible location

•Use a separate fuse circuit for installation

NOTE

Terminal connections cable cross section

•Terminal connections relay, temperature sensor and M-Bus

oBraid up to 2.5 mm2

oTorque 0.4 Nm

•Terminal connections S0 inputs and power supply

oBraid up to 6 mm2

oTorque 1.3 - 1.6 Nm

AMBUS® Link 10

5.1 Connection scheme

Terminals

Function

Rel 1 NO/Rel 1 C

Relay 1

Normally open

Rel 2 NO/Rel 2 C

Relay 2

Normally open

PT1000 1/PT1000 C

Temperature sensor

PT1000

PT1000 2/PT1000 C

Temperature sensor

PT1000

M-BUS1-/M-BUS1+

M-BUS output 1

Master

M-BUS2-/M-BUS2+

M-BUS output 2

Master

M-BUS3-/M-BUS3+

M-BUS output 3

Master

S0 1A/S0 1B

S0 pulse input 1

Active encoder signal

S0 2A/S0 2B

S0 pulse input 2

Active encoder signal

S0 3A/S0 3B

S0 pulse input 3

Active encoder signal

S0 4A/S0 4B

S0 pulse input 4

Active encoder signal

+24V/GND 24VDC supply voltage

RJ45

Ethernet port

USB type A

USB interface of type A

WLAN and modems

USB type B USB interface of type B

Level converter and mainte-

nance

AMBUS® Link 11

5.1.1. Power supply:

1. Assure that the power cable

is voltage-free!

2. The disconnector needs to be switched

off!

3. Flip up the protective cover

4. Loosen the terminal connection

(terminal 9 (+24V DC) /10 (GND))

5. Connect the power supply to

terminal 9 (+24V DC) /10 (GND).

6. Tighten the terminal connection

7. Close the protective cover

AMBUS

®Link is ready for use

5.1.2. Attach the protective covers

1. Attach included protection cover with

slight pressure

2. Attach included protection cover with

slight pressure

3. Attach included protection cover with

slight pressure

The interfaces are protected

5.2 M-Bus network (field level)

In the following the installation of the M-Bus network with AMBUS®Link is described

ATTENTION

Material damage caused by neglected installation conditions

Danger of malfunction or damage!

•Generously dimension the main cable cross section and possibly

divide it into 3 terminal groups

•Apply voltage only to the intended terminals

AMBUS® Link 12

NOTE

High voltage drops of 5 VAC on the M-

Bus cables between data central and

terminal node need to be avoided.

•Divide the main strand into several part strands (largest strands)

•Increase cable cross section

•Apply star shape network topology instead of chained network

topology

•Apply no circular network topologies

5.2.1. Connect M-Bus meter

1. Open the protective cover

2. Loosen the terminal connection

(terminals 10-15)

3. Connect M-Bus participant to terminal

10/11, 12/13 or 14/15

4. Tighten the terminal connection

5. Close the protective cover

AMBUS

®Link is physically connected with the

M

-Bus participants

5.2.2. Connect the temperature sensor

1. Open the protective cover

2. Loosen the terminal connection

(terminals 6-9)

3. Connect the temperature sensor with the

terminal 6/7 or 8/9

4. Tighten the terminal connection

5. Close the protective cover

The temperature sensor is connected

AMBUS® Link 13

COMMENT

Operating principle alarm relay 1

•Operating principle as normally open

•The following signals appear

oMeter cannot be read out

oParameter error flag

oM-Bus short circuit

5.2.3. Connect alarm relay 1

1. Open the protective cover

2. Loosen the terminal connection

(terminals 1/2)

3. Connect the participant to terminal 1/2

4. Tighten the terminal connection

5. Close the protective cover

The relay output is connected

COMMENT

Operating principle alarm relay 2

•Operating principle as inverted normally open

•The following signals appear

oMeter cannot be read out

oParameter error flag

oM-Bus short circuit

AMBUS® Link 14

5.2.4. Connect alarm relay 2

1. Open the protective cover

2. Loosen the terminal connection

(terminals 3/4)

3. Connect the participant to terminal 3/4

4. Tighten the terminal connection

5. Close the protective cover

The relay output is connected

5.2.5. Connect pulse inputs

1. Open the protective cover

2. Loosen the terminal connection

(terminals 1-8)

3. Connect pulser to terminal 1/2,

3/4, 5/6 or 7/8

4. Tighten the terminal connection

5. Close the protective cover

The pulser is connected

5.2.6. Connect USB type A

1. Plug the USB type A into the intended

port

The external USB device is

connected.

AMBUS® Link 15

5.2.7. Connect USB type B

1. Plug the USB type B into the intended

port

The external USB device is connected.

5.2.8. Connect network cable RJ45

1. Plug the RJ-45 connector into the intend-

ed port

The network cable is connected

AMBUS® Link 16

5.2.9. Inserting a mini SD card

1. Insert the microSD card centred into the

intended port

2. Press the microSD card with slight pres-

sure over the snap-in point

3. The microSD card snaps in the port

The microSD card is connected.

NOTE

In case of improper handling the microSD card falls into the housig between the

slot and the surface.

•Control the exact positioning of the microSD card before inserting it

•Use a slotted screwdriver to insert it.

AMBUS® Link 17

6 Commissioning

AMBUS®Link can be commissioned in two ways, which are described in the following

chapter.

6.1 Switchig on the AMBUS®Link

WARNING

Burns and paralysis resulting in death when touching or grabbing energised system parts.

Life hazard due to electrical shock!

•Perform installation and maintenance work only when the system is

off power

•Work on and with voltage shall only be performed by authorised spe-

cialists under consideration of applicable regulations

•Apply voltage only to the intended terminals

•Protection by external protection elements to assure a safe switch-off

in case of an error

•Install a labelled disconnector (fuse) at an accessible location

Use a separate fuse circuit for installation

Switching AMBUS® Link on

1. Start the supply via the disconnector

2. AMBUS®Link starts

3. The reading and scanning LEDs are

"slightly" glowing

4. The display is flashing after 30 sec.

AMBUS

®Link is ready for use

AMBUS® Link 18

6.2 Operation via AMBUS®Link

COMMENT

The delivery state of the network configuration ex works

•DHCP is activated, IP address is automatically obtained

•DHCP is deactivated by manual entry of the network parameters

oActivating DHCP by entering zeros for all network parameters

COMMENT

Functionality of the secondary search

•The search via secondary address is conducted as reverse search

6.2.1. Quick commissioning M-Bus network

1. Hold the button for more than 5 sec.

2. M-Bus meter search is started via

secondary address

3. The reading and scanning LEDs are glow-

ing "brightly"

4. The operating mode reports SCAN

5. Scanned meters are shown on the

display (slaves)

All meters have been read in

COMMENT

Finalising the quick configuration of the network parameters

•The set parameters are activated after the configuration has been

finished

•The configuration is finished after de-selecting the last digit

AMBUS® Link 19

6.2.2. Quick configuration network parameters

1. Hold the button for more than 2 sec.

first position at IP is selected and

configurable

2. When pressing the button the marked

digit increases by one (0-9)

3. The button confirms the set digit and

jumps to the next

IP address, subnet

mask and default gateway

are set, the network is configured

6.2.3. Restart AMBUS®Link

1. Hold the button and button

together longer than 5 sec.

2. After releasing the buttons a restart is per-

formed

AMBUS

®Link restarts and the settings remain

preserved

AMBUS® Link 20

6.3 Operation via web server

COMMENT

Reachability of the web server concerning the firewall

•The communication takes place via TCP, HTTP and websocket

•Port 80 is the communication port

COMMENT

Explanation of the connection indicator

connected (connection established)

connecting (connection in establishment)

not connected (connection failed)

COMMENT

Operation

•Button for home screen view

•Automatic logout after 10 minutes without operation

COMMENT

Role rights

•The rights of each role are fixed and cannot be changed

•Administrator «all rights»

•Standard user «read rights» cannot make changes to the system

•In the delivery state a user is predefined

oAdmin (administrator role)

Table of contents

Popular Data Logger manuals by other brands

Allen-Bradley

Allen-Bradley 1770-SB user manual

Sea-Bird Scientific

Sea-Bird Scientific SBE 25plus Sealogger CTD Basic user manual

Pego

Pego PLUS EXPERT DL3 Use and maintenance manual

NI

NI myDAQ Safety and Usage Guide

BIOPAC Systems

BIOPAC Systems BioNomadix Smart Center user guide

Microtronics

Microtronics myDatalogNANOamr user manual