eDAQ e-corder User manual

e-corder®www.eDAQ.com

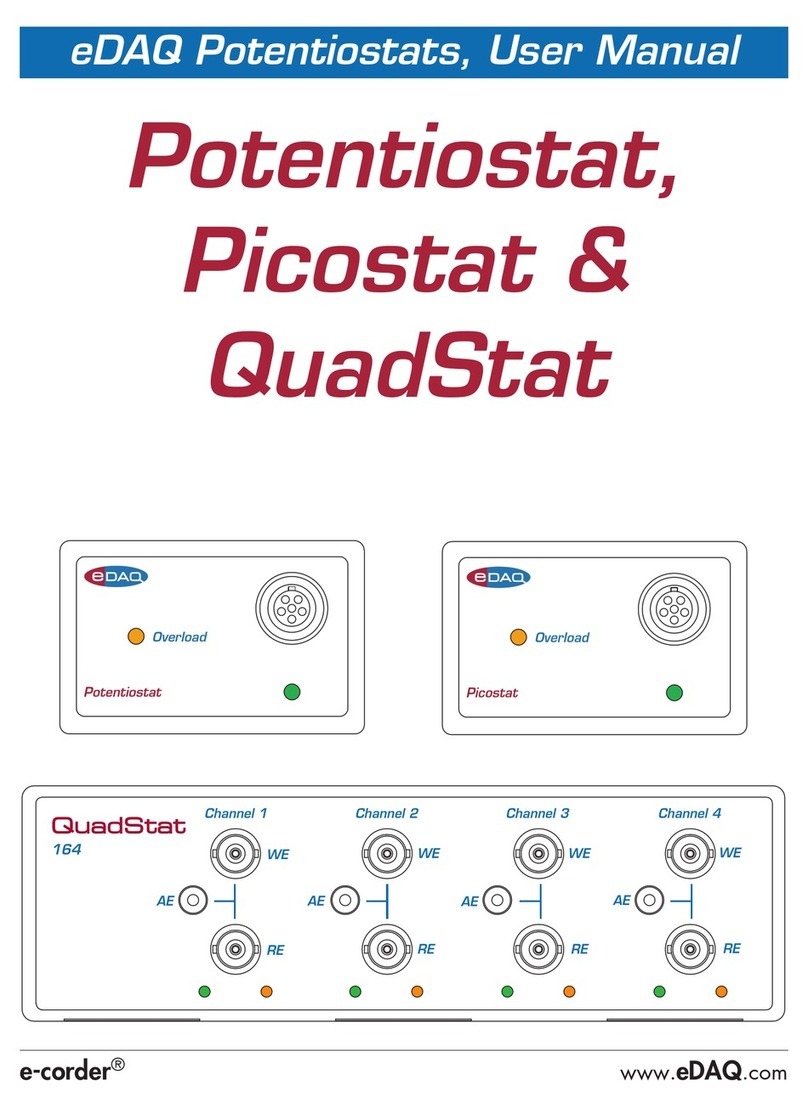

eDAQ Modular Potentiostats

Potentiostat,

Dual Picostat

& QuadStat

WE WE WE WE

QuadStat

RE RE RE RE

AE AE AE AE

Channel 1 Channel 2 Channel 3 Channel 4

164

Potentiostat

Overload

Dual PicoStat

362

Status

Power

Trigger

Overload Overload

Channel 1 Channel 2

ii eDAQ Potentiostats

This document was, as far as possible, accurate at

the time of printing. Changes may have been made

to the software and hardware it describes since

then: eDAQ Pty Ltd reserves the right to alter

specifications as required. Late-breaking information

may be supplied separately. Latest information and

information and software updates can be obtained

from our web site.

Trademarks of eDAQ

e-corder and PowerChrom are registered

trademarks of eDAQ Pty Ltd. Specific model

names, such as e-corder 210, PowerChrom

280, Dual Picostat, Picostat, QuadStat, and

isoPod, are trademarks of eDAQ Pty Ltd. Chart

and Scope are trademarks of ADInstruments

Pty Ltd and are used under license by eDAQ.

EChem is a trademark of eDAQ Pty Ltd.

Other Trademarks

Windows XP, Vista, and Windows 7 are trademarks

of Microsoft Corporation.

PostScript, and Acrobat are registered trademarks of

Adobe Systems, Incorporated.

All other trademarks are the properties of their

respective owners.

Products: Potentiostat (EA161)

Potentiostat (EA163)

Dual Picostat (EA362)

QuadStat (EA164)

Document Number: UM-EA161/3/4/362-1212

Copyright © December 2012

eDAQ Pty Ltd

6 Doig Avenue

Denistone East, NSW 2112

Australia

http://www.eDAQ.com

email: [email protected]

All rights reserved. No part of this document may be

reproduced by any means without the prior written

permission of eDAQ Pty Ltd.

eDAQ Potentiostats iii

Contents

1 Overview 1

How to Use this Manual 2

eDAQ Modular Potentiostats 2

Checking the unit 2

2 The Potentiostat 3

The Front Panel 4

The Electrode Connector 4

Electrode Cable 5

The Online Indicator 6

The Overload Indicator 6

The Back Panel 7

E Out, I Out and E In Connectors 8

I2C Connectors 8

Grounding Connector 8

Connecting the Potentiostat 9

First Use 11

Potentiostat Control Window 13

Maintenance 20

3 The Dual Picostat 21

The Front Panel 22

Electrode Connectors 22

Electrode Cable 23

The Power Indicator 23

The Status Indicator 24

The Overload Indicator 24

The Back Panel 25

Power Connector, On/Off 25

E Out, I Out and E In Connectors 25

USB socket 26

I2C Connectors 26

Grounding Connector 26

Connecting the Dual Picostat 27

First Use 30

Dual Picostat Control Window 30

Maintenance 37

4 The QuadStat 39

The Front Panel 40

Electrode Connectors 40

Electrode Cables 40

The Online Indicators 41

The Overload Indicators 41

The Back Panel 43

E Out, I Out and E In Connectors 43

I2C Connectors 43

Grounding Connector 44

Connecting the QuadStat 46

Using a Common Reference and Auxiliary

49

Using Multiple References and Auxiliaries

50

iv eDAQ Potentiostats

First Use 50

QuadStat Control Window 51

QuadStat Potential Window 56

Maintenance 57

5 Techniques 59

Introduction 60

Linear Scan Techniques 61

Fast Cyclic (or Linear Sweep) Voltammetry

61

Chronoamperometry with Chart 62

Chronoamperometry with Scope 64

Chronocoulometry 65

Chronopotentiometry 67

Chart software 69

Controlled Potential Electrolysis 70

Controlled Current Electrolysis 71

Amperometric Sensors 72

Biosensors 73

Microdialysis Sensor 73

Dissolved Oxygen (dO2) Sensors 74

Nitric Oxide (NO) Sensors 75

A Technical Aspects 77

Potentiostat 77

Dual Picostat 79

QuadStat 81

B Troubleshooting 85

C Specifications 91

Potentiostat 91

Dual Picostat 94

QuadStat 96

D Electrochemical Equations 99

Linear Sweep and Cyclic Voltammetry 99

Chronoamperometry 101

Chronocoulometry 102

License & Warranty 107

eDAQ Potentiostats 1

CHAPTER ONE

1Overview

There are three eDAQ modular potentiostats:

• Potentiostat (EA163), Chapter 2. Single channel, three electrode

potentiostat/galvanostat with gain ranges of 20 nA to 100 mA;

• Dual Picostat (EA362), Chapter 3. Two channel, three electrode,

high sensitivity potentiostat with gain ranges of 2 pA to 10 μA; and

• QuadStat (EA164), Chapter 4. Four channel, three electrode

potentiostat with gain ranges of 200 pA to 10 mA.

They are designed for use with an e-corder®system.

Some of the uses of the Potentiostat, Picostat, and QuadStat, are

mentioned in Chapter 5, and also in the EChem Software Manual

which describes the use of the optional EChem software.

NOTE

This manual is for the

EA163 Potentiostat,

EA362 Dual Picostat, and

EA164 QuadStat. If you

have an older model

EA160 or EA161

Potentiostat, or EA162

Picostat then please ask

us to send you the

appropriate manual.

2eDAQ Potentiostats

How to Use this Manual

This manual describes how to set up and begin using your Potentiostat

(Chapter 2), Dual Picostat (Chapter 3), or QuadStat (Chapter 4). Their

use with Chart and Scope software is also described (Chapter 5).

The appendices provide technical and trouble shooting information.

See the EChem Software Manual for a description of the use of these

potentiostats with the optional EChem software.

eDAQ Modular Potentiostats

The Potentiostat, Dual Picostat and QuadStat are modular units and

must be used with an e-corder data recording system.

They can performing various voltammetric and amperometric

experiments under full software control and are automatically

recognised by the Chart, Scope or EChem software which control their

gain range, signal filtering, and other settings.

See our web site at www.eDAQ.com for more information.

Checking the unit

Before you begin working with your Potentiostat, Dual Picostat, or

QuadStat please check that:

• all items described in the packing list are included; and that

• there are no signs of damage that may have occurred during

transit.

Contact your eDAQ distributor if you encounter a problem.

You should also become familiar with the basic features of your e-corder

system, which are discussed in the e-corder Manual which will be

placed as a pdf file on your computer hard disk when you install the

software.

eDAQ Potentiostats 3

CHAPTER TWO

2The Potentiostat

This chapter describes how to connect and use your model EA163

Potentiostat. If you have an older model EA160 or EA161 Potentiostat

please refer to the documentation that came with your unit or contact

IMPORTANT: Always make sure that the e-corder is turned off before you

connect or disconnect the Potentiostat. Failure to do this may result in

damage to the e-corder and/or the Potentiostat.

NEW FEATURES: If you have used the older EA161 Potentiostat then you

will notice it is very similar to the new EA163 Potentiostat which has

higher bandwidth (100 kHz) and so is more suitable for

electrochemical impedance spectroscopy (EIS).

4eDAQ Potentiostats

The Front Panel

The front panel of the Potentiostat is shown in Figure 2–1.

The Electrode Connector

The electrode connector of the Potentiostat provides connection pins for

the Working, Auxiliary and Reference electrode lead wires. The

connector also provides connections for the lead shields which protect

the signals in the cable wiring from electrical interference (noise

pickup).

The pin assignments of the Potentiostat electrode connector are shown

in Figure 2–2. The Auxiliary and Reference electrode leads have

Potentiostat

Overload

Overload

indicator light

Electrode connector,

Lemo socket,

to electrodes

Online indicator light

Working Electrode Auxiliary Electrode

Reference Electrode Shield

Reference Electrode

Working Electrode Shield Not connected

Alignment dot

Figure 2–1

The Potentiostat front

panel.

Figure 2–2

The Potentiostat electrode

connector as seen when

looking at the front

panel.

Chapter 2 — The Potentiostat 5

coaxial shields which are maintained at the respective electrode

potential.

Electrode Cable

The Potentiostat is supplied with an electrode cable comprising three

leads, with each lead terminated by an alligator clip. The Reference

and Working electrode leads are shielded to protect the signals from

external interference. The alligator clips allow connection to a wide

variety of electrodes, and the leads are color–coded to indicate the

type of electrode to which they should be attached (Table 2–1).

For normal three–electrode potentiostat, page 13, or galvanostat,

page 14, use, the reference electrode must never be connected to

either the auxiliary (red) or working (green) leads, otherwise the current

that would be passed through the electrode could effectively destroy it

as a reference potential source.

When two–electrode potentiostat, or galvanostat, operation is required

the auxiliary and reference leads (red and yellow) should be attached

to the single ‘counter electrode’. The green lead is attached to the

working electrode.

When using in ZRA (zero resistance ammeter) mode, connect the

working (green) and auxiliary (red) leads to the two electrodes (or

circuit test points) across which to measure the current, page 14. The

reference lead (yellow) can be connected to a reference electrode (or

circuit test point) to measure the potential difference to the auxiliary

(and working) leads.

When using High Z (high impedance) mode, connect the working

(green) lead to one electrode and the reference lead (yellow) lead to a

reference electrode to measure the potential difference between the

leads, page 14. On the EA163 Potentiostat the auxiliary electrode lead

To ensure good grip, the

electrode cable alligator

clips use a spring made

from a good quality steel

(stainless steel is

unsuitable for strong

springs). Avoid wetting

of the alligator clips,

especially with

electrolyte solutions

which can hasten

corrosion. If the alligator

clips are wetted then

immediately disconnect

from the Potentiostat,

rinse the clips with a

little deionized water

from a wash bottle, to

remove the electrolyte,

and immediately dry by

patting with paper

tissue. The whole cable

must then be allowed to

dry thoroughly (several

hours at least) before

reuse.

Never immerse any part

of the electrode cable in

water, or other liquid!

Color Electrode

Yellow Reference

Green Working

Red Auxiliary

Table 2–1

Color–coding on the

leads of the electrode

cable.

6eDAQ Potentiostats

is internally disconnected, so that an open circuit potential can be

monitored. On an EA161 Potentiostat the auxiliary lead (red) must be

disconnected for an open circuit potential measurement — if connected

to a third electrode (or test point) then a ZRA current signal will be

provided at E Out, Figure 2–3.

The Online Indicator

Located at the bottom right of the front panel is the Online indicator.,

Figure 2–1. When lit, it indicates that the software (such as EChem,

Chart or Scope) has located and initialised the Potentiostat. If the light

does not go on when the software is run, check that the Potentiostat is

properly connected. If there is still a problem, please refer to

Appendix B, page 85.

The Overload Indicator

Located on the left-hand side of the front panel is the Overload

indicator, Figure 2–1. When lit, this indicates that the Potentiostat is (or

has gone) out of compliance, which usually occurs because of an open

circuit or excessive resistance in the electrochemical cell. Higher

resistances can be often be encountered when electrodes are fouled by

the products of electrolysis reactions. The Potentiostat tries to

compensate by increasing the compliance potential (that is, the

potential between the auxiliary and working electrodes). If the

compliance voltage exceeds specification (about 11 V) potential control

of the cell is lost and drifting, or oscillation, of the signal can be seen.

Any data collected during this period is unreliable and should be

discarded.

The Overload indicator will light as soon as there is an overload and

will stay on until the recording has stopped.

If the indicator light comes on repeatedly, and your connections are

good, then try bringing your electrodes closer together, and/or

increasing electrolyte concentration, and/or modifying your

experimental conditions to avoid fouling of the electrodes. Redesigning

your electrochemical cell may be necessary. Normally cells are

designed to keep the reference and working electrodes very close

together, however, when a potential overload occurs, you also need to

consider the distance between the auxiliary and working electrodes.

Chapter 2 — The Potentiostat 7

Note that a potential overload is quite different from a current overload

condition. A current overload is caused when the current signal

exceeds the full scale limits of the range setting of the current channel,

and is usually caused by a low resistance between the electrodes.

The Back Panel

The back panel of the Potentiostat is shown in Figure 2–3.

BNC output

connectors

DB-9 pin, I2C connectors

4 mm socket,

ground connector

BNC input

connector

Digital Ground

Regulated –17 V DC

Regulated +8 V DC

Regulated +17 V DC

Power lines

SCL

DSC

SDA

DSD

INT

I2C control signals

Digital Ground

Regulated –17 V DC

Regulated +8 V DC

Regulated +17 V DC

SCL

DSC

SDA

DSD

INT

I2C control signals

Input Output

1

69

5 5

96

1

Figure 2–3

The Potentiostat back

panel.

Figure 2–4

The pin assignments for

the I2C DB-9 connectors.

8eDAQ Potentiostats

E Out, I Out and E In Connectors

The Potentiostat back panel has three BNC connectors labelled E Out,

I Out, and E In. The E In is connected to the Output of the e-corder,

usually Output + is used.Reverse the polarity of the Potentiostat by using

e-corder Output –.

The Potentiostat provides two signals: the current signal (I Out)

indicating the current flow between the working and auxiliary

electrodes, and the potential signal (E Out) indicating the potential

difference between the working and reference electrodes. Note that the

E Out signal is inverted with respect to the applied potential.

For most situations I Out is connected to e-corder input channel 1, and

E Out to e-corder input channel 2. However, when you are using Chart

software and recording data from various sources on more that just two

channels you may want to connect the Potentiostat to other e-corder

input channels.

I2C Connectors

The Potentiostat back panel, Figure 2–3, has two DB-9 pin ‘I2C bus’

connectors labelled Input and Output. The Input connector provides

power to the Potentiostat and carries the various control signals (for

gain range and filter selection) to and from the e-corder. A cable is

provided with the Potentiostat for this purpose. The pin assignments are

shown in Figure 2–4.

The Output connector can be used for the attachment of other eDAQ

Amps.

More information about the I2C connector can be found in your

e-corder Manual.

Grounding Connector

The Potentiostat back panel, Figure 2–3, has a 4 mm grounding socket.

This enables connection of a Faraday cage (with the green grounding

cable included with the Potentiostat) the use of which can greatly

diminish electrical noise. The Potentiostat is supplied with a green

WARNING!

The I2C connectors are

for the power and

control of eDAQ

Modular Potentiostats,

page 2, and should not

be used for connection

to any other device.

Chapter 2 — The Potentiostat 9

colored ground cable terminated with a 4 mm pin (attaches to

Potentiostat back panel) and an alligator clip (for attachment to

Faraday cage). If your Faraday cage is already earthed by its own

ground connection then you should not use this cable (otherwise a

second pathway to earth would exist which could result in a ‘ground

loop’ and increased signal interference! You can try grounding the

Faraday cage via its own connection to earth, or via the Potentiostat

ground cable — but not by both methods simultaneously.

The construction of the Faraday cage can range from a simple

cardboard box covered with aluminium foil, in which the

electrochemical cell is located, to a more sophisticated copper mesh

enclosure or sheet-metal box. But in all cases, it is essential that the

Faraday cage be electrically grounded to act as an effective shield

against electrical interference.

The Potentiostat itself is grounded via its connection to the e-corder unit

which is in turn earthed via the three pin mains power connector. It is of

course important that the power socket that you are using is well

earthed.

Connecting the Potentiostat

Your Potentiostat will have been supplied with an I2C cable (DB–9 pin

connectors at either end), and three cables with BNC connectors at

either end.

Potentiostat rear panel e-corder front panel

I Out Input 1

E Out Input 2

E In Output +

Potentiostat rear panel e-corder front panel

I Out Input 1

E Out Input 2

E In Output –

Table 2–2

Potentiostat to e-corder

connections as shown in

Figure 2–5 and Figure

2–6.

Table 2–3

Potentiostat to e-corder

connections, reverse

polarity.

10 eDAQ Potentiostats

First make sure that the e-corder is turned off. Then connect the I2C

cable to the I2C connector on the back panel of the e-corder, and the

other the other end to the I2C Input connector on the back panel of the

Potentiostat. Use the three BNC cables to connect the back panel of the

Potentiostat to the front panel of the e-corder as shown in Table 2–2.

With these connections, when you use the software to set a more

positive voltage, a more oxidising potential will be applied at the

working electrode.

Such an arrangement is shown in Figure 2–5 and Figure 2–6.

To operate the Potentiostat with the reverse polarity make the

connections as shown in Table 2–3. With these connections, when you

Trigger

Power

Status Output

Input 1 Input 3Input 2

Input 4

401

Overload

Potentiostat

Figure 2–5

The Potentiostat shown

connected to an e-corder,

front view, as described

in Table 2–2.

Figure 2–6

The Potentiostat shown

connected to an e-corder,

back view.

Chapter 2 — The Potentiostat 11

use the software to set a more positive voltage, a more reducing

potential will be applied at the working electrode.

Check that all connectors are firmly attached. Loose connectors can

cause erratic behaviour, or may cause the Potentiostat to fail to work.

The Potentiostat uses two e-corder input channels during normal

operation. The reminder of this chapter assumes that you have

connected the current signal to e-corder Input Channel 1 and the

potential signal to e-corder Input Channel 2. (It is possible when using

Chart or Scope software to connect the Potentiostat to other e-corder

input channels, in which case the description that follows would change

accordingly).

When using EChem software, Channel 1 is always set to be the current

signal (the I channel), and Channel 2 is automatically set to be the

potential signal (the E channel). Thus when using EChem software you

must always connect the current signal (I Out) to Input Channel 1, and

the potential signal (E Out) to Input Channel 2 of the e-corder.

Channel 2 normally displays the applied potential, and its settings are

controlled using the standard Input Amplifier dialog box, described in

the Chart Software Manual and Scope Software Manual which are

installed as pdf files in the eDAQ Documentation folder on your

computer hard disk.

First Use

After you have installed the software, connected the e-corder and

computer as described with the booklet supplied with the e-corder

system, and connected the Potentiostat as described above, you are

ready to begin.

When the e-corder is turned on, and Chart software started, the

Potentiostat Online indicator (green) should light.

From the Channel 1 Function pop-up menu, select the ‘Potentiostat’

command, which opens the Potentiostat Control window, Figure 2–7.

This window allows you to preview the current signal without actually

recording the signal to your computer’s hard disk. (If the menu says

‘Input Amplifier’ instead of ‘Potentiostat’ then the software has not

12 eDAQ Potentiostats

recognised the Potentiostat. Exit the software, check all your

connections and try again).

By default, the control window opens with the Potentiostat in Standby

mode, that is with the reference and working electrodes isolated so that

no current will flow through your electrodes. To connect to the

Potentiostat lead wires you must select Real mode. When you click

Cancel or OK the Potentiostat will revert to Standby mode until

recording is started.

Now select Dummy mode operation. You will need to adjust the gain

range to 20 μA to accommodate your signal amplitude. You can now

adjust the applied potential with the slider bar, or by entering the exact

potential with the A-button. The resulting current signal should obey

Ohm’s law:

I = E/R

so that an applied potential of 1 V should produce a current of 10 μA,

while other potential settings should produce corresponding currents.

Select Potentiostat in the

Channel pop-up menu

Signal display area

Drag ticks and

labels to adjust axis

Figure 2–7

Potentiostat controls with

Chart software.

Chapter 2 — The Potentiostat 13

Potentiostat Control Window

With Chart software, the Potentiostat Control window, Figure 2–7, is

accessed from the Potentiostat command in the Channel Function pop-

up menu. It control the various current ranges and filtering options for

the Potentiostat.

With Scope software, the corresponding controls are shown in Figure

2–8.

Modes of Operation

The EA161 Potentiostat can be operated in several different modes by

selecting the appropriate radio button:

• Potentiostat (Chart, Scope or EChem software), described below.

For three–electrode use connect the working (green), reference and

auxiliary (red) leads appropriate electrodes (or circuit test points)

The current signal is provided at I Out, Figure 2–3. The potential

signal is provided at E Out. When two–electrode potentiostat

operation is required the auxiliary and reference leads (red and

yellow) should be attached to the single ‘counter electrode’.

Use the Potentiostat button

Signal display area

Drag ticks and

labels to adjust axis

Pause/Resume

scrolling

Figure 2–8

Accessing the

Potentiostat controls with

Scope software.

14 eDAQ Potentiostats

• Galvanostat (Chart and Scope software), page 67. Connect the

electrodes as described for potentiostat operation, above. Note

especially that the potential signal is now provided at I Out, Figure

2–3. The current signal is provided at E Out.

• ZRA,zero resistance ammeter, (Chart and Scope software).

Connect the working (green) and auxiliary (red) leads to the two

electrodes (or circuit test points) across which to measure the current,

the current signal is provided at I Out. The auxiliary (red) lead is

earth return. The reference lead (yellow) can be connected to a

reference electrode (or circuit test point) to measure the potential

difference to the auxiliary (and working) leads. The high impedance

potential signal (if used) is supplied at E Out, Figure 2–3.

• High Z, high impedance voltmeter (Chart and Scope software).

Connect the working (green) lead to one electrode and the reference

lead (yellow) lead to a reference electrode to measure the potential

difference between the leads. The high impedance potential signal

is delivered at I Out. The auxiliary lead (red) can be connected to a

third electrode (or test point) to provide a ZRA current signal at E

Out, Figure 2–3.

Please make sure the electrode lead wires are connected appropriately

to your experiment, before operating in any of these modes. In

particular, incorrect placement of leads may damage the reference

electrode, if one is being used.

Signal Display

The current signal is previewed in the scrolling display area. Note that

the signal is not being recorded to hard disk at this stage, and that

when the window is closed the signal trace will be lost.

By using the Dummy or Real modes you can investigate the effect of the

Applied Potential, page 19, on the current signal.

You can stop/start the signal scrolling by clicking the Pause/Resume

button .

You can shift or stretch the vertical Amplitude axis to make the best use

of the available display area — similar to the amplitude axis in the

main Chart, Scope or EChem window.

NOTE. When using

early models of EA161

Potentiostat (serial

numbers 161-001 to

161-022) as a ZRA you

should connect the

working electrode lead,

and the cable of the

Grounding Connector

(page 8), to the two

electrodes (or circuit test

points) across which to

measure the current.

Chapter 2 — The Potentiostat 15

Setting the Range

Use the Range pop-up menu to select the input current range (channel

sensitivity). The Potentiostat has ranges of 100 mA to 2 nA, while

resolution within each range is 16 bits or 0.0015%. You should set the

range so that it is larger than the biggest current that you expect to

encounter during your experiment. If, during the experiment the current

signal exceeds the range, then the signal will go off scale and be lost.

Filtering

The Potentiostat incorporates four low-pass filters at 10 kHz, 1 kHz,

100 Hz and 10 Hz for removal of high frequency signals (‘noise’).

In addition the e-corder provides filter settings at 1, 2, 5, 20, 50, 200,

500, and 2000 Hz.

As a general rule the 10 Hz filter setting is highly effective for the

removal of mains hum (50 or 60 Hz interference) and should be

employed whenever possible. However, it should not be used for pulsed

amperometric, or voltammetric experiments, where the pulses are

shorter than 100 ms, or for experiments where rapid scan rates (greater

than about 100 mV/s) are used.

With Chart and Scope software, there is an additional Mains Filter

checkbox, . If this is ticked, then the e-corder will apply a

mains filtering algorithm to the incoming signal which removes

repetitive signals occurring at 50 or 60 Hz which are typical of mains

interference. Note that the mains filter is not a notch filter, and that it

can remove a 50 or 60 Hz interference even if it is not a pure

sinusoidal function. However, the mains filter does take a few seconds

to ‘learn’ the pattern of the interference so that you will need to record

for longer than this for it to take full effect. The mains filter can be

employed even for experiments in which there are sudden potential

jumps.

Inverting the Signal

The Invert checkbox, allows you to reassign the direction (up or down)

of an anodic (or cathodic) current. Please note that this affects the

16 eDAQ Potentiostats

display of the signal only — it does not reverse the direction of actual

current flow at the electrodes!

Cell Control

The Potentiostat can be in one of three cell modes, controlled by the

Cell radio buttons:

• Standby:If Standby mode is selected the electrode lead wires are

disconnected, and the internal dummy cell is connected. The

external (real) cell is not connected until the Potentiostat Control

window is closed and the Chart, Scope or EChem Start button is

clicked. This mode is used if you do not wish to alter the state of the

external cell until the method is actually performed. The Applied

Potential slider bar control is disabled in this mode.

• Dummy: the Potentiostat is connected to the internal 1 M¾ dummy

cell. You can then use the Applied Potential slider control to vary the

voltage applied to the dummy cell. The Potentiostat will remain

connected to the dummy cell even when the Potentiostat Control

window is closed and Chart, Scope or EChem is recording. This is

useful for testing the Potentiostat.

• Real: the external electrodes are connected to the Potentiostat. The

Applied Potential slider control, Figure 2–7 and Figure 2–8, can be

used to set the potential applied to the electrodes while the

Potentiostat control window is open. When you close the control

dialog (using EChem or Scope software) the Potentiostat will revert

to Standby mode until the Start button is clicked to begin a scan. If

you are using Chart software, the Potentiostat will remain in Real

mode when the dialog is closed — so that when you start and stop

recording data the electrodes will remain active. This allows

periodic recording of the signal from, for example, amperometric

biosensors without disturbing the environment around the electrodes.

High Stability Operation

If the High Stability box is ticked then extra capacitance is introduced

into the Potentiostat control loop. This stabilizes the Potentiostat in

situations where oscillation is encountered (for example where large

surface area electrodes are being used in highly resistive solutions).

Other manuals for e-corder

1

Table of contents

Other eDAQ Laboratory Equipment manuals