Page 6

E-BB14E&BB14G-I-0416

EQUIPMENT DEVELOPMENT CO., INC.

Safety Guidelines

Safety warnings and guidelines do not by themselves eliminate danger.

They are not substitutes for proper accident prevention procedures and good judgement.

Read and understand this Operator’s Instruction Manual,

and the Engine Manufacturer’s Owner’s Manual

before operating this equipment.

Death of serious injury can result if this machine is used improperly.

Eye and ear protection must be worn at all times while the saw is in use. During normal operation, sound

pressure levels exceed 85dBA. Use only ANSI approved safety glasses to help prevent eye injury. Standard

eyeglasses have only impact resistant lenses; they are NOT safety glasses.

Operator must wear appropriate clothing and footwear. Do not wear loose clothing or jewelry that can

get tangled in moving parts. Footwear should provide sure footing and protection from debris that may be

dropped. Take steps to insure hair will not be caught in moving parts. If necessary, tie it back.

•When loading or unloading the saw, use caution. Make sure rolling table is locked so that the blade will not

be damaged. Do not move the saw while the engine is running.

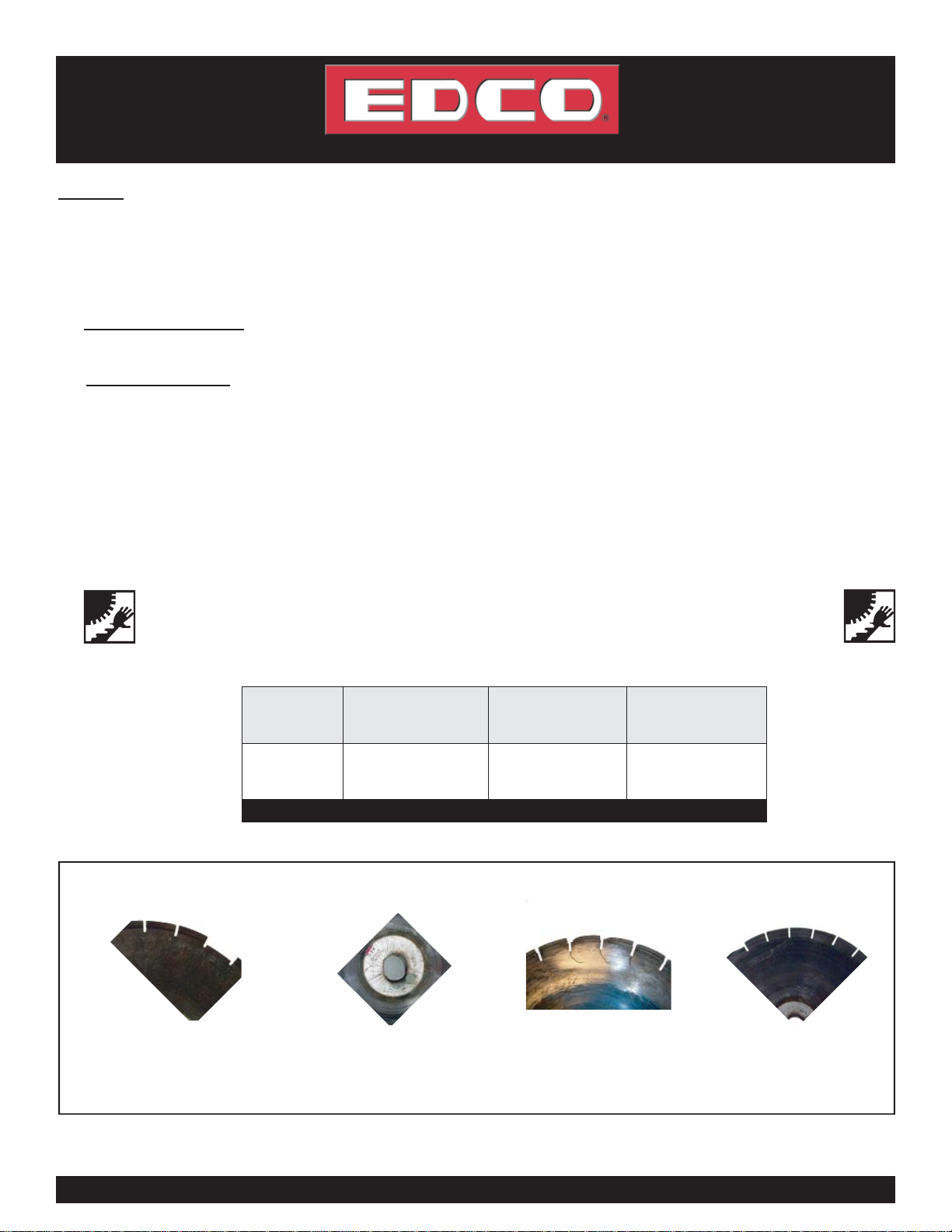

• Never exceed the maximum operating speed of the blade. Match the blade speed rating with the arbor shaft

speed. (See page 11)

• Never leave the saw running unattended.

• Never operate this saw under the influence of drugs, alcohol or when taking medications that impair the senses or

reactions, or when excessively tired or under stress.

• Do not lend or rent this equipment without including the Operator’s Instruction Manual and the Engine Manufac-

turer’s Manual.

• Make sure all safety decals can be clearly read and understood. Replace damaged or missing decals immeditely.

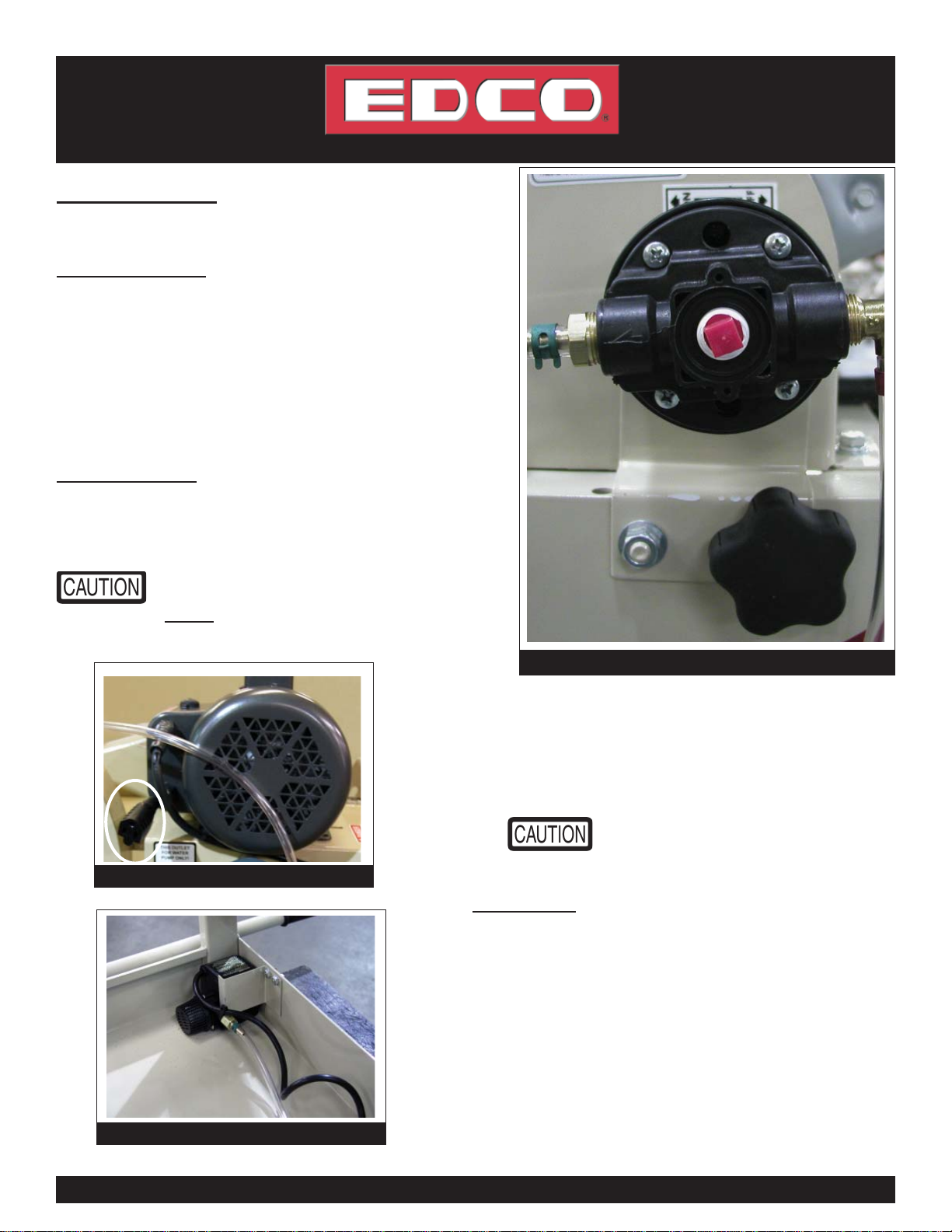

For Electric Models:

• Electric motor must be properly grounded at all times. Check the outlet box to be sure the electrical service is

properly grounded and that adequate power is available. Insufficient power will cause motor to overheat and burn

out. Use only grounded extension cords correctly sized for the current draw and voltage drop (amp rating and

length). Never use frayed, damaged, taped or under rated extension cords. Electrical shock could result in death

or serious injury and damage to the equipment.

For Gasoline Models:

• Poisonous exhaust gas. Do not operate gasoline powered equipment without adequate ventilation. Carbon

monoxide is an invisible, odorless gas that can kill. NEVER REFUELAN ENGINE WHILE IT IS HOT OR AN

ENGINE WHILE IT IS RUNNING. Only refuel in a well-ventilated area and only refuel after the engine has cooled

completely. Thoroughly cleanup any spilled fuel before starting the engine.

Dry cutting creates a large volume of airborne dust. For health reasons, the operator should wear an

applicable respirator. The dust may contain chemicals known to cause serious illnesses, including

Silicosis - a fatal disease of the lungs. Check the chemical properties of the material to be cut and

follow all EPA/OSHA regulations.