©

2007 Edelbrock Corporation

Brochure No. 63-641580

Catalog #641580, 541583, 641590, & 641593

Rev. 10/07 - AJ/mc

Page 3 of 4

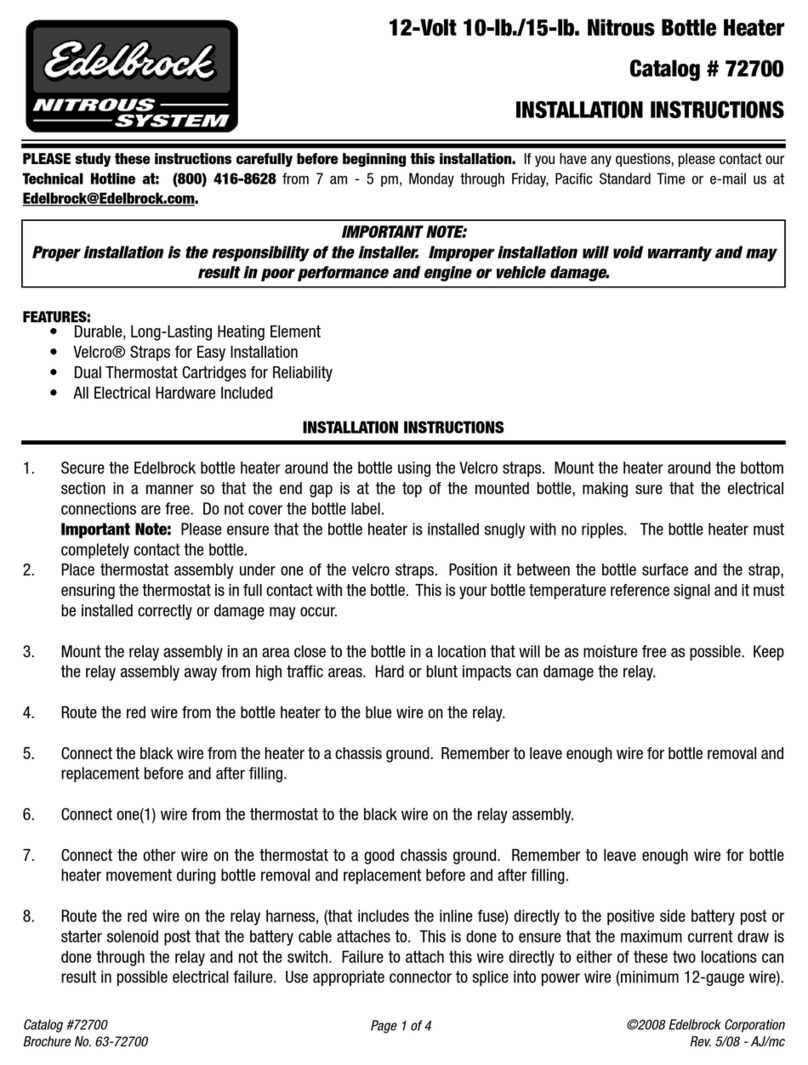

HOSE ASSEMBLY

10. Select appropriate Russell hose ends for each section

and temporarily screw them onto their respective

adapter fittings to determine hose length. Use supplied

Russell hose clamp with cosmetic socket cover to

attach hose to barbed hard line coming off fuel tank.

NOTE: Route hoses away from exhaust system and

hazards such as driveshaft, exposed electrical

connections (641580/641590 kit), and suspension

pinch points. Do not expose hose to road hazards by

routing below framerails. Also, some motorsports

sanctioning bodies have regulations on fuel hose

routing. Consult appropriate rulebook if vehicle will be

used in competition.

11. Mark supplied Russell hose at point to cut and wrap

hose over cut point with masking or strapping tape to

minimize fraying. Allow enough slack in length for hose

expansion, movement of components, and smooth

bends. Hold hose in vise and cut with a pneumatic

cutoff wheel, heavy-duty shears, or hacksaw. Cut hose

as straight and square as possible

(See Fig. 4)

.

Remove tape after cutting hose.

12. Unscrew red socket from hose end and hold in vise.

Push hose into socket, turning counter-clockwise, until

hose is seated on step in socket

(See Fig. 5)

. Make a

mark on hose at end of socket.

13. Apply assembly lube (motor oil, etc.) to threads on hose

end and in socket. Insert hose end nipple into

socket/hose and start threads by hand (clockwise). Turn

hose end with wrench until there is less than 1/16”

between nipple hex and socket

(See Fig. 6)

. Make

sure socket did not move on hose by observing mark

made in Step 16.

14. Repeat Steps 15, 16, & 17 for other end of hose.

15. Flush hose with solvent or hot soapy water and blow out

with compressed air or let air dry

(See Fig. 7)

. Install

hose. Use supplied cushion clamps and/or cable ties to

secure hose

(See Fig. 8)

.

FUEL PUMP RELAY

16. Mount Edelbrock fuel pump relay at suitable location

under hood (e.g. radiator support, inner fender, firewall)

away from extreme heat

(See Fig. 9)

.

17. Run one large (12 gauge) red relay wire back to red lead

wire on fuel pump. Wire can be routed underneath

along with other wires, hardlines, etc., or through

interior. A 10A inline fuse is recommended on this

circuit (not supplied). NOTE: Route wires so that any

possible cutting, chafing, snagging, pinching, or burning

from suspension, driveline, or exhaust components will

be avoided. Cover wires with supplied Russell Wrap-It

protective sleeve, and use supplied cable ties to secure

wires.

Fig. 4

Fig. 5

Fig. 6

Fig. 7