Catalog #6607

©2003 Edelbrock Corporation Page 2of 3 Rev. 12/03

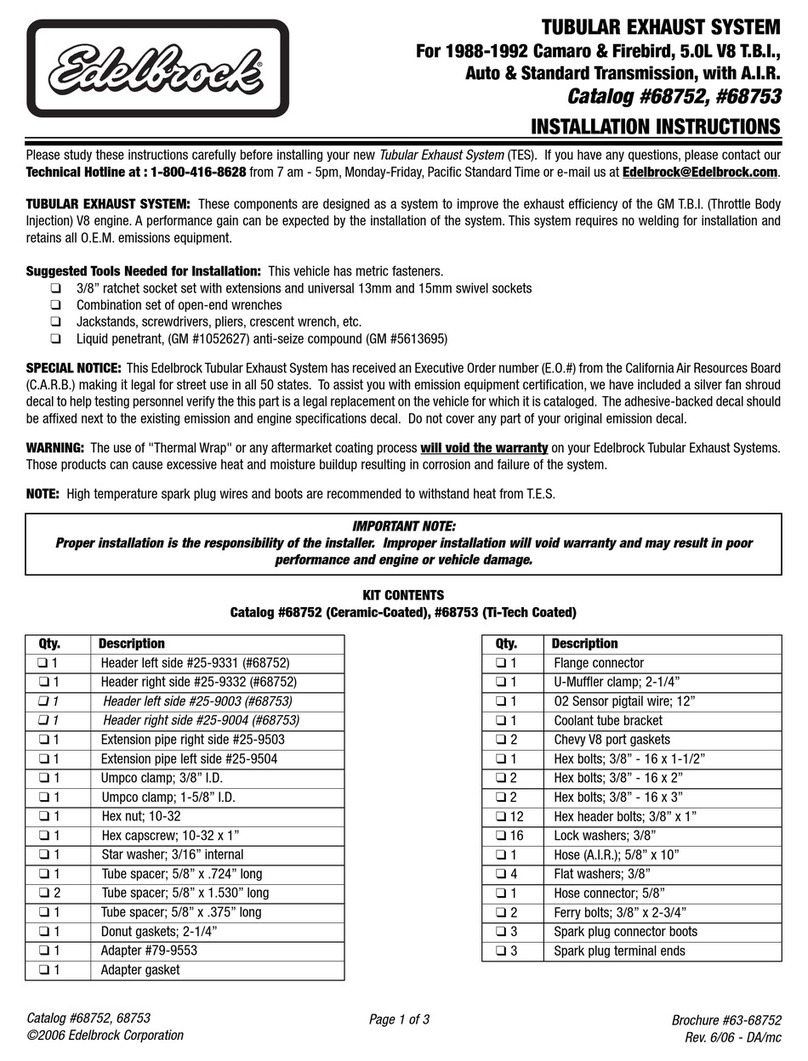

Disassembly

1. Disconnect negative battery cable.

2. Remove O2 sensor in front of catalytic converter. Be

careful not to damage.

3. Remove extension pipe. This is the pipe between

catalytic converter and crossover pipe. This may

require cutting of pipe. (See “Cutting

Instructions”).

4. Unbolt the EGR tube (if equipped), from left manifold.

5. Remove insulation from firewall behind crossover

pipe.

6. Remove throttle valve cable retaining bracket from

left side of engine and bolt holding cable to top of

transmission bellhousing (auto transmission only).

Remove the two-piece throttle valve cable retaining

bracket from the left side of engine and the bolt

holding cable to top of bellhousing. Lower half of

bracket will be re-used with T.E.S.

7. Unbolt and remove stock exhaust manifolds.

8. Remove stock crossover pipe. This pipe is removed

by rotating crossover around bellhousing toward

passenger side frame rail. It is a very tight fit so take

your time and do not try to force it out. Once the

lower flange is past the frame rail, the crossover

should come out through the bottom of the vehicle

between frame and engine. Installation of T.E.S. will

be easier if you remove the splined steering shaft

from steering coupler located on steering box. Be

sure when re-installing this shaft that your wheel is

straight and the coupler bolt is re-tightened properly.

Assembly

1. If your vehicle is not equipped with EGR, install the

supplied block-off plate, 8mm studs and EGR gasket

onto the EGR flange of the left header.

2. Clean gasket surface on cylinder heads. NOTE: Be

sure when installing left header, the collector heat

shield is toward the transmission.

3. NOTE: For Auto transmission, be sure throttle valve

cable is routed around the outside of the left header.

Install headers along with new gaskets and stock

manifold nuts, start all nuts onto studs evenly before

tightening. Then tighten all nuts evenly starting from

the center bolts and working your way out. NOTE:

The lower center nut on the left side may require the

use of an offset open-end wrench.

4. Use the 1/2” long spacer tube 8mm bolt and lock

washer supplied to hold dipstick tube bracket to

cylinder head, (Automatic transmission only).

5. From under the vehicle, install new T.E.S. crossover

and Y-pipe assembly using exhaust donut and bolts

supplied. Before tightening bolts, align crossover

and Y-pipe assembly with header flanges and

catalytic converter inlet. Check clearance at sway

bar. Top of Y-pipe/catalytic flange should be 1-3/4”

from the floor board heatshield. NOTE: See

“Welding Instructions” for 4-Runner.

6. After you have completed the installation of the Y-

pipe assembly, re-install O2 sensor into new Y-pipe

assembly. NOTE: On stick shift models, the parking

brake cable will need to be relocated. Remove the

nut holding the cable to the floor pan closest to

where the cable comes through the fire wall and

simple move to the stud just to the left of its original

location. Then use plastic tie wrap to hold clutch

slave cylinder flex line to parking brake cable (away

from left header).

7. Separate the upper and lower halves of the throttle

valve cable retaining bracket by removing the two

6mm bolts in the middle of the bracket (you will be

re-using these bolts). The zinc-plated bracket in kit

gets bolted to the lower half of the stock throttle

valve cable bracket using the two bolts removed

earlier and 6mm nuts supplied. Use Loctite. Next

install the zinc-plated bracket onto the EGR stud

closest to the firewall position.

Final Check

1. After all bolts have been properly installed and

torqued, re-connect battery cable.

2. Start car and check for exhaust leaks. DO NOT

DRIVE AT THIS TIME.

3. After letting engine fully warm up, shut off and let

engine fully cool down.

4. Re-tighten all bolts and nuts on T.E.S. headers.

NOTE: If your truck has an EGR system, install the

8mm studs along with new gasket onto the left

header. Then attach EGR to flange using supplied

8mm nuts and lock washers.

INSTALLATION INSTRUCTIONS