13. Remove crankshaft pulley, and using a suitable puller, crankshaft

dampener.

14. Remove two front oil pan bolts. Remove bolts securing timing chain

cover to block.

NOTE: Bolts vary in length and must be installed in same location as

removed. Pull cover forward until free of locating dowel pins.

NOTE: The front cover oil seal should be replaced before the front

cover is re-installed.

15. Remove fuel pump and fuel pump pushrod. Rotate engine until timing

marks are aligned as in Figure 2.

16. Remove bolts retaining camshaft sprocket. Remove sprocket and

chain.

17. Remove crank sprocket using a gear puller.

18. Remove camshaft.

• VALVE SPRINGS

WARNING ABOUT YOUR WARRANTY:

In order for this

Performer-Plus

cam and lifter kit to be covered under ANY

WARRANTY you must use either the correct Edelbrock

Sure Seat

valve

springs or the stock original equipment valve springs. Failure to do so

could cause the cam lobes to wear excessively and could cause addi-

tional engine damage.

1. This camshaft is designed to function either with the stock springs or

with Edelbrock

Sure Seat

valve springs #5832 (std. retainer set), or

for use with valve rotators, use #5932.

2. For older vehicles and vehicles with high mileage we highly recom-

mend replacing the valve springs with Sure Seat Valve Springs #

5832 (std. retainer set), or for use with valve rotators, #5932.

3. Check spring height and set to factory specifications for correct year

and model.

• DUE TO THE MANY POSSIBLE SETTINGS OVER THE YEARS, WE

ADVISE CHECKING MOTORS, CHILTON, OR FACTORY SERVICE MANU-

ALS FOR CORRECT SPRING HEIGHT FOR YOUR VEHICLE.

• LIFTERS

1. New lifters must be used with a new camshaft. Use only the lifters

supplied with your kit .

2. Check to make sure all lifters fit freely in lifter bores.

• INSTALLATION INSTRUCTIONS

1. Coat cam lobes and bottom of each lifter with MOS2 lube supplied

with your kit. This will prevent cam lobe and lifter wear from occur-

ring during initial engine start up. Do NOT pre-oil or "pump-up" lifters

before installation as this may hold valves off the valve seat leading

to loss of compression and/or bent valves during initial engine start

up.

2. Install new camshaft with new sprockets and timing chain.

CAUTION: When using

Performer-Link True Rolling Timing Chain and

Gear Set

#7818 with an Edelbrock cam and lifter kit, straight up tim-

ing alignment is achieved. If any other timing gear set is used, it is

necessary to check camshaft position for correct timing alignment.

This requires indexing the camshaft with a degree wheel to verify

timing alignment. O.E.M. or non-Edelbrock timing gear sets are not

recommended for use with Edelbrock camshafts. Use locking com-

pound material on bolt threads holding gear to cam. Torque to factory

recommendations (30 ft./lbs.).

3. Install camshaft with timing marks lined up as recommended by fac-

tory specifications. See Figure 2.

• PUSHROD AND ROCKER ARM INSTALLATION—After the cam is

installed and timed correctly (see Figure 2), install pushrods, lifters and

rocker arms.

• VALVE ADJUSTMENT

1. Rocker arm adjustment is 0 lash. Install push rods and rocker arm

assembly and tighten rocker arm nuts on early models and bridge

cap screws on late models. NOTE: On late models, alternately tighten

cap screws one turn at a time.

• FRONT COVER OIL SEAL REMOVAL & INSTALLATION

1. For front seal removal, pry seal out from the inside of the cover.

Clean seal bore and apply light coat of suitable sealer such as

Edelbrock Gasgacinch #9300 to outer surface of new seal. Drive seal

into place from inside cover using suitable tool. When seal contacts

outer flange of cover it is installed correctly. Apply a light film of

engine oil to lips of neoprene seal.

• INSTALL FRONT COVER

1. Remove lower locating dowel pin from engine block and clean all

gasket surfaces.

2. Cut both sides of oil pan gasket flush with engine block. Using old

gasket as a guide, trim new gasket to correspond to amount cut off

at oil pan. Apply suitable sealer such as RTV Silicone sealant to both

sides of gasket and install on engine front cover.

3. Install front oil pan seal and align tongues of new oil pan gasket

pieces with seal and cement into place on cover. Apply suitable seal-

er to cut-off edges of original oil pan gaskets and place cover into

position, then install two front oil pan bolts. Tighten bolts slowly and

evenly until cover aligns with upper locating dowel. Install lower

dowel through cover and drive into corresponding hole in engine

block. Install cover retaining bolts in same location they were

removed from and tighten.

5. Torque front timing cover bolts to 25 ft. lbs.

6. Install front harmonic balancer and torque to 80 ft.-lbs,.

7. Install fuel pump and pushrod.

8. Install water pump using new gaskets and torque to 4 ft.-lbs.

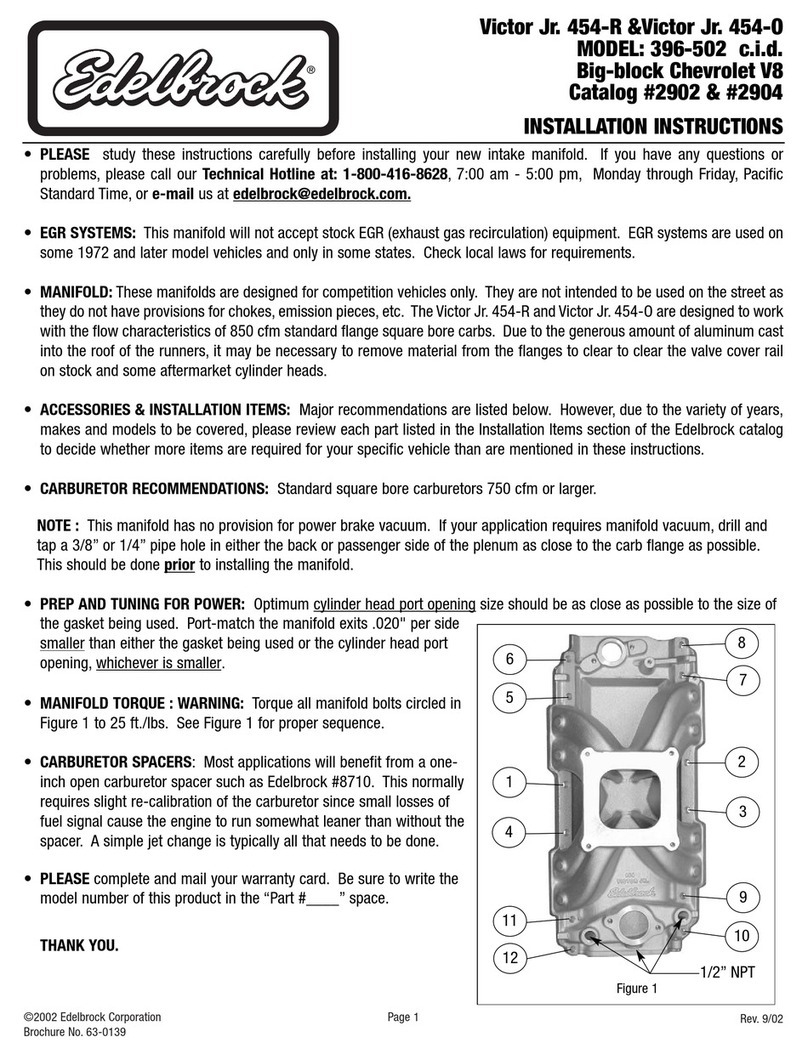

9. Install intake manifold using new intake gasket set and torque bolts

to 25 ft/lbs.

• DISTRIBUTOR INSTALLATION AND ENGINE TIMING

1. Turn the engine over in direction of rotation until the No. 1 intake

valve closes and continue until the pointer on the front cover is

approximately five degrees before top dead center (BTDC). See Figure

1 for firing order.

2. Re-install the distributor with the rotor pointing towards No. 1 termi-

nal in the cap, and with the distributor housing in its original position.

If distributor will not drop down all the way to the flange on the

engine, it will be necessary to align the distributor shaft with the oil

pump drive. Slowly rotate the engine until the distributor drops down

against the engine, then continue turning until two complete revolu-

tions are completed and the timing marks once again come to five

degrees BTDC.

©2008 Edelbrock Corp. Rev. 9/08 - AJ/mc

Brochure #63-2132