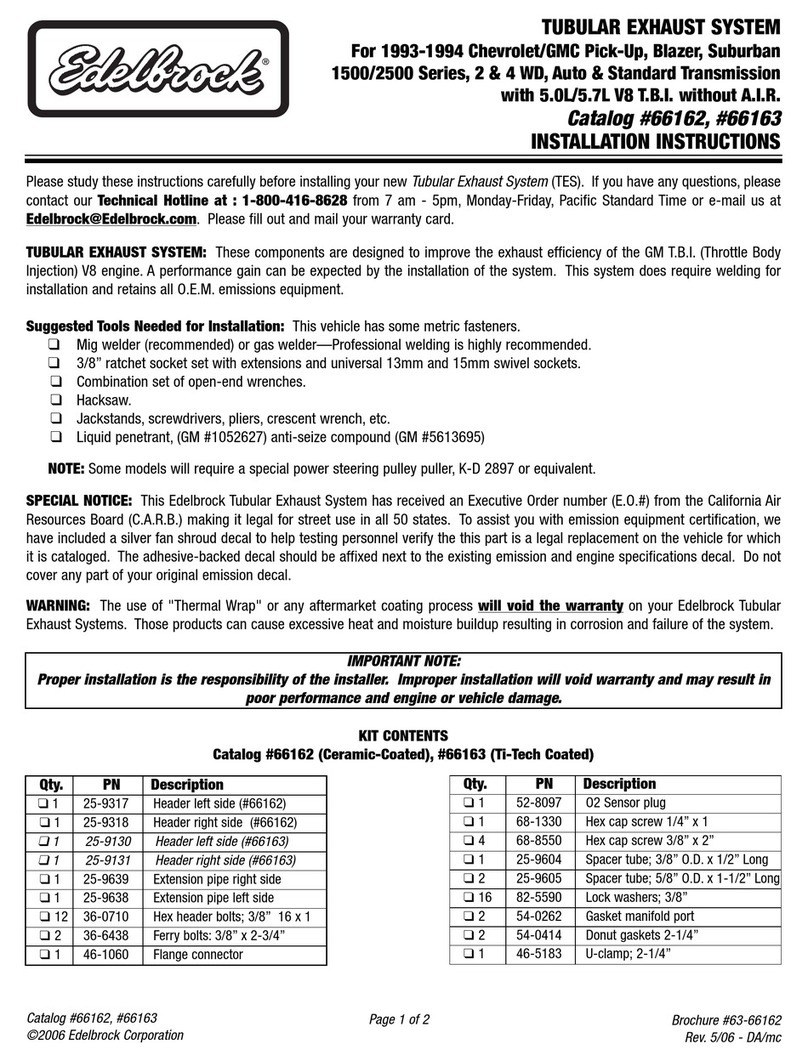

©2003 Edelbrock Corporation

Catalog #6893 ᫮ Page 2of 3 Rev. 1/03

DISASSEMBLY AND ASSEMBLY

Right Side

1. Disconnect and remove alternator.

2. Remove spark plugs.

3. Disconnect A.I.R. fitting from manifold.

4. Remove dipstick and tube assembly.

5. Unbolt E.G.R. flange from manifold (#6894 only).

6. Remove manifold.

Note: At front of cylinder head are two manifold

boltholes. Forward hole will be used to re-attach

alternator support bracket. Hole #2 will be used to

secure your new T.E.S. manifold.

7. Install T.E.S. flange gasket and one 3/8-16 x 1” bolt,

lock washer and flat washer at rearmost bolthole

(leave bolt loose enough to accept T.E.S.).

8. Place manifold into position from underneath

vehicle and start one bolt at front.

Note: Use flat washers at slotted ends and lock

washers on all bolts.

9. Using 1-1/8 long spacer tube, 3/8 x 2-1/4 12-point

head cap screw and 3/8 lock washer, re-attach

alternator support bar to forward bolthole in

cylinder head (do not tighten).

10. Install all manifold bolts and tighten.

11. Re-attach E.G.R. tube (#6894 only).

12. Re-install spark plugs and wires.

Note: Alternator and dipstick tube must be

removed for future spark plug changes.

13. Re-install alternator and A.I.R. fitting. Use A.I.R.

adapter fitting and kit, if necessary.

14. Re-install dipstick tube.

15. Take wire pack (wrapped with aluminum tape) out

of plastic clip on crossmember and re-position

toward front of vehicle for additional protection

from heat. Use tie wrap (in kit) to secure.

Left Side

1. Remove spark plugs.

2. Unplug temperature sensor wire connector.

3. Remove plastic cover around lower steering shaft.

Steering shaft must be removed for installation of

T.E.S.

4. Remove by unbolting at top of upper universal joint

andbottom oflower universaljoint. Slip upperjoint

up steering shaft while sliding lower joint off

steering box serrated shaft.

5. Disconnect A.I.R. hose.

6. Remove exhaust manifold.

7. Install T.E.S. flange gasket and one 3/8”-16 x 1”

bolt, lock washer and flat washer at rearmost

bolthole (leave bolt loose enough to accept T.E.S.).

8. Place manifold into position from above. Start all

manifold bolts, and washers, then tighten.

9. Replace steering shaft and plastic cover.

10. Replace water temperature wire.

11. Replace spark plugs and wires.

12. Re-install A.I.R. fittings (use A.I.R. adapter fitting in

kit, if necessary).

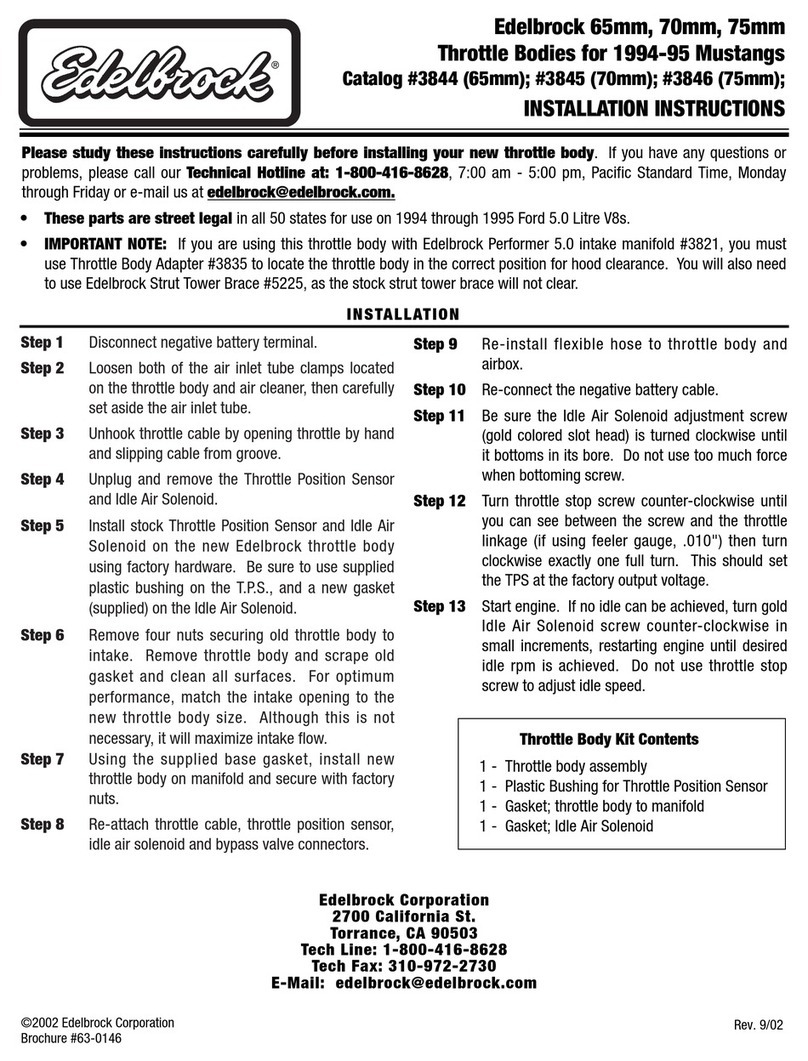

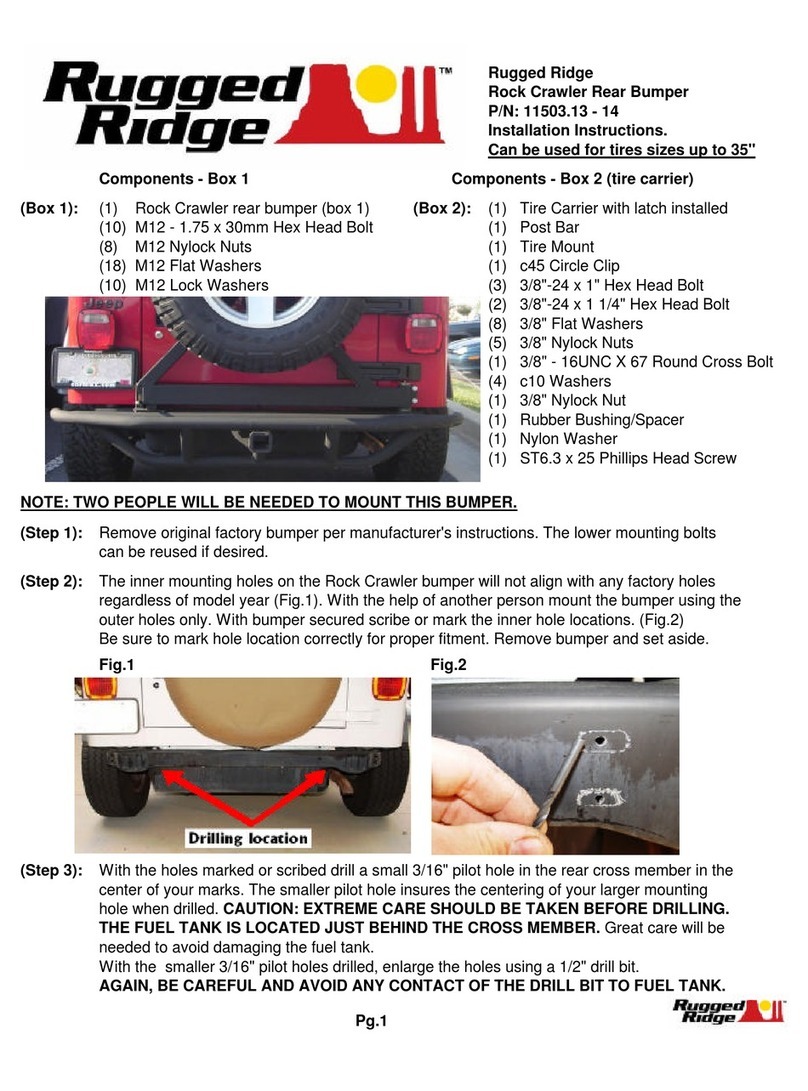

1. Disconnect negative battery cable.

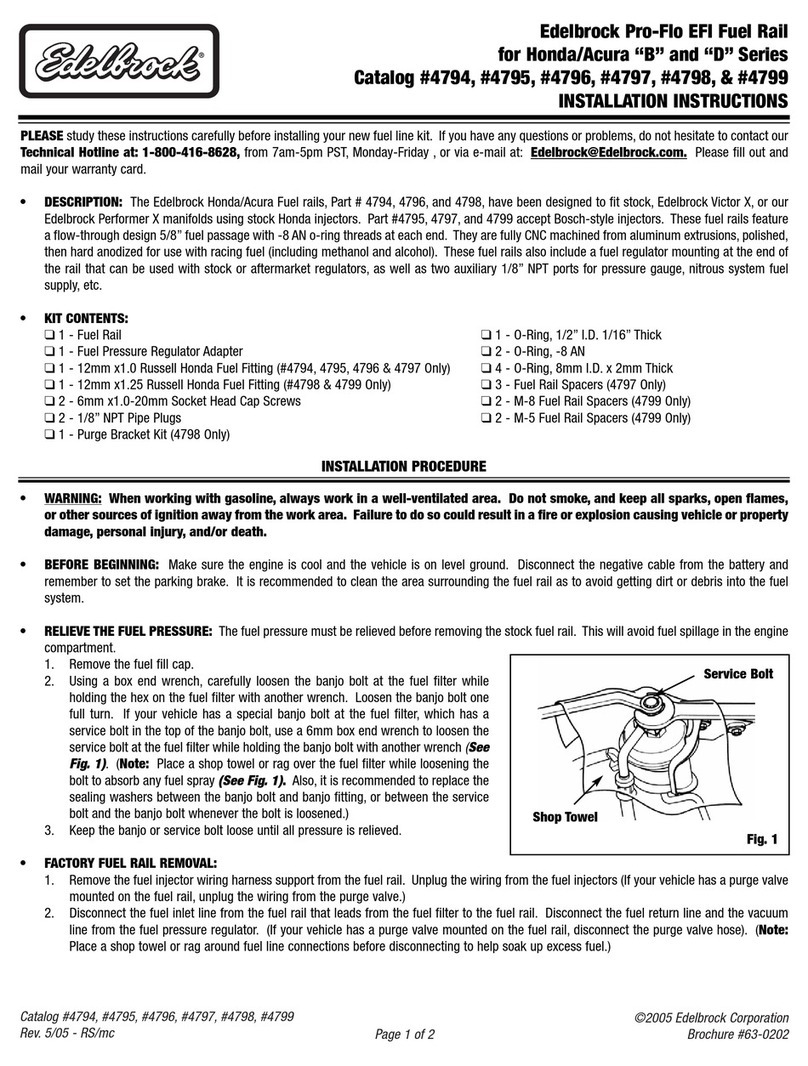

2. Raise vehicle and remove O2 sensors from right and left sides being careful not to damage.

3. Unbolt and remove exhaust pipe/catalytic converter assembly. Before removing exhaust pipe/catalytic converter

assembly determine the position of catalytic inlet for re-installation. Either note measurements or mark bottom of

floorboard with chalk to show catalytic location (Do not damage converter).

INSTALLATION INSTRUCTIONS