EDG C1 User manual

Centrifuge C1

01

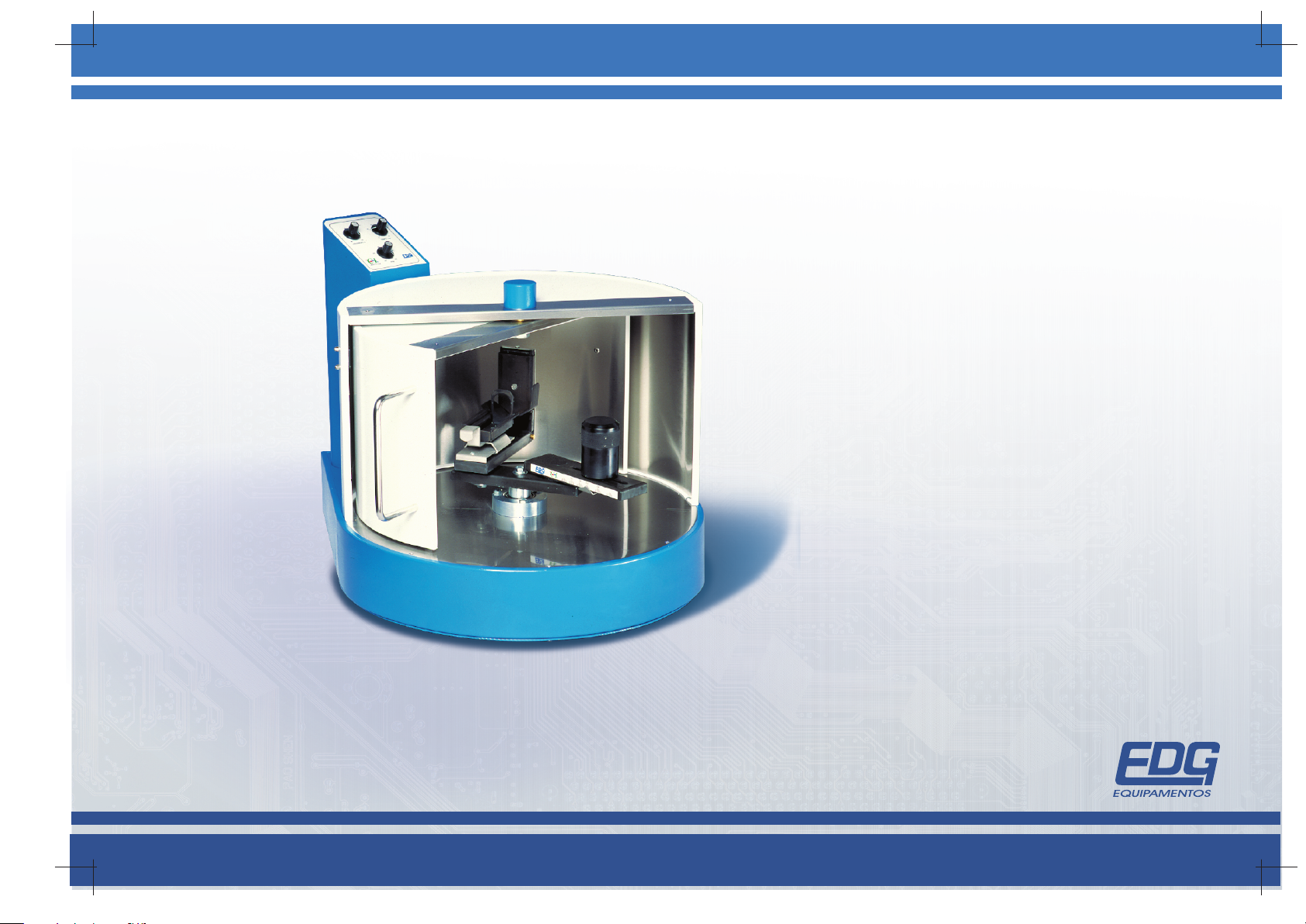

EDG MOD. -C1 Centrifuge

INSTRUCTION MANUAL

EDG EQUIPAMENTOS thanks for your preference. We describe the procedures for the proper

installation, operation and utilization of the available resources in your EDG - CI CENTRIFUGE.

The technological advances have provided new materials and revolutionary techniques to the

professionals of the prosthesis area, however, the old spring centrifuge continues the same of

100 years ago.

The was designed to provide conditions that allow a loyal model reproduction,

responding to the requisites of efficiency and security to the professional.

To better use your equipment it is necessary to consider some factors that influence in the good

filling of the model (ring).

EDG – C1 Centrifuge

PRESENTATION

02

The metal must be injected in the ring the fastest and softest as possible, avoiding chocks

and turbulence.

In the this is reached by the set of the articulated arm and the electronical

start sensor. Together they smooth the initial movement, allowing that the liquid metal flow fill in

the ring cavity without any turbulence, which is a cause of coating erosion.

EDG – C1 Centrifuge

Casting pressure

Permanence of casting pressure until the total metal solidification

Parameters settings, according to the utilized metal

The old spring centrifuges when started reach the maximum rotation that decreases gradually

during the time. In this process the pressure is in excess in the metal inlet and not enough during

its solidification, causing coating erosion at the start and the formation of depression on the

casting piece.

In the the rotation reaches the ideal value and keeps in this rotation until the

total solidification of the metal; as a result, we have a reliable casting to the model, without

bubbles and especially, without depressions, which are the most difficult ones to correct.

EDG – C1 Centrifuge

To keep the casting pressure according to the acceptable values, the working rotation must be as

bigger as smaller the density of the utilized metal is.

The start acceleration control allows that total security independent on the volume (weight) of the

metal to be cast is obtained. For small volumes the acceleration must be high and for large volumes

the acceleration must be lower in order that the metal flux in the feeding canal of the ring be allowed.

The centrifuging time control minimizes casting errors. It keeps the casting pressure until the total

solidification of the metal.

03

Casting pressure

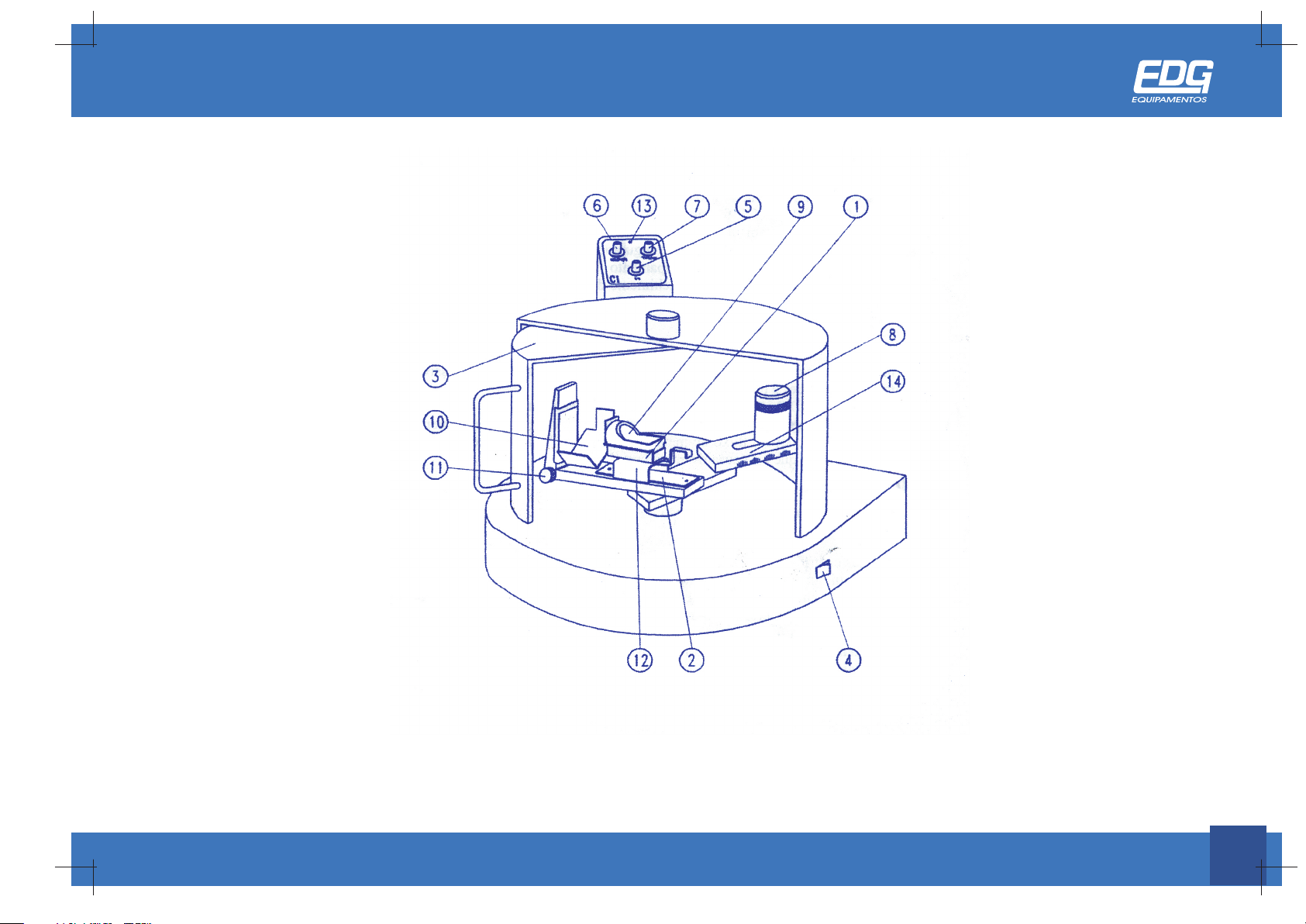

FIG. 1

04

The security is no doubt the most critical item related to casting with spring centrifuge.

In the all the care to keep the security to the user was taken.EDG – C1 Centrifuge

(The numbers between parenthesis refer to fig. 1)

Install your in a very ventilated local, on a table or workbench. We suggest

as ideal place a brick-built workbench.

Install the equipment in such a way that facilitates its handling with the soldering pipe and the

ring furnace. Preferentially, use an automatic lighter with support, like , thus, you will

have a free hand to regulate the soldering pipe.

The leaves the factory to operate in 200 volts.

In case of 110 volts, with a screwdriver, change the tension switch placed in the backside of the

equipment to 110 volts (in order to achieve this operation it is necessary to lay down the equipment).

In the electrical installation we suggest the use of a 6mm2 wire for 110 volt network and 4mm2

wires for 220 volts. .

For your own security, do not forget to connect the grounding terminal to the proper grounding.

EDG - Cl Centrifuge

BINGA EDG

EDG - Cl centrifuge

Never use the network neutral as grounding.

1 – The centrifuge only starts after closing the protection.

2 – If, during the casting, the protection is opened inadvertently, the process will be aborted.

3 – Fast deceleration.

4 – Exclusive ring fixing that avoids the rolling of it.

5 – Ring height easy setting.

6 – Approximating device of melting pots.

7 – Exclusive balance system.

Security

Installation

05

The leaves the factory ready to operate with American- type melting

pots. If the user prefers the German- type ones, unscrew the screws that fix the melting pot’s

rack (1) to its support (12) and substitute it for a German- type rack, which comes with the machine.

EDG - C 1 Centrifuge

16 a 18 350

13 a 15

11 a 14

7 a 10

Open the protection (3) rotating it to the left.

Turn on the general switch (4) placed in the right side of the equipment base.

The pilot lamp (13) will light.

Set the casting checking the table –1.

Operation

Procedure

table –1

METAL TYPE

NOBLE METALS

CERAMICS GOLD

YELLOW GOLD

LOW FUSION

SEMI-PRECIOUS

AVERAGE DENSITY gr/cm INDICATED ROTATION RPM

400

425

450

3

PALLADIUM ALLOYS

NICKEL-CHROMIUM

BASALT CHROMIUM

NON-NOBLES METALS

06

0..................25

10..................20

100

20 10

26..................45

46......................

90

30

80

40

the (7) is the time in which the casting metal must be under pressure until its

total solidification. Several parameters influence the solidification time: ring type, coating type and

volume, alloy features, molding design, metal weight, casting temperature and etc.

The ideal centrifuge time that practically attends to all the cases is around 20 to 40 seconds. A good

parameter is the metal weight.

The table-3 below suggests values.

centrifuging time

adjust in the panel the key (6) using the criteria established in the table -2acceleration

21..................

Table -2

Table -3

METAL WEIGHT (GR)

METAL WEIGHTTIME SEC.

ACCELERATION

%

07

Counterweight setting EDG - C1 CENTRIFUGE(8): the exclusive arm design (2) of the compensates

small balance errors, letting this operation easy and simple to be executed. 4 rings come with

the centrifuge having the following sizes: 1x, 3x, 6x, 9x. In the equipment arm there are marks (14)

that indicate the counterweight position for each one of the rings above. Remove the counterweight

(8) by rotating it from the right to the left. Place it in the position relative to the used ring. Tighten the

counterweight (8) rotating it from the left to the right. To obtain the fixation of the counterweight (8) just

tighten it softly and a locking device will fixate it in the required position. For the use of rings of different

sizes from the ones provided with the equipment, it is necessary a previous test to check in which position

of the counterweight (8) it is obtained the best balance.

We will start the casting after setting all the parameters.

Take the support of the melting pot rack (12) in the direction of the center of the centrifuge arm.

Using a pincer adjust the melting pot (9) previously heated to the rack (1).

Put metal in compatible amount with the work to be executed in the melting pot (9) and heat it

with the EDG soldering pipe.

When the metal is melted, remove the ring from the furnace with a pincer and put it on its rack (10).

Adjust by means of the elevator (11) the height of the ring in such a way that the ring center be

the same as the melting pot outlet orifice.

Still using the pincer, approximate the melting pot support (12) to the ring.

When the metal is ready to melt, remove the soldering pipe quickly and rotate the protection from

the left to the right until it closes totally.

The centrifuge will automatically start and will be rotating until the end of the determined time. An

alarm will be sounded and the melting will be finished.

After the total stop of the centrifuge arm, open the equipment protection (3).

The equipment will be ready for a new melting.

08

Safety warnings

Problems & solutions

Don’t forget to connect the grounding wire.

Always calculate the amount of metal in relation to the size of the piece. Excess causes the

launching of melted metal that can damage the equipment.

Avoid keeping melting pots, rings, etc. inside the centrifuge compartment.

If they are forgotten there they will be launched in high speed causing serious damages.

When you finish a series of castings, turn off the general switch before closing the protection.

Avoid activating the equipment without melting pot or ring; it will be totally unbalanced.

The inferior lid of the equipment base can only be opened by authorized people.

The EDG Equipamentos will always be ready to attend you in case your centrifuge needs settings

or repair. However, even if the equipment is under warranty, before asking for technical assistance

check if the problem doesn’t have a simple solution. This can avoid waste of time and unnecessary

removal of the equipment.

Problem

Causes & solution

If the equipment, even being with the general switch on, does not light the pilot lamp and does not work.

Poor contact in the electrical outlet. Check if the outlet is well connected and if the electrical

network is energized.

09

Problem

Causes & solutions

If the lamp lights but the equipment works very slowly or in an irregular way.

Your electrical network tension is below the minimum allowed tension or the equipment

is selected in 110 volts and the commuter switch is in the 220 volts position. Check the

network tension and the commuting switch.

Problem

Causes & solutions

If the equipment vibrates too much.

The table on which the equipment is installed is too weak (unstable) causing the spring

effect. As a test put the equipment on the floor and turn it on.

If the vibration stops, use a stronger base.

Check if the position of the counterweight is according to the ring. Take testes varying the

position of the counterweight.

Check if the arm articulation is nor locked by accumulation of dirty or metal remaining. Clean

the articulate joint of the arm.

Check if the network tension is below the specified.

Problem

Causes & solutions

If the protective lid scratches when closed or the equipment does not work.

Metal or coating remainings are accumulated between the protective lid and

the equipment base, not allowing the free working and the total closing of the protection.

10

Problem

Causes & solution

If the ring tends to get out of the position and the metal is injected out of it

.

The ring is not fitted properly in the melting pot.

The melting pot extremity that is adapted to the ring is broken or defective.

Nominal supply sources - 110 or 220 volts (commuter)

Admissible minimum and maximum tensions - 100, 130 for nominal 110 volts

205, 230 for nominal 220 volts

Start current - 20 amp. 110 volts

10 amp. 220 volts

course current - 2,6 amp. 110 volts

1,3 amp. 220 volts

course consume - 290 watts

Network frequency 50/60 hzo

Timer from 5 to a 45 sec 15%

Rotation from 350 to 450 rpm. 5%

Dimensions (cm.) width 54 height 46 depth 57

Weight- 33Kg

Accessories - 4 rings carbon steel (lx, 3x, 6x, 9x)

- 1 base for melting pots

- Instruction manual

- warranty certificate

Technical assistance

São Carlos SP - Tel. 55 (I6) 3375-7720 * industry

Other localities call the telephone above.

Specification

Industry:

Rua Eduardo Gobato, nº 300

Bairro CEAT CEP: 13.573-440

Caixa Postal - 2096

São Carlos SP Brazil

Phone / Fax: 55 (16) 3377-9600

Sales:

Phone: 55 (11) 5051 - 5043

www.edg.com.br

Other EDG Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

WPI

WPI Z-LITE instruction manual

Weinmann

Weinmann ACCUVAC WM 15261 Description of the equipment and instructions for use

Gilson

Gilson MyPipetman user guide

TSI Instruments

TSI Instruments AEROTRAK 9310 Operation manuals

VERDER

VERDER Carbolite Gero HT 5/95 Installation, operation and maintenance instructions

Hettich

Hettich EBA 21 Series Repair instructions