Page 2/33

INDEX

1Introduction ..................................................................................................3

1.1 Safety information.............................................................................................................................3

1.2 Warranty............................................................................................................................................5

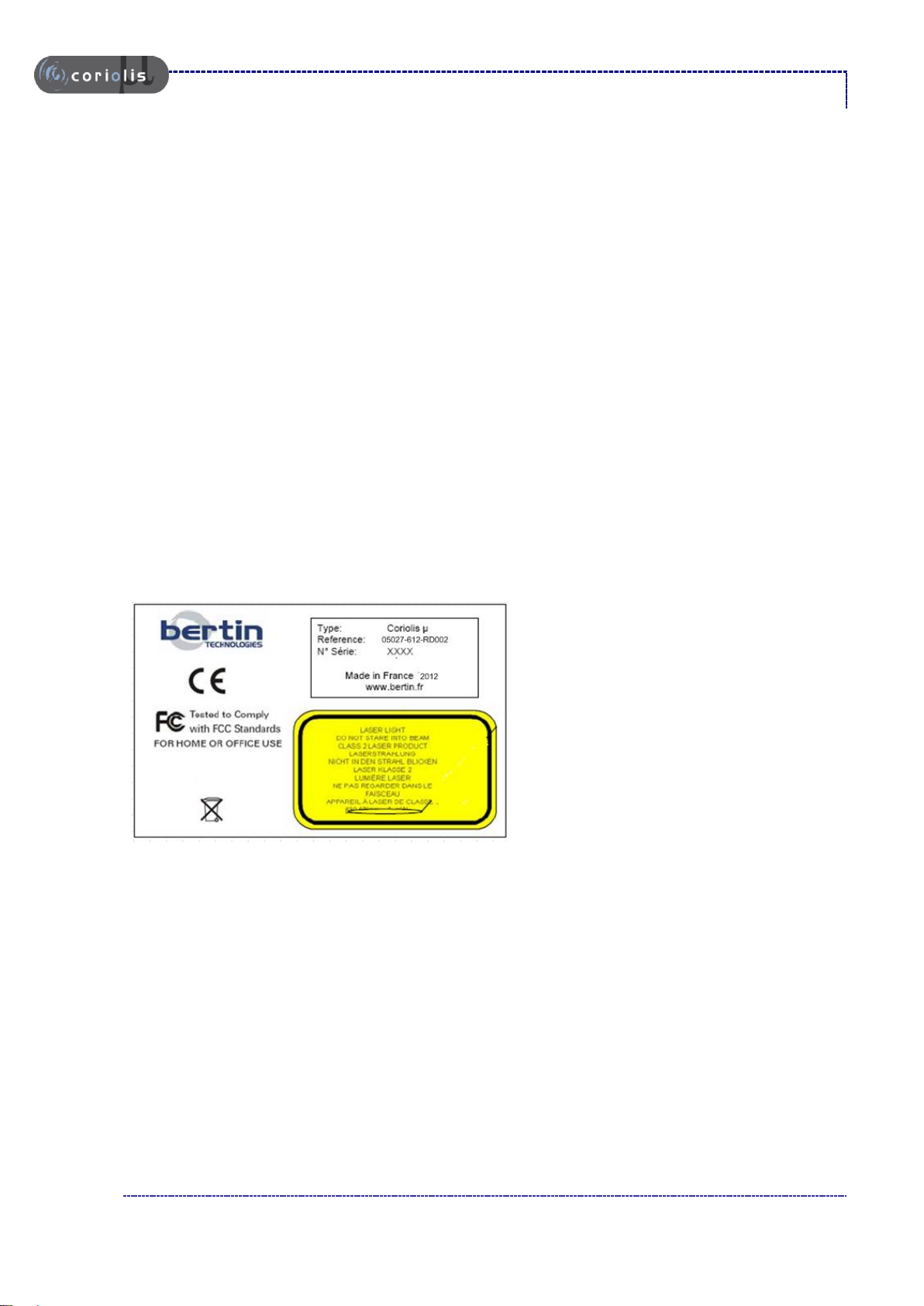

1.3 Manufacturer information..................................................................................................................5

1.4 Technical support..............................................................................................................................5

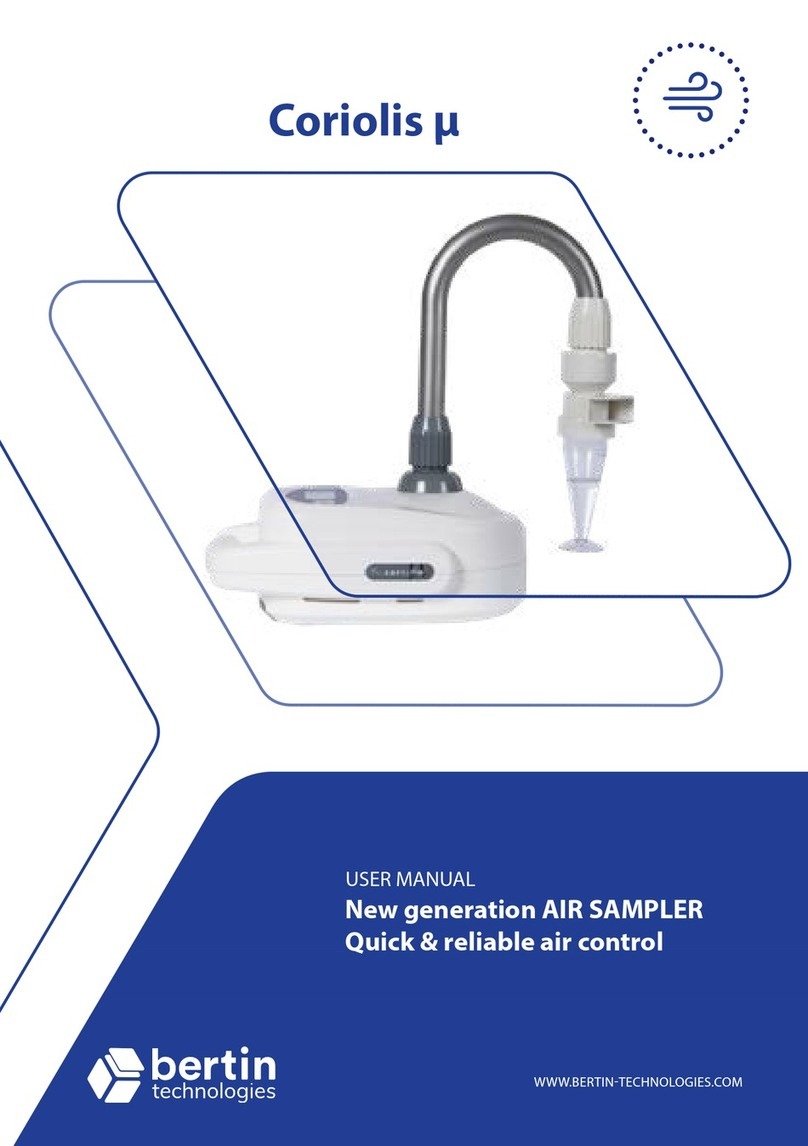

2Description of Coriolis®µ Air Sampler........................................................6

2.1 Product overview...............................................................................................................................6

2.2 Presentation of the Keypad...............................................................................................................7

2.3 Setting...............................................................................................................................................7

2.4 Technical features.............................................................................................................................8

2.5 Operating principle............................................................................................................................9

2.6 Normative requirements....................................................................................................................9

3Transport / Storage ....................................................................................10

3.1 Transport........................................................................................................................................ 10

3.2 Storage........................................................................................................................................... 10

4Installation ..................................................................................................11

4.1 Unpacking...................................................................................................................................... 11

4.2 Assembling..................................................................................................................................... 11

4.3 Recommendations......................................................................................................................... 12

5Instructions for use....................................................................................13

5.1 Turning on the equipement............................................................................................................ 13

5.2 Auto-tests....................................................................................................................................... 13

5.3 Using parameters for “stand alone” mode ..................................................................................... 15

5.4 Using parameters for “long time monitoring” mode ....................................................................... 19

5.5 Run failure...................................................................................................................................... 25

5.6 Battery supply ................................................................................................................................ 26

5.7 Administrator Menu........................................................................................................................ 27

6Flow Control Option...................................................................................28

6.1 Flow Control Option overview........................................................................................................ 28

6.2 Using the flow control option.......................................................................................................... 28

6.3 Maintenance of the flow control option .......................................................................................... 29

7Cleaning & decontamination.....................................................................30

7.1 Routine decontamination / sterilisation.......................................................................................... 30

7.2 H2O2: vapour peroxide hydrogen decontamination....................................................................... 30

7.3 Maintenance................................................................................................................................... 30

8References list............................................................................................31

Annexe 1 : Example of a flow control report ........................................................................................... 32