EDG sinter press alumini User manual

Manual

Manual 01

Date of manufacture

200

Serial number

1Recepting

Theequipmentispackedseparatelyfromthevacuumpump,checkifyouhavetwo

boxes if you have acquired the furnace and the pump. Check the general

conditionsof thepackage, ifany damageis noticedcontact theshipping company.

We remind you that the equipment is shipped at the purchaser's account and risk

anditisinsuredbytheshippingcompany.

Furnace with Triple Function

Manual 02

1.1The Sinter Press package should include

A)Afurnacesettledininjectedfoam

B)AspoolforconventionalceramicPic4-Item-15;

C)Aspoolforpressedceramic.Pic-5-item-19.

D)Arigidmat–Iforceramic.Pic-4-Item-17.

E)Arigidmat–IIforsinteringPic-4-Item-16.

F)Asoftmat.

G)ArefractoryplatformforpressedceramicPic-5-Item-20.

H)Aseethroughrefractoryplatformforceramic.

I)Asetofisothermalpins.Pic-4-Item-18.

J)Three1.5mhosesN.A.T.

K)Metallicclamps.(6pieces).

L)Instructionmanual.

M)Warrantydocument.

1.2The vacuum pump package should include

A)Thevacuumpump

B)Rubber,floorinsulatingcapsforfixation(4pieces).

C)Connectorsidentificationlabels

2S.A.L.V. System

Your Sinter Press has highly technological devices that allow it to perform 4

functions perfectly: traditional ceramic burn, pressed ceramic, sintering and

infiltration of alumina composites. When sintering alumina, the lining used heated

over 500º C releases sub-products which are absorbed by the muffle under

vacuum and can contaminate the ceramic, staining and fissuring it during the

sinteringprocess.

Long periods under high temperatures (1,200°C) in pressurized chambers

(vacuum muffles) can shorten the heating resistance useful life. The S.A.L.V.

systemwasspeciallydevelopedtoovercomesuchproblems

Manual 03

Sistema de aquecimento de longa vida.

(Long Life Heating System)

Two years guarantee at high temperatures.

The metallic alloys used as heating resistance have chemical elements in

itscompositionthat, when heatedandin contact withair, create anoxideadherent

layerwhichprotectsthemfromoutwear.

In ceramic furnace muffles, the process for the oxide layer formation can

beimpairedduetotheresistanceimprisonmentandtothevacuumoperation.

The exclusive S.A.L.V. system, developed and patented by EDG,

promotes airflow inside the quartz pipe that supports the muffle resistance. This

flow renews and maintains the protective oxide layer, increasing the useful life of

theresistanceathightemperatures.

This exclusive technological advance allowed EDG to extend the

guaranteeto2yearsforthefurnacesequippedwiththissystem.

To endure the high temperatures involved in the processes, the sensor

(termopar) should be made of platinum which, on the other hand, is not adequate

for low temperatures and for the necessary speed for eliminating water during the

sintering process. High level software was developed to compensate the platinum

limitationsinlow temperatures. Due to the characteristicsofthe sintering process,

new thermal insulating materials were used and an efficient ventilation system

keepsthecomponentstemperatureunderadequatevalues.

3Main Characteristics

• Quartz muffle with thermal insulation ceramic mat molded through low thermal

massvacuum,whichinsuresperfecttemperaturehomogeneity.

The exclusive system S.A.L.V® Sistema de aquecimento de longa vida (long life

heatingsystem)

· Muffle forced ventilation for the sintering/infiltration process which eliminates

stainsandminimizesfissures.

99programs:79forceramicand20forsintering/infiltration.

Managementbymicroprocessing.

•

•

•

•

Manual

Note:Thenumbersinparenthesesrefertothepicturethatfollows.

04

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Easyoperationandvisualizationoftheburningparameters.

Ambient working temperature at 1,100°C for ceramic and at 1,200°C for

sintering/infiltration.

Maximumtemperaturelimiterat1,200°C

Lineardecimalheatingspeedfrom0.1to70.0°C/min.

Thyristoredpowercontrol

Ceramicburntimefrom0to30minutes.

Sintering/infiltrationtimefrom0to9hours59minutes.

Decreasingtimevisualization.

Vacuumtimefrom0to30minuteswithdecreasingvisualization.

Automatic or manual (which can be activated ant any stage of the process)

vacuumoperation

Programmableandindependentascendinganddescendingelevatortimes.

Safetysystemsprotecttheequipmentfromoperationmistakesordefects.

Flashingandbeepingsignsofallprocesssteps.

Toavoidambienceheatingandsaveenergy,analarmwillsoundafter5minutesif

the equipment is not being operated the muffle will be partially closed

automatically.

Night Mode: after 2 hours without any operation, the muffle is closed and the

temperatureiskeptat100°C.

Programmablequickcooling.

Operationtimetotalizer.

Lowcostmufflereplacingsystem.

Elevatorwithbottomentranceperfectlybalanced

Electronicsystemforcedventilationkeepsthecomponentssafe.

ARGONSYSTEM, allows thecleaning and helpswith ceramicburnemphasizing

itscolors,enhancingthetranslucenceandopalescence.

Serialcommunicationformaintenanceandsystemchecking.

Temperature safety devices, temopar, vacuum, elevator, power, muffle with

S.A.L.Vsystem,pistonandcompressedairsystem.

Digitalpanelinliquidcrystalwith4linesby20columnsonabluebackground.

Sensitivemembranewithsoundrecognitionoftheoperator'stouch.

4Installing

Manual

Your Sinter Press shouldbe farfromcurtains andinflammable material.Afurnace

isaheat generator whichneedsto be dissipated; otherwiseits components will be

overheated. Therefore, place the equipment at a ventilated area which allows free

aircirculation.

It is advisable to leave a 15cm clearance between the furnace and anything that

canimpairtheventilation.

Place the furnace far from taps or basins which can sprinkle water over the

equipment.

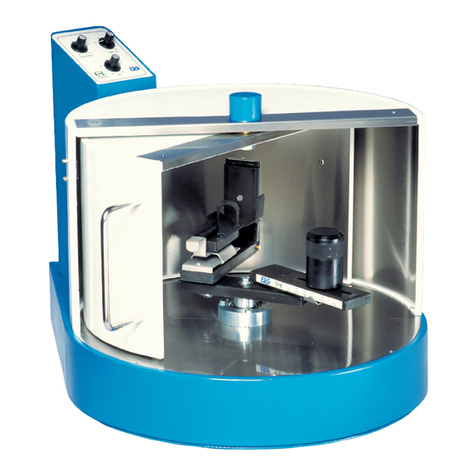

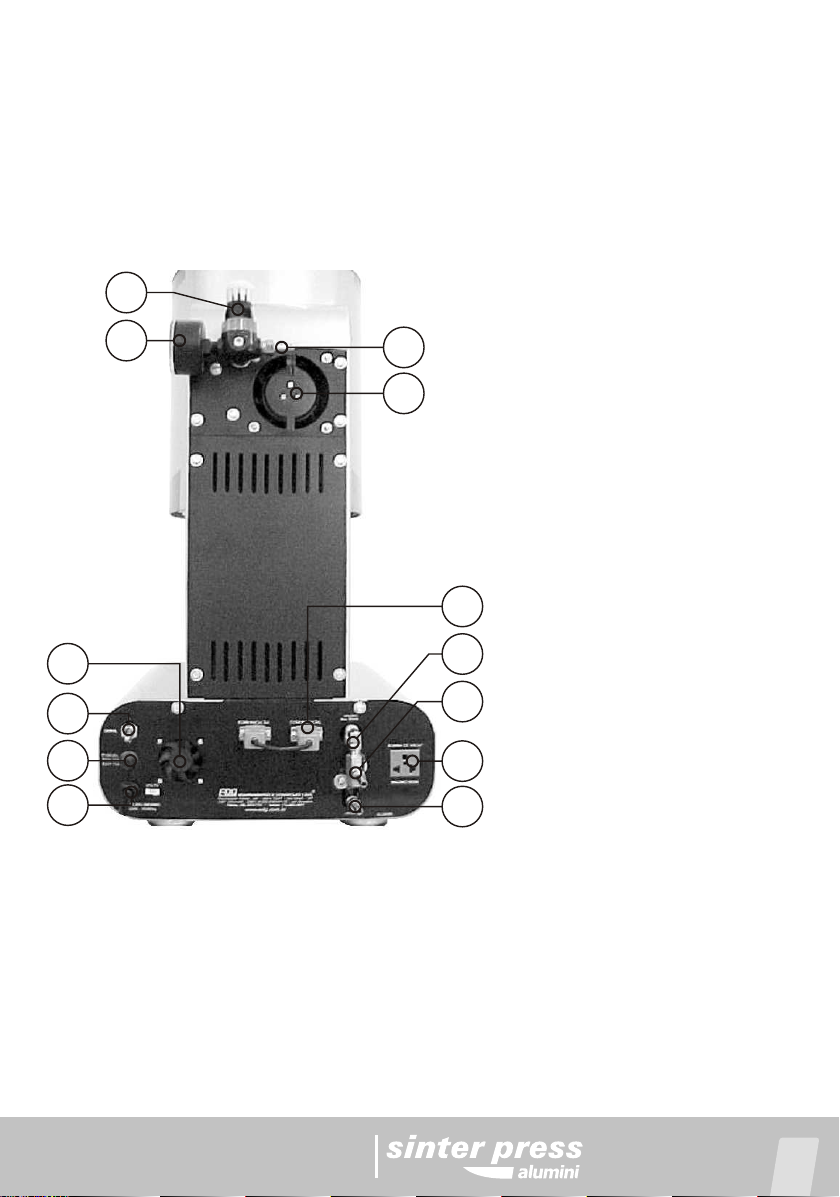

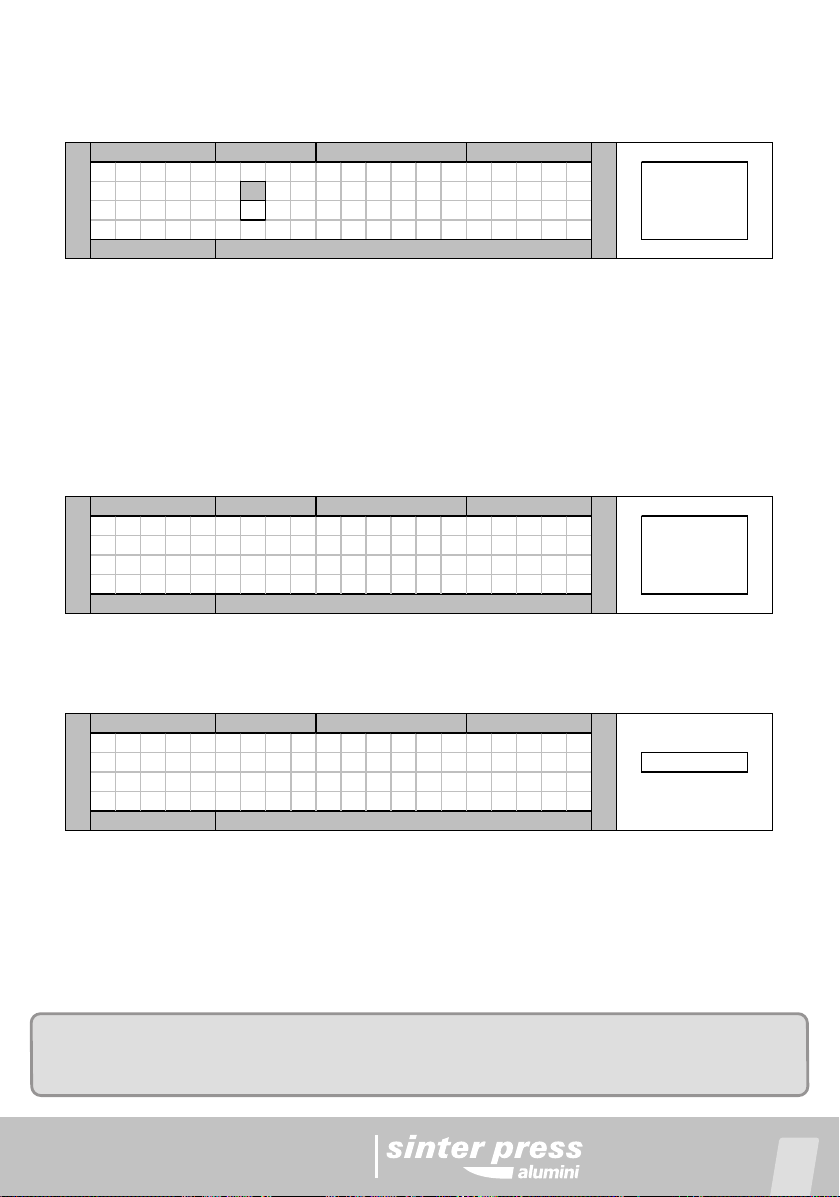

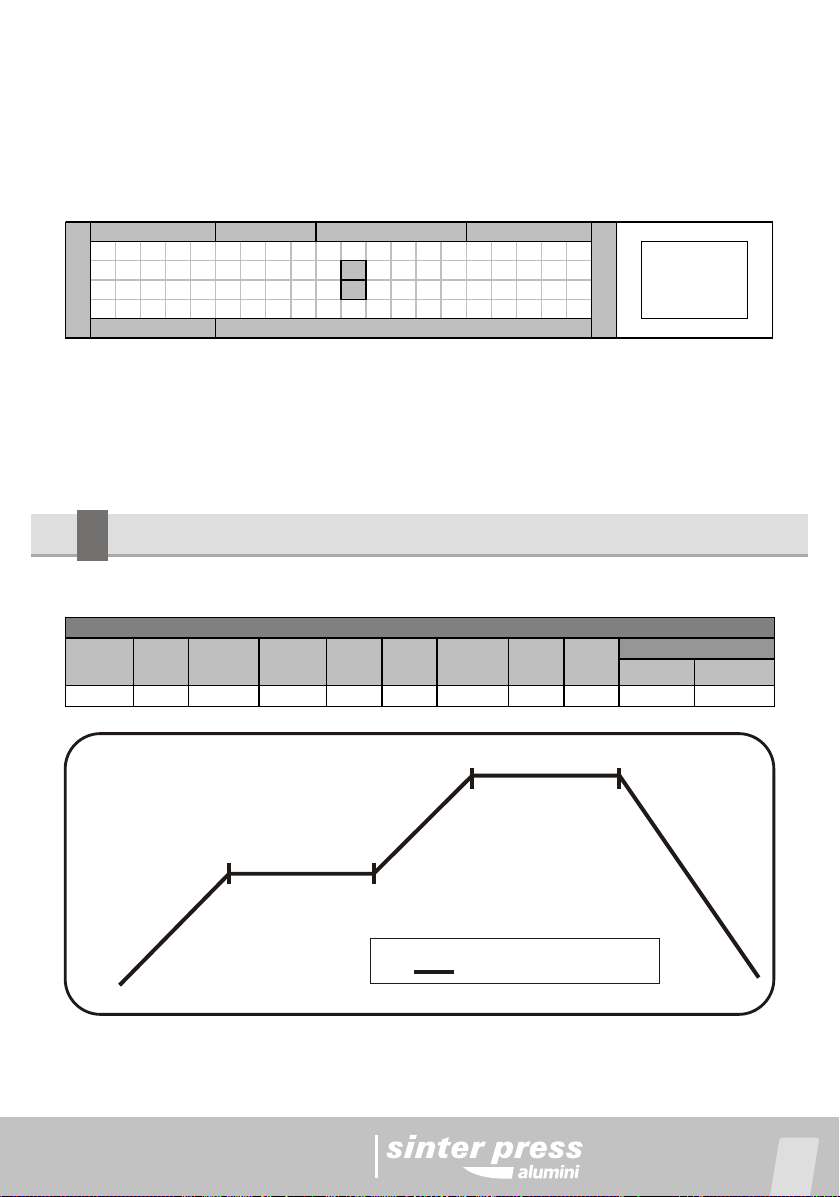

(1) - Network voltage identifier

/powercable.

(2)-Fuseholder.

(3)-Mainswitchon/off.

(4)- control system forced

ventilation.

(5)-Vacuumhoseconnection

(6)- Argon system hose

connection.

(7)-Vacuumpumpsocket.

(8)-SALVsystemvalve.

(9)-Serialcommunication.

(10)-Muffleventilation.

(11)- Compressed air hose

connection.

(12)- Pressing system

pressureregulator.

(13)- Pressing system

pressuremanometer.

13

12

10

11

09

08

06

07

05

01

02

03

04

Pic. 1

4-1)CheckifyournetworkvoltageisthesameastheoneshownonthefurnacePic

(1).–item(1).

4-2) Install the furnace into an exclusive electrical network using 6mm wiring to a

110voltsnetwork,or4mmwiringtoa220voltsnetwork.

4-3) Never connect the furnace to the same network in which other furnaces,

compressors, electrical taps or any other high electricity consumption devices are

alreadyconnected.

05

Manual

4-4)Checkifthe outletinwhichthefurnacewillbepluggedinisinperfectcondition

andofgoodqualitytobearatleast20amperes.

4-5) Connect the grounding end (round pin) to a grounding rod and never to the

electricalnetworkneutral.

!Note:Notcheckingtheproceduresabovewillinterfereontheequipment

correctworking,onitsguaranteeandalsoontheoperatorsafety.

4-6)Ifyourelectricalnetworkisveryinstable(thelightsflashalot),itisadvisableto

use a voltage regulator such as a saturated autotransformer with at least 2kw

capacity.

!Warning:Neveruse,byanymeans,regulatorsusedincomputers.

4-7) Connect the vacuum hose to the furnace Pic-1 item (5). Plug the vacuum

pump power cable to the outlet which is at the backside of the furnace Pic-1 item

(7)

4-8)connectthecompressedairhosetothefurnacePic-1item(11).Theairshould

be supplied dry by the compressor at a minimum pressure of 2 kg/cm² (30lbf/pol²).

Thispressureshouldbekeptwhilethefurnaceisworkingwithpressedceramic.

!Warning:The lack of pressure during this process will abort the burn

andamessagewillbeshownonthecontroldisplay.

4-9) Connect the argon hose to the furnace and to the cylinder outflow regulator

Pic-1item(6).Theargonusedisofcommercialtype.Thecylinderandtheregulator

are not supplied with the equipment. We recommend to contact a gas supplier in

your area. The maximum argon outflow should be adjusted in 10 L/m (liters per

minute). Note: We remind you that the argon provides better colors, opalescence

andtranslucence. However, itsuse canbe discharged.For thatdo notconnect the

argon hose and do not program the function for argon. Check the hoses

connectionsiftheyaretighttoavoidunpleasantleakages.

06

Manual

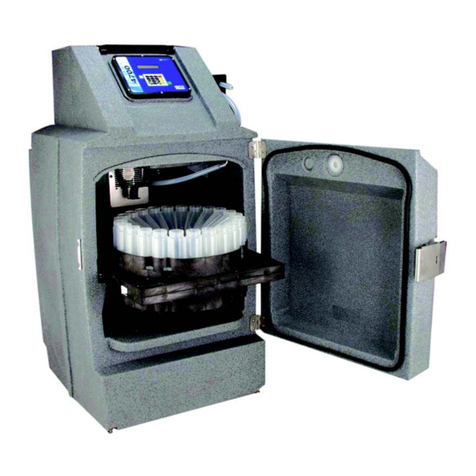

5Control panel

5-1) The panel has liquid crystal display with 4 lines by 20 columns on a blue

background and yellow printing with BACKLIGHT inside illumination that allows

easyidentificationoftheprogrammingfunctionsandlogmonitoring.

5-2) It has a membrane sensitive to the operator's touch, which makes the

functionsactivationeasierwithbeepingsoundrecognition.

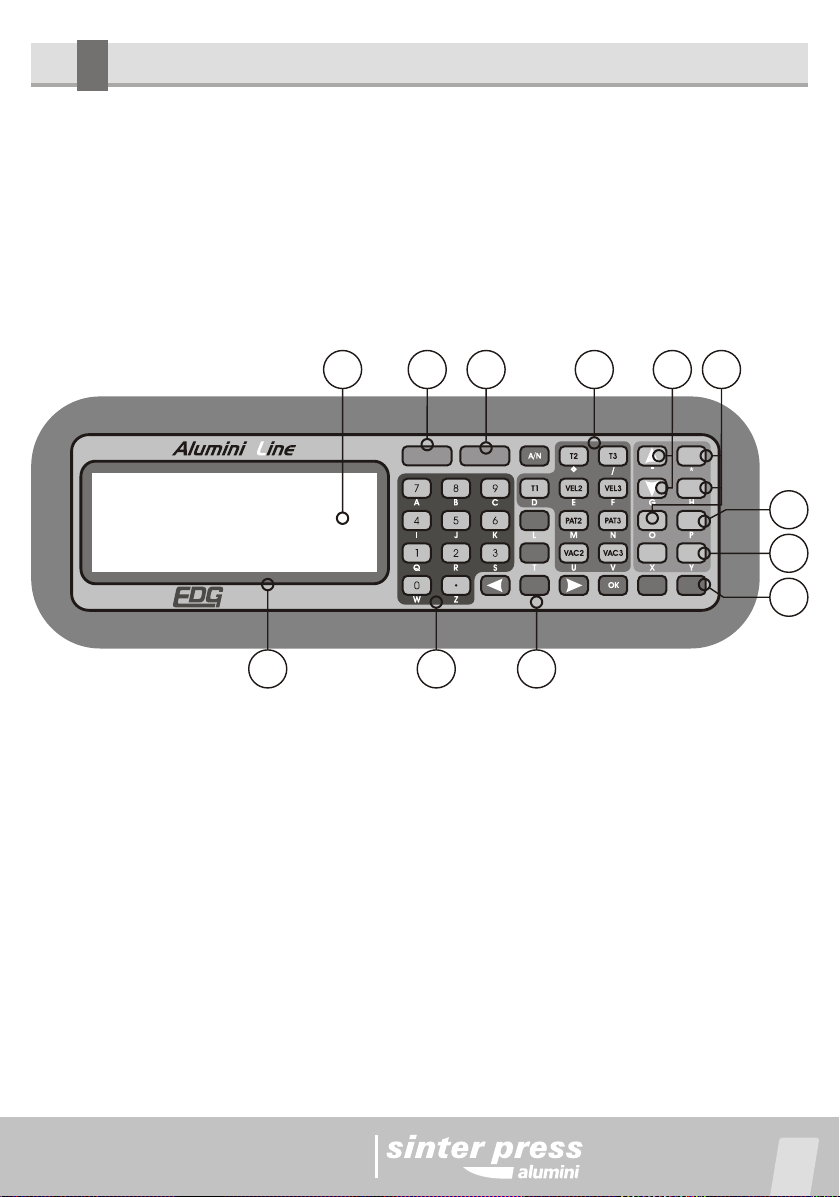

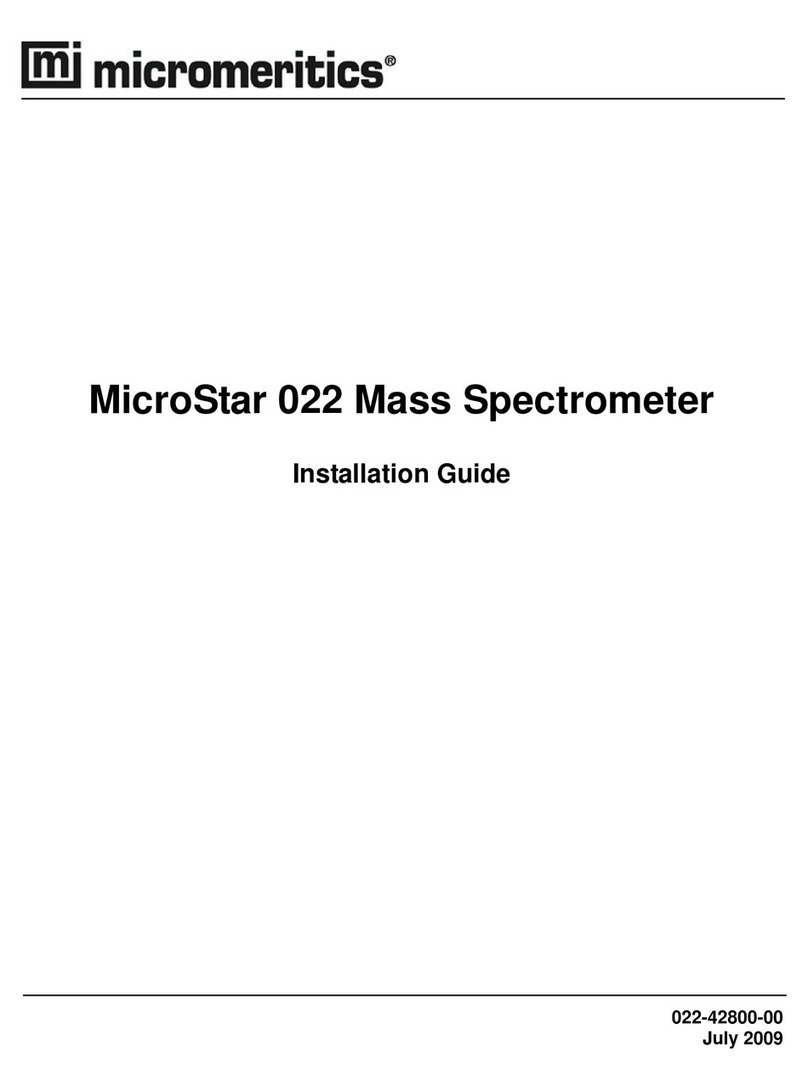

5-3)Panelidentificationanditsmainfunctions.PIC-2

5-4)VISOR(display)–Liquidcrystaldisplay4/20blue. Item-21.

5-5)PROGRAMA(program)–Sequentialprogramkey.Item-22.

5-6)MONITORAÇÃO(monitoring)–controlsystemmonitoringkey.Item-23.

5-7)FUNÇÕES RÁPIDAS (quick functions) – Use the PROGRAMA key, the

sequentialscreensforprogrammingandmonitoring-Item-24.

5-8) ELEVADOR SOBE E DESCE (elevator up and down)– touch sensitive digital

commandwhichturnstheelevatormotoronandoff.Item-25.

5-9)FUNÇÕESAUXILIARES(auxiliary functions)–Argonwashing, quickcooling,

preburnandpressing.Item-26.

5-10) NIGHT –Automatic or manual resting system, it only operates with ceramic.

Item-27.

5-11) AUTO-START – This operation allows the automatic burn start from the

ambienttemperature.Item-28.

5-12)START/STOP- Itallowstostartorinterrupttheburnthroughtheoperator's

pré

read

register send

press

auto

start

clear

set up

start

stop

night

cool.

argon.up

down

set up nº temperature ºC

status vacuum

elevator messages

program monitoring

Pic. 2

21 22 23 24 25 26

27

28

29

303132

07

Manual

command.Item-29.

5-13) CONJUNTO DE TECLAS COM FUNDO CINZA (Keys set with gray

background)–Programmingandcontrolsystemexclusiveoperation.Item-30.

5-14) TECLADO NUMÉRICO (numeric keyboard) – Keyboard for inserting the

numericcontentfortherecipesvariables. Item-31.

5-15) MENSAGENS (messages) – Field reserved for visualizing the process

stages.Item-32.

6System start-up – step-by-step

6-1) Plug the furnace to a godd quality wall socket properly grounded to a copper

rod and never to the network neutral, check if your network voltage is the same as

theoneshownonthefurnacelabel.Pic-1item(1).

6-2)TurnthemainswitchonPic-1item(3)andwaitfortheequipmentstart-up.The

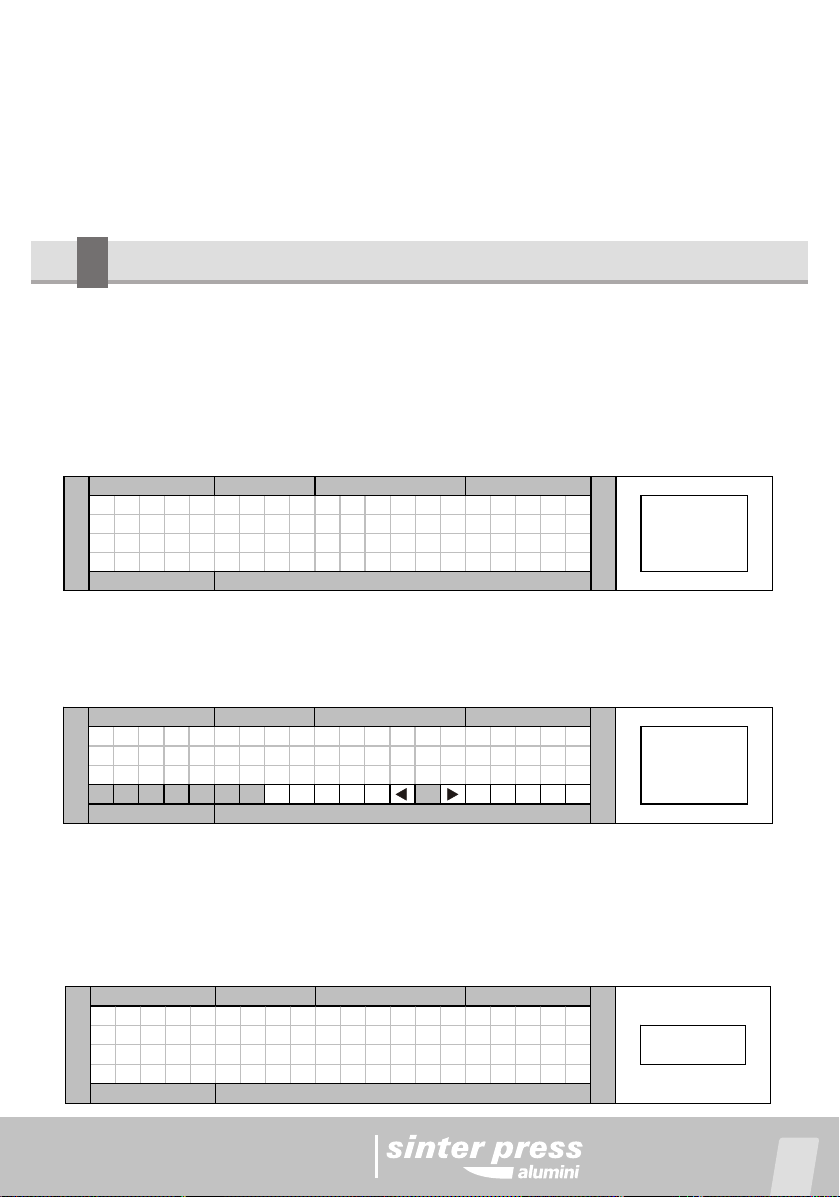

firstscreenoncontainstheprogramversionsdata.Ex-1.

E D G E Q U I P A M E N T O S TELA - 1 DE

E D G H A N D V 2 . 2 INICIALIZAÇÃO E

E D G B A S E V 1 . 3 CHECAGEM DO

W W W . E D G . C O M . B R FORNO

EX - 1

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

6-3) The next screen shows the starting-up and the whole system checking-up, a

scroll bar keeps running through the screen while it performs the initial

configurations.Ex-2.

TELA - 2 DE

I N I C I A L I Z A N D O INICIALIZAÇÃO E

CHECAGEM DO

FORNO

EX- 2

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

6-4) When the checking-up is over, the system loads the sintering standard recipe

nº 80 and waits for the operator's command to perform a new function. We remind

you that when sintering, the furnace will just heat up after the start command is

activated; therefore the temperature on screen is close to the ambient

temperature. Ex-3.

08

M O N I T 0 8 0 0 0 2 5 0 0

T 1 = 0 2 0 0 P A T 1 = H 0 : 3 0 MONITORAÇÃO

V E L 1 = 0 5 . 0 SINTERIZAÇÃO

S D D M . P A D R Ã O . S I N T E R . EX- 3

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

Manual

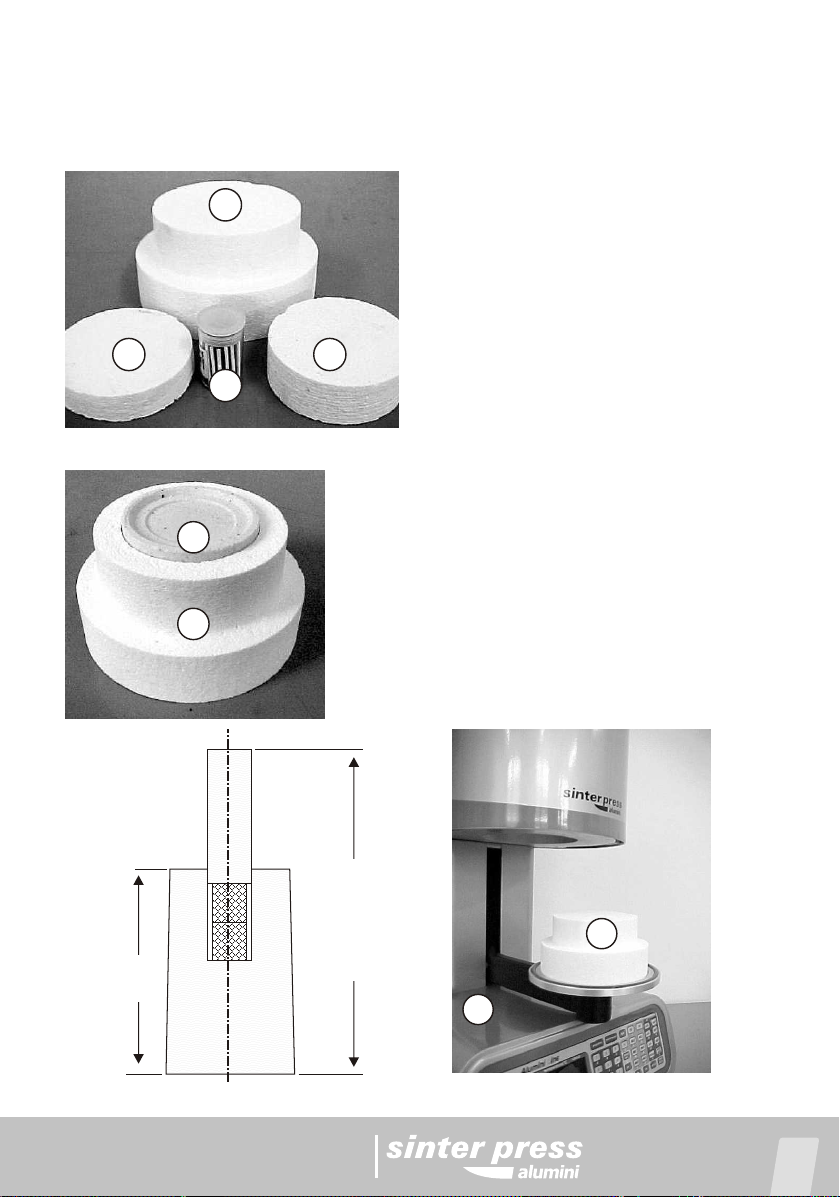

6-5) The furnace should not start the burn process without the spool on the tray;

otherwise the sealing ring and the tray will be seriously damaged and will need to

bereplaced.Choosetheproperaccessoryfor thetype ofworktobeburn. PIC-4 e

PIC-5. 6-6) Accessories for the burning -

SINTERING.

A)Usespool-item(15).

B) Use the rigid mat item (16) on the

spool.

6-7) Accessories for the burning -

.CERAMIC–Conventional.

C)Usespool–item(15)

D) Use the rigid mat item (17) on the

spool.

E) Use isothermal pins for supporting

thepiece.Item(18).

6-8) Accessories for the burning -.CERAMIC

–PRESSED.

F)Usespool–item(19).

G) Use refractory platform item (20) inserted

inthespooltoplacethering.

09

17 16

18

15

Pic.4

20

19

Pic.5

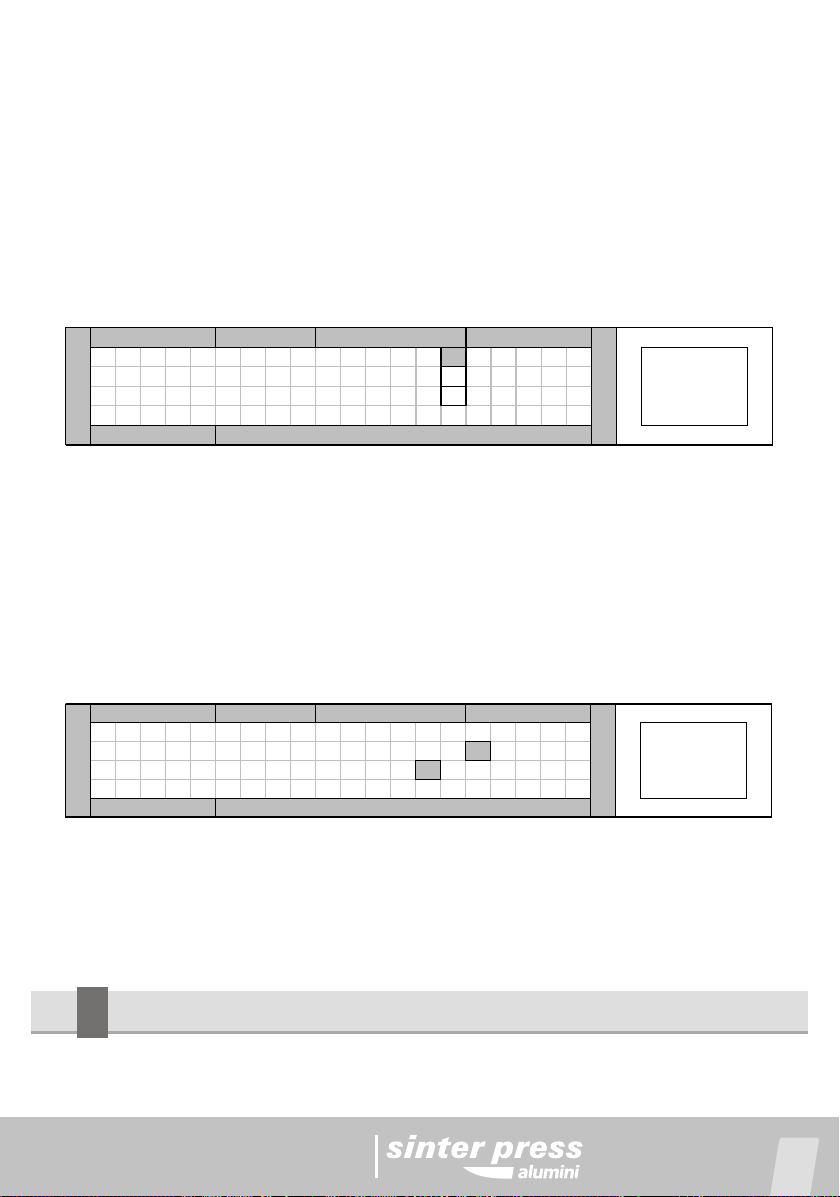

Pic.6

58,0

MÁXIMO 92,0

Pic.3

15

14

Manual

!Warning:The set of RINGS, PADS and PLUNGER should not be

higherthanthemaximumheightof92millimeters,asshownonPIC-(6).

6-9)Movetheelevatortraytothefrontitem-(14)holdingitbyitsknobandplacethe

spool item-(15) on its fitting, next bring the tray back to its correct position on the

platformtostarttheequipmentoperation.

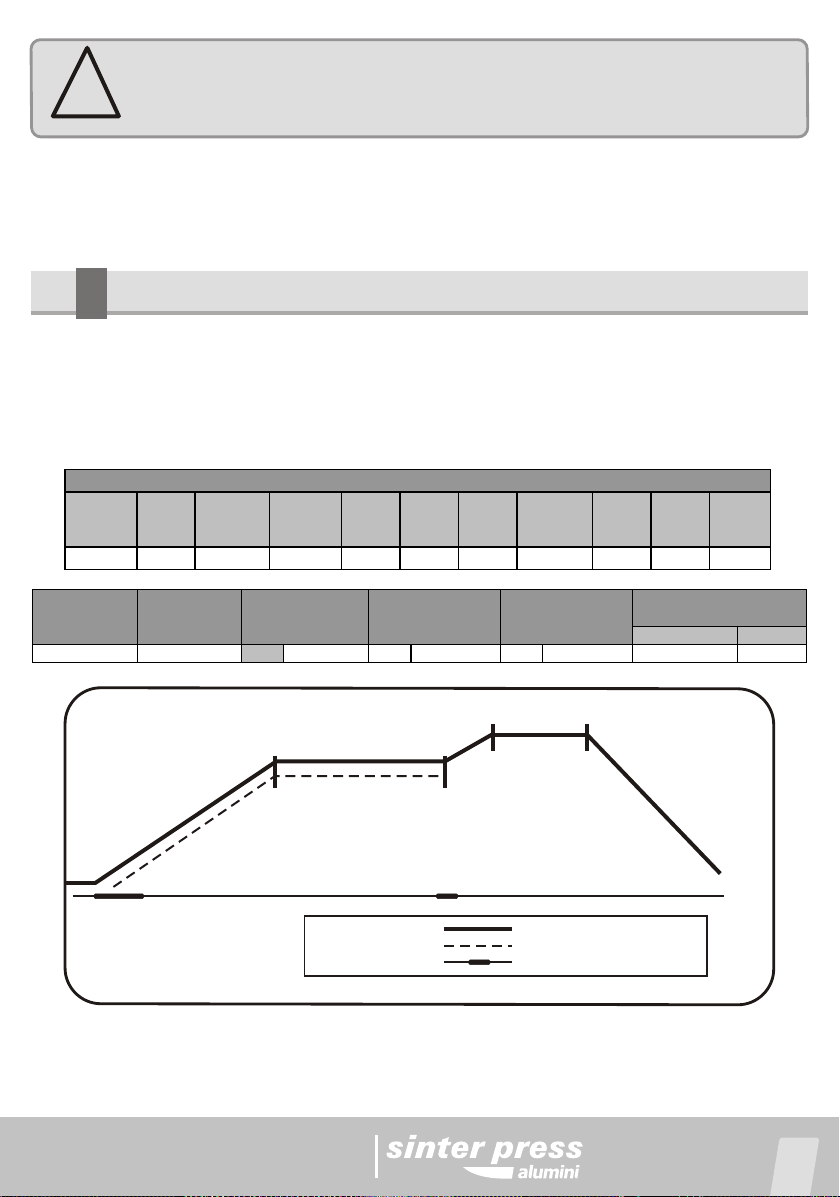

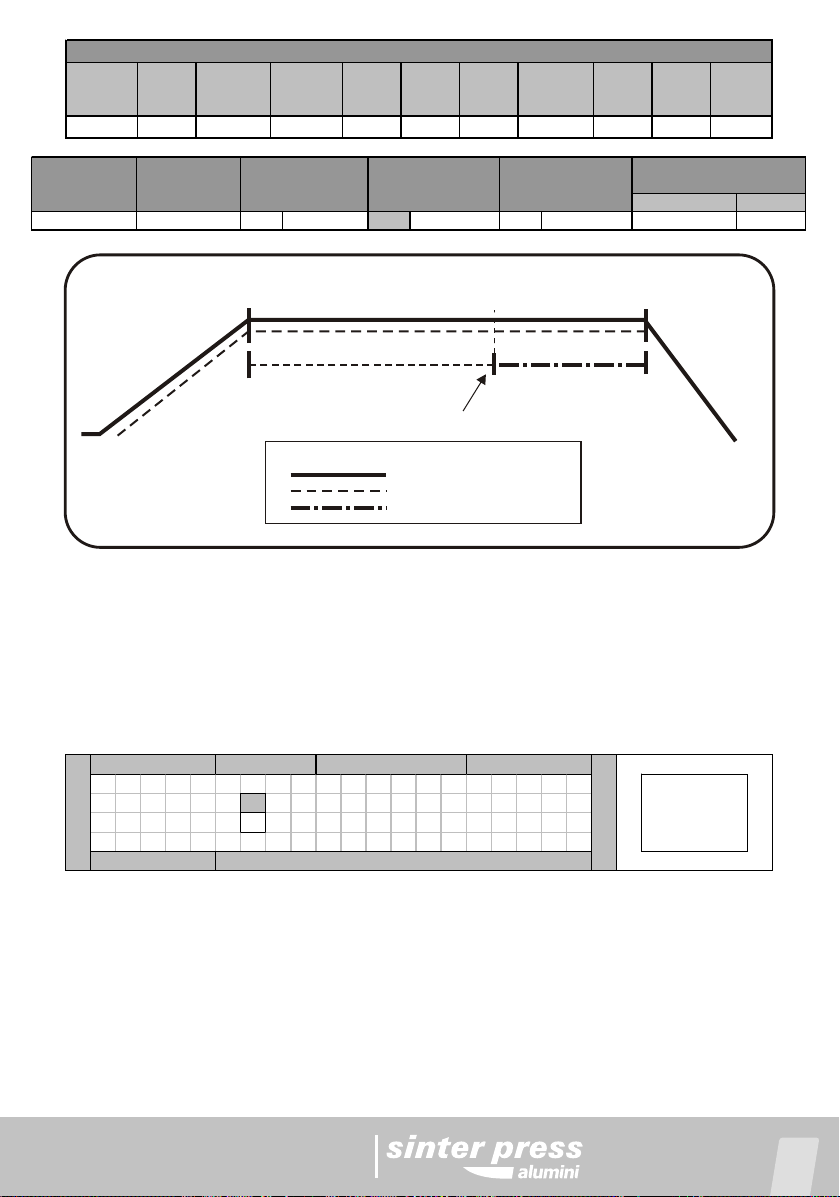

7Programming ceramic recipes

7-1) For better illustrating, we will follow some practical recipes examples for

conventionalceramic,pressedceramic,sinteringandinfiltration.

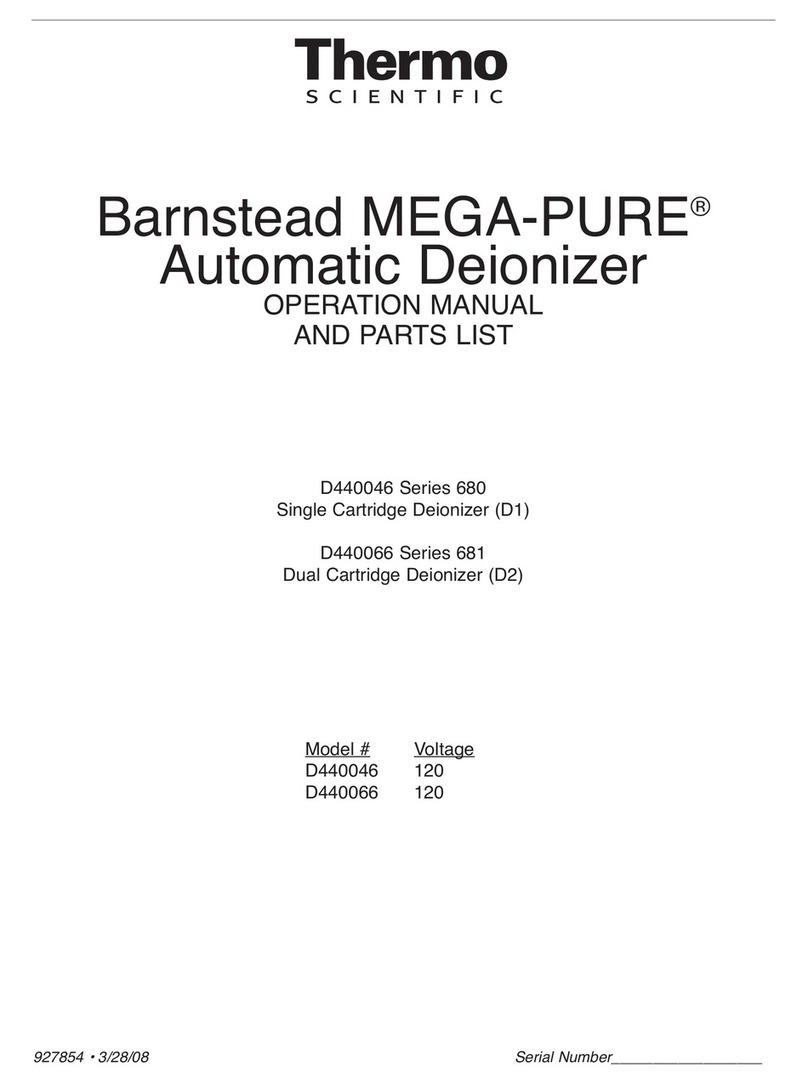

Ex-1 recipemodel-conventionalceramic

TEMP-1

ºC VEL-1

Fixo PAT-1

Elevador TEMP-2

ºC VEL-2

ºC/min PAT-2

min VAC-2

min TEMP-3

ºC VEL-3

ºC/min PAT-3

min VAC-3

min

600 60 BASE 960 55 01:00 01:00 980 20 01:00 0

EXEMPLO DE RECEITA PARA CERÂMICA CONVENCIONAL

10

UP DOWN

05:00 00:00 X YES NO NO 5 3

AUTO-START

Campo preenchido ELEVATORPRENSAGEM

min

PRÉ. QUEIMA

min ARGON

Campo preenchido RESFRIAMENTO

Campo preenchido

VEL-2=55ºC

T2=960ºC PAT-2=1:00

VAC-2=1:00 VEL-3=20ºC

T3=980ºC PAT-3=1:00

T1=600ºC

LIFT BELOW CAPTION HEATING CURVE

VACUUM CURVE

ARGON CURVE

NATURE

COOLING

7-2) Start the programming by reading the standard ceramic recipe (01); it will

serveasreferenceforprogrammingtheotherrecipes.

Manual

L E R LEITURA

0 1 à 7 9 C E R Â M I C A DAS RECEITAS

8 0 à 9 9 S I N T E R I Z A Ç Ã O DE

CERÂMICA

EX- 4

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-4) On the next screen choose receita 01 typing número 1 on the REC field, or

navigate through the options list using the esquerda (left) or direita (right) arrows,

the name of the recipe will be shown on the messages field (PADRÃO CERAM)

EX-5, at this time you should confirm the option by activating the LER (read) key

again to complete with the operation. The recipe will automatically be sent to the

platformandwhenthereisnoreciperecorded,themessage(RECEITAVAZIA)will

beonthedisplay.

L E R LEITURA

R E C : 0 0 1 . . C E R Â M I C A . . DAS RECEITAS

A L F A DE

N O M E : . P A D R Ã O . C E R Â M . CERÂMICA

EX- 5

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

11

7-3) Activate the LER (read) key and choose the type of work to be performed,

ceramic or sintering. To alternate between the two options use the OK key and

confirmtheoperationagainusingtheLER(read)key.Ex4.

7-5) After the standard recipe is read the system will return to its monitoring

screen.EX-11

M O N I T 0 0 1 0 6 0 0 0 0

T 1 = 0 6 0 0 MONITORAÇÃO

V E L 1 = 0 6 0 EX- 11

S D . D D P A D R Ã O . C E R Â M

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-6) To start programming a new recipe you should activate the PROGRAMAkey,

and the display will show the message TELA1, the cursor will be flashing over the

field related to temperature T1=600. At this time we have two options, we can

simply type new values on the already filled fields or we erase all values using the

LIMPARECkey,thenwecantypeontheemptyfields.EX-12

Note: For CONVENTIONAL CERAMIC EX-1, we will use the empty fields

activatingthefunctionLIMPAREC.

Manual

T E L A 1 0 0 1 FUNÇÃO

T 1 = 0 0 0 0 LIMPA REC

CAMPOS VAZIOS

N O M E : . . . . . . . . . . . . . . . INSERIR DADOS

EX- 12

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-7) On the screen TELA-1, now with the empty fields, you will see the cursor

flashing on the T1=0000 field. Type the new value T1=0600 following the steps

presentedforstandardconventionalceramicrecipeEX-6.

T E L A 1 0 0 1 PROGRAMAÇÃO

T 1 = 0 6 0 0 SEQUENCIAL

DAS RECEITAS

N O M E : P A D R Ã O . C E R Â M DE CERÂMICA

EX- 6

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-8) Activate the PROGRAMA key again and a new screen TELA-2 can be

visualized, in which the cursor will be flashing on the T2=000 field. Type the new

value of T2=960 and confirm using the OK key, then the cursor will be flashing on

the velocity field VEL2=000, type the new value of VEL2=55 and confirm it using

theOKkey.NowtypethenewvalueforthebaselinetimePAT2=01:00andvacuum

time VAC2=01:00, these times are programmed using minutes. Confirm the

operationbyusingtheOKkey.EX-7.

12

T E L A 2 0 0 1 PROGRAMAÇÃO

T 2 = 0 9 6 0 P A T 2 = 0 1 : 0 0 SEQUENCIAL

V E L 2 = 0 5 5 V A C 2 = 0 1 : 0 0 DAS RECEITAS

N O M E : P A D R Ã O . C E R Â M DE CERÂMICA

EX- 7

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-9) Activate the PROGRAMA key again and a new screen TELA-3 can be

visualized, in which the cursor will be flashing on the T3=000 field. Type the new

value of T3=980 and confirm using the OK key, then the cursor will be flashing on

the velocity field VEL3=000, type the new value of VEL3=020 and confirm it using

theOKkey.NowtypethenewvalueforthebaselinetimePAT3=01:00andvacuum

time VAC3=00:00, these times are programmed using minutes. Confirm the

operationbyusingtheOKkey.EX-8

T E L A 3 0 0 1 PROGRAMAÇÃO

T 3 = 0 9 8 0 P A T 3 = 0 1 : 0 0 SEQUENCIAL

V E L 3 = 0 2 0 V A C 3 = 0 0 : 0 0 DAS RECEITAS

N O M E : P A D R Ã O . C E R Â M DE CERÂMICA

EX- 8

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

Manual

T E L A 4 0 0 1 A R G O N PROGRAMAÇÃO

P R É Q = 0 5 : 0 0 R E S F R SEQUENCIAL

P R E N = 0 0 : 0 0 A U T O S DAS RECEITAS

N O M E : P A D R Ã O . C E R Â M DE CERÂMICA

EX- 9

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-11) Activate the PROGRAMA key again and a new screen TELA-5 will be

visualized,inwhichthecursor willbeflashingonthe “D”fieldof theascentfunction

SOBE, move the cursor to the position (5) using the left and right arrows and

confirm the operation by using the OK key. This option confirmation will be

visualized in parenthesis on the ascent field SOBE. Repeat the previous step to

program the descent function of the elevator DESCE, move the cursor to the

position (3) using the left and right arrows and confirm the operation by using the

OKkey. EX-10.

13

7-10) Activate the PROGRAMA key again and a new screen TELA-4 will be

visualized, in which the cursor will be flashing on the pre burn field PRÉQ=00:00,

typethenewvalueofPRÉQ=05:00andconfirmitusingtheOKkey,thenthecursor

will be flashing on the press field PREN=00:00, keep the value in ZERO and

confirm it using the OK key. Now the cursor will be flashing on the argon field

ARGON,toconfirmthisoperationactivatetheleftarrowandtherelatedfieldwillbe

filled,andconfirmitusingtheOKkey,ARGON=SIMATIVADO,repeattheprevious

step to program the quick cooling field RESFR=NÃO and also the auto start field

AUTOS=NÃO. When these fields are filled, the selected function will be enabled

anditwillmakepartoftherecipe.EX-9.

T E L A 5 0 0 1 E L E V A D O R PROGRAMAÇÃO

S O B E ( 5 ) M D 1 2 3 4 5 6 7 8 9| SEQUENCIAL

D E S C E ( 3 ) M D 1 2 3 4 5 6 7 8 9| DAS RECEITAS

N O M E : . . . P R E N S A D A . . . DE CERÂMICA

EX - 10

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

7-12) Activate the PROGRAMA key again and the system will be back to the

programming beginning TELA-1. At this stage the recipe is ready to be saved

GRAVADAin the memory, check the step-by-step for saving recipes PG-24-item-

11. To send the recipe to the platform just activate the monitoring key

MONITORAÇÃO.

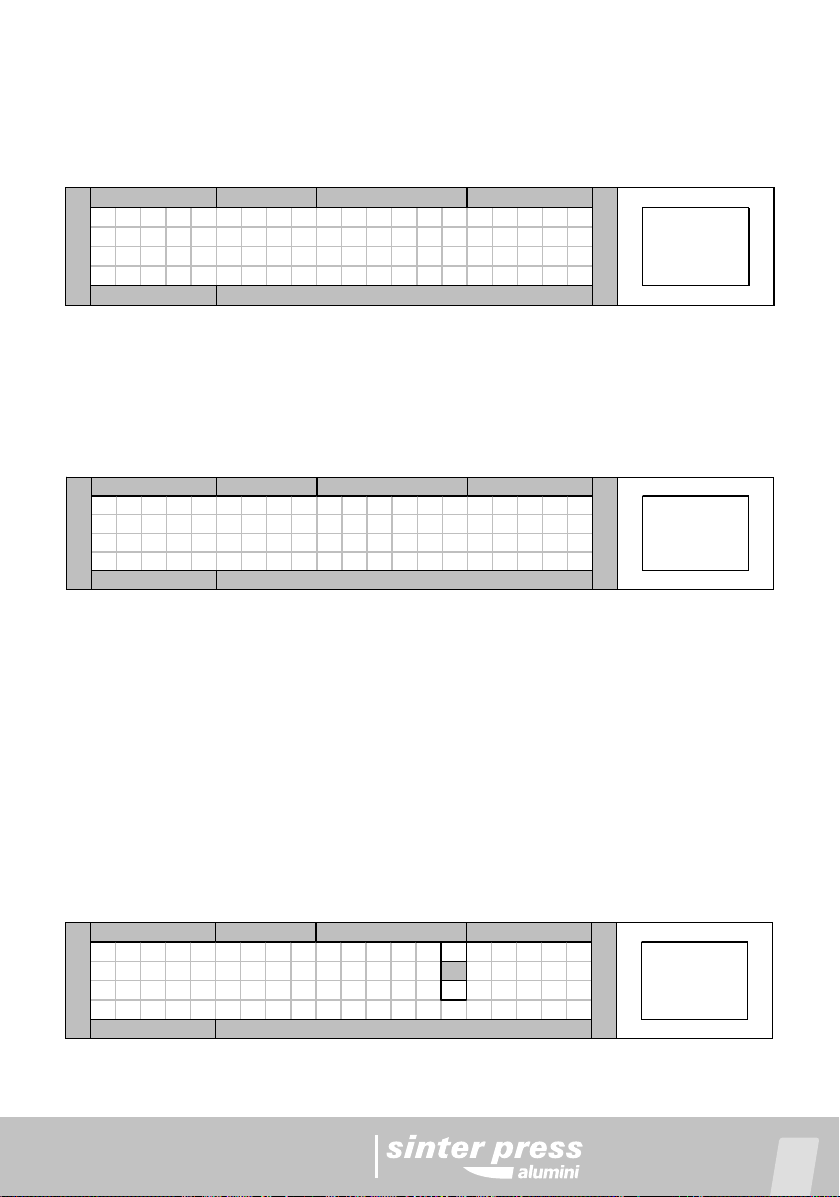

8Programming pressed ceramic recipes

Ex-2 recipemodel–pressedceramic

Manual

VEL-2=55ºC

T2=960ºC PAT-2= 29:00-minutos PREN=9:00-minutos

FORCED

COOLING

PRESSING TIME

TOTAL = 9 MINUTES

SHOOT THE STOP WATCH

PRESS WITH GO 20 MINUTES

CAPTION

T1=800ºC

LIFT BELOW HEATING CURVE

VACUUM CURVE

PRESS CURVE

TEMP-1

ºC VEL-1

Fixo PAT-1

Elevador TEMP-2

ºC VEL-2

ºC/min PAT-2

min VAC-2

min TEMP-3

ºC VEL-3

ºC/min PAT-3

min VAC-3

min

800 60 BASE 960 55 29:00 29:00 0 0 00:00 0

EXEMPLO DE RECEITA PARA CERÂMICA CONVENCIONAL

UP DOWN

00:00 09:00 NO X YES NO D D

AUTO-START

Campo preenchido ELEVATORPRENSAGEM

min

PRÉ. QUEIMA

min ARGON

Campo preenchido RESFRIAMENTO

Campo preenchido

8-1) Start the programming by reading the standard ceramic recipes (01); it will

serveasreferenceforprogrammingtheotherrecipes.

8-2) Activate the LER (read) key and choose the type of work to be performed,

ceramic or sintering. To alternate between the two options use the OK key and

confirmtheoperationagainusingtheLER(read)key.Ex4.

14

L E R LEITURA

0 1 à 7 9 C E R Â M I C A DAS RECEITAS

8 0 à 9 9 S I N T E R I Z A Ç Ã O DE

CERÂMICA

EX- 4

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-3) On the next screen choose receita 01 typing número 1 on the REC field, or

navigate through the options list using the esquerda (left) or direita (right) arrows,

the name of the recipe will be shown on the messages field (PADRÃO CERAM)

EX-5, at this time you should confirm the option by activating the LER (read) key

again to complete with the operation. The recipe will automatically be sent to the

platformandwhenthereisnoreciperecorded,themessage(RECEITAVAZIA)will

beonthedisplay.

Manual

L E R LEITURA

R E C : 0 0 1 . . C E R Â M I C A . . DAS RECEITAS

A L F A DE

N O M E : . P A D R Ã O . C E R Â M . CERÂMICA

EX- 5

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-4)Afterthestandardrecipeisreadthesystemwillreturntoitsmonitoringscreen.

EX-11.

M O N I T 0 0 1 0 6 0 0 0 0

T 1 = 0 6 0 0 MONITORAÇÃO

V E L 1 = 0 6 0 EX-11

S D . D D P A D R Ã O . C E R Â M

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-5) To start programming a new recipe you should activate the PROGRAMAkey,

and the display will show the message TELA1, the cursor will be flashing over the

field related to temperature T1=600. At this time we have two options, we can

simply type new values on the already filled fields or we erase all values using the

LIMPARECkey,thenwecantypeontheemptyfields.EX-12.

T E L A 1 0 0 1 FUNÇÃO

T 1 = 0 0 0 0 LIMPA REC

CAMPOS VAZIOS

N O M E : . . . . . . . . . . . . . . . INSERIR DADOS

EX- 12

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

Note:For PRESSED CERAMIC EX-2, we will use the empty fields activating the

functionLIMPAREC.

15

8-6) On the screen TELA-1, now with the empty fields, you will see the cursor

flashing on the T1=0000 field. Type the new value T1=0800 following the steps

presentedforstandardpressedceramicrecipeEX-13.

T E L A 1 0 0 1 PROGRAMAÇÃO

T 1 = 0 8 0 0 SEQUENCIAL

DE CERÂMICA

N O M E : . . . P R E N S A D A . . . . PRENSADA

EX- 13

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-7) Activate the PROGRAMA key again and a new screen TELA-2 can be

visualized,inwhichthecursorwillbeflashingontheT2=000field. Typethenew

Manual

T E L A 2 0 0 1 PROGRAMAÇÃO

T 2 = 0 9 6 0 P A T 2 = 2 9 : 0 0 SEQUENCIAL

V E L 2 = 0 5 5 V A C 2 = 2 9 : 0 0 DE CERÂMICA

N O M E : . . . P R E N S A D A . . . . PRENSADA

EX- 14

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

T E L A 3 0 0 1 PROGRAMAÇÃO

T 3 = 0 0 0 0 P A T 3 = 0 0 : 0 0 SEQUENCIAL

V E L 3 = 0 0 0 V A C 3 = 0 0 : 0 0 DE CERÂMICA

N O M E : . . . P R E N S A D A . . . . PRENSADA

EX - 15

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-8) Activate the PROGRAMA key again and a new screen TELA-3 can be

visualized, in which the cursor will be flashing on the T3=000 field. For this recipe,

stagethree(três)willnotbeused,soallthefieldsonthisscreenshouldbeatZERO

EX–15.

T3=000, VEL3=000, PAT3=00:00, VAC3=00:00

8-9) Activate the PROGRAMA key again and a new screen TELA-4 will be

visualized, in which the cursor will be flashing on the pre burn field PRÉQ=00:00,

keepitat ZERO and confirmitusing the OK key, thenthecursor will be flashingon

the press field PREN=00:00, type the new value of PREN=09:00 and confirm it

usingtheOKkey.NowthecursorwillbeflashingontheargonfieldARGON,keepit

deactivated ARGON=NÃO and confirm this operation using the OK key. To

program the quick cooling field RESFR, activate the left arrow to fill in the field

RESF=SIM and confirm this operation using the OK key. The cursor will then be

flashing on the auto start field, keep it deactivatedAUTOS=NÃO and confirm it by

usingtheOKkey.Whenthesefieldsarefilled,theselectedfunctionwillbeenabled

anditwillmakepartoftherecipe.EX-16.

16

T E L A 4 0 0 1 A R G O N PROGRAMAÇÃO

P R É Q = 0 0 : 0 0 R E S F R SEQUENCIAL

P R E N = 0 9 : 0 0 A U T O S DE CERÂMICA

N O M E : . . . P R E N S A D A . . . . PRENSADA

EX- 16

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-10) Activate the PROGRAMA key again and a new screen TELA-5 will be

visualized,inwhichthecursorwillbeflashingonthe“D”fieldoftheascentfunction

value of T2=960 and confirm using the OK key, then the cursor will be flashing on

the velocity field VEL2=000, type the new value of VEL2=55 and confirm it using

theOKkey.NowtypethenewvalueforthebaselinetimePAT2=29:00andvacuum

time VAC2=29:00, these times are programmed using minutes. Confirm the

operationbyusingtheOKkey.EX-14.

Manual

T E L A 5 0 0 1 E L E V A D O R PROGRAMAÇÃO

S O B E ( D ) M D 1 2 3 4 5 6 7 8 9 SEQUENCIAL

D E S C E ( D ) M D 1 2 3 4 5 6 7 8 9 DE CERÂMICA

N O M E : . . . P R E N S A D A . . . PRENSADA

EX- 17

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

8-11)Activate the PROGRAMA key again and the system will be back to the

programming beginning TELA-1. At this stage the recipe is ready to be saved

GRAVADAin the memory, check the step-by-step for saving recipes PG-24-item-

11. To send the recipe to the platform just activate the monitoring key

MONITORAÇÃO

9Programming sintering recipes.

UP DOWN

200 7.0 00:10 1100 40.0 01:00 0 0 00:00 D 2

VEL-3

ºC/min PAT-3

H/min

EXEMPLO DE RECEITA PARA SINTERIZAÇÃO ELEVATOR

TEMP-1

ºC VEL-1

ºC/min PAT-1

H/min TEMP-2

ºC VEL-2

ºC/min PAT-2

H/min TEMP-3

ºC

T1=220ºC

PAT-1 = 00:10 min

VEL-1 = 7.0ºC

25ºC

VEL-2 = 40.0ºC

PAT-2 = 01:00 Hora

T2 = 1100ºC

NATURAL

COOLING

CAPTIONHEATING CURVE

17

SOBE,if necessary,movethe cursorto thedesiredposition usingthe leftandright

arrowsandconfirmtheoperationbyusingtheOKkey.Thisoptionconfirmationwill

bevisualizedinparenthesisontheascentfieldSOBE. Repeatthepreviousstepto

program the descent function of the elevator DESCE, move the cursor to the

position (D) using the left and right arrows and confirm the operation by using the

OKkey. EX-17.

Ex-3 recopemodel–sintering/infiltration

9-1) Start the programming reading the standard sintering recipe Receita (80), it

willserveasreferenceforprogrammingtheotherrecipes.

Manual

L E R LEITURA

0 1 à 7 9 C E R Â M I C A DAS RECEITAS

8 0 à 9 9 S I N T E R I Z A Ç Ã O DE

SINTERIZAÇÃO

EX - 19

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

9-3) On the next screen choose receita 80 typing número 80 on the REC field, or

navigate through the options list using the esquerda (left) or direita (right) arrows,

the name of the recipe will be shown on the messages field (PADRÃO SINTER)

EX-20, at this time you should confirm the option by activating the LER (read) key

again to complete with the operation. The recipe will automatically be sent to the

platformandwhenthereisnoreciperecorded,themessage(RECEITAVAZIA)will

beonthedisplay.Itisnotpossibletoread(LER).

L E R LEITURA

R E C : 0 8 0 S I N T E R I Z A Ç Ã O DAS RECEITAS

A L F A DE

N O M E : P A D R Ã O . S I N T E R . SINTERIZAÇÃO

EX - 20

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

9-4) After the standard sintering recipe is read the system will return to its

monitoringscreen.EX-25

M O N I T 0 8 0 0 0 2 5 0 0

T 1 = 0 2 0 0 P A T 1 = H 0 : 1 5 MONITORAÇÃO

V E L 1 = 0 5 . 0 SINTERIZAÇÃO

S D D M . P A D R Ã O . S I N T E R . EX - 25

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

9-5) To start programming a new recipe you should activate the PROGRAMAkey,

and the display will show the message TELA1, the cursor will be flashing over the

field related to temperature T1=600. At this time we have two options, we can

simply type new values on the already filled fields or we erase all values using the

LIMPARECkey,thenwecantypeontheemptyfields.EX-26.

Note: For SINTERING EX-3, we will use the empty fields activating the function

LIMPAREC.

18

9-2) Activate the LER (read) key and choose the type of work to be performed,

ceramic or sintering. To alternate between the two options use the OK key and

confirmtheoperationagainusingtheLER(read)key.Ex-19

Manual

T E L A 1 0 8 0 FUNÇÃO

T 1 = 0 0 0 0 LIMPA REC

CAMPOS VAZIOS

N O M E : . . . . . . . . . . . . . . . INSERIR DADOS

EX- 26

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

9-6) On the screen TELA-1, now with the empty fields, you will see the cursor

flashing on the T1=0000 field. Type the new value T1=220 and confirm using the

OKkey,thenthecursorwillbeflashingonthevelocityfieldVE1=00.0,typethenew

valueofVEL1=07.0andconfirmitusingtheOKkey.Nowtypethenewvalueforthe

baseline time PAT1=H0:10 this time is programmed using hours. Confirm the

operation by using the OK key. EX-21. Follow the step-by-step of the standard

sinteringrecipeEX-3

Note: The sintering velocities can be fractional, values lower than 1ºC/minute,

minimum0.1ºC/minute.

T E L A 2 0 8 0 PROGRAMAÇÃO

T 2 = 1 1 0 0 P A T 2 = H 1 : 0 0 DE

V E L 2 = 4 D . 0 SINTERIZAÇÃO

N O M E : P A D R Ã O . S I N T E R . INFILTRAÇÃO

EX - 22

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

T E L A 1 0 8 0 PROGRAMAÇÃO

T 1 = 0 2 2 0 P A T 1 = H 0 : 1 0 DE

V E L 1 = 0 7 . 0 SINTERIZAÇÃO

N O M E : P A D R Ã O . S I N T E R . INFILTRAÇÃO

EX - 21

TEMP ºC VÁCUO

ELEVADOR

STATUS RECºN

MENSAGENS

9-7) Activate the PROGRAMA key again and a new screen TELA-2 can be

visualized, in which the cursor will be flashing on the T2=000 field. Type the new

value of T2=1100 and confirm using the OK key, then the cursor will be flashing on

thevelocityfieldVEL2=00.0,typethenewvalueofVEL2=40.0andconfirmitusing

theOKkey. Now typethenew value for thebaselinetime PAT2=H1:00, this timeis

programmed using hours with minutes visualization. Confirm the operation by

usingtheOKkey.EX-22.

9-8) Activate the PROGRAMA key again and a new screen TELA-3 can be

visualized, in which the cursor will be flashing on the T3=000 field. For this recipe,

stagethree(três)willnotbeused,soallthefieldsonthisscreenshouldbeatZERO

EX–15.

T3=000,VEL3=000,PAT3=00:00, VAC3=00:00

ConfirmtheoperationbyusingtheOKkey.EX-23.

19

Table of contents

Other EDG Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Nordson EFD

Nordson EFD E2V operating manual

Hanna Instruments

Hanna Instruments HI97705 instruction manual

Micromeritics

Micromeritics MicroStar 022 installation guide

Ele

Ele 38-1000 operating instructions

Thermo Scientific

Thermo Scientific MEGA-PURE 680 D440046 Series Operation manual and parts list

Idexx

Idexx CardioPet ECG user guide