Edin univox Unisign User manual

Installation Guide

Unisign

Super-slim induction loop system

for integration

Part no 204200

2

Content

Safety���������������������������������������������������������������������������������������������������������������������������������������������������������� 3

Introduction����������������������������������������������������������������������������������������������������������������������������������������������� 3

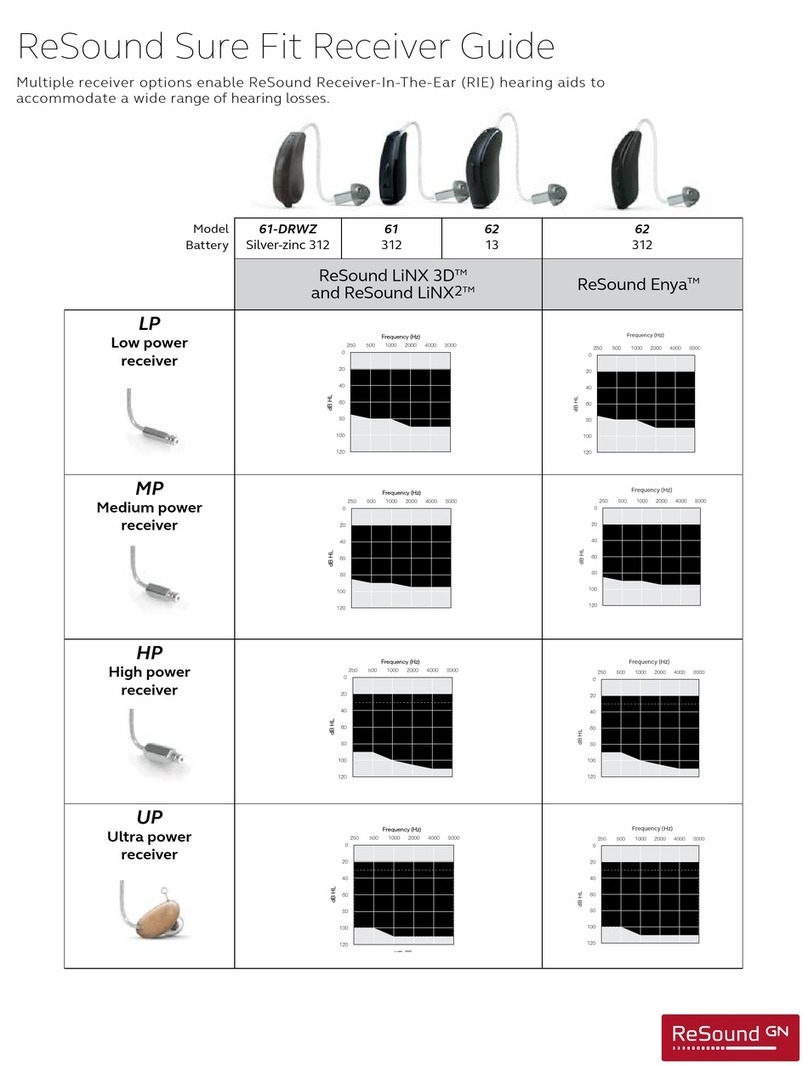

Product overview�������������������������������������������������������������������������������������������������������������������������������������� 4

Installation setup ������������������������������������������������������������������������������������������������������������������������������������� 4

Input jumper settings������������������������������������������������������������������������������������������������������������������������������ 6

MLC �������������������������������������������������������������������������������������������������������������������������������������������������������������� 7

Loop specification ������������������������������������������������������������������������������������������������������������������������������������ 7

Warranty����������������������������������������������������������������������������������������������������������������������������������������������������� 7

Environment���������������������������������������������������������������������������������������������������������������������������������������������� 7

Technical Data������������������������������������������������������������������������������������������������������������������������������������������� 8

3

Safety

1� Please read this Installation guide carefully before installing and operating the product�

2� Keep the Installation Guide available on-site�

3� Do not install the unit near any heat sources such as radiators, heat registers, vents or

other apparatus that produce heat�

4� Never expose the unit to dripping or splashing, nor to liquid or moisture of any kind�

5� Do not make any modifications, extensions, or adaptations to the unit�

6� All installation, service and maintenance work must be performed by qualified

personnel only� No user serviceable parts�

Introduction

The Unisign is a hearing loop integration kit, featuring a compact powerful induction loop

amplifier and a super-slim multi-turn loop, only 3 mm thick� The module is designed for

wide range applications, where necessity of a hearing loop system is required�

Unisign allows for quick and easy installation as a perfect addition to small area

communication systems, such as intercoms, emergency phones, information-and help

points, kiosks or any other system to enhance the intelligibility for hearing impaired

individuals�

Designed on efficient class-D technology and with dual action AGC function, MLS-1 allows

for simple connection to different input signal levels� Univox® MLS-1 features Metal Loss

Compensation (MLC) which enables fine tuning and compensation for metal loss and

attenuation effects�

A fully integrated, correctly installed Unisign system complies with all the requirements of

the IEC 60118-4 standard�

4

Installation setup

Unisign should be mounted on a flat and stable surface, below or at the side of the

intercom panel� (4xM4 screws can be used)� Adjust the amplifier accordingly:

1� Set all level controls (6, 7, 8) to minimum setting (counterclockwise)�

2� Connect the Unisign to the Loop clamp connector (4)� Any additional feed cable

connected between Unisign and MLS amplifier should be twisted�

3� Connect a suitable input signal source to the Input clamp connector (1), see page 6 for

balanced/unbalanced and Mic/Line jumper settings�

4� Connect DC power supply to the Power clamp connector (3), (see connection diagram)�

Observe the power polarity! Verify the power LED indication (2)�

5� Adjust the input signal (6) until the input LED (5) flickers occasionally, indicating

program peaks�

1� Input clamp

connector

2� Power LED 3� Power clamp

connector

4� Loop clamp

connector

5� Input LED 6� Input level

adjustment

7� Parametric

MLC control

8� Loop current

adjustment

9� Output LED

Product overview

10� JP2

balanced/

unbalanced

jumper

11� JP1

sensitivity

jumper

5

6� Adjust the loop current output level (8) to achieve a filed strength compliant

with IEC60118-4 requirements� The output LED (9) indicates that the amplifier is

transmitting correctly� Use a Field Strength Meter to verify the field strength level

within defined distance, at the reference position and direction appropriate for the

application�

Note: In smaller systems the listening level will vary as a function of distance (as for a

loudspeaker)� Check the sound quality (clear sound with no distortion) with the loop

receiver, Univox® Listener�

Unisign connection

6

Input jumper settings

The Input connector (1) can be adjusted for balanced/unbalanced Line and/or Mic

sensitivity according to following:

• Input Line sensitivity, balanced

Input sensitivity jumper JP1 (10) should be ON (sensitivity set to min

85 mVrms to 1�5 Vrms)

Balanced/unbalanced jumper JP2 (11) set to pin 1-2 (bottom and

mid pin), default setting�

Connect the signal cable to Input connector (1)� Leave GND/

screen open, not connected

• Input Line sensitivity, unblanced

Input sensitivity jumper JP1 (10) should be ON (sensitivity set to min 85

mVrms to 1�5 Vrms)

Balanced/unbalanced jumper JP2 (11) set to pin 2-3 (top and mid pin)

Connect the signal cable to Input connector (1), signal line and GND

• Input Mic sensitivity, +9 V phantom ON

Input sensitivity jumper JP1 (10) should be OFF (removed)

Sensitivity level is now set to min 15 mVrms to 1�5 Vrms� Phantom is ON�

Set JP2 (11) to pin 1-2 for balanced or 2-3 for unbalanced (mic dependent)

Connect the signal to the Input connector (1) according to the following:

GND

SIGNAL

7

MLC

The metal loss control function enables system frequency response correction in

installations where the signal strength is strongly influenced by the surrounding metal�

The frequency response can be fine-tuned by adjusting the MLC potentiometer (7),

compensating for the effects of different metal types and configurations�

Loop specification

Recommended loop resistance for the highest system efficiency is approximately 1-1�5Ω�

Warranty

The installer is responsible for installing the product in a way that may not cause risk of

fire, electrical malfunctions or danger�

Misuse of the product in any way, including but not limited to:

• Incorrect installation

• Force majeure e�g� lightning strike

• Ingress of liquid

• Mechanical impact

will invalidate the warranty�

Bo Edin AB shall not be held responsible or liable for interference to radio or TV equipment,

and/or to any direct, incidental or consequential damages or losses to any person or

entity, if the equipment has been installed by unqualified personnel and/or if installation

instructions stated in the product Installation Guide have not been strictly followed�

Environment

Please follow existing disposal regulations in your country� If you respect these

instructions you help ensure human health and environmental protection�

Hearing excellence since 1965

(Univox) Bo Edin AB

Stockby Hantverksby 3,

SE-181 75 Lidingö, Sweden

+46 (0)8 767 18 18

www.univox.eu

unisign-du-gb 221019 Copyright © Bo Edin AB

Technical Data

MLS-1

Power supply External PSU 6-24V DC System voltage 12 V

Power consumption Idle current 36 mA@12 V

Input Galvanically isolated balanced input

Mic/Line sensitivity 15 mV-1�5 Vrms, -34 dBu - +5�7 dBu

Max input level 1�5 Vrms, +5�7 dBu

Phantom power 12 VDC

Source impedance 0-2 kΩ

Output Max voltage 48 Vpp

Max current 5�3 Arms

Distortion <1%

Univox AGC Dynamic Range >50-70 dB (+1�5 dB)

LED indication Power

Input level

Output current

Weight 38 g

Unisign

Dimensions Height 300 mm

Width 210 mm

Depth 3 mm

Weight 220 g

Environment IP54 class

Temp range MLS-1 -40 to 75°C

Table of contents

Other Edin Hearing Aid manuals