EDS-TECHNICALINSTRUCTIONS

5

what’s following

8.6 - the P1 trimmer (regulation of the signal level) is regulated in

factory to the 50-60% and it corresponds to a signal of 5V to the

maximum distance

8.7 - To get the best results in the following operations, we

recommend the use a measuring instrument (Multimeter),

preferably an analog hand type, for better control of the variations

of the signal during the setup. Good results are also obtained using

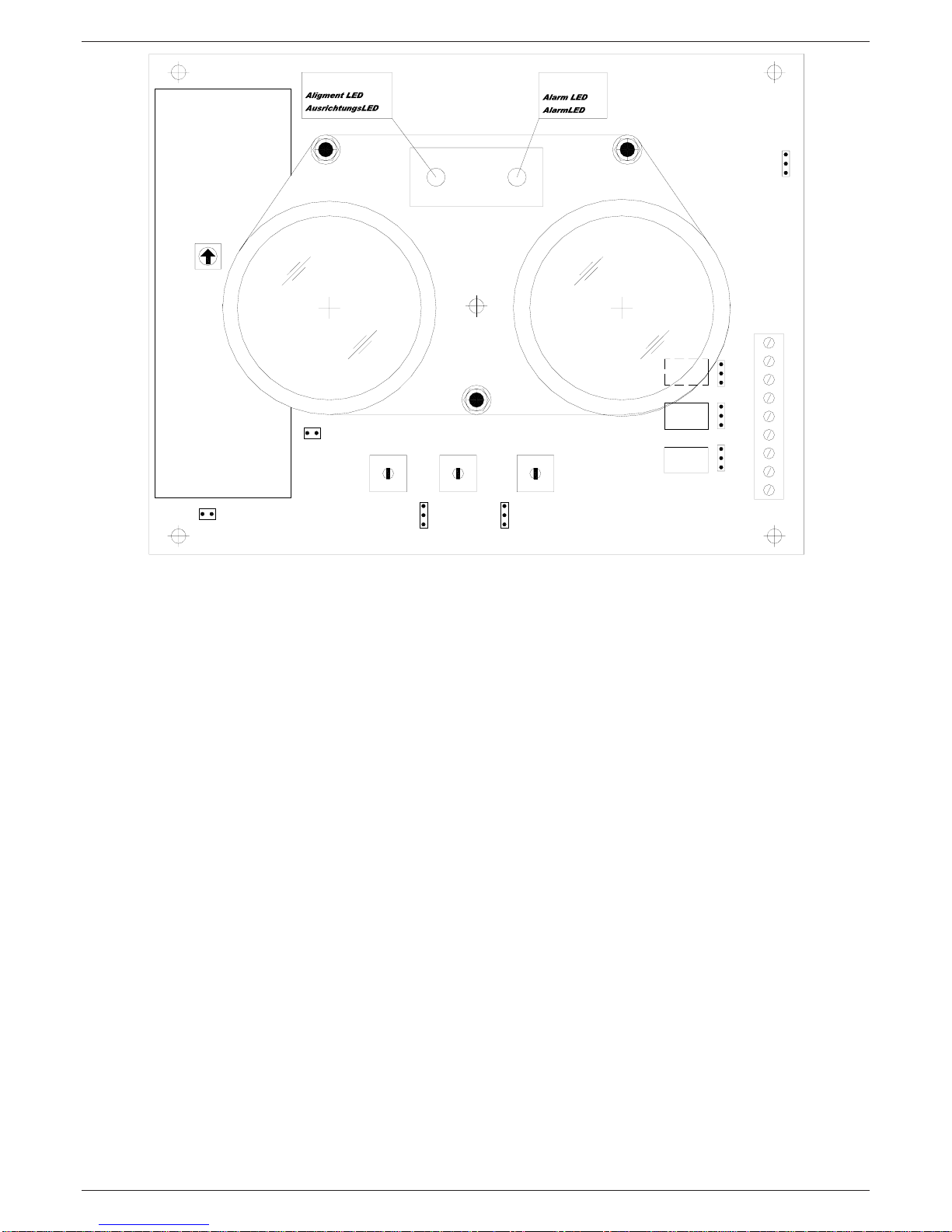

analog meter STS01 (optional), designed for this application, that

must be inserted on the special connector CN4, set on the printed

circuit of the detector (v. fig. 11). If you don’t have a Multimeter

or the STS01, you can perform the setup operations anyway

evaluating the signal level with the frontal Leds indications as

described in chap.8.12

8.8 - If available, connect a 5V fullscale multimeter between the

SIGterminaland the negative power supply one and read the analog

output signal. Instead of the multimeter, it is possible to use the

STS01 meter (optional - fig. 11). If the output signal is very low, it

means that the operations of optical alignment described in chapter

5, have not been performed in the right way and therefore must be

repeated

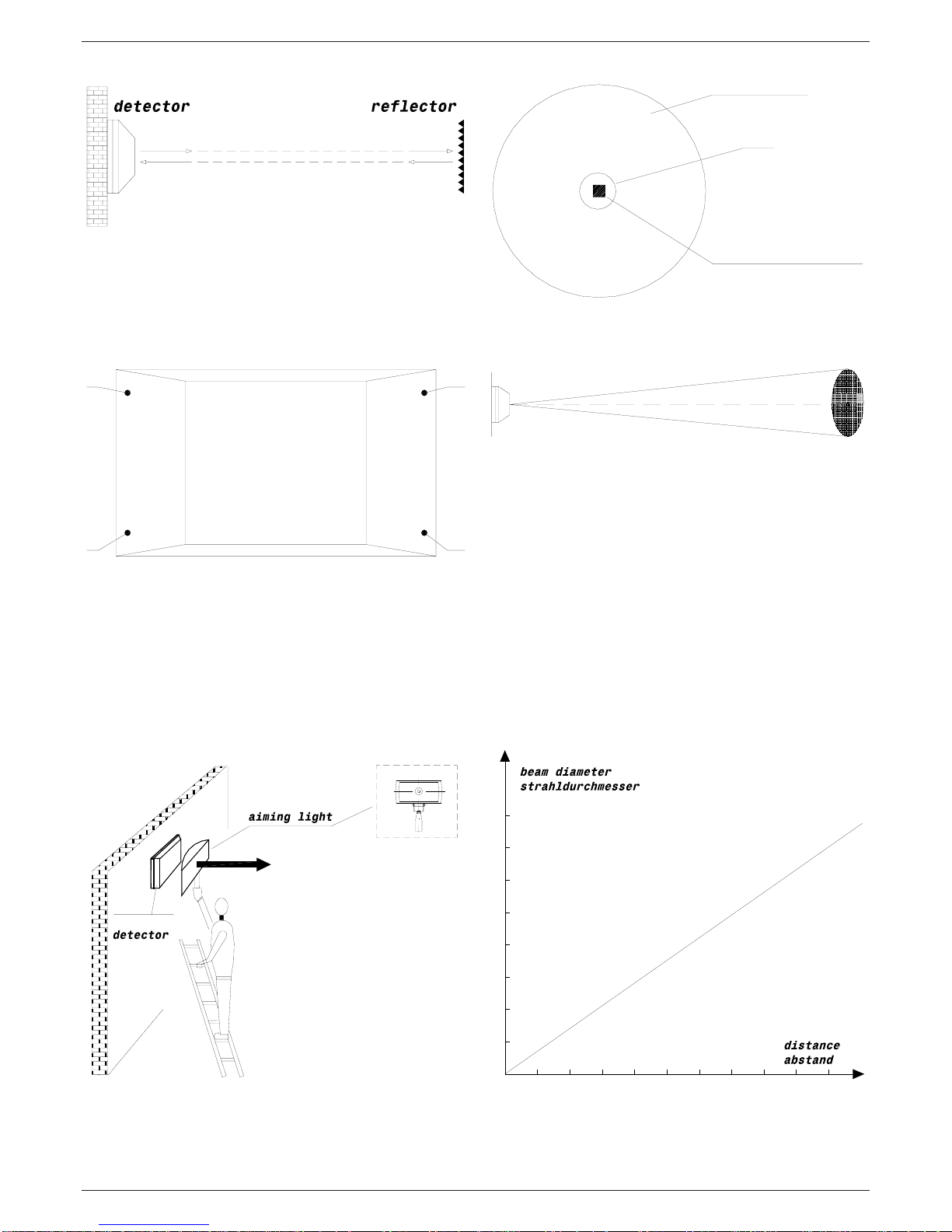

8.9 - The detector emits a conic beam which form and dimension,

in relation with the distance between detector and FX, are

explained in figures 5 -6.

It’s important that the FX is in the center of the detector’s conic

beambecause,undertheseconditions,even if some small movements

of the wall on which the transmitter is mounted on happen (caused

by deformations), the reflector remains always within the beam and

therefore active.

Toobtainthis,theoperations of fine centering with output signal

measuring,explainedbelow, mustbeperformedwithcare.

8.10- Regulate the signal to about 3V acting on the trimmer P1

(fig.9)

8.11 - Search for the maximum output signal optimizing the optical

alignment of the Transmitter acting slowly and in sequence on the

3 screws of regulation V1-V2-V3 set on the optic crew. This pro-

cedure take some time however, if well performed, it assures a

perfect work of the detector for many years. We advise to use the

following procedure:

• On the detector slowly turn the screw V1 clockwise and then

look at the value of the signal visualized on a multimeter. If the

signal increased (for example from 3V it rised to 3,5V) then again

turn the screw V1 of the detector clockwise and then look at the

value of the signal.

• Continue with this procedure as long as the signal increases.

When it has the tendency to decrease instead, stop the operation

on the screws V1 of the detector returning to the previous position.

• If during the operation the signal overcomes 4,5V, to avoid the

saturation, act on the trimmer P1 to bring the signal back to 3 V,

allowing the best evaluation of the variations of the signal.

• After finding out the maximum og the signal acting on the screw

V1, perform the same operations on the screws V2 and V3.

In such way the best possible position of optical allignment is

reached. This procedure is important because it will assure a perfect

operation of the detector for long time.

8.12 - If you don't have a multimeter, it is still possible to get good

results in the optical alignment of the detector, looking at the

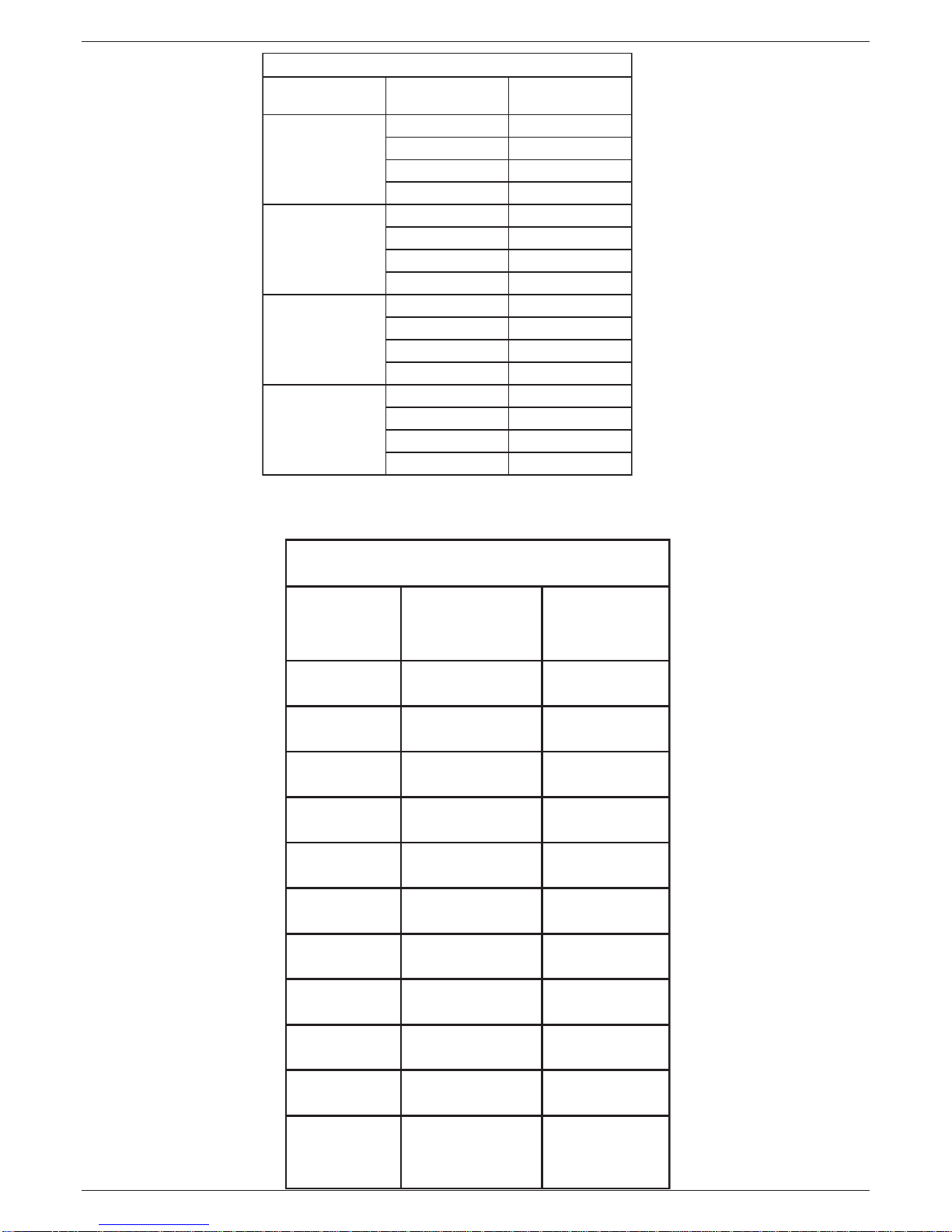

detector’s blue and red leds indications. Operation is the following:

• 1 flash of the blue Led: 1 Volt

• 1 flash of the red Led: 0.5 Volts

• if the signal is smaller of 0.5V the blue led and red one are off

• if the signal in the range 0.5-1 V the red led performs 1 flash,

remains off for 2 seconds and then it repeats the sequence

• if signal is among 1-1.5 V the blue led flashes once, remains

off for 2 seconds and then it repeats the sequence

• if signal is among 1.5-2V the blue led flashes once and the red

led flashes once. They remain off for 2 seconds and then the

sequence is repeated

• if signal is among 2-2.5 V the blue led flashes 2 times, remains

off for 2 seconds and then it repeats the sequence

• if signal is among 2.5-3V the blue led flashes 2 times and the

red led flashes once. They remain off for 2 seconds and then

the sequence is repeated

• same type of indication up to 4 V

• if the signal overcomes 4 V, the blue Led flashes faster and

faster as the frequency signal increases up to 4.7V

• when the signal overcomes the 4.7V and in the range 4.7V -

4.9V, the blue led is continously ON. This is the position of

optimal setup

• if the signal gets over 4.9V the two blue and red leds are

permanently on. This is the saturation indication.

The table of fig.8 recaps the leds operation.

8.13 - After doing the operations of fine optical alignment using

the Tester or the indications of the Leds, you must regulate the

signal slowly acting on the trimmer P1, between 4.7V and 4.9V.

When the signal it is included within this range, the blue Led is

costantly ON. This it is the position of optimal setup. If the signal

overcomes the 4.9V, the detector goes in saturation and the blue

and red leds are both ON. Therefore acting on P1, it is necessary

to set the signal between 4.7-4.9V so that the red Led switches

OFF and is only the blue Led remains ON (to avoid saturation).

Attention! - this regulation is not critical. The procedure

indicated above is the optimal one, but it is enough if the blue

Led is flashing or constantly ON to have a good setting.

However it is necessary to avoid the saturation (red Led ON).

The microprocessor automatically compensates the

inaccuracies of the setting.

8.14 - It must be checked out that, since the detector founds its

operation on the reflection of the projected beam, this reflection

is effected by the FX reflector only and not from other elements.

To be certain that the signal is produced by the reflection of its FX

reflector and not from other elements, it is useful to do a simple

verification. It is necessary to obscure the reflector with a non

reflecting screen (opaque). In that case the signal on SIG terminal

must decrease under 0,5V. (check indications in the following

pages).

8.15 - Select the alarm threshold level of the circuit sensible to

obscuration acting on the selector SW2 keeping in mind the

following :

• position 1 - low sensitivity - obscuration alarm threshold set to 70%

• position 2 - low to medium sensitivity - obscuration alarm threshold set

to 60%

• position 3 - medium to high sensitivity - obscuration alarm threshold

set to 50%

• position 4 - high sensitivity - obscuration alarm threshold set to 40%

8.16 - Sensitivity must be regulated according to the environmental