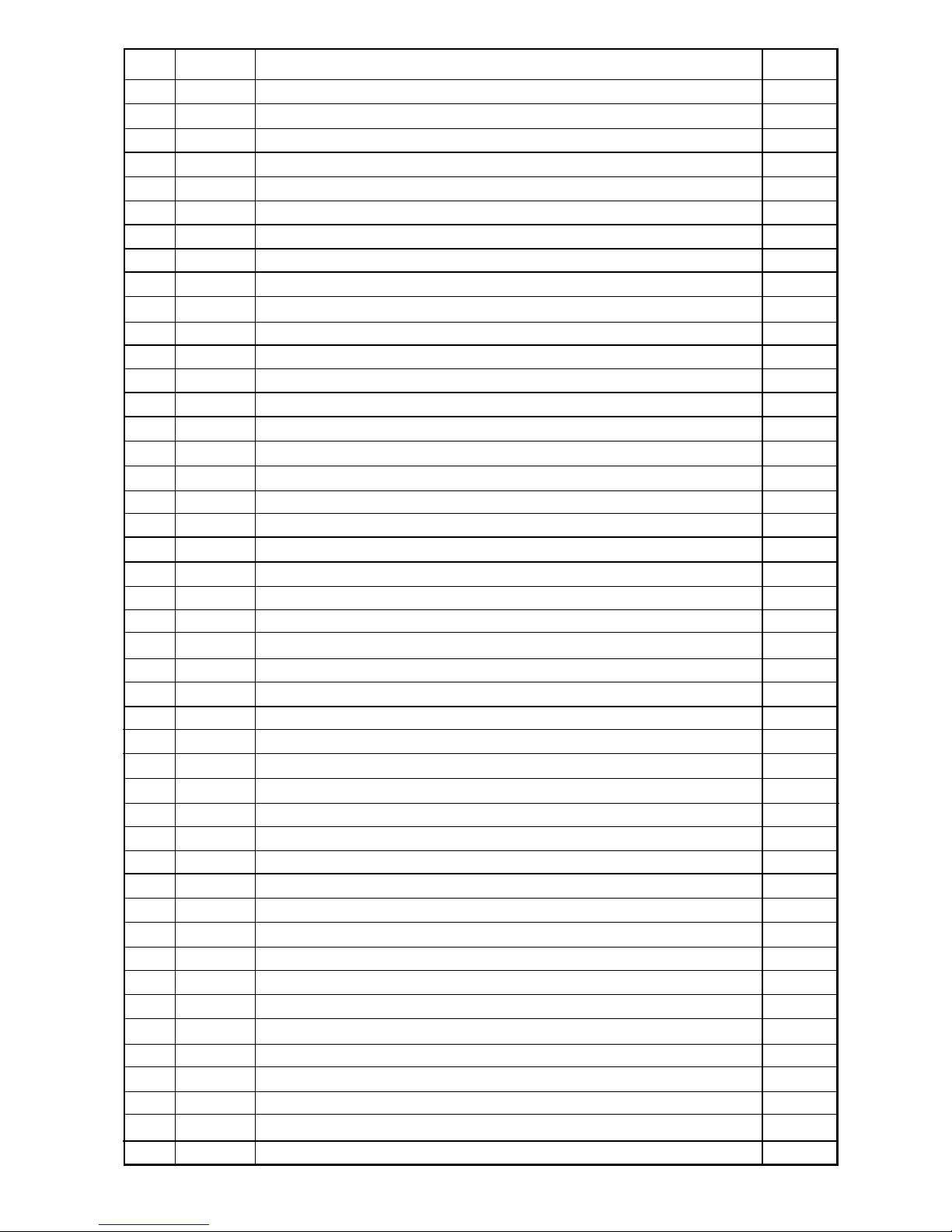

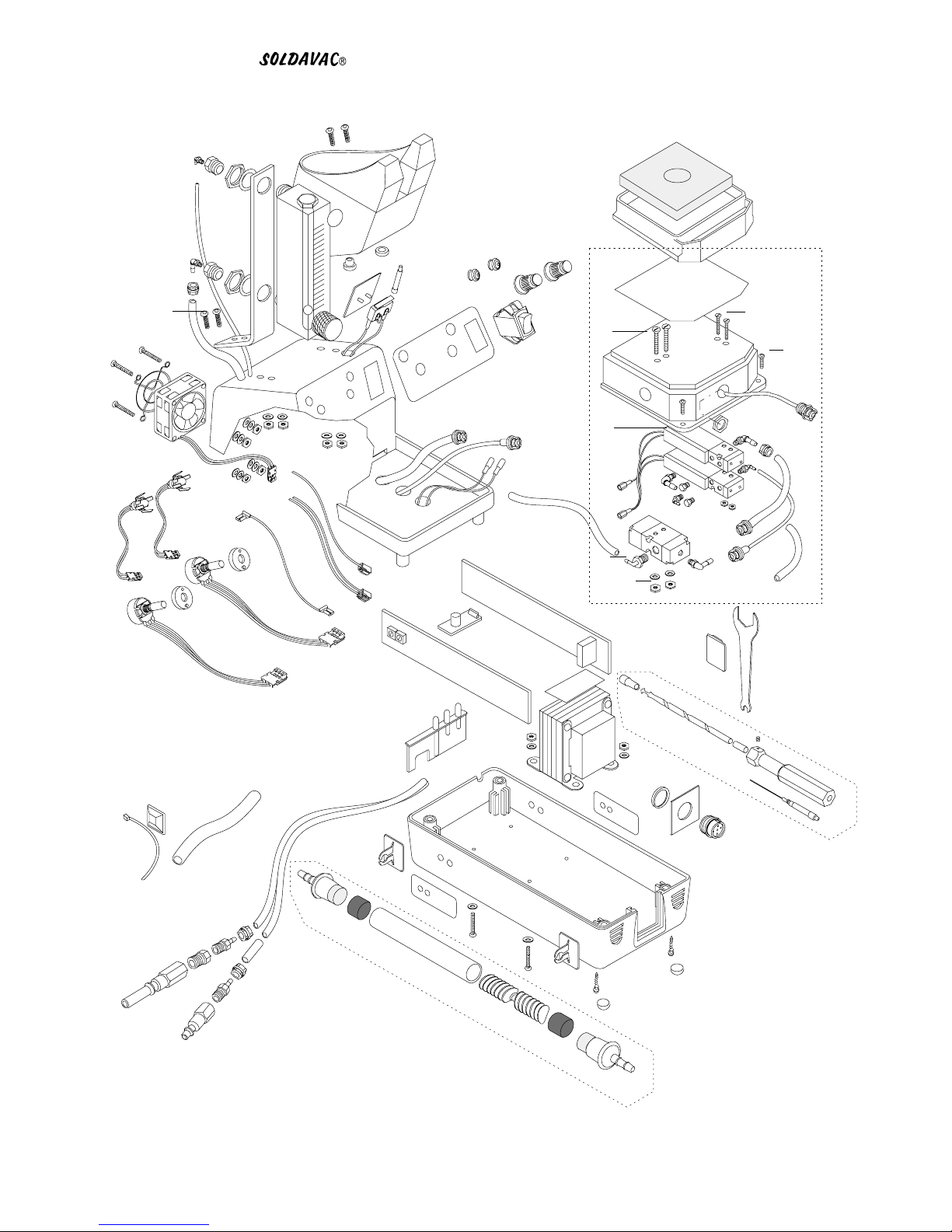

10 SR006 Index Flange (nut side) 1

11 SR122 Screw, Pan Hd, Slotted, 2-56 x 1/8 3

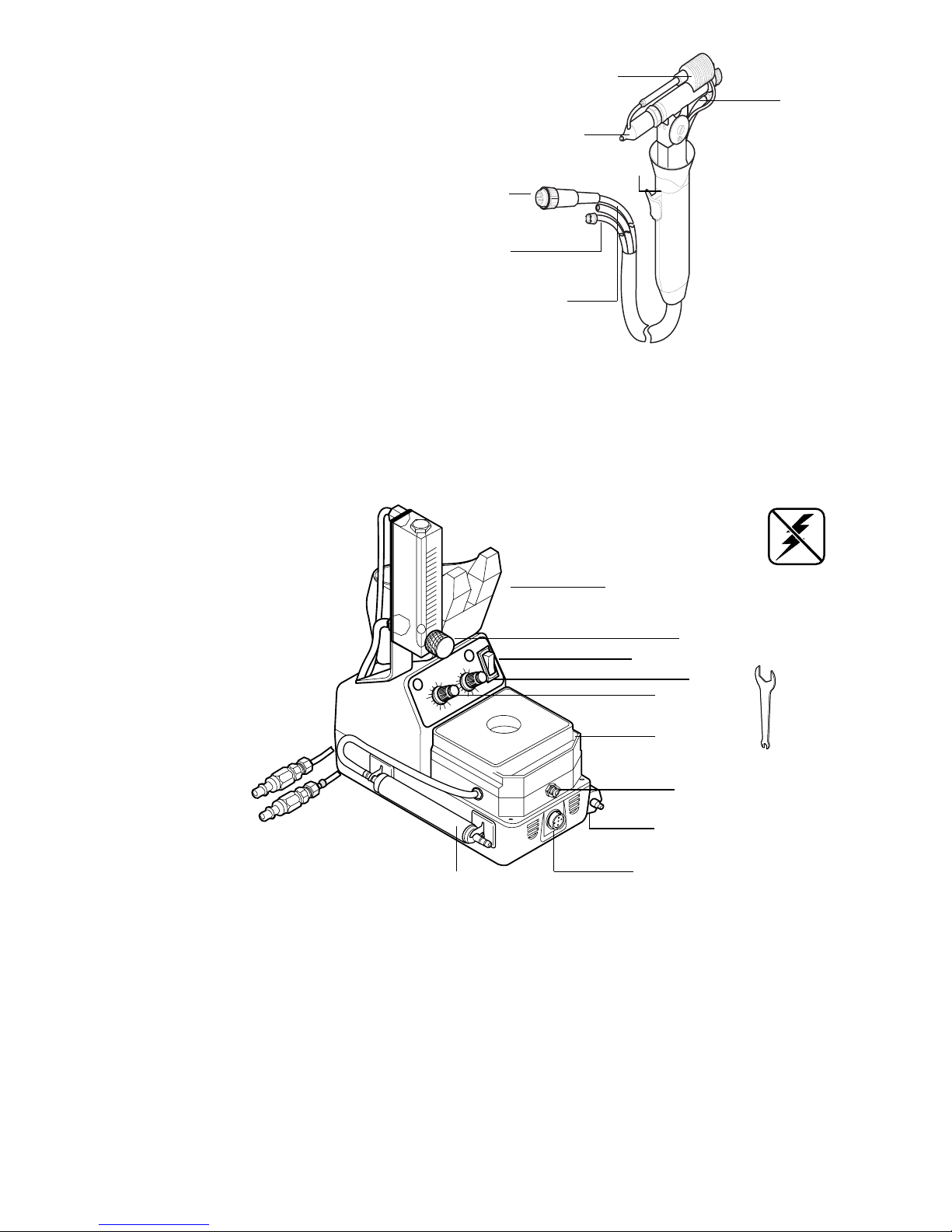

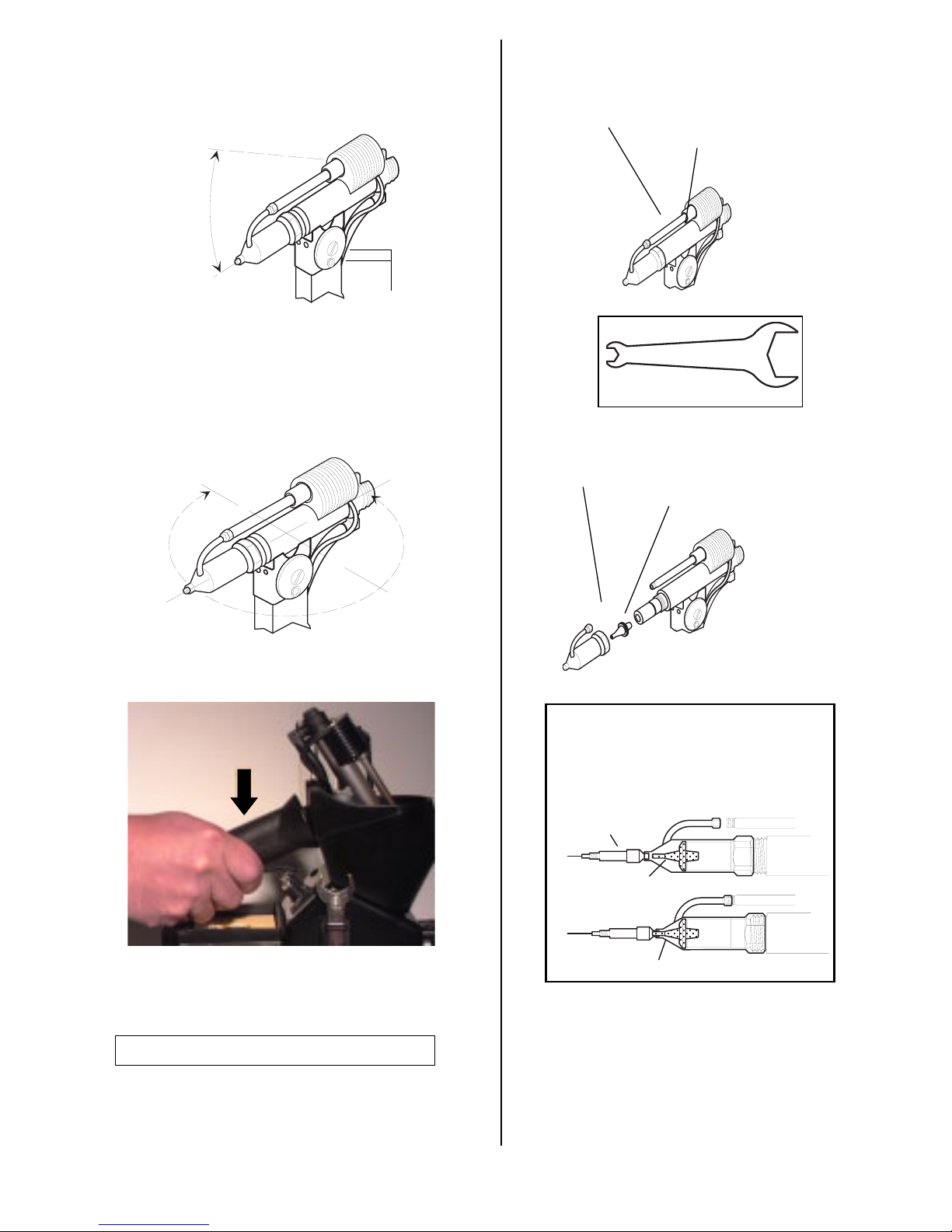

12 SR440 Housing, Desold Head Assy. 1

13 SR345 Screw, Pan Hd, Phillips, 4-40 x 3/8 2

14 SR119 Teflon Spacer 1

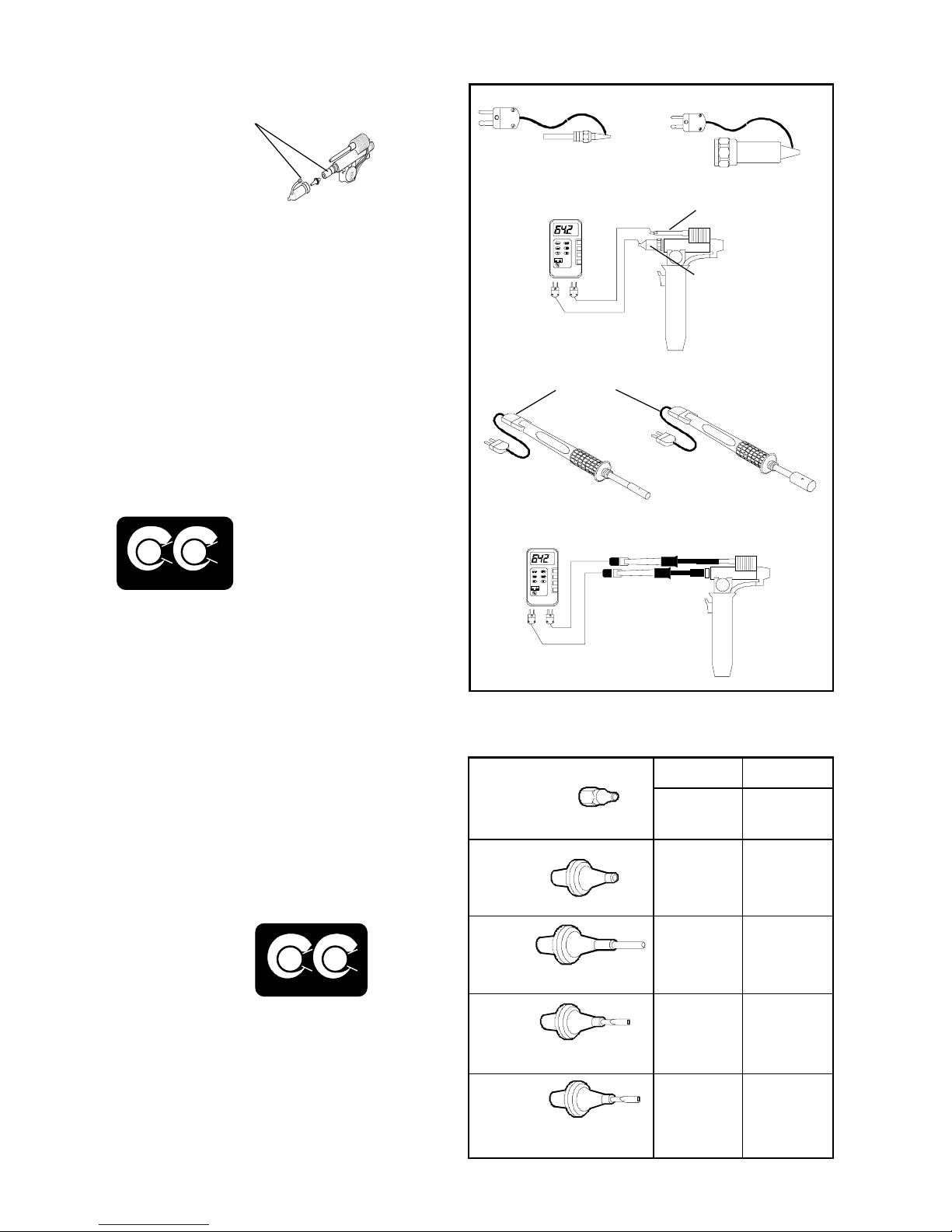

15 SR120 Heater Element, 24V, 70W 1

16 SR117 Teflon Bushing 1

17 SR118 Heater Restrainer 1

19 OS731 O-Ring for Heater Bushing and End Cap 2

20 OS133 Silicone Washer 1

21 SR145 Teflon Braided Fiberglass 2

22 RSX72 Retaining Sleeve for Heater Assy. 1

23 TSX713 Desoldering Tip 1

24 SR629 Head Shaft 1

26 SR126 Washer, Nylon 2

27 SR121 Grounding Wire 1

28 SR005 Index Flange (screw side) 1

29 SR169 Washer, Flat, .32 O.D. x .17 I.D 1

30 SR008 Screw, Flat Head, Slotted, 2-56 x 1 2

31 SR168 Screw, Pan Head, Phillips, 8-32 x 1 1

32 SC525 Solder Cone 1

33 AF625 Felt Filter (set of 10) 1

35 SR148 Housing for End Cap 1

36 OS132 O-Ring for Elbow Connector of End Cap 1

37 SR147 Elbow Connector of End Cap 1

38 MS229 Mica Sheet 3

39 SR128 Trigger 1

40 SR348 Gas Tube 1

41 SR349 Handle Base 1

42 SR125 Spring for Head Shaft 1

43 SR127 Retaining Nut for Head Shaft 1

44 SR129 Valve Housing 1

46 OS730 O-Ring Set for Valve Assy. (3 O-Rings) 1 set

48 SR130 Poppet (O-Ring included) 1

49 SR131 Spring 1

50 SR132 Seat for Spring 1

51 SR350 Handle Cover 1

52 FC639 End Cap Assy. 1

55 SR352 Fitting, Quick Disconnect, Female 1

56 HL603 Hose, Low Static Silicone, 3/16 i.d. 5"

57 SR353 Plug, Male Cable Connector 1

60 SR393 Retaining Nut for Handle 1

62 SR143 Wire Guide, 3/8 Length, Nylon 2

68 SR335 Valve Assy. 1

69 SR356 Hose and Wiring Assy. 1

PART NO.

QTY

REQ'D

DESCRIPTION

ITEM

NO.