EDWARDS SYSTEMS TECHNOLOGY IRC-3 Programming manual

IRC-3

Maintenance and Troubleshooting Manual

P/N 270245

Revised 21NOV97

firealarmresources.com

DEVELOPED BY Edwards Systems Technology

6411 Parkland Drive

Sarasota, FL 34243

(941) 739-4300

COPYRIGHT NOTICE Copyright © 1997 Edwards Systems Technology, Inc.

This manual and the products it describes are copyrighted by

Edwards Systems Technology, Inc. (EST). You may not reproduce,

translate, transcribe, or transmit any part of this manual without

express, written permission from EST.

This manual contains proprietary information intended for distribution

to authorized persons or companies for the sole purpose of

conducting business with Edwards Systems Technology, Inc. If you

distribute any information contained in this manual to unauthorized

persons, you have violated all distributor agreements and we may

take legal action.

CREDITS This manual was designed and written by the EST Technical

Services - Documentation Department, Sarasota.

firealarmresources.com

Maintenance and Troubleshooting Manual i

Content

IRC-3 Recommended Spare Parts List • 1

Routine Maintenance • 2

Sensor Cleaning • 3

Troubleshooting the ZAS Line • 5

Required Equipment • 5

Normal Operation • 5

Potential Problems • 5

System Logs • 8

firealarmresources.com

ii Maintenance and Troubleshooting Manual

Important information

Limitation of liability

The content of this manual is proprietary in nature and is intended

solely for distribution to authorized persons, companies, distributors

and/or others for the sole purpose of conducting business associated

with Edwards Systems Technology, Inc. The distribution of

information contained within this manual to unauthorized persons shall

constitute a violation of any distributor agreements and may result in

implementation of legal proceedings.

This product has been designed to meet the requirements of NFPA

Standard 72, 1996 Edition; Underwriters Laboratories, Inc., Standard

864, 7th Edition; and Underwriters Laboratories of Canada, Inc.,

Standard ULC S527. Installation in accordance with this manual,

applicable codes, and the instructions of the Authority Having

Jurisdiction is mandatory. EST, Inc. shall not under any circumstances

be liable for any incidental or consequential damages arising from loss

of property or other damages or losses owing to the failure of EST, Inc.

products beyond the cost of repair or replacement of any defective

products. EST, Inc. reserves the right to make product improvements

and change product specifications at any time.

While every precaution has been taken during the preparation of this

manual to ensure the accuracy of its contents, EST assumes no

responsibility for errors or omissions.

FCC warning

This equipment can generate and radiate radio frequency energy. If this

equipment is not installed in accordance with this manual, it may cause

interference to radio communications. This equipment has been tested

and found to comply within the limits for Class A computing devices

pursuant to Subpart B of Part 15 of the FCC Rules. These rules are

designed to provide reasonable protection against such interference

when this equipment is operated in a commercial environment.

Operation of this equipment is likely to cause interference, in which

case the user at his own expense, is required to take whatever measures

may be required to correct the interference.

firealarmresources.com

Maintenance and Troubleshooting Manual iii

Related Documentation

R

NFPA

National Fire Protection Association (NFPA)

1 Batterymarch Park

P.O. Box 9101

Quincy, MA 02269-9101

NFPA 70 National Electric Code

NFPA 72 National Fire Alarm Code

R

UL

Underwriters Laboratories, Inc. (ULI)

333 Pfingsten Road

Northbrook, IL 60062-2096

UL 38 Manually Actuated Signaling Boxes

UL217 Smoke Detectors, Single & Multiple Station

UL 228 Door Closers/Holders for Fire Protective Signaling Systems

UL 268 Smoke Detectors for Fire Protective Signaling Systems

UL 268A Smoke Detectors for Duct Applications

UL 346 Waterflow Indicators for Fire Protective Signaling Systems

UL 464 Audible Signaling Appliances

UL 521 Heat Detectors for Fire Protective Signaling Systems

UL 864 Standard for Control Units for Fire Protective Signaling Systems

UL 1481 Power Supplies for Fire Protective Signaling Systems

UL 1638 Visual Signaling Appliances

UL 1971 Visual Signaling Appliances

R

Underwriters Laboratories of Canada (ULC)

7 Crouse Road

Scarborough, Ontario M1R 3A9

ULC S527 Standard for Control Units for Fire Alarm Systems

ULC S524 Standard for the Installation of Fire Alarm Systems

ULC S536 Standard for the Inspection and Testing of Fire Alarm Systems

ULC S537 Standard for the Verification of Fire Alarm Systems

PLUS... Requirements of state and local building codes.

Requirements of the Authority Having Jurisdiction.

firealarmresources.com

iv Maintenance and Troubleshooting Manual

Document history

Maintenance and Troubleshooting Manual P/N 270245

Revision Status

Revision Date Reason For Change

1.0 September 1995 Initial Release.

1.5 November 1997 Layout and content revisions.

firealarmresources.com

Maintenance and Troubleshooting Manual 1

IRC-3 Recommended Spare Parts List

As a general guideline, 10% or a minimum of one piece of the

following installed equipment should be available as spare:

• Power Supply

• Zone Cards

• Relay Cards

• ZAS Cards

• CM1N

• CM2N

• Amplifier (If no backup installed in system)

• Printer ribbon

• Horn, bell, strobe, and speaker

As a general guideline, 10% or a minimum of three pieces of the

following installed equipment should be available as spare:

• Monitor Modules

• Control Modules

• Heat Detectors

• Ionization Smoke Detectors

• Photoelectronic Smoke Detectors

• Base, Detector

• Duct detector Filter Kits

• Breakglass Replacement for Pull Stations

• Breakglass Replacement for Warden Stations

System batteries should be replaced at intervals recommended by the

battery manufacturer. Stocking of spare batteries is NOT recommended

because of shelf-life limitations.

firealarmresources.com

2 Maintenance and Troubleshooting Manual

Routine Maintenance

Caution: Disconnect power before removing or installing any modules.

Lethal voltages from other systems may be present even with fire alarm

disconnected.

Single and multi-line network hardware has been designed for ease of

maintenance. Repairs are accomplished by removing a suspected bad

module or card and replacing it with a known good module or card.

Field repair of modules should not attempted. Defective modules

should be replaced and defective modules returned to the factory for

service, where the necessary test equipment and software is available.

Routine maintenance should be performed in accordance with the

procedures in NFPA 72 and the Local Authority Having Jurisdiction.

All panels should be checked for proper operation, and the batteries

should be tested under load.

The following suggested routine maintenance should be performed

annually.

Basic Tools:

1. Common screwdriver, 3/16 x 6 inch blade with insulated handle.

2. High input impedance digital multimeter and probes.

3. One each, 15 KΩ, 1/2 watt resistor.

4. One each, 12 inch jumper lead with clips.

5. Panel door key.

Note: Inform all responsible personnel and the central station of system

maintenance.

1. Visually inspect all connections, wiring and shields. Tighten loose

connections and replace missing cover plates and screws.

2. Remove the positive (red) battery lead from the stand-by battery.

The trouble LED will turn ON after a momentary delay. Pressing

the trouble silence switch will turn OFF the buzzer. Reconnect the

battery.

Caution: Batteries can deliver extremely high currents for short

periods. Remove all jewelry to prevent serious burns caused by short

circuiting the battery.

3. Remove the AC source and verify the panel continues to operate

properly.

Battery Test

To test the batteries, using a 12 inch jumper, short across a fire alarm

input zone (type "A"). After 5 minutes the batteries must not be lower

than 24 volts. If the batteries are low they may be defective.

Upon completion of this test, restore AC power and insure that all

trouble and alarm conditions are reset.

firealarmresources.com

Maintenance and Troubleshooting Manual 3

4. By shorting the various zones with a jumper wire, the various visual

alarm indicators may be visually checked for operation; this test will

also electrically test the panel for proper operation.

Upon conclusion of routine and/or preventative maintenance actions,

verify system operation and inform all responsible parties of system

restoration.

Sensor Alert

A "SENSOR ALERT" message is displayed on the CM1N when the

sensitivity of an addressable analog detector has increased to a level

where unwarranted alarms may occur. Inspection and cleaning of the

detector is indicated.

Magnet Testing

Addressable analog sensors are equipped with a reed switch for testing

purposes. To test the sensor, place a magnet near the plastic base

directly across from the Test Socket. This activates the sensor and

generates an alarm response for the sensor's address.

Sensor Cleaning

NFPA 72 states ,"All smoke detectors shall be visually inspected in

place at least semi-annually to identify missing detectors, detectors

with impeded smoke entry, abnormally dirty detectors, and detectors

no longer suitably located because of occupancy or structural changes".

NFPA 72 also states that a test shall be performed annually "to assure

that each smoke detector is operative and produces the intended

response".

The following recommendations have been extracted from field

bulletins published by the manufacturer of 400 and 500 detectors.

400 and 500 Series Photoelectronic Smoke Detectors

Before cleaning, notify the proper authorities that the system is being

tested. Disable the zone or system to prevent undesirable, unwanted

alarms and proceed with testing and/or maintenance.

1. Remove detector cover by inserting a small blade screwdriver into

the slot provided 90° from the test jack receptacle and twisting the

cover clockwise.

2. Lift screen from photo chamber. Vacuum screen and cover before

using clean compressed air to dislodge and remove any remaining

debris. Replace screens if necessary; part number RS24 (photo) and

RS24T (thermal).

3. Vacuum photo chamber and then use compressed air to remove any

remaining debris and blow area clean.

4. Before re-assembly, be sure all parts are clean.

firealarmresources.com

4 Maintenance and Troubleshooting Manual

5. Replace screen by aligning arrow with the field test slot on the base

of the detector. Push screen gently into place; should fit tightly into

place.

6. Replace cover by gently turning cover clockwise until it locks into

place.

7. Test and verify detector operation.

8. When cleaning and testing has been completed, restore the zone or

system, verify proper operation and notify the proper authorities of

system restoration.

400 and 500 Series Ionization Smoke Detectors

Before cleaning, notify the proper authorities that the system is being

tested. Disable the zone or system to prevent undesirable, unwanted

alarms and proceed with testing and/or maintenance.

1. Remove detector cover by depressing the three lock prongs on top

of the cover and rotating the cover counter-clockwise.

2. Carefully remove the screen.

3. Clean screen thoroughly with a soft brush or vacuum. Screens on

the ionization unit may also be rinsed under clean warm water, then

dried thoroughly before re-assembly.

4. Brush or vacuum the inside area of cover, then remove any

remaining residue with cleaned compressed air: Do not apply water

to this area.

5. Vacuum sensing chamber before using cleaned compressed air to

remove remaining residual debris. Do not apply water to this area.

6. Press screen back into cover.

7. Replace detector cover and turn clockwise to lock into place.

8. Test detector and verify limits as per label on back of detector.

9. When cleaning and testing has been completed, restore the zone or

system, verify proper operation, and notify the proper authorities of

system restoration.

Aerosol Testing

Aerosol should not be used for testing; cigarette, wick or pipe smoke

are the only accepted methods. If aerosol testing must be used; it

should be used only as a go-no-go test and under no circumstances be

used to determine or to verify calibrated sensitivity. Canned aerosol is

not recommended since the use of these products may cause the plastic

to break down and deteriorate.

firealarmresources.com

Maintenance and Troubleshooting Manual 5

Troubleshooting the ZAS Line

Required Equipment

The material in this topic applies to ZAS-1S and ZAS-FIB lines only.

For other types of ZAS line, see the IRC-3 Network Controller Option

Cards Installation Manual for the specific device in question. To

completely troubleshoot ZAS-1S and ZAS-FIB lines, the following

equipment is required:

• computer with IRC-3 download program and download cable

• digital multimeter

• decade resistor box

• oscilloscope

Normal Operation

The communication protocol between the ZAS module and the

analog/addressable devices is digital.

24 V

5 V

0 V

ZAS COMMUNICATIONS ANALOG / ADDRESSABLE DEVICE COMMUNICATIONS

[M&T-001.CDR]

Figure 1

Figure 1 shows the normal polling communication sequence between a

ZAS module and a single analog/addressable module. When multiple

devices are connected to the ZAS line, the first half of the waveform

appears the same but the second half of the waveform will jump

around. For troubleshooting purposes, the system MUST be

temporarily programmed to communicate only to a single module or

device.

Potential Problems

There are three basic causes of erratic ZAS line operation:

1. Excessive Wiring Resistance:

Rarely is excessive wiring resistance the sole cause of ZAS line

problems. For any length of cable, the amount of resistance and

capacitance per foot doesn't change and the ZAS circuit capacitance

limits are usually reached before the resistance limits. Referring to

Figure 1, the digital signal operates between 0 and 24 VDC.

Excessive line resistance causes the signal to shrink from a

firealarmresources.com

6 Maintenance and Troubleshooting Manual

maximum of 26.4 VDC to a lower voltage, for example 23 VDC.

The 3.4 volt drop in the wiring is due to wire resistance.

To measure ZAS line voltage drop, use an oscilloscope to measure

the peak voltage at the ZAS module and at each analog/addressable

device. If the voltage difference is greater than 2 VDC, the

resistance in the wire run is excessive. Too much resistance in the

ZAS wire run is typically caused by small wire size or a bad

connection.

If the wire size is too small for the run length, the only remedies are

to replace the wire with a larger size or install additional ZAS

modules, dividing the line into acceptable lengths. Breaks or bad

connections in the ZAS loop wiring can be identified by comparing

the calculated loop resistance value (described earlier) with the

measured loop resistance value. The measured wiring loop

resistance should not be different from the calculated loop resistance

by much more than a few ohms.

2. Excessive Wiring Capacitance:

The second cause of erratic ZAS line operation is too much

capacitance in the ZAS circuit wiring. Capacitance distorts the

digital signal. Compare the waveform in Figure 1 with that of Figure

2. The capacitance causes the distortion shown in Figure 2 (note 1).

As wiring capacitance increases, the square edges of the digital

wave form start to curve. Excessive wiring capacitance causes the

waveform to curve beyond the point where a device can recognize

the waveform and respond when polled.

24 V

5 V

0 V

ZAS COMMUNICATIONS ANALOG / ADDRESSABLE DEVICE COMMUNICATIONS

[M&T-002.CDR]

NOTE 1

NOTE 2

Figure 2

Wiring capacitance also effects the turn on current spike shown as

note 2 in Figure 2. If the turn on current spike is not present in the

digital sequence, there is a high probability the analog/addressable

device's communication will not be understood by the ZAS

communication module.

To determine if excessive capacitance is the cause of ZAS line

problems, write and download into the CM1/2(N) which contains

the problem ZAS card, a short program which communicates with

only one device on the ZAS line. Disabling all but one device on the

ZAS line will not accomplish the required task.

With all devices connected to the ZAS line and the single device

program loaded, use the oscilloscope to verify the observed

waveform on the terminals of the devices is similar in appearance to

firealarmresources.com

Maintenance and Troubleshooting Manual 7

Figure 1 . The Pulses should not be excessively curved, and the

turn-on pulse must be present. If some pulses appear excessively

rounded and/or the start pulse is missing, too much capacitance is

the problem.

Note: Referring to Figure 1, the pulse width for all values below 5

VDC must be at least 70% of the pulse width for values above 5 VDC,

or the waveform is said to be excessively curved.

ZAS line capacitance problems are typically caused by long wire

runs, ground faults on the ZAS line, improper T-taps, or improper

shielding.

The shield must be treated as a third conductor. It must be free of all

ground faults and have continuity throughout. If the wire

capacitance is too large for the run length, the only remedies are to

replace the wire with a cable having a lower capacitance per foot or

install additional ZAS modules, dividing the line into acceptable

lengths.

3. Ground Faults:

Eliminating ground faults on the ZAS line reduces the amount of

capacitance on the ZAS wiring.

Verify the ZAS line is free of ground faults. Remove all field wiring

except the ZAS line under test from all panels which share a

common power supply with the CM1/2(N) containing the ZAS card.

Verify jumper J1 is installed the trouble sense (lower) card of the

power supply and J2 has been removed. If the CM1/2(N) displays

either a GND0 or P 002 then the ZAS line has a ground fault, which

must be corrected.

If the ZAS circuit is wired with improper T-taps (described earlier)

corrective measures include designing the ZAS line properly and re-

pulling the wire, or balancing the line. Balancing the line can help in

some cases but is not a substitute for proper wiring practice. If line

balancing is required, call EST Technical Services for additional

information.

firealarmresources.com

8 Maintenance and Troubleshooting Manual

System Logs

System Firmware Log

Installation Name: ______________________________________________________________

Date Of Installation: ______________________________________________________________

Installing Distributor: ______________________________________________________________

Installation Performed By:_____________________________________________________________

Component Revision Checksum Date Comment

Data Entry

Program Used

N/A

CM1

CM1N

CM1NX

CM2

CM2N

DCPU

FCCD

PCPU

REM

RZB12-6

SAN

ZAS

CCA

CGP

VDU-3

firealarmresources.com

Maintenance and Troubleshooting Manual 9

Fire Alarm System Log

Installation Name: ______________________________________________________________

Date Of Installation: ______________________________________________________________

Installing Distributor: ______________________________________________________________

Inspection & Test Date: ______________________________________________________________

I & T Performed By: ______________________________________________________________

Time &

Date

Recorded

By

Fire Trouble Display

Message

Probable

Cause

Action

Taken

Action Taken By:

Name & Date

firealarmresources.com

10 Maintenance and Troubleshooting Manual

firealarmresources.com

Other manuals for IRC-3

2

Table of contents

Other EDWARDS SYSTEMS TECHNOLOGY Security Sensor manuals

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY EST3 User manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY IRC-3 User manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY EST3 User manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY CMDN Owner's manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY CRC Product manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY IRC-3 Owner's manual

EDWARDS SYSTEMS TECHNOLOGY

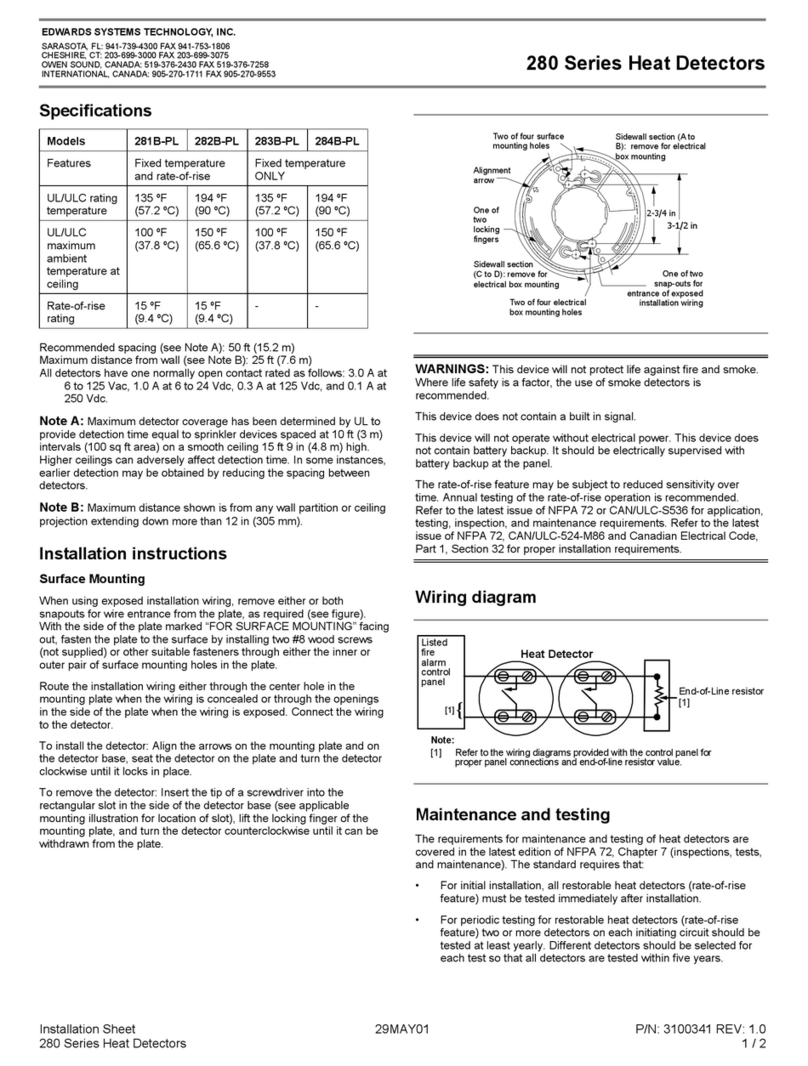

EDWARDS SYSTEMS TECHNOLOGY 280 Series Assembly instructions

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY EST2 User manual

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY EST3 User manual