– Protective measures are installed on the system (e.g.flow control valve or

control valve, check valve, pressure limitation valve).

Cleaning the valve

• Remove all transport packaging. The material used in the packaging has been

specifically chosen for its recyclability.

• Traces of residual grease may be evident on the product due to the produc-

tion process used. Clean the valve immediately before installation.

Connecting the media line

NOTICE!

To eliminate direct access to the valve opening during operation, connect a line to

both ports, even if the valve is located at the end of the piping.

• Screw the valve connections to the line.

– Tightening torque: 10Nm

Connect the operating medium line

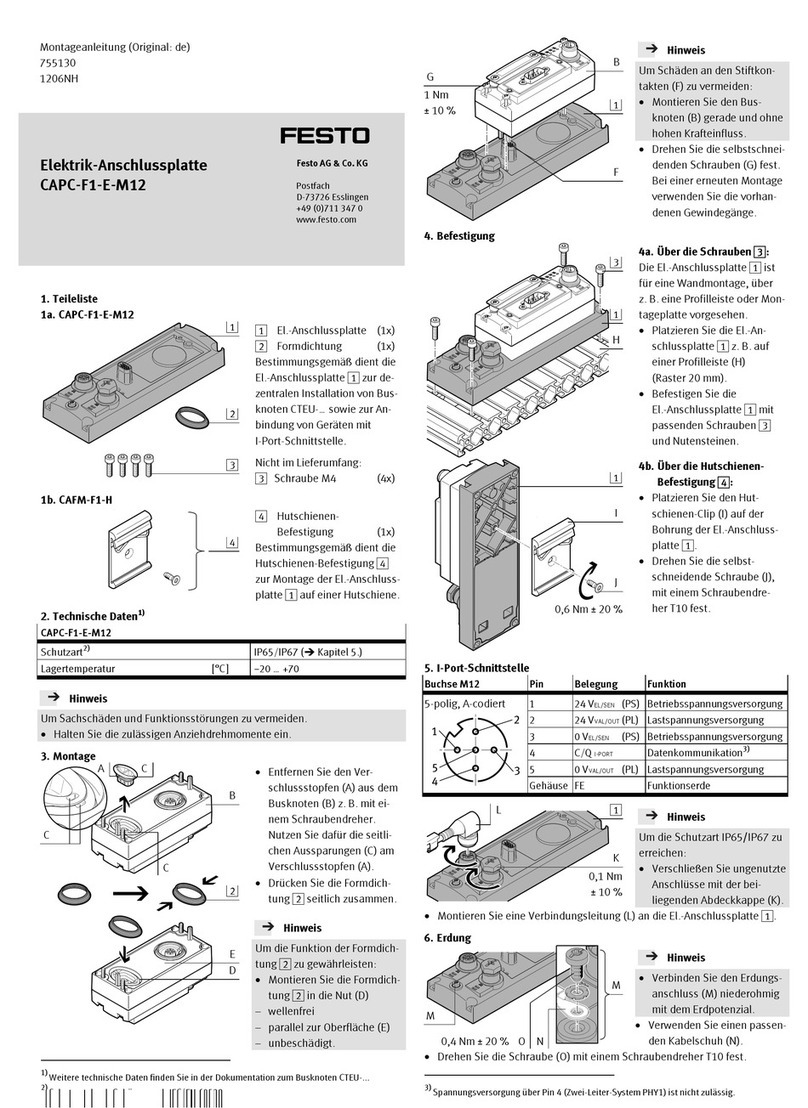

1. Mount the fitting on the operating medium connection.

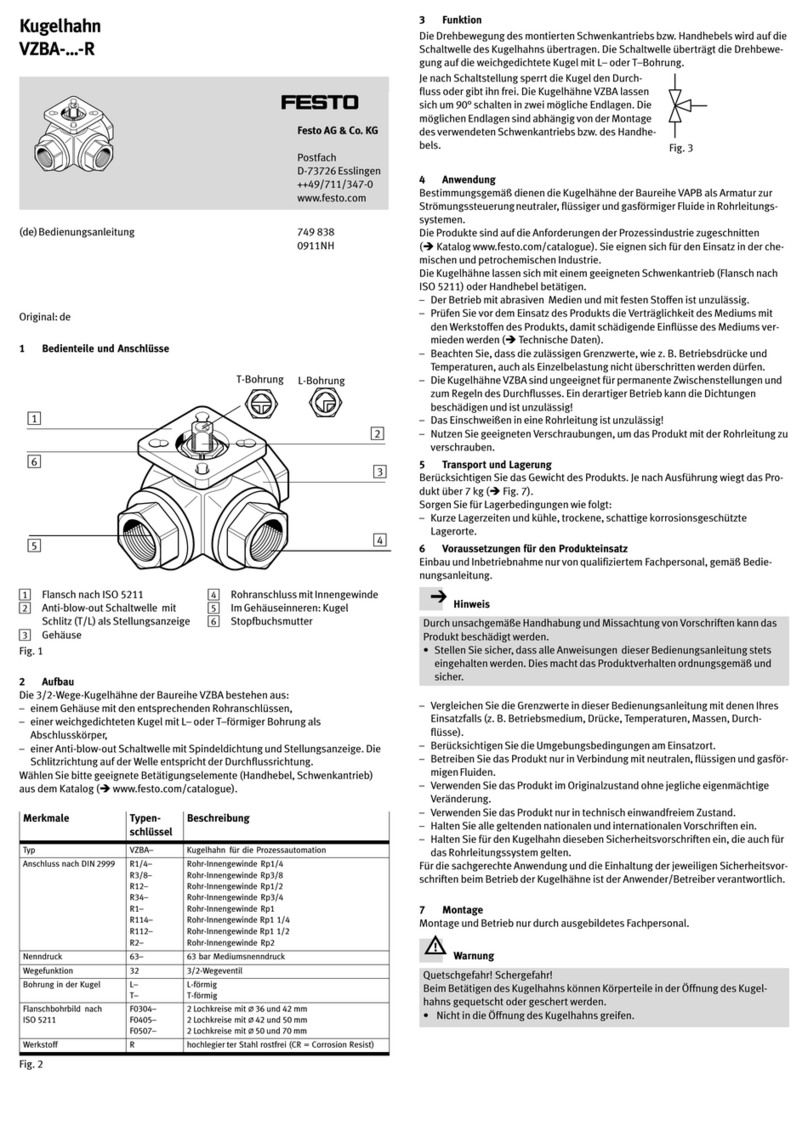

– Max. permissible screw-in depth (è Fig.1,4 und 5): 3mm

2. Connect the operating medium line.

3. Mount the plug screw on the exhaust port.

Additional steps for ducted exhaust air:

1. Remove the plug screw at the exhaust port.

2. Connect the piping for the ducted exhaust air to the exhaust port.

– Max. permissible screw-in depth (è Fig.1,4 und 5): 3mm

7 Commissioning

Requirements

– Protective measures are installed on the system (e.g. flow control valve or

control valve, check valve, pressure limitation valve).

– The valve is fully mounted and connected.

Checking operating conditions

WARNING!

Risk of injury from hot media under pressure.

Dependent on the medium and the operating conditions, pressure peaks that

exceed the permissible pressure range can develop in the system. The valve can

open accidentally, and medium can exit.

• Do not exceed the maximum permissible medium pressure. In doing so, take

pressure peaks in the system into account.

• Check operating conditions and critical limits è 13 Technical data.

• Check connection points for tightness.

• Check compatibility of the devices in the system for maximum pressure (con-

sider pressure peaks). If necessary, adjust the application parameters.

Commissioning the valve

1. Supply medium.

2. Supply operating pressure to the valve.

ÄThe valve opens.

8 Operation

WARNING!

Risk of injury from hot media under pressure.

If the seal cartridge (shut-off element) leaks and the exhaust port is plugged (or

the ducted exhaust air is plugged or in the case of exhaust air in an equalising

volume), the flow medium can enter the operating medium.

• Use only media that will not cause dangerous reactions if mixed.

WARNING!

Risk of injury due to hot surface.

The valve can become hot if the temperature of the medium is high.

• Do not touch the valve during operation or immediately afterward.

• Observe the operating conditions.

• Comply with permissible critical limits.

• Comply with maintenance conditions è 9 Maintenance and care.

Recommendation: Switch valve several times per day.

After longer idle times:

• Actuate the valve several times and check for correct function.

9 Maintenance and care

WARNING!

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Traces of medium can remain in the product and can escape when open or dis-

mantled.

• Allow the valve and piping to cool and depressurize them.

• Wear specified protective equipment.

Checking and cleaning the valve

• Check product regularly from the outside for leakage and function.

• Check plug screw and ducted exhaust air for passage. Remove blockages

• Clean product regularly.

• Comply with replacement interval of the spring, guiding band and piston seal:

max. 5million switching cycles.

NOTICE!

Allow for ducted exhaust air when cleaning the outside.

• Replace the plug screw with a threaded insert or connector. Observe the max-

imum permissible screw-in depth.

Checking and replacing the seal cartridge

NOTICE!

Seal cartridge may only be changed by qualified personnel following the assembly

instructions èAssembly instructions for seal cartridge.

The seal cartridge is subjected to mechanical loads and ageing. A damaged or

worn seal cartridge results in leakage.

• Check and replace seals and seal cartridge regularly (intervals dependent on

the medium).

• Replace seal cartridge and seals if they are damaged. Use a seal cartridge

with the same specification.

•Comply with replacement interval of the seal cartridge: max. ½½million

switching cycles.

10 Fault clearance

Fault description Cause Remedy

Valve is blocked. Clean valve or replace seal cart-

ridge.

Operating medium line is

blocked.

Clean or replace operating

medium line.

Shut-off element is stuck

together because the material

of the shut-off element is not

suited for the medium.

Replace product with a product

variant made of appropriate

materials.

Valve does not open or opens

too slowly.

Seal cartridge is faulty. Replace seal cartridge.

Medium pressure is too high. Reduce medium pressure.Valve opens accidentally.

Seal cartridge is faulty. Replace seal cartridge.

Operating pressure is still

present.

Shut off the operating pressure.Valve does not close or closes

too slowly.

Seal cartridge is faulty. Replace seal cartridge.

Leakage Seal cartridge is faulty. Replace seal cartridge.

Tab. 2

11 Disassembly

WARNING!

Risk of injury from combustion and chemical burns.

The media in the piping system and the valve can be hot and under pressure.

Traces of medium can remain in the product and can escape when open or dis-

mantled.

• Allow the valve and piping to cool and depressurize them.

• Wear specified protective equipment.

1. Depressurise the piping and the operating medium line.

2. Allow the valve and piping to cool.

3. Empty the piping and valve completely.

– Make sure no one is located in front of the outlet opening.

– Catch discharging media in a suitable container.

4. Disconnect the operating medium line from the valve.

5. Disconnect the piping connections and remove the valve.

12 Disposal

• Observe the local regulations for environmentally friendly disposal.

• Dispose of the product in an environmentally friendly manner. When doing

this, also take residual media into account (recycling of hazardous waste

where appropriate).