MICO, Inc. (2) Form No. 81-463-008 Revised 2010-11-08

SERVICE INSTRUCTIONS

Disassembly

(Refer to Figure 1)

1. Remove plug (1) from housing (7). Remove o-ring (2) from

plug (1). NOTE: Plug (1) is under spring tension.

2. Remove spring (3) and rod (4) from housing (7).

3. Remove plug (8) from housing (7). Remove o-ring (2) from

plug (8).

4. Remove spool (6) from housing (7) through plug (1) end ONLY.

Remove quad ring (5) from spool (6).

5. Earlier design: Loosen nut (9) on screw assembly (11) and

remove screw assembly (11) from housing (7). Remove o-ring

(10) from screw assembly (11). Remove spring (12), steel ball

(13), seat (14), and o-ring (15) from housing (7).

Later design: Some later designs use a directional spring

(12). Directional spring (12) is attached to screw assembly

(11) by means of the small diameter end of spring (12)

being snapped into a groove on the nose end of screw

assembly (11). See Figure 1c. Remove nut (9) and remove

screw assembly (11) from housing (7). Remove o-ring (10)

from screw assembly (11) from nut (9) side of screw assembly.

Remove shim (31), spring (12), steel ball (13), seat (14), o-ring

(15), and washer (32) from housing (7).

6. Thread a 3/8-16UNC cap screw into washer (16) and remove

washer (16) from housing (7).

7. Remove plug (29) from housing (7). Remove o-ring (15) from

plug (29).

8. BEFORE moving screw (28), ACCURATELY MEASURE ITS

DEPTH from the end of housing (7) and record for reassembly

purposes. Remove screw (28) from housing (7).

9. Remove spring (27), retainer (26), and ball (25). Be sure to

keep ball (25) separate from ball (20) for reassembling.

10. Remove pin (30) from screw (28) using a drive pin punch.

NOTE: Be careful not to damage threads.

11. Remove plug (17) from housing (7). Remove o-ring (15) from

plug (17). NOTE: Be careful not to damage threads.

12. Remove spring (18), stop (19), and ball (20) from housing (7).

13. Place housing (7) on bench with plug (17) end down. Spool (21)

may or may not fall out at this point.

14. Using a 6.3-7.9 mm (0.25-0.31 in) diameter wood or plastic

dowel, carefully remove insert (22) and spool (21) from housing

(7). Insert (22) must come out plug (17) end of housing (7). Be

careful not to scratch or mar valve seats on insert (22).

15. Remove spool (21) from insert (22). Remove o-rings (23 & 24)

from insert (22).

Assembly

(Refer to Figure 1)

WASH ALL PARTS WITH CLEAN SOLVENT AND DRY. LUBRICATE

ALL RUBBER PARTS WITH CLEAN SYSTEM FLUID PRIOR TO

ASSEMBLY. BE SURE ENTIRE ASSEMBLY PROCEDURE IS

DONE USING CONTAMINATION FREE METHODS.

1. Install new o-ring (2) on plug (8). Install plug (8) into housing (7)

and torque 122.0-135.6 N∙m (90-100 lb∙ft).

2. Install new quad ring (5) on spool (6). Be sure quad ring (5)

does not twist in groove.

3. Lubricate spool (6) with clean system uid and insert into

housing (7) as shown in Figure 1.

4. Install spring (3) and rod (4) into housing (7).

5. Install new o-ring (2) on plug (1). Install plug (1) into housing (7)

and torque 122.0-135.6 N∙m (90-100 lb∙ft).

6. Install new o-rings (23 & 24) on insert (22) and install insert (22)

into housing (7). Note direction of assembly. Seat insert (22)

using a 12.7 mm (0.50 in) diameter wood or plastic dowel.

7. Install spool (21) into insert (22) in housing (7). Note direction

of spool (21), long shoulder end is up toward end plug (17),

see Figure 1a.

8. Install ball (20) on insert (22) in housing (7). Install stop (19)

over ball (20) and spring (18) over stop (19).

9. Install new o-ring (15) on plug (17) and carefully install into

housing (7), centering spring (18). Torque plug (17) 47.5-54.2 N∙m

(35-40 lb∙ft).

10. Turn housing (7) so plug (8) is vertically upward. Install ball (25)

in housing (7). Be sure ball (25) is centered in bottom of hole.

Install retainer (26) and spring (27) into housing (7).

11. Insert new pin (30) in screw (28). Be sure pin (30) is aligned

properly and is evenly driven into screw (28). NOTE: Be careful

not to damage threads.

12. Thread screw (28) in housing (7) to the depth recorded during

disassembly.

13. Install new o-ring (15) on plug (29). Install plug (29) in housing

(7) and torque 47.5-54.2 N∙m (35-40 lb∙ft).

14. Install washer (16) in housing (7). Note direction of washer (16),

see Figure 1b.

15. Earlier Design: Install new o-ring (10) on screw assembly (11).

Install o-ring (15), seat (14), steel ball (13), spring (12), and

screw assembly (11) into housing (7). Torque screw assembly

24.4-29.8 N∙m (18-22 lb∙ft). Then install nut (9) on screw

assembly (11) and torque nut 43.4-51.5 N∙m (32-38 lb∙ft).

Later Design: Some later designs use a directional spring

(12). Directional spring (12) is attached to screw assembly

(11) by means of the small diameter end of spring (12)

being snapped into a groove on the nose end of screw

assembly (11). If necessary, reattach the small diameter of

spring (12) into the groove on the nose end of screw

assembly (11) using a slight twisting motion. See Figure 1b.

Install new o-ring (10) on screw assembly (11) from nut (9) side

of screw assembly. Install washer (32), new o-ring (15), seat (14),

steel ball (13), and spring (12) in housing (7). Fully lubricate

shim (31) with clean system uid and install in housing (7) on

end of seat (14). Install screw assembly (11) in housing (7).

Torque screw assembly (11) 24.4-29.8 N∙m (18-22 lb∙ft). Then

install nut (9) on screw assembly (11) and torque nut 43.4-51.5 N∙m

(32-38 lb∙ft).

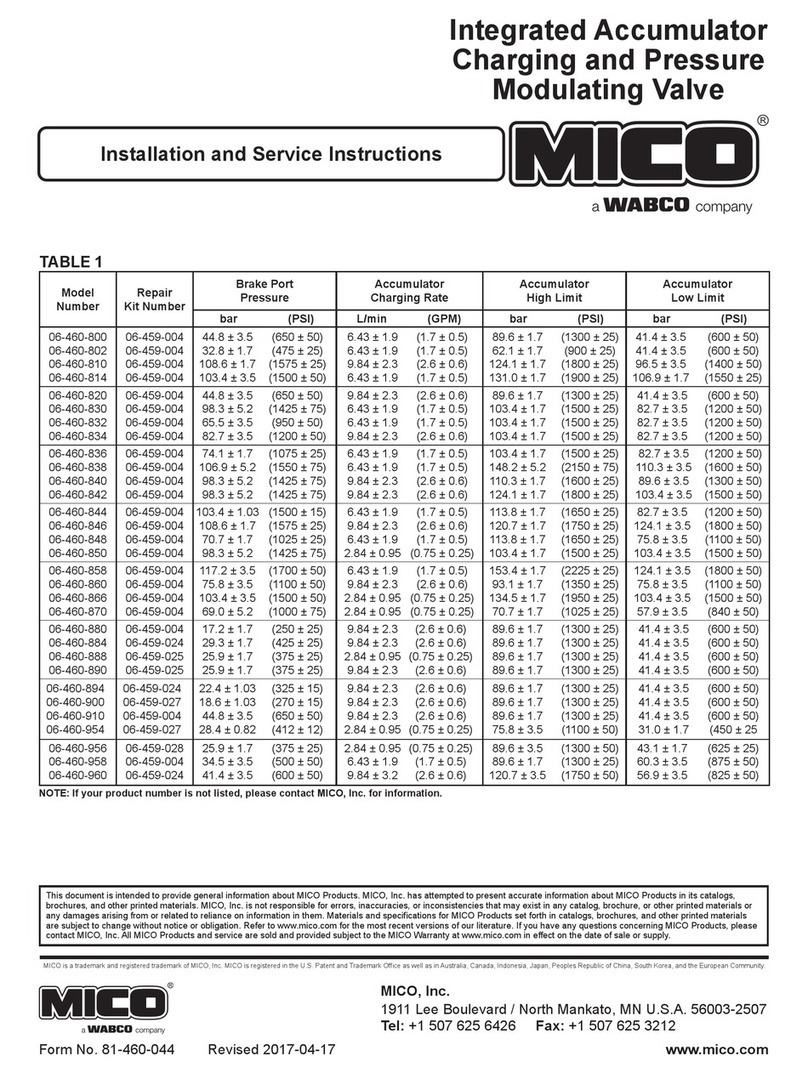

VALVE ADJUSTMENT

(Refer to Table 1)

1. See machine servicing instructions to properly reinstall the

accumulator charging valve. Tee an accurate pressure gauge

on an accumulator line.

2. Start pump and allow approximately one minute for charging to

start (pressure in gauge will read accumulator precharge plus).

If valve does not begin to charge, stop the pump and remove end

plug (29) and turn screw (28) approximately 1/4 turn clockwise

Reinstall end plug (29). Check the high limit specications

(see TABLE 1). Repeat adjustment of screw (28) as needed

until the high limit setting is met. Pressure limits can be checked

correctly only if after each adjustment of screw (28) the

accumulator pressure is reduced below the low limit setting

and the system recharges the accumulator pressure to its

high limit. NOTE: Be sure to reinstall plug (29) before

starting pump.

3. Torque end plug (29) 47.5-54.2 N∙m (35-40 lb∙ft).

Be sure system energy is relieved from accumulator charge

valve before removing from machine. See machine service

manual for procedures to relieve system energy.

NOTE

Locate the model number on the accumulator charging valve and

compare it to the model number in TABLE 1. Be sure you have the

proper service instructions.

NOTE

Observe torque specications as indicated in assembly procedures

or system damage or failure may occur.

Do not exceed the high limit pressure setting indicated in

TABLE 1 or system damage or failure may occur.