It's an Emak S.p.A. trademark Member of the Yama Group

Via E. Fermi, 4 • 42011 Bagnolo in Piano (Reggio Emilia) Italy

Tel. +39 0522 956611 • Fax +39 0522 951555

venditeitalia@efco.it • www.efco.it

MODEL1. DS 240 S DS 240 T

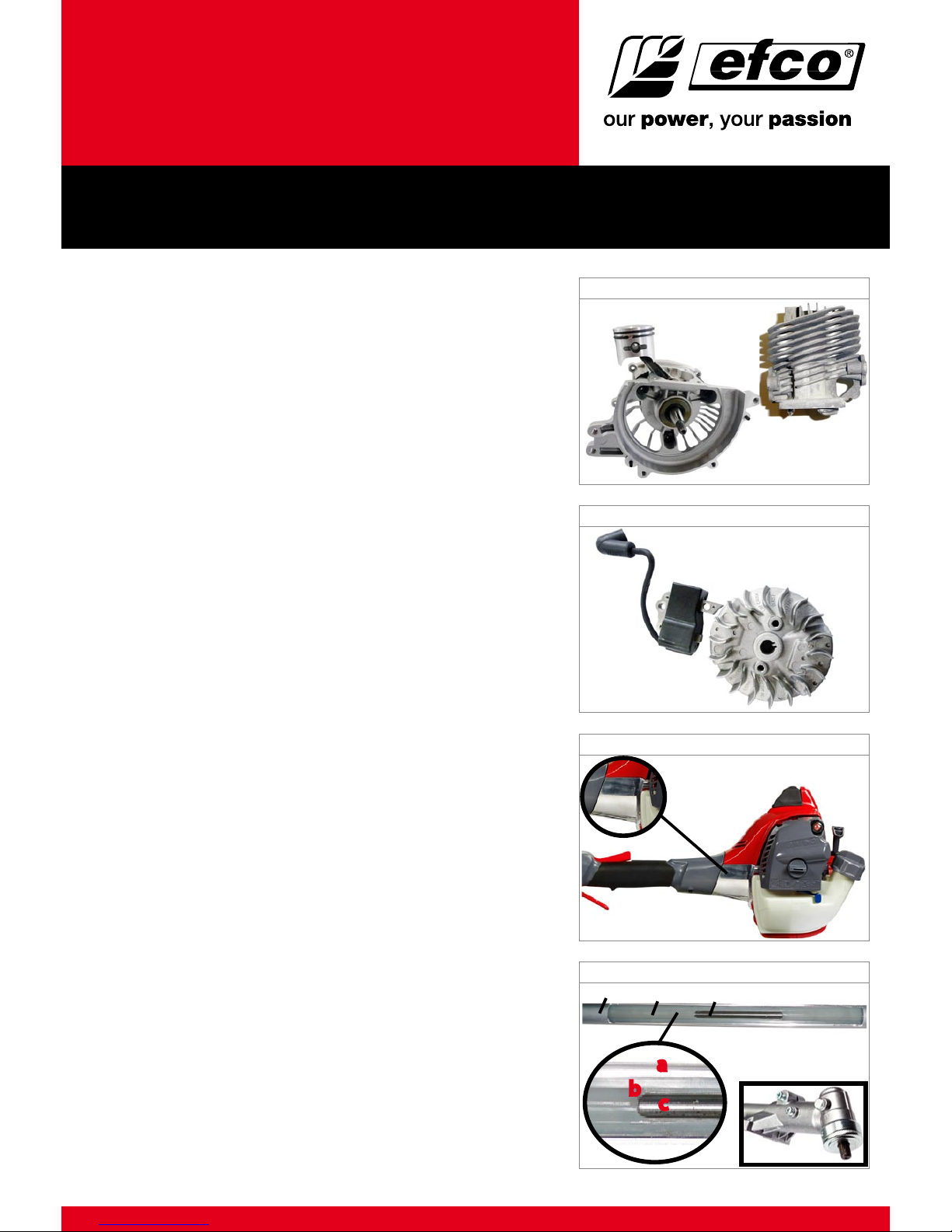

ENGINE

TYPE Emak 2-stroke / EURO 1

DISPLACEMENT cm321,7

BORE x STROKE mm x mm 32 x 27

MAXIMUM POWER OUTPUT HP/kW (rpm) 1,2 / 0,9 (8500)

MAXIMUM TORQUE Nm (rpm) 1,2 (6500)

IDLING SPEED rpm 2800-3100

MAXIMUM NO LOAD SPEED rpm 10300

HOURLY FUEL CONSUMPTION (at max power output) g/h (rpm) 410 - 450 (8500)

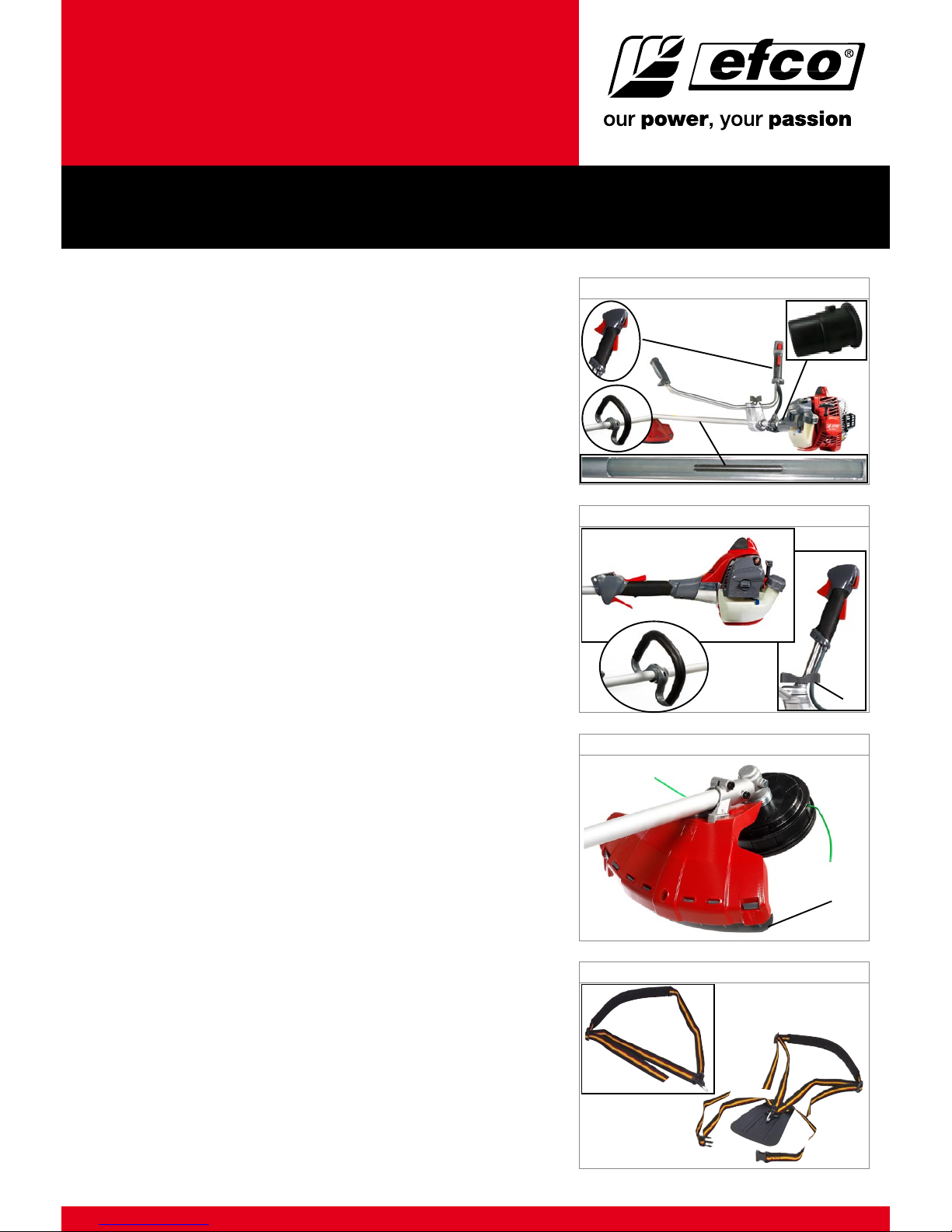

IGNITION SYSTEM

TYPE Digital with variable ignition advance and speed limitetor

COIL WALBRO MBU53

SPARK PLUG NGK CMR7H

EASY START Yes

FUEL & LUBRICATION SYSTEM

CARBURETTOR WALBRO WT-1041

FUEL Compatibility with alkylate mix

FUEL TANK CAPACITY l 0,4

AIR FILTER Generously sized cloth

PRIMER Si

TRANSMISSION SYSTEM

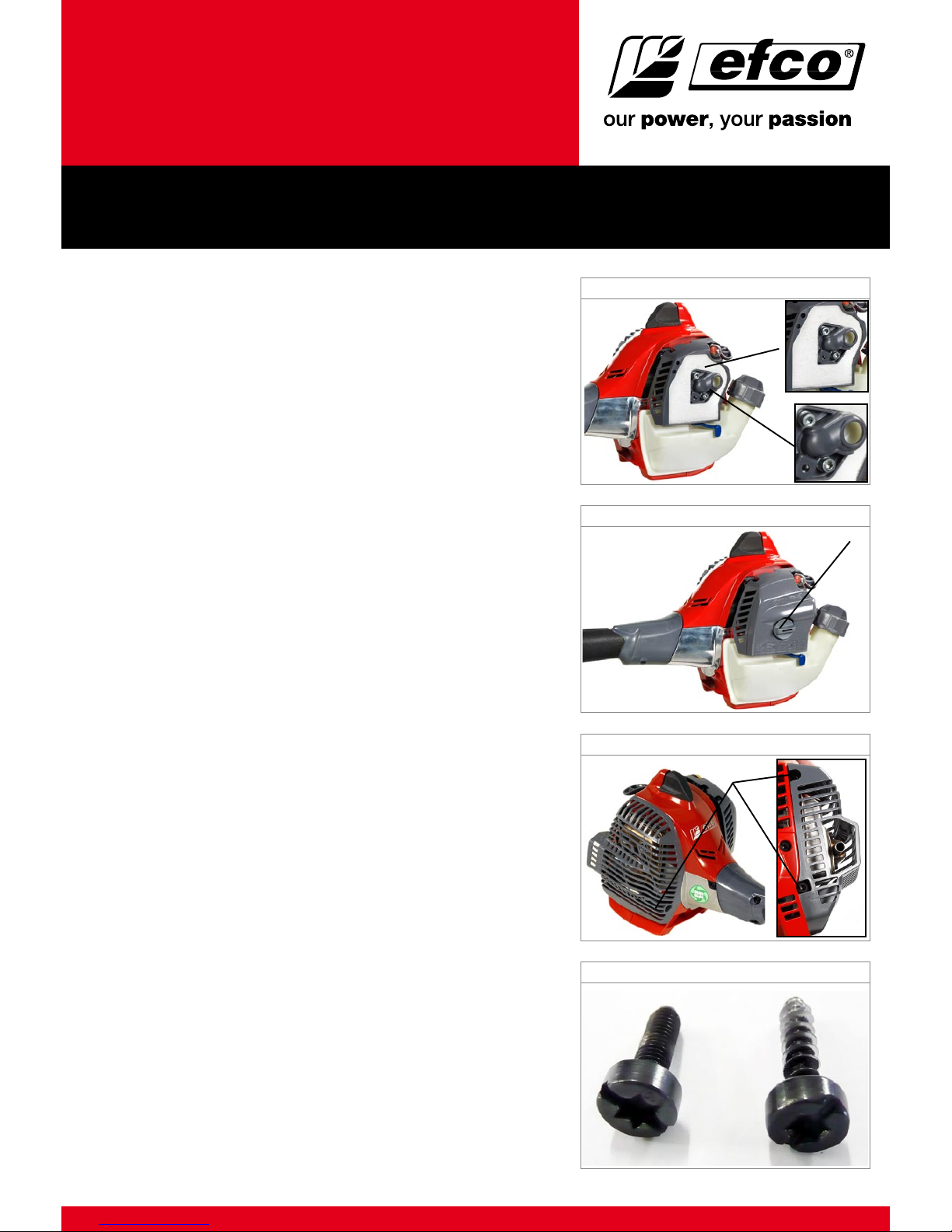

DRIVE SHAFT ( Ø ) “Outer / Inner” mm Ø24 (Ø7internal rigid shaft)

BEVEL GEAR PAIR Pin male M10x1,25 sx

CLUTCH COVER Aluminium

CLUTCH (DIMENSION) mm Yes

ERGONOMICS

HARNESS Single harness Simple with cushion

FRONT HANDLE Ergonomic loop and handles clad in soft rubber ergonomic aluminium handlebar adjuster knob

REAR HANDLE Ergonomic with moulded rubber grips

ON / OFF SWITCH A button (always on)

ANTI-VIBRATION SYSTEM Nylon sheath + antivibration rubber on the

clutch cover

Nylon sheath + antivibration rubber on the

clutch cover + 2 on handlebar support

CUTTING SYSTEM

STANDARD CUTTING DISC Steel disc cutter with 3 teeth Ø 10”/ 255 mm, thickness1,8 mm

STANDARD NYLON STRINGHEAD Load &Go Ø130mm line 2,4 mm

CUTTING GUARD - CUTTING WIDTH (with stringhead) Ø mm 370

IN COMPLIANCE WITH

WEIGHT (Without cutting tools) kg 4,5 5,25

POWER-TO-WEIGHT RATIO kg / Kw 5,0 5,8