BRUSCHCUTTERS DS 2200 - DS 2400

pag. 9

Workshop manual

2. SAFETY

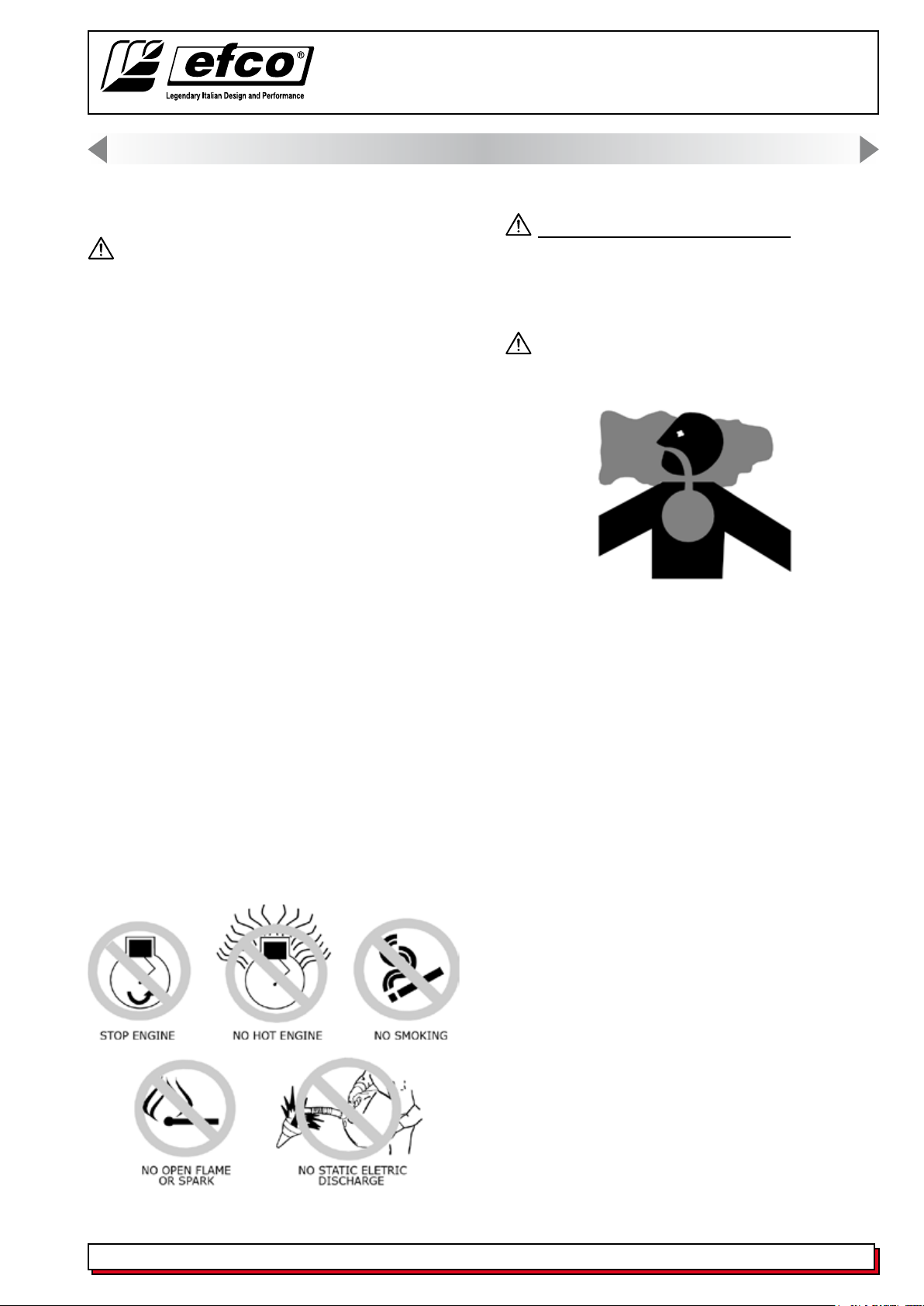

Work In Ventilated Area

Engine exhaust fumes can cause sickness or

death. If it is necessary to run an engine in an

enclosed area, remove the exhaust fumes from

the area by opening doors to get outside air into

the area.

Warning: California Proposition 65 Warning

Gasoline engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects, or other

reproductive harm. Remove Paint Before Welding

or Heating Avoid potentially toxic fumes and dust.

Hazardous fumes can be generated when paint

is heated by welding, soldering, or using a torch.

Do all work outside or in a well ventilated area.

Dispose of paint and solvent properly. Remove

paint before welding or heating: If you sand or

grind paint, avoid breathing the dust. Wear an

approved respirator. If you use solvent or paint

stripper, remove stripper with soap and water

before welding. Remove solvent or paint stripper

containers and other ammable material from

area. Allow fumes to disperse at least 15 minutes

before welding or heating.

Avoid Injury From Rotating Blades

Keep hands and feet away while machine is

running. Shut off power to service, lubricate, or

remove blades.

Handle Chemical Products Safely

Direct exposure to hazardous chemicals can cause

serious injury. Potentially hazardous chemicals

used with EMAK equipment include such items as

lubricants, coolants, paints, and adhesives.

Dispose of Waste Properly

Improperly disposing of waste can threaten the

environment and ecology. Potentially harmful

waste used with EMAK equipment include such

items as oil, fuel, coolant, brake uid, lters, and

batteries. Use leakproof containers when draining

uids. Do not use food or beverage containers

that may mislead someone into drinking from

them. Do not pour waste onto the ground, down

a drain, or into any water source. Inquire on the

proper way to recycle or dispose of waste from

your local environmental or recycling center, or

from your EMAK dealer.

Live With Safety

Before returning machine to customer, make sure

machine is functioning properly, especially the

safety systems. Install all guards and shields.