EG4 6500 User manual

Version 2.0.0 - August 2022

6.5KVA 120V AC

6500 EX-48

EG4 Electronics

www.eg4electronics.com

1

Table of Contents

About This Manual

• Purpose & Scope 3

• Safety Notice 3

Introduction

• Features 4

• Basic System Architecture 4

• Product Overview 5

• Specifications 6

• Dry Contact Relay 9

Preparation & Installation

• Unpacking and Inspection 10

• Mounting the Inverter 11

• Battery Connection 12

• BMS Communications 13

• EG4 Battery Communications and Configuration 14

○ AC Input and Output Connections 17

○ PV Connections 19

• Parallel Inverter Connections 20

• Remote Display 27

• Final Assembly 27

Operating the Inverter/Charger

• Powering On/Off 29

• Display Panel 29

• Operating Modes 37

• System Settings 40

• USB Function Settings 51

Commissioning

• Single Phase 120V 54

• Split-Phase 240V 55

• Three Phase 56

Maintenance & Troubleshooting

• Cleaning and Care 58

• Troubleshooting Tables 59

Appendix I

• Fault Code Table 61

• Warning Code Table 63

• Lead Battery Chemistry Equalization 64

Appendix II

• Wifi Operation Guide 65

Appendix III

• UL Documentation 74

EG4 Electronics

www.eg4electronics.com

2

ABOUT THIS MANUAL

Purpose

This manual describes installation, commissioning, operation, and troubleshooting. Please read the

manual fully and carefully before installing and operating. Keep this manual for future use.

Scope

This manual provides basic safety and installation guidelines as well as information on tools and wiring.

SAFETY NOTICE

ATTENTION: The following contains important safety and operating instructions. Read

and keep this manual for future reference.

1. Before installing or using the unit, read all instructions and cautionary markings on the unit, the

batteries, and all appropriate sections of the manual.

2. CAUTION- Do not disassemble the unit. Take it to a qualified service center when service or repair

is required. Incorrect re-assembly may result in a risk of electric shock or fire.

3. To reduce risk of electric shock, shutdown and disconnect all wirings before attempting any

maintenance or cleaning. Turning off the unit alone will not reduce the risk of shock or injury.

4. CAUTION – Only qualified personnel can install this equipment.

5. NEVER charge a battery below specified minimum temperature; refer to the battery data sheet.

6. Wire size is critical for safe operation, and optimal performance of the equipment. Refer to a

accredited sizing resource or cable manufacturer specifications to meet inverter/charge requirements.

7. Use caution when working with metal tools on or around all systems and batteries. Risk of electrical

arcs and/or short circuiting of equipment can lead to severe injury and damage.

8. Strictly follow installation procedure when connecting and disconnecting AC or DC terminals. Refer to

INSTALLATION section of the manual for details.

9. The included breaker is not a guarantee of battery protection. Size and install the correct over current

protection for the batteries if not included with the product.

10. GROUNDING -This inverter/charger should be connected to a permanent grounded wiring system.

The grounding system must meet the Authority Having Jurisdiction (AHJ) requirements in your area.

11. NEVER short AC output and DC inputs. Do NOT connect to the grid with a shorted DC input.

12. Warning!! Only qualified service persons are able to service this device. If errors still persist after

following troubleshooting table, please contact your retailer for further assistance.

13. WARNING: Because this inverter is non-isolated, only three types of PV modules are acceptable:

Mono-crystalline, Polycrystalline with class A-rated, and CIGS modules. To avoid any malfunction, do

not connect any PV modules with possible current leakage to the inverter. For example, grounded PV

modules will cause current leakage to the inverter. When using CIGS modules, please be sure NOT to

ground.

14. CAUTION: DC breakers and surge protection on PV lines is recommended. Without breakers the

equipment is at higher risk of damage from sources such as surges and lighting strikes.

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

3

INTRODUCTION

This is a residential self consumption multi-function inverter, combining the functions of an inverter, solar

controller, and battery charger to offer uninterrupted power support in a single package. The

comprehensive LCD display offers user-configurable and easily-accessible button operations such as

battery charging current, AC or solar charging priority, and acceptable input voltage based on different

applications.

Configurable color with the built-in RGB LED bar

Built-in Wi-Fi for mobile monitoring (APP is required)

Supports USB On-the-Go function to easily upgrade firmware

Built-in anti-dust kit

Detachable LCD control module with multiple communication ports for BMS (RS485, CAN-BUS,

RS232)

Configurable input voltage tolerances for home appliances and personal computers via LCD control panel

Configurable AC/PV output usage timer and prioritization

Configurable AC/Solar charger priority via LCD control panel

Configurable battery charging current based on applications via LCD control panel

Compatible with the grid or generator power

Auto restart on AC reconnect

Overload / Over temperature / short circuit protection

Smart battery charger design for optimized battery performance

Basic System Architecture

The following illustration is an example of a basic application for this unit showing multiple inputs and

outputs. Please note an AC source may not be required for operation and is listed as an example only:

Generator or Utility

48V Battery

PV modules

Consult with a system installer and/or designer for other possible system design options

depending on the specific site requirements. System design is key to proper function and

performance and sites and systems vary greatly.

Figure 1 Basic PV System Overview

Features

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

4

1. LCD display

2. Status indicator

3. Charging indicator

4. Fault indicator

5. Function buttons

6. Power on/off switch

7. AC input connectors

8. AC output connectors (Load connection)

9. PV terminal

10. Battery connectors

11. Remote LCD module communication

12. Current sharing port

13. Parallel communication port

14. Dry contact

15. OTG-USB port as USB communication port and USB

function port

16. BMS communication port: CAN, RS-485 or RS-232

17. Output source indicators (refer to OPERATION/Operation

and Display Panel section for details) and USB function

setting reminder (refer to OPERATION/Function Setting for

the details)

18. RS-232 communication port for firmware updates from a

PC

19. RGB LED bar (refer to LCD Setting section for the details)

Port

EG4 Electronics

www.eg4electronics.com

Product Overview

EG4 Electronics

www.eg4electronics.com

5

Installation Note: The EG4 6.5KW unit is a parallel capable model. For parallel 120V, 240V Split-phase, or

3-phase installation diagrams and instructions, please check the

Parallel Connections

and

Commissioning

sections of the manual for further details.

SPECIFICATIONS

Table 1 Line Mode Specifications

MODEL

6.5KW

Input Voltage Waveform

Sinusoidal (utility or generator)

Nominal Input Voltage

120Vac

Low Loss Voltage

90Vac±7V (UPS)

80Vac±7V (Appliances)

Low Loss Return Voltage

100Vac±7V (UPS);

90Vac±7V (Appliances)

High Loss Voltage

140Vac±7V

High Loss Return Voltage

135Vac±7V

Max AC Input Voltage

150Vac

Max AC Input Current

60A

Nominal Input Frequency

50Hz / 60Hz (Auto detection)

Low Loss Frequency

40±1Hz

Low Loss Return Frequency

42±1Hz

High Loss Frequency

65±1Hz

High Loss Return Frequency

63±1Hz

Output Short Circuit Protection

Line mode: Circuit Breaker (70A)

Battery mode: Electronic Circuits

Efficiency (Line Mode)

>95% ( Rated R load, battery full charged )

Transfer Time

10ms typical (UPS);

20ms typical (Appliances)

Power Limitation

Input Voltage

Output Power

Rated Power

50%

Power

80V110V140V

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

6

Table 2 Inverter Mode Specifications

MODEL 6.5KW

Rated Output Power 6,500W

Output Voltage Waveform Pure Sine Wave <3% THD

Output Voltage Regulation 120Vac±5%

Output Frequency 60Hz or 50Hz

Peak Efficiency 91%

Overload Protection 100ms@≥205% load;5s@≥150% load; 10s@110%~150% load

Surge Capacity 13,000W

Nominal DC Input Voltage 48.0Vdc

Cold Start Voltage 46.0Vdc

Low DC Warning Voltage

@ load < 20% 46.0Vdc

@ 20% ≤ load < 50% 42.8Vdc

@ load ≥ 50% 40.4Vdc

Low DC Warning Return Voltage

@ load < 20% 48.0Vdc

@ 20% ≤ load < 50% 44.8Vdc

@ load ≥ 50% 42.4Vdc

Low DC Cut-off Voltage

@ load < 20% 44.0Vdc

@ 20% ≤ load < 50% 40.8Vdc

@ load ≥ 50% 38.4Vdc

High DC Recovery Voltage

64.0Vdc

High DC Cut-off Voltage 66.0Vdc

DC Voltage Accuracy +/-0.3V@ no load

THDV <5% for linear load,<10% for non-linear load @ nominal voltage

DC Offset ≦100mV

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

7

Table 3 Charge Mode Specifications

Utility Charging Mode

MODEL 6.5KW

Charging Current (UPS)

@ Nominal Input Voltage 120A

Bulk Charging

Voltage

Flooded

Battery 58.4Vdc

AGM / Gel

Battery 56.4Vdc

Floating Charging Voltage 54.0Vdc

Overcharge Protection 66.0Vdc

Charging Algorithm 3-Step

Charging Curve

Time

Battery Voltage, per cell Charging Current, %

100%

50%

Bulk

(Constant Current)

Absorption

(Constant Voltage)

Maintenance

(Floating)

Current

Voltage

T1 = minimum 10mins, maximum 8hrs

2.43Vdc (2.35Vdc)

2.25Vdc

Solar Input

MODEL 6.5KW

Rated PV 8000W

Max. PV Array Open Circuit

Voltage 500Vdc

PV Array MPPT Voltage Range 90Vdc~450Vdc

Max. Input Current Draw 18A x 2

Start-up Voltage 80V +/- 5Vdc

Power Limitation

PVCurrent

MPPTtemperature

18A

9A

75°85°

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

8

Table 4 General Specifications

MODEL 6.5KW

Safety Certification UL 1741 Certificate by TUV

Operating Temperature Range -10°C to 40°C

Storage temperature -15°C~ 60°C

Humidity 5% to 95% Relative Humidity (Non-condensing)

Dimension

(D*W*H), in 58.03in x 170.2in x 226.6in (244.3in) (with extension box)

Net Weight, lbs 40.5lbs

Table 5 Parallel Specifications (Parallel model only)

Max parallel numbers

6

Circulation Current under No Load Condition

Max 2A

Power Unbalance Ratio

<5% @ 100% Load

Parallel communication

CAN

Transfer time in parallel mode

Max 50ms

Parallel Kit

YES

Note: Parallel feature will be disabled when only PV power is available

EG4 Electronics

www.eg4electronics.com

Dry Contact Relay

There is one dry contact (3A/250VAC) available on the bottom of the inverter display. It can be used to

deliver signal to external device when battery voltage reaches a set warning level.

Unit Status Condition

Dry contact port:

NC & C NO & C

Power Off Unit is off and no output is powered. Close Open

Power On

Output is

powered

from Battery

power or

Solar energy.

Program 01

set as USB

(utility first)

or SUB (solar

first)

Battery voltage < Low DC

warning voltage Open Close

Battery voltage > Setting

value in Program 13 or

battery charging reaches

floating stage

Close Open

Program 01 is

set as SBU

(SBU priority)

Battery voltage < Setting

value in Program 12 Open Close

Battery voltage > Setting

value in Program 13 or

battery charging reaches

floating stage

Close Open

EG4 Electronics

www.eg4electronics.com

9

PREPERATION & INSTALLATION:

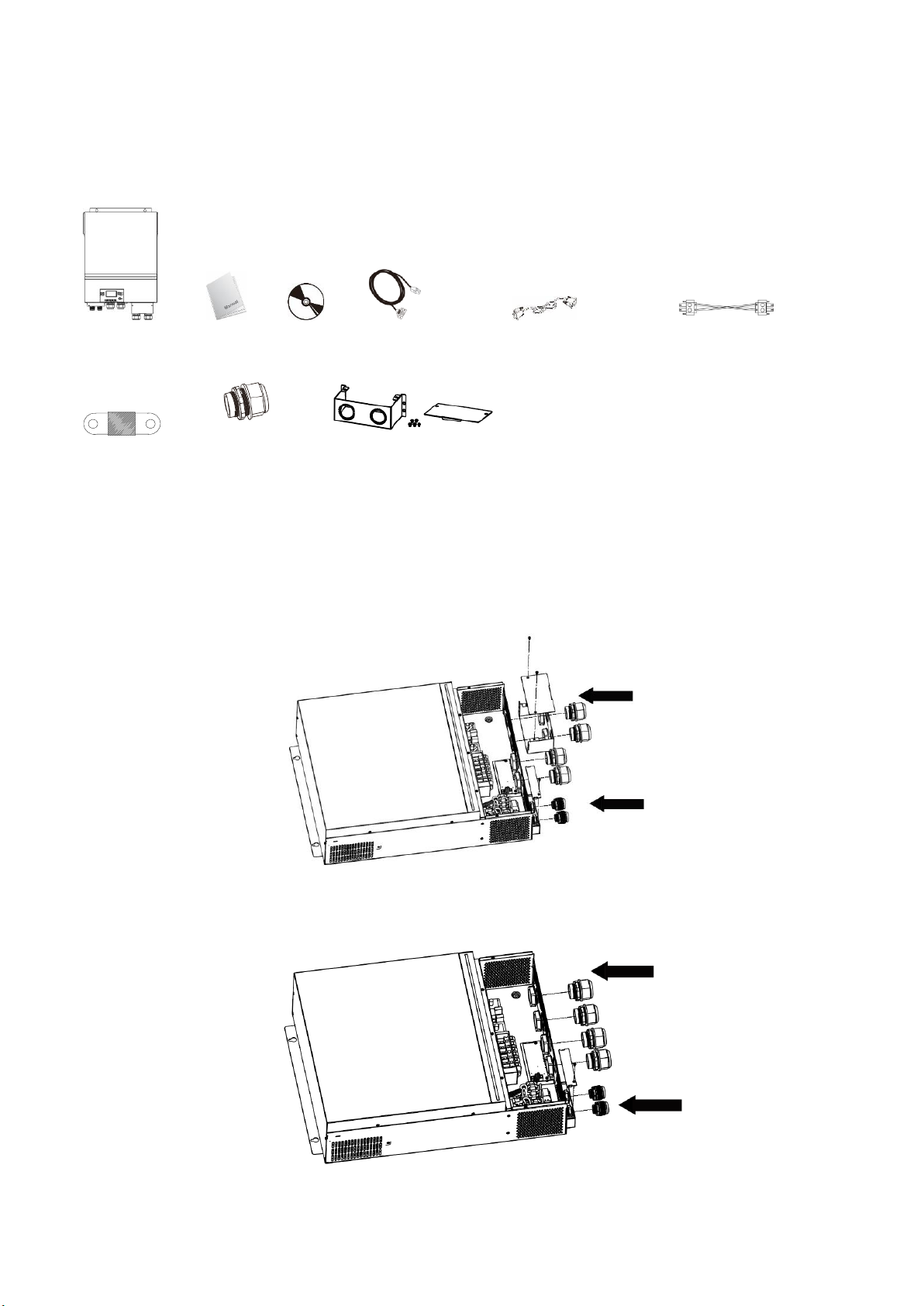

Unpacking and Inspection

Before installation, please inspect the unit. Be sure that nothing inside the package is damaged. The

following items should be included in the package:

Inverter unit Manual software CD RS-232 cable Parallel communication cable Current sharing cable

DC Fuse Cable gland x 4 pcs Extension Box Kit

Installation of Battery Wiring Extension Box, Cable Glands, and

Conduit Fittings 1/2" or 3/4"

Install two (2) cable glands or conduit fittings on the extension box, then fix the extension box on the

rear panel of the inverter.

Note: Installation of the battery wiring extension box is necessary for UL

conformity. If UL conformity is not required in your region, it is sufficient to only install the cable glands

(Graphic 2) shown below.

Fig.1 6500 with Extension Box

Fig.2 6500 without Extension Box

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

10

Before connecting all wirings, please take off bottom cover by removing the five screws. When

removing the bottom cover, be carefully to remove three cables as shown below.

Mounting the Inverter

Consider the following points before selecting an install location:

⚫Do not mount the inverter on flammable materials.

⚫Mount on a solid surface.

⚫For optimal operation, install in a location where ambient

temperature stays between 0℃ - 40℃ (32℉ - 104℉).

⚫Mount the unit in a vertical position and following the clearance

guide for proper cooling and longevity.

⚫Follow clearance guidelines shown to the right diagram to

guarantee sufficient heat dissipation and clearance for conduit

and wire runs.

⚫Ensure mounting location follow your local authority having

jurisdiction rules on working space requirements. For the US

market, refer to the NEC version adopted by your AHJ.

Mount the unit using the 4 holes denoted below. M5 (#10 Imperial) screw/bolt diameter is recommended.

SUITABLE FOR MOUNTING ON CONCRETE OR OTHER NON-COMBUSTIBLE SURFACE ONLY.

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

11

Battery Connection

CAUTION: For safe operation and regulation compliance, DC overcurrent protection and means of

disconnect should be installed between the battery and inverter. In many cases individual battery units

will come with breakers, however overcurrent and disconnecting means should be added for banks of

multiple batteries. Please refer to the typical amperage in table below for required fuse or breaker size.

WARNING! All wiring design and install must be performed by qualified personnel.

WARNING! For safe and efficient operation use the appropriate cable size for

battery connections. To reduce risk of injury and equipment damage, use properly

rated cable and terminal sizes.

Recommended battery cable and terminal size:

Model Typical

Amperage

Battery

capacity

Minimum

Wire Size

Cable

mm2

Ring Terminal Torque

value

Dimensions

D (mm) L (mm)

6.5KW 153A 250AH 1*2/0AWG 67 8.4 47 5 Nm

Please follow the below steps for battery connection:

1. Insert the ring connection end of the battery cable through the cable gland of the inverter.

2. Ensure the bottom (flat) side of the cable ring termination is fully seated on the inverter battery terminals.

3. Tighten the terminal nuts to a torque of 5 Nm (3.6ft lbs). Make sure polarity at both the battery and the

inverter/charge is correctly connected and ring terminals are tightly screwed to the battery terminals.

WARNING: Shock Hazard

Arc and shock hazards are present! Do not touch uninsulated wires, and use caution when

making connections. Ensure all equipment is turned off, use proper safety equipment, and follow

best practices.

CAUTION!! Do not place anything between the inverter terminal and the battery cable ring

connector. Overheating and equipment damage can occur.

CAUTION!! Do not apply anti-oxidant substance on the terminals.

CAUTION!! Before making the final DC connection or powering on DC circuits ensure both

positive and negative cable runs are correctly connected throughout the system. Incorrect or loose

connections will damage equipment and pose electrical shock, arc, and fire risks.

Ring terminal:

EG4 Electronics

www.eg4electronics.com

EG4 Electronics

www.eg4electronics.com

12

BMS Communication Installation- EG4-LL

1. Introduction

When connecting to LFP battery, it is recommended to purchase a custom-made RJ45 communication

cable. Please check with your dealer or integrator for details.

This custom-made RJ45 communication cable delivers information and signal between lithium battery and

the inverter. The information is listed below:

⚫Re-configure charging voltage, charging current and battery discharge cut-off voltage according to the

lithium battery parameters.

⚫Starting and stopping of charging is based on the batteries SOC (State Of Charge)

2. Pin Assignment for BMS Communication Port

Definition

PIN 1

RS232TX

PIN 2

RS232RX

PIN 3

RS485B

PIN 4

NC

PIN 5

RS485A

PIN 6

CANH

PIN 7

CANL

PIN 8

GND

EG4 Electronics

www.eg4electronics.com

13

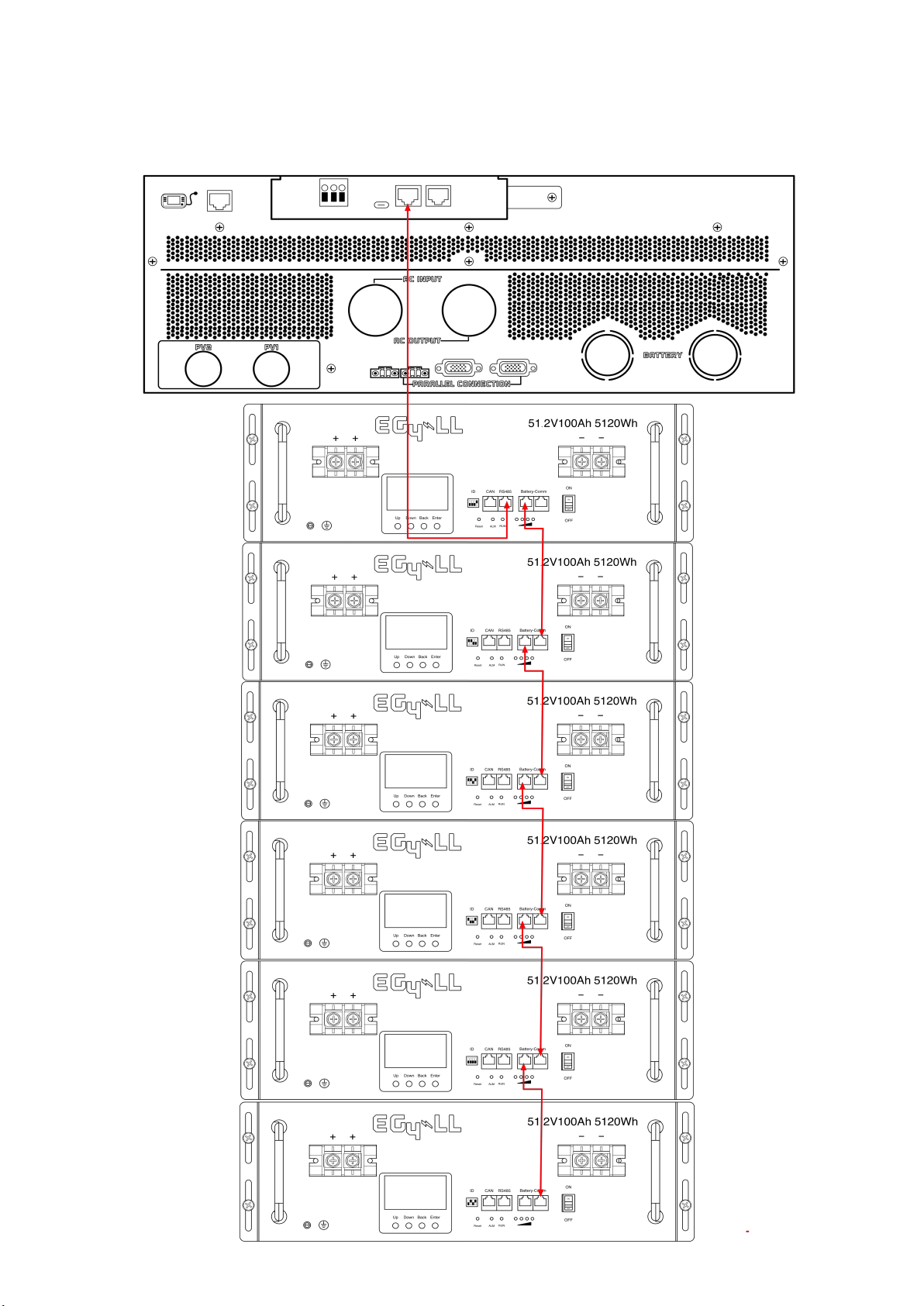

Battery Networking- EG4-LL

Using the 1ft RS485 cable interconnect your batteries as illustrated in the

diagram below.

EG4 Electronics

www.eg4electronics.com

14

Battery Networking-LiFePower4

Using the 1ft RS485 cable interconnect your batteries as illustrated in the

diagram below.

EG4 Electronics

www.eg4electronics.com

15

Settings for EG4 Lithium Batteries- Master/Slave

1). Dip Switch: There are 4 Dip Switches which set different baud rates and battery

group addresses. If switch position is turned to the “OFF” position, it means “0”. If

switch position is turned to the “ON” position, it means “1”.

•Dip 1, 2, and 3 are in the

“ON” position*on = down

•Dip 4 is in the "OFF"

position*off = up

•The 1-3 "ON" & 4 "OFF"

configuration is to indicate

Master battery status and

is reserved for

communications with the

inverter.

•A Max of 16 batteries can

communicate in a single

battery bank using

different dipswitch

addresses.

EG4-LL Battery

•Dip 1, 2, 3, and 4 are in the

“OFF” position*off = down

•The ALL "OFF" position is to

indicate the Master battery

status and is reserved for

communications with the

inverter

•A Max of 16 batteries can

communicate in a single

battery bank.

EG4-LifePower4 Battery

Please Note: If you change the dipswitches, you must power cycle the batteries

for the BMS to recognize the new dipswitch address.

2). Installation

Step 1. Use the RS485 cable to connect the inverter and Lithium battery as Fig 1.

Step 2. Switch on the battery breaker/s.

Step 3. Turn on the inverter.

Step 4. Select battery type as “EG4” in LCD program 5 for the Master inverter. For other paralleled

inverters, set to "USE".

If communication between the inverter and battery is successful, the battery icon on LCD display will flash

EG4 Electronics

www.eg4electronics.com

16

NOTE:

For EG4-LL ensure the red power switch is set to "ON" as well as the breaker.

NOTE:

Even with the EG4 batteries having built-in breakers, a minimum 150A in line breaker is required, and a 200A

in line breaker is recommended.

NOTE:

Refer to each battery manual for setting master and follower battery address settings.

AC Input/Output Connections

CAUTION!! Install a breaker at the source of the AC input power source per requirements of authority

having jurisdiction. Ensure the AC source circuit is properly rated for the inverter/charger load

specification.

CAUTION!! There are two terminal blocks with “IN” and “OUT” markings. Do NOT reverse the input and

output connections. Ensure Line, Neutral, and Ground are wired to the correct terminals.

WARNING! All wiring must be performed by a qualified personnel.

WARNING! It is very important for system safety and efficient operation to use appropriate cable for AC

input connection. To reduce risk of injury and equipment damage, use properly sized cables according to local

jurisdiction and electrical code/requirements.

Suggested cable requirement for AC wires

Model Gauge Torque Value

6.5KW 4 AWG Max 1.4~ 1.6Nm

Follow the below steps to connect the AC input and output:

1. Before making AC input/output connection, be all power sources are off.

2. Remove 10mm (3/8in) wire insulation from the ground wires. Remove 7mm (~1/4in) of wire insulation

from the Line and Neutral conductors. Ensure no conductor is exposed beyond terminal block, paying

special attention to possible stray wire strands.

3. Fix two cable glands into input and output sides.

4. Insert AC input wires according to polarities indicated on terminal block and tighten the terminal screws. Be

sure to connect PE protective conductor ( ) first.

L→LINE(Black for Line 1)(Red for Line 2 in 120/240 split-phase configuration)

N→Neutral (White or Gray)

WARNING:

Ensure all AC sources remain off and all loads are turned off at the breakers before continuing with the

wiring process. Confirm AC source is off with multi-meter or non-contact voltage pen/tester.

EG4 Electronics

www.eg4electronics.com

17

Ground (Green or Green with Yellow stripe)

5. Connect the AC output wires according to labels printed on the case above the terminal blocks.

Connect the ground wire first ( ).

Ground (Green or Green with Yellow stripe)

L→LINE (Black for Line 1)(Red for Line 2 in 120/240 split-phase configuration)

N→Neutral (White or Gray)

6. Make sure the wires are properly connected and the terminal blocks are torqued to spec.

CAUTION: Appliances with heavy start and run demands, such as air conditioners, require

special consideration. For many air conditioners for example, at least 2~3 minutes to restart

can be required to allow enough time to balance refrigerant gases. If a power outage occurs and

recovers in a short time, it may cause damage to connected appliances. To prevent damage,

please check with the manufacturer of the appliance to see if it is equipped with a time-delay function

or soft-start feature before installation. Overload of the inverter/charger may trigger a fault leading

to sudden loss of AC output power, which may cause damage to appliances with motors/compressors.

CAUTION: Important

Connect AC wires to the correct terminals. If L and N wires are reversed, it will cause a

short-circuit and damage the equipment and loads connected to the system.

EG4 Electronics

www.eg4electronics.com

18

i. Remove 10 mm (3/8in) of insulation for positive

and negative conductors.

ii. Check correct polarity of connection cable from

PV modules and PV input connectors at the

disconnect. Connect positive pole (+) of

connection cable to positive pole (+) of PV input

connector. Connect negative pole (-) of connection

cable to negative pole (-) of PV input connector.

Step 3: Step 3: Make sure the wires are fully

inserted and the terminals are torqued to spec.

CAUTION! Ensure no wire strands are exposed

outside of the terminals blocks. No copper of the

conductions should be visible.

It is highly recommended to use red PV wire for

positive and black PV wire for negative to

reduce risk of reversing polarity in the system.

PV Connections

CAUTION: Before connecting PV modules/strings, install separate DC circuit breakers or a means of

disconnect paired with properly sized fuses between inverter and PV array/s. DO NOT work with or

connect live PV conductors to the unit. Ensure all exposed conductors are safely disconnected from

the power source.

NOTE: Use a 600VDC/30A rate circuit breaker. DC rated breakers must be used. The over voltage

category of the PV input is II. Please follow the steps below to implement PV module connection.

Step 1: Check the voltage of the PV modules/strings; ensure open circuit voltage (Voc) is designed to

never exceed the units rating (500V DC). This unit is equipped with two PV MPPT string inputs. Ensure

the maximum operating amperage (Imp) of each PV input is 18A or less. When using Rapid Shut Down

equipment refer to the RSS manufacturer's specifications for per-device and per-string ratings.

Step 2: Disconnect the circuit breaker and switch off the DC disconnect. Follow wiring process below.

CAUTION: Exceeding the maximum input voltage can destroy the unit! Check the system before wire connections.

WARNING: Because the inverter/charger is non-isolated, only three types of PV modules are

acceptable: monocrystalline and polycrystalline with class A-rated and CIGS modules.

To avoid malfunction, do not connect PV modules with possible current leakage. For example, grounded

PV modules will cause current leakage to the inverter. When using CIGS modules, please be sure NOT to

ground.

CAUTION: It is required to use a PV surge protection device. Damage to the inverter can occur from

surges such as lightning or short circuiting.

WARNING!

Open circuit Voltage (Voc of PV strings must not exceed the maximum PV array open circuit voltage of the

inverter. Check for environmental impacts on Voc, such as temperature in accordance to the module

manufacturers data sheet and reliable weather data for the installation location.

Voltage at Maximum Power (Vmp) of PV strings must be higher than the start-up voltage.

EG4 Electronics

www.eg4electronics.com

19

EG4 Electronics

www.eg4electronics.com

Parallel Inverter Connections

1. Introduction

This model of inverter is a 120V Single-phase unit able to operate in parallel with multiple other units. The

parallel function can be used to support multiple electrical system types, including multi-inverter Single-phase,

240 Split-phase, or 3-phase.

ATTENTION: Carefully review the paralleling requirements, specifically the current sharing cable connection

tables and parallel settings.

Battery Bank Considerations:

When designing the system, ensure the battery bank of the system is able to support both the potential max

load/s and constant load. Multiple inverters meeting a high load requirement with an undersized battery bank

will result in a system shutdown and potentially damage equipment.

Recommended Battery Sizing:

Inverters per System 2 3 4 5 6

Battery Capacity (48V) 200AH 300AH 400AH 600AH 600AH

WARNING! All inverters of a system must share the same battery bank. Ensure all batteries are connected to

common bus bars, with equal cable lengths between both the batteries/bus and inverter/bus connections.

2. Parallel Connections for 120V Single-phase:

Communication Connection

2

1

AC connections are the same for units 3-6.

EG4 Electronics

www.eg4electronics.com

•Inverter 1 Port A → Inverter 2 Port A

•Inverter 1 Port B → Inverter 2 Port B

Current Sharing Cables - configuration will be

noted on each diagram with dashed lines (green

when printed in color) in the following format:

•Inverter X Port A → Inverter X Port A

•Inverter X Port B → Inverter X Port B

WARNING: Damage to the inverters can occur

if current sharing cables are incorrectly

installed.

See Split-phase and 3-phase communication

connection guides for specifics.

EG4 Electronics

www.eg4electronics.com

20

Table of contents

Other EG4 Inverter manuals

Popular Inverter manuals by other brands

BARRON

BARRON EXITRONIX Tucson Micro Series installation instructions

Baumer

Baumer HUBNER TDP 0,2 Series Mounting and operating instructions

electroil

electroil ITTPD11W-RS-BC Operation and Maintenance Handbook

Silicon Solar

Silicon Solar TPS555-1230 instruction manual

Mission Critical

Mission Critical Xantrex Freedom SW-RVC owner's guide

HP

HP 3312A Operating and service manual