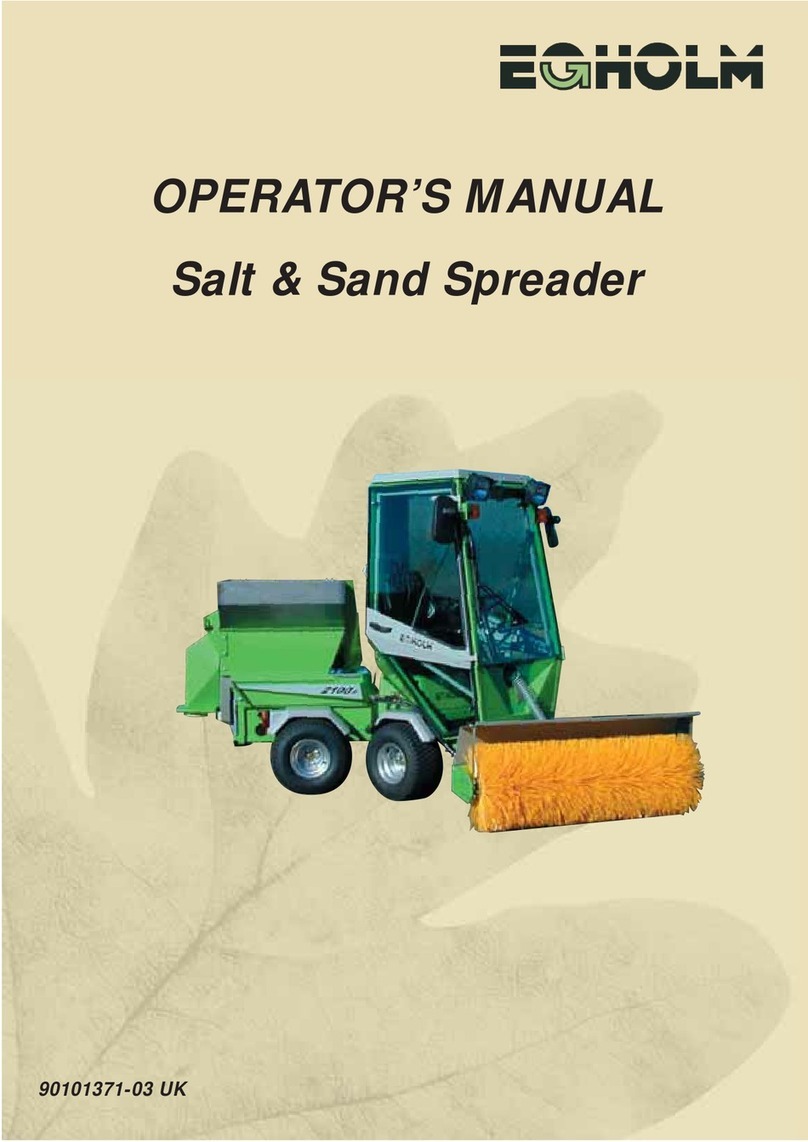

33Operator’s Manual Park Ranger 2150 Salt and sand spreader

General information

The salt and sand spreader was designed

especially for the Egholm. It will ensure winter

maintenance by use of salt, sand, gravel and

grit.

The salt and sand spreader can ideally be

combined with the dozer blade and the snow

sweeper. In that way the driver is enabled to

remove snow and spread salt at one go and

thereby provide a safe route for the motorists

and pedestrians.

A special designed roller stand enables one

person to safely t or remove the spreader.

The salt and sand spreader features a stainless

steel container and a built-in air scoop,

supplying the cooler with fresh air and thereby

also protecting the engine of the basic unit from

the ne salt particles.

The construction features only robust

components. The new deflector plate with high

wear resistance handles salt, sand and gravel.

Contents

General information ..........................................................................5

1.1 Safety .................................................................................5

1.2 EC Declaration of Conformity for Machinery...............................................7

1.3 Technical data .........................................................................8

Operator’s manual ..........................................................................10

2.1 Assembly of the roller stand ............................................................10

2.2 Assembly/disassembly ................................................................10

2.3 Start-up ..............................................................................12

2.4 Adjustment...........................................................................13

2.5 Assembly/disassembly of the stirrer system.............................................14

2.6 Important.............................................................................15

2.7 Field of application ....................................................................15

Service and Maintenance ....................................................................17

3.1 Cleaning ..............................................................................17

Conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.1 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

4.2 Complaints ...........................................................................21

4.3 Disposal ..............................................................................21

Wearing parts...............................................................................23

5.1 Wearing parts - Park Ranger 2150 salt and sand spreader .................................23

Notes .....................................................................................24