Toro 33525 User manual

FormNo.3433-272RevA

SpreaderAttachment

Stand-onAerator

ModelNo.33525—SerialNo.400000000andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3433-272*A

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Theintendeduseofthisspreaderattachmentisfor

dispersinggrassseed.Thisisnottobeusedfor

fertilizeroranyotherchemicalapplications.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

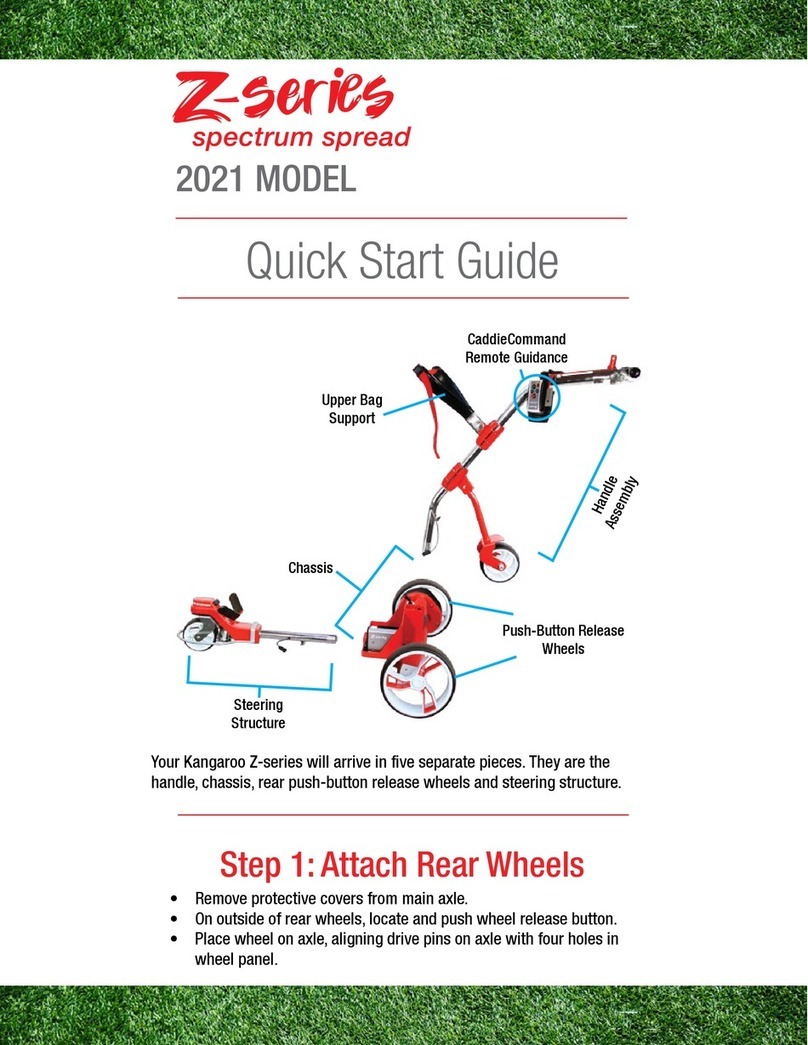

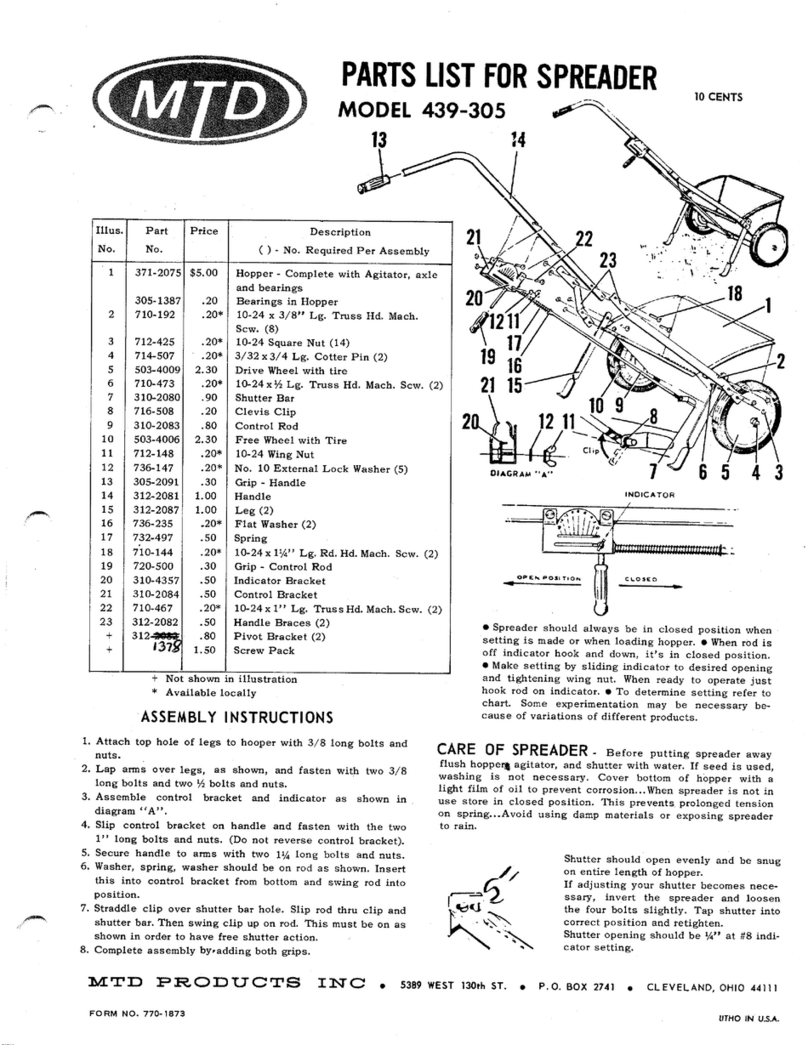

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

g253435

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................5

Setup........................................................................6

1PreparingtheMachine.....................................7

2InstallingtheFlowControlPanel......................7

3InstallingtheHopperAssembly........................7

4InstallingtheCable-MountBracket...................8

5InstallingtheControlCable..............................8

6InstallingtheWireHarness............................10

7InstallingtheCover.........................................11

ProductOverview...................................................12

Specications..................................................12

Operation................................................................12

Controls............................................................12

Pre-Start...........................................................13

OperatingInstructions......................................14

OperatingtheSpreaderAccessory...................14

OperatingTips..................................................17

RemovingtheSpreaderAttachment.................17

Maintenance...........................................................18

RecommendedMaintenanceSchedule(s)...........18

.............................................................................18

CheckingforLooseHardware...........................18

AdjustingtheSpreaderPatternControl

Cable............................................................18

AdjustingtheGateClosure...............................19

Cleaning..............................................................19

CleaningDebrisfromtheMachine....................19

Troubleshooting......................................................20

Schematics.............................................................21

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions,

andpayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructions

mayresultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator'sManualforthemachineand

thisaccessoryandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

Preparation

•Donotmodifytheaccessory.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,andhearingprotection.Tie

backlonghair,securelooseclothing,anddonot

wearloosejewelry.

3

CAUTION

Themachinethatthespreaderaccessory

attachestoproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjectsfromtheareabeforeusing

themachine.

Operation

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•Donotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Operatethemachineonlyinwell-litareas,keeping

awayfromholesandhiddenhazards.

•Beawareofweatherconditionsandcheckthat

spreaderpatternsandvolumearesuitable.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Stopspreadingwhenmakingtightturnsto

minimizeunevendistributionpatternand

applicationrate.

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningthemachine.

•Materialloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausethe

machinetotipover.

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientstoppingdistance.

Useextracautiononslopes.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

MaintenanceandStorage

•Closethespreadergate,engagetheparking

brake,shutofftheengine,andremovethekeyor

disconnectsparkplugwire.Waitforallmovement

tostopbeforeadjusting,cleaningorrepairingthe

machine.

•Emptythehopperbeforetiltingthemachinefor

maintenanceandbeforestoring.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theengineand/ortheimpellerrunning.

•Keepallguards,shields,andsafetydevicesin

placeandinsafeworkingcondition.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

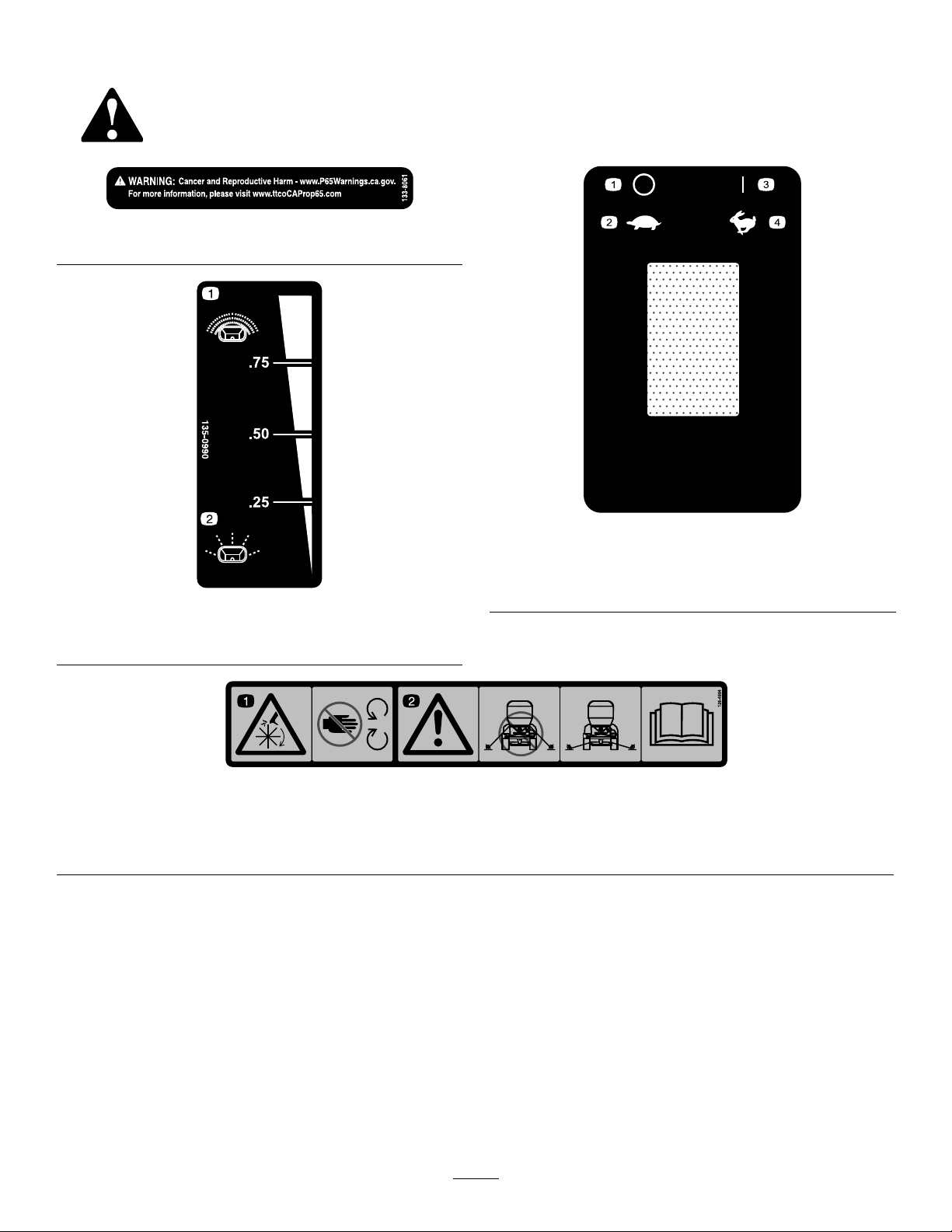

decal133-8061

133-8061

decal135-0990

135-0990

1.Spreadpattern-heavy2.Spreadpattern-light

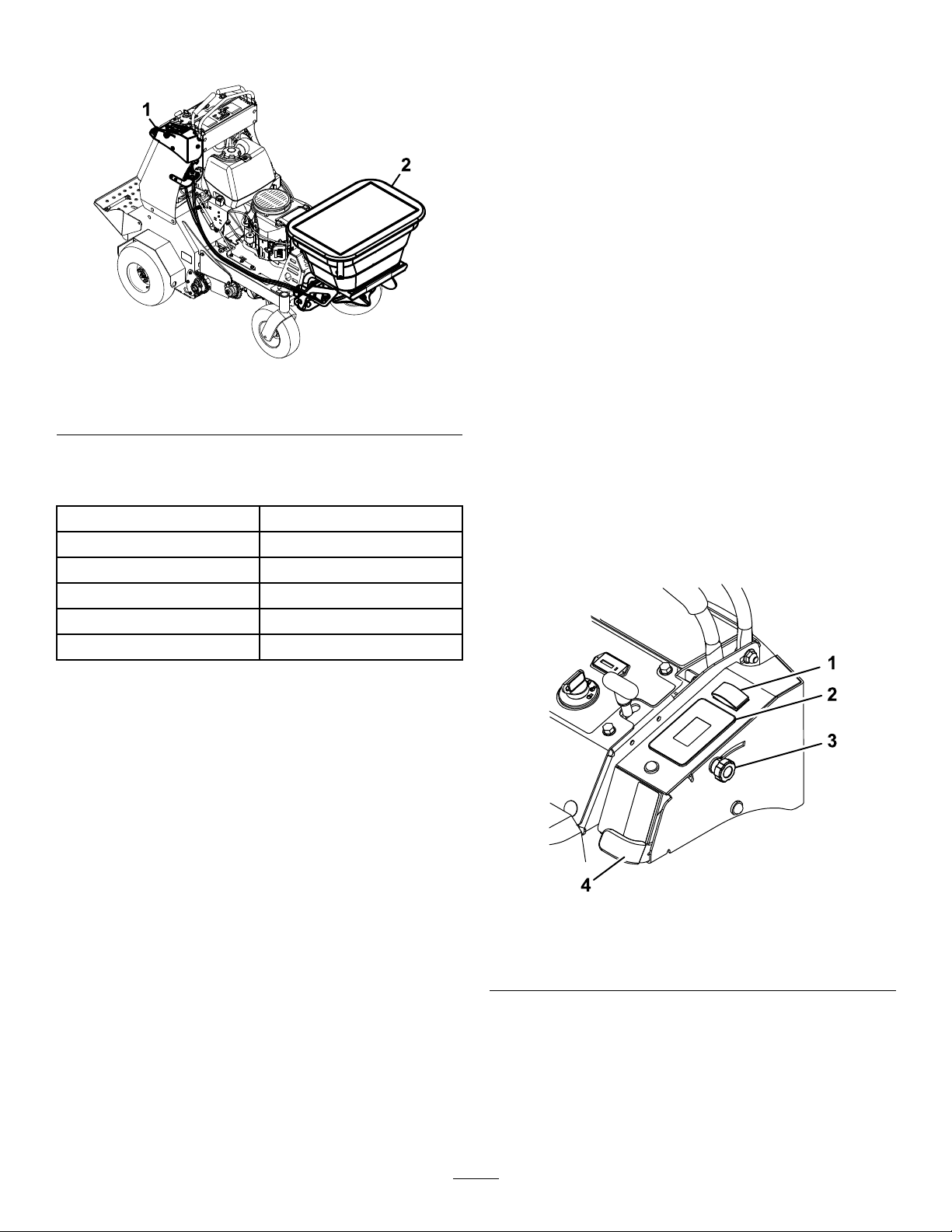

decal135-0739

135-0739

1.Impeller—off3.Impeller—on

2.Impeller—slow4.Impeller—fast

decal126-4994

126-4994

1.Cutting/dismembermenthazard—keepawayfrommoving

parts.

2.Warning—donotusetheupperfrontlocationsastiedown

points,onlyusethespeciedtie-downpoints;seethe

Operator’sManualforlocation.

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescriptionQty.Use

1Nopartsrequired–Preparethemachine.

Bolt(3/8x1-1/4inches)—30-inch

machinesonly1

Locknut(1/4inch)—30-inchmachines

only1

Bolt(1/4x5/8inch)—30-inchmachines

only1

Bolt(5/16x3/4inch)—24-inchmachines

only3

2

Locknut(5/16inch)—24-inchmachines

only3

Installtheowcontrolpanel.

Hopperassembly1

Hairpincotter1

3Hitchpin1

Installthehopperassembly.

Cable-mountbracketfor24-inch

machines1

Cable-mountbracketfor30-inch

machines1

Carriagebolt(5/16x1inch)—24-inch

machinesonly1

Carriagebolt(1/4x1inch)—24-inch

machinesonly1

Locknut(1/4inch)—24-inchmachines

only1

Locknut(1/4inch)—30-inchmachines

only2

4

Bolt(1/4x5/8inch)—30-inchmachines

only2

Installthecable-mountbracket.

Controlcable1

Locknut(1/4inch)2

5Washer2

Installthecontrolcable.

Wireharness1

6Cabletie10Installtheharness.

Cover1

Washer4

Locknut(1/4inch)4

7Bolt(1/4x3/4inch)4

Installthecover.

6

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Disconnectthenegative(black)batterycable

fromthenegative(-)batteryterminal.

2

InstallingtheFlowControl

Panel

Partsneededforthisprocedure:

1Bolt(3/8x1-1/4inches)—30-inchmachinesonly

1Locknut(1/4inch)—30-inchmachinesonly

1Bolt(1/4x5/8inch)—30-inchmachinesonly

3Bolt(5/16x3/4inch)—24-inchmachinesonly

3Locknut(5/16inch)—24-inchmachinesonly

Procedure

1.Holdtheowcontrolpanelagainsttheright

sideofthemachinetodeterminethemounting

holeconguration.Removeandretainthe

mountinghardwarefromwherethebracketwill

beinstalledonthemachine.

g238611

Figure3

Outercoverhiddenforclarity

1.Installationfor30-inch

machine

5.Reuseretainedhardware

2.Locknut(1/4inch)6.Installationfor24-inch

machine

3.Bolt(1/4x5/8inch)7.Hex-headbolt(5/16x3/4

inch)

4.Bolt(3/8x1-1/4inches)8.Locknut(5/16inch)

2.Placetheowcontrolpanelontothemachine

andsecureitusingthehardwareshownin

Figure3.

Note:Additionalhardwareisshippedwiththe

spreaderiftheretainedhardwareisnotlong

enoughtomountthecontrolpanel.

7

3

InstallingtheHopper

Assembly

Partsneededforthisprocedure:

1Hopperassembly

1Hairpincotter

1Hitchpin

Procedure

1.Insertthehopperhitchtubeintothereceiveron

themachine.

g213510

Figure4

1.Hopperhitchtube3.Cotterpin

2.Hitchpin

2.Usethehitchpinandhairpincottertosecurethe

hopperassemblytotheaerator.

4

InstallingtheCable-Mount

Bracket

Partsneededforthisprocedure:

1Cable-mountbracketfor24-inchmachines

1Cable-mountbracketfor30-inchmachines

1Carriagebolt(5/16x1inch)—24-inchmachinesonly

1Carriagebolt(1/4x1inch)—24-inchmachinesonly

1Locknut(1/4inch)—24-inchmachinesonly

2Locknut(1/4inch)—30-inchmachinesonly

2Bolt(1/4x5/8inch)—30-inchmachinesonly

Procedure

Choosetheappropriatecable-mountbracketby

matchingtheholestotherightsideofthemachine.

UsethehardwareshowninFigure5toinstallthe

bracket.

g213563

Figure5

1.Bracketfor30-inchaerator5.Carriagebolt(5/16x1

inch)

2.Bolt(1/4x5/8inch)6.Removeandusethisnut

tomountthebracket.

3.Locknut(1/4inch)7.Carriagebolt(1/4x1inch)

4.Bracketfor24-inchaerator8.Locknut(1/4inch)

8

5

InstallingtheControlCable

Partsneededforthisprocedure:

1Controlcable

2Locknut(1/4inch)

2Washer

Procedure

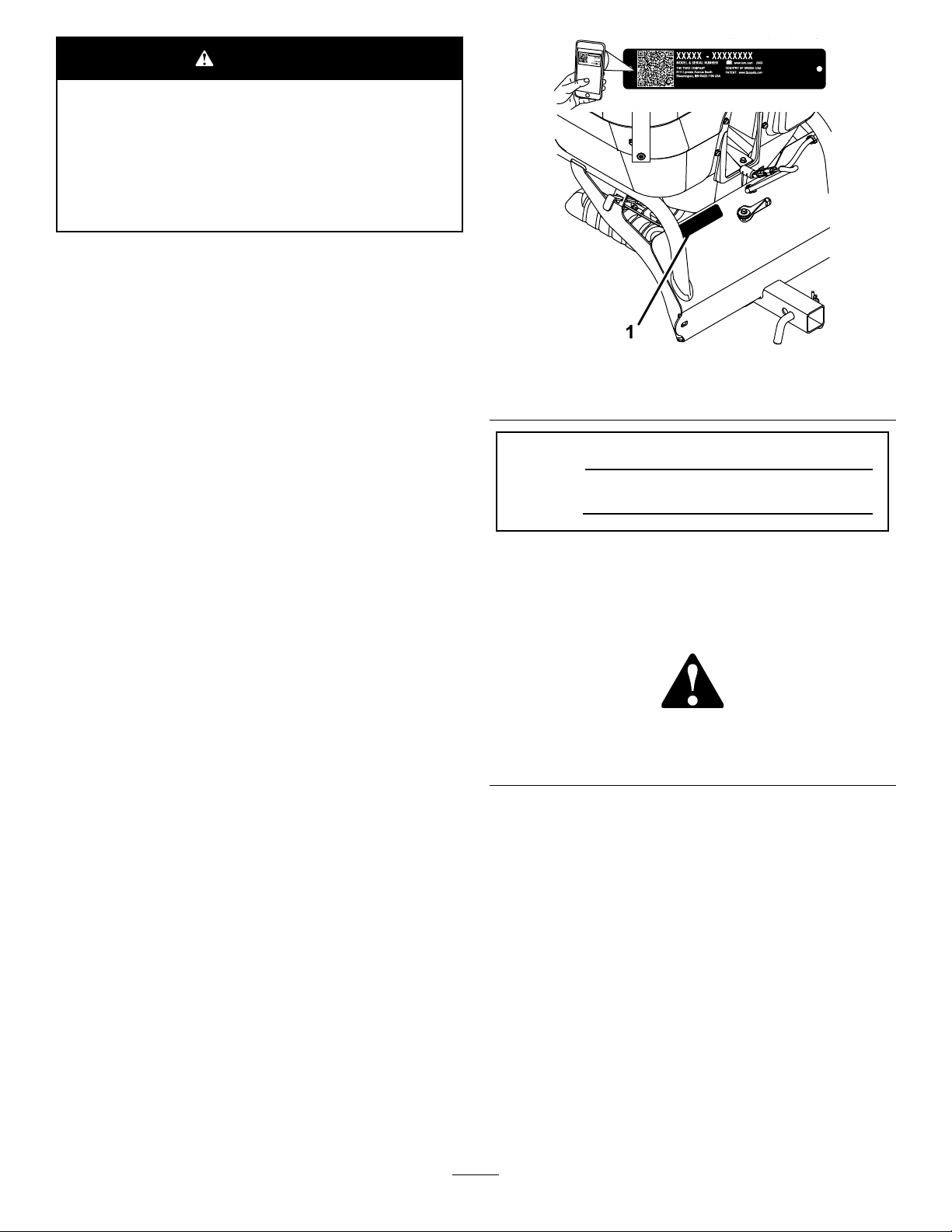

1.Ensuringthatthecableballjointissecurely

attachedtothecable,connecttheballjointto

thecontrolarmandsecureitwithawasherand

locknut(1/4inch)asshowninFigure6.

g221603

Figure6

1.Cableballjoint5.Knob

2.Controllever6.Washer

3.Locknut(1/4inch)7.Jamnut

4.Cable-mountbracket

2.Loosentheknobandslidethecontrolcableinto

thenotchofthemountbracketandtightenthe

knob.

3.Routetheotherendofthecontrolcabletothe

gatearm.

g213569

Figure7

1.Locknut(1/4inch)4.Cableend

2.Washer5.Hopperbracket

3.Gatearm

4.Insertthecableendintotheholeofthegate

arm;securethecableendwithawasherand

locknut(1/4inch)asshowninFigure7.

5.Loosenthenutsoneachsideofthecontrolcable

andslideitintothenotchofthehopperbracket.

Tightenthenutsoneachsideofthebracket.

6.Movetheowcontrolleverforwardand

rearward,makingsurethatthegatearmfully

opensandcloses.Ifitdoesnotclose,loosen

theknoband/ornutstoadjustthecableuntilthe

gatecanbefullyclosed;tightenallcomponents.

Makesurethatthejamnuthasbeensecurely

tightenedagainstthecableballjointafterall

adjustmentshavebeenmade(Figure6).

9

6

InstallingtheWireHarness

Partsneededforthisprocedure:

1Wireharness

10Cabletie

Procedure

Important:Besurethemachineisnotrunning

andthekeyhasbeenremovedfromtheignition

switchpriortoproceedingwiththeharness

installation.

1.Disconnectthebattery;refertoyourOperator’s

Manual.

2.PlugthehourmeterandON/OFFconnectorson

thespreaderharnessintotheswitchesonow

controlpanel(Figure8).

g213636

Figure8

1.Harness3.On/offswitch

2.Hourmeterconnector4.Motorconnector

3.Routetheharnessalongtherightsideofthe

machine,followingthecontrolcable.Placethe

harnessontopofthecontrolcableandslideit

intothenotchofthehopperbracket.Continue

toroutetheharnessbetweentherighthopper

bracketandhoppertube.Connectthespreader

harnesstothespreadermotorasshownin

Figure8.Insertthe3harnesstieclipsintothe

holesofthehoppermainframetosecurethe

harness.

4.Removethecapfromtheaccessorywireon

themainharnessandplugintothespreader

accessoryharnessasshowninFigure9.

24InchModelsOnly:Removetheadaptor

plugfromthemainaccessoryharness.

g213882

Figure9

1.Spreaderharness

2.Accessoryplug

3.Battery

4.Positivebatteryterminal

5.Spreaderharnesspositivebatteryconnection

6.Spreaderharnessnegativebatteryconnection

7.Negativebatteryterminal

5.Removeandretainthenutandscrewfrom

thepositiveterminalonthebattery.Installthe

accessoryharnesspositivecable(secondtolast

terminalring—Figure9)andthepositivecable

ofthemainharnesstothefrontofthepositive

batteryterminalandsecurewiththenutand

screw.Repeatfornegativebatterycable.

6.Usetheedgecliptosecuretheharnesstothe

rightaeratorpanel.

10

7.For24-inchmachines,use1cabletietosecure

thecableandharnesstothespringorspring

mount.

g253434

Figure10

1.Cableandharness3.Springmount

2.Cabletie4.Spring

8.Usetheremainingcabletiestosecurethe

harnesstotheframeand/orcontrolcable.

7

InstallingtheCover

Partsneededforthisprocedure:

1Cover

4Washer

4Locknut(1/4inch)

4Bolt(1/4x3/4inch)

Procedure

1.Attachthecovertothehopperin2placesby

insertingabolt(1/4x3/4inch)andwasher

throughthecovertabgrommetandhopperas

showninFigure11.

g221638

Figure11

1.Cover3.Bolt(1/4x3/4inch)

2.Washer4.Locknut(1/4inch)

2.Securewithalocknut(1/4inch).

3.Plugtheother2holesinthehopperwith

remaininghardware.

11

ProductOverview

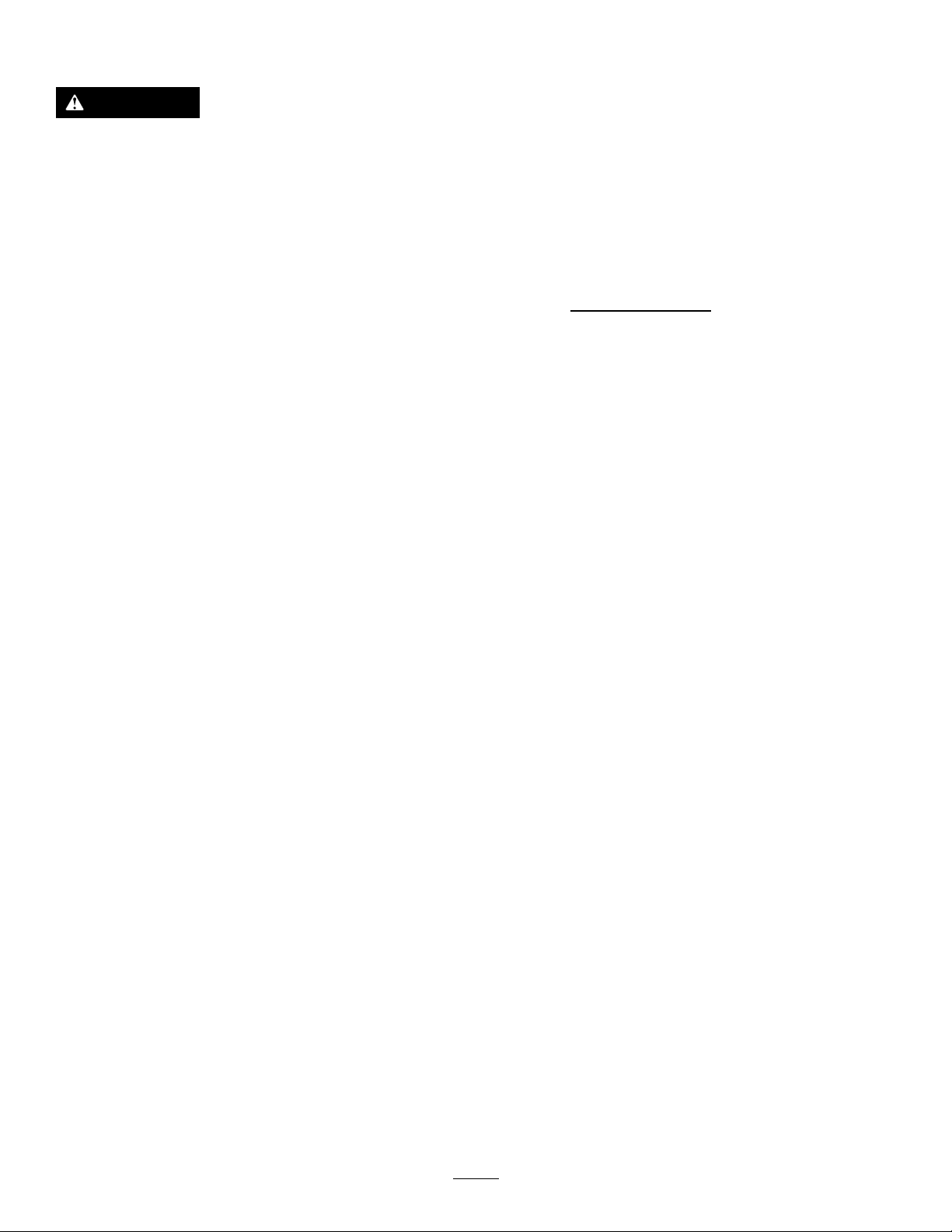

g228584

Figure12

1.Controls2.Hopper

Specications

Width69cm(27inches)

Length81cm(32inches)

Height71cm(28inches)

Weight32kg(70lb)

Maximumhoppercapacity36kg(80lb)

Spreadingwidth1.2to6.7m(4to22ft)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Theintendeduseofthisspreader

attachmentisfordispersinggrassseed.Thisis

nottobeusedforfertilizeroranyotherchemical

applications.

Controls

ImpellerSpeedControl

Theimpellerspeedcontrolislocatedatthetopofthe

spreaderaccessorycontrolpanel(Figure13).

Pushdownontherightsideoftheswitch1timeto

turnthespreaderon;continuetotaptherightsideto

increasetheimpellerspeed.

Taptheleftsideofthecontroltodecreasethespeed;

pushandholdtheleftsideoftheswitchtoturnitoff.

Note:Theimpellerspeedcontrolcanbeturnedoff

atanyspeedrate.Itisnotnecessarytodecreasethe

speeduntilitturnsoff.Thelastsetspeeddisplays

whenyouturnonthecontrol.

g207672

Figure13

1.Impellerspeedcontrol3.Distributionlimitlockknob

2.Impellerspeeddisplay4.Flowcontrollever

ImpellerSpeedDisplay

Locatedbelowtheimpellerspeedcontrol.

Thisdisplayshowsthespeedsettingnumberfrom1

to10(1istheslowestspeedand10isthefastest).A

circledisplayswhenthecontrolhasbeenturnedoff.

12

FlowControlLever

Locatedtotherightofthemaincontrols.

Lifttheleverupwardtostarttheowandcontinue

liftingittoincreasethedistributionrate.Pullthelever

downwardtodecreaseorstopthedistributionrate.

DistributionLimitLockKnob

Locatedontherightpanelofthespreaderaccessory

controlpanel.

Thisknobisusedtolimitthemaximumamount

ofgrassseedbeingdispensedtohelpmaintain

consistentdistribution.

SideDeectorControlLever

Locatedontheleftsideofthehopper(Figure14).

g207876

Figure14

1.Sidedeectorcontrollever2.Sidedeector

Usethesidedeectorcontroltotemporarilystopor

deectgrassseedawayfromsidewalks,parkinglots,

patios,oranywheregrassseedisnotdesiredtobe

dischargedfromtheleftsideofthespreader.

Totemporarilydeectthegrassseed,lifttheleverup

andpulloutwarduntilthenotchseatsintothelower

narrowportionofthebracket,whichlowerstheside

deector(Figure15).

g208735

Figure15

LeverPositions

1.Sidedeectorraises

2.Pullleveroutward

3.Pushdown—sidedeectorlowers

Toraisethedeector,lifttheleverintothewideportion

oftheslotandpushtheleverinwarduntilitstops.

g207826

Figure16

1.Fence3.Sidedeectorlowered

2.Flowers

Pre-Start

Ensurethatyouunderstandthecontrols,their

locations,functions,andsafetyrequirements.

Ensurethatthehopperanditscomponentsarein

goodcondition,properlyattached,andlatched.

13

OperatingInstructions

CAUTION

Machinecanspinveryrapidlybypositioning

1levertoomuchaheadoftheother.Youmay

losecontrolofthemachine,causinginjuryto

youorbystandersanddamagetothemachine

orproperty.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Note:Thestoppingdistancemayvarydependingon

thespreaderload.

OperatingtheSpreader

Accessory

causinginjurytoyouorbystandersanddamageto

themachineorproperty.

Thespreaderaccessoryisdesignedtodispersegrass

seed.

BeforeOperatingtheSpreader

Ensurethatthespreaderhasbeencalibratedforthe

correctapplicationrateofthegrassseedtobespread

beforestarting;refertoCalculatingtheApplication

Rate(page14).

FillingtheSpreaderHopper

Important:Verifythattheproperapplicationrate

hasbeensetpriortollingthehopper.

1.Parkthemachineonalevelsurface,movethe

motion-controllevertotheNEUTRALposition,

shutofftheengine,removethekey,andengage

theparkingbrake.

2.Ensurethatthespreadergateisclosed.

3.Removethecoverfromthehopper,addthe

grassseedtobespread,andreplacethecover.

Note:Donotoverloadthehopper;the

maximumweightcapacityofthehopperis36

kg(80lb).

CalculatingtheApplicationRate

1.Determinethekg(lb)per93m2(1,000ft2)of

producttobeapplied.

2.Determinethecalibrationcourse:

A.Determinetheamountofproduct

tobespreadper93m2(1,000ft2).

Usetherecommendedratefromthe

SpreadingChart(page15)ortheproduct

manufacturer’slabelasaguide.

B.Determineacourselengthbydividing93

m2(1,000ft2)bytheeffectivespreadwidth.

Forexample,iftheeffectivewidthis1.8

m(6ft),thenthecalibrationcourselength

equals51m(167ft).

CourseLength

93m2(1,000ft2)

1.8m(6ft)

=51m(167ft)

C.Thecalibrationcourseis1.8m(6ft)by51

m(167ft).

D.Measureandvisiblymarkthecourselength.

Makesuretoallowampledistancebefore

thestartingmarkertoensurethespreader

isatfullspeedwhencrossingtherstmark

ofthecourse.

3.Settheappropriategatesetting(referencethe

SpreadingChart(page15)sectionasastarting

point).

4.Addgrassseedtothehopper(forexample,11.3

kg(25lb)wasadded).

5.Drivethespreaderoverthecalibrationcourse

whileapplyingthegrassseed.

6.Emptytheremaininggrassseedofthehopper

intoacleanbucket.

7.Weighthebucketcontainingthegrassseedand

recordtheweight.Pourthecontentsbackinto

thehopperandthenweightheemptybucket.

Subtractthese2amountstodeterminethe

amountofgrassseedremaininginthehopper

(forexample,9kg(20lb)remains).

8.Subtracttheamountremaininginthehopper

(step7)fromtheamountoriginallyadded(step

4);theresultistheamountappliedtothecourse.

AmountApplied

11.3kg–9kg(25lb–20lb)=5lb(2.3kg)

Forthisexample,2.3kg(5lb)wasappliedto

93m2(1,000ft2).

9.Ifnecessary,adjusttheratelevertoachievethe

recommendedamounttobeappliedandrepeat

theprocedure.Oncethecorrectapplicationrate

isachieved,repeatthisprocedureanadditional

timetoverifytheresults.

14

SpreadingChart

Thechartbelowisforreferenceonly.

GrassSeedApplicationatMaximumGroundSpeed

(Coverage93m2or1,000ft2)

Typekg(lb)/93m2(1,000ft2)GateOpeningSpreadWidth

BlueGrassorRedT op0.9kg(2lb).251.2m(4ft)

Park,Merion,Delta,orKentucky

Bluegrass0.2kg(0.5lb).251.2m(4ft)

HulledBermuda0.9kg(2lb).751.8m(6ft)

MixturesIncludingCoarseSeeds2.7kg(6lb).751.8m(6ft)

RyeGrassesorT allFescue2.7kg(6lb).75tomaximumopen1.8m(6ft)

Dichondra0.3kg(0.75lb).252.4m(8ft)

PensacolaBahia2.7kg(6lb).502.1m(7ft)

Spreading

SpreadingTips:

•Toensureuniformapplication,overlapthegrassseeddistribution.Thehighestamountofseeddispenses

fromthefrontofthehopperandlessfromeachside.Adjustthedistributionpatterntoachievethedesired

results.

•Watchforchangesinthedistributionpattern;unequaldistributionmayleadtostriping.

g207791

Figure17

1.Narrowdistribution-sidedeectorlowered5.Endofspreadingjob

2.Forward6.Propertyfence

3.Effectivespreadingwidth—variable1.2to6.7m(4to22ft)7.Gate

4.Donotspreadwhenturning180degrees

1.StarttheengineandplacethethrottlemidwaybetweentheSLOWandFASTpositions.

15

2.Turnontheimpellerspeedcontrol.

3.Settheimpellerspeedtotheappropriatesetting.

4.MovethethrottletotheFASTpositionanddriveforward.

5.Openthehoppergateandbeginspreading.

g207728

Figure18

1.Effectivespreadingwidth—variable1.2to6.7m(4to22ft)

6.Evaluatethespreadpattern.Ifadjustmentsareneeded,refertoSpreaderPatternAdjustment(page17).

7.Whennishedspreading,closethehoppergate.

16

SpreaderPatternAdjustment

Ifthespreadpatternisskewedordispensingtoolight

ortooheavyto1side(Figure19),adjustthegate

asfollows:

g025543

Figure19

1.Heavytoleftside3.Heavytorightside

2.Moveramppatternto

shadedposition

Note:Donotadjusttherampstosplitproductow.

Useonlythefrontorrearramppositionsasshown.

1.Unlockthespreaderpatterncontrolknobby

turningitcounterclockwise90degrees.

g207877

Figure20

1.Spreaderpatterncontrol

knob

2.Controlhandle

Toadjustwhenthegrassseedpatternisheavy:

•Totheleftside,slightlypullthecontrolhandle

rearward.

•Totherightside,slightlypushthecontrol

handleforward.

2.Lockthespreaderpatterncontrolbyturningthe

controlknobclockwise90degrees.

OperatingTips

Overseeding

Important:Donotputdownmoreseedthan

recommendedbytheseedcompany.Overseeding

cancausethegrasstobetoothickandbecome

susceptibletofungus.

Note:Themachineseedsatthesamerategoing

bothforwardandrearward.

Note:Ifthereisexcessivethatch,itmaybe

necessarytoremovethethatchpriortoseeding.

RemovingtheSpreader

Attachment

1.Shutofftheengine,removethekey,waitforall

movingpartstostop,andengagetheparking

brake.

2.Unplugthespreaderaccessoryharness(Figure

9).

3.Disconnectthecableballjointfromthecontrol

lever(Figure6).Loosentheknobonthecable

mountbracket.

4.Removeandretainthehitchpinfromthe

receiver(Figure4)

5.Removethehopperassembly,controlcable,

andaccessoryharness.

Note:Allotherspreaderattachment

componentsmaystaymountedonthemachine.

Makesurecomponentsaresecureandaway

frommovingparts.

17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitch,engageparkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenancetothemachineorattachment.Alsopushthewire(s)

asidesoitdoesnotaccidentallycontactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Beforeeachuseordaily•Checkforloosehardware.

•Cleanthedebrisbuildupfromthemachine.

CheckingforLoose

Hardware

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,removethekey,waitforall

movingpartstostop,andengagetheparking

brake.

2.Visuallyinspectthemachineforanyloose

hardwareoranyotherpossibleproblem.Tighten

anyloosehardwareorcorrecttheproblem

beforeoperatingthemachine.

AdjustingtheSpreader

PatternControlCable

1.Shutofftheengine,removethekey,waitforall

movingpartstostop,andengagetheparking

brake.

2.Closethegranulargate.

3.Ensurethatthespreadpatterncontrolhandleis

pusheddownandlockedatthecontrolpanel.

4.Loosenthejamnutattheendofthecable.

g027205

Figure21

1.Jamnut

2.Linkagerod

3.Impellershaft

4.3.2mm(1/8inch)gapbetweenramptoothandimpeller

shaft

5.Ramptooth

5.Pullthelinkageroduntilthereis3.2mm(1/8

inch)gapbetweentheramptoothandthe

impellershaft.

6.Tightenthejamnut.

18

AdjustingtheGateClosure

1.Ifthegatearmisnotfullyclosing,adjustthe

controlcableattheknoblocatedonthecable

mountbracketorthenutslocatedoneitherside

ofthehopperbracket.

2.Continuetoadjustuntilthegatecanbefully

closed;tightenallcomponents.

Cleaning

CleaningDebrisfromthe

Machine

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,removethekey,waitforall

movingpartstostop,andengagetheparking

brake.

2.Cleanoffanydebrisorbuilduponthemachine,

especiallytheimpeller.

19

Troubleshooting

Thefollowingtablelistssomeofthecommoncausesoftrouble.Ifaproblemcontinues,contactanAuthorized

ServiceDealer.

ProblemPossibleCauseCorrectiveAction

Messagedisplays“STALLED(02)”1.Controllerhasdetectedanexcessive

electricalcurrenttotheimpellermotor.

1.Checktheimpellerandhopperfor

obstructionsthatmayaddanexcessive

loadtotheimpellermotor.Checkthe

electricalconnectionstotheimpeller

motortoensuretheyarenotshorted.

Pressthe“ON”switchtoretry.

Messagedisplays“WIREFAULT(04)”1.Thecontrollerisunabletodetectmotor

feedbackvoltage.

1.Checkpins18onthecontroller

connectorforproperpinseatingand

locking.

Messagedisplays“WIREFAULT(05)”1.Oneoftwooutputsarenotproviding

powertotheimpellermotor.

1.Checkpins6and8onthecontroller

connectorforproperpinseatingand

locking.

Messagedisplays“WIREFAULT(06)”1.Thecontrollerisunabletodetect

connectiontotheimpellermotor.

1.Powerofftheimpellerandcheckthe

electricalconnectionstotheimpeller

motor.

1.Afuseisblown.1.Replacetheblownfuse.

2.Thereareimproperelectrical

connections.

2.Checktheelectricalconnectionsat

theaccessorypowerconnectorand

batteryringterminalsandensureboth

havepower.

Thecontrollerdoesnotpoweron.

3.Thecontrollermoduleisfaulty.3.Replacethecontrollermodule.

Thecontrollerfailstokeeprunning.1.Electricalconnectionsarecorroded,

loose,orfaulty.

1.Checktheelectricalconnections

forgoodcontact.Cleanconnector

terminalsthoroughlywithelectrical

contactcleaner,applydielectricgrease

andreconnect.

1.Theswitchconnectormaybeloose.1.Ensurethattheswitchconnectoris

connectedtotherockerswitch.

Aswitchisunresponsive.

2.Pinsmaynotbeinsertedintothe

correctterminals.

2.Checkforincorrectpinpositions.

20

Table of contents

Other Toro Spreader manuals