EHA Transprint HP 2010 User manual

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 1of 23 Release: M. Klein

EHA Hoffmann International GmbH

User manual EHA-TRANSPRINT HP 2010

Machine-No.: Year:

EHA Hoffmann International GmbH

Michelsbergstraße 24

D-57080 Siegen

Telephone: +49 271 39 32 - 0

Telefax: +49 271 39 03 37

E-mail: info@eha-group.com

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 2of 23 Release: M. Klein

EHA Hoffmann International GmbH

User manual EHA -Transprint HP 2010

All technical and technological information included in this user manual as well as any

drawings and technical specifications made available remain the property of EHA Hoffmann

International GmbH. They shall not be used (other than for the operation of this product),

copied, reproduced, transmitted or disclosed to third parties without our prior written

consent

EHA Hoffmann International GmbH

Michelsbergstraße 24

D-57080 Siegen

Telephone: +49 271 39 32 - 0

Telefax: +49 271 39 03 37

E-mail: info@eha-group.com

2016 EHA Hoffmann International GmbH

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 3of 23 Release: M. Klein

CONTENTS

1TYPE DESCRIPTION 5

1.1 Introduction 5

1.1 Technical specifications .............................................................................. 6

2SAFETY 7

2.1 Obligations of the owner............................................................................... 7

2.2 Obligations of the personnel......................................................................... 7

2.3 Dangers caused by operation of the machine.............................................. 7

2.4 Intended use ................................................................................................ 8

2.5Safety features............................................................................................. 8

2.6Informal safety measures............................................................................. 8

2.7Machine operating system ........................................................................... 8

2.8Safety measures for normal operation ......................................................... 9

2.9Dangers caused by electricity ...................................................................... 9

3MACHINE DESCRIPTION 10

3.1 Description of Main components………………………………………………..10

4TRANSPORT 11

5INSTALLATION 11

5.1 Installation area requirements.....................................................................11

5.2 Installation...................................................................................................12

5.3 Installation of the power supply...................................................................12

6GENERAL OPERATION 13

6.1 Start up........................................................................................................13

6.2 Insert foil......................................................................................................14

6.3 Prerequisites vehicle number plates............................................................15

6.4 Hot stamping - normal operation ……………………………………………..15

6.5Changing the foil .........................................................................................15

6.6Powering down the machine …………………………………………………...15

6.7 Unwind brake ……………………………………………………………………16

6.8 Changing the hot-stamping pressure …………………………………………16

6.9 Control Panel ..............................................................................................18

6.10 Activate Control Panel.................................................................................19

6.11 Changing the temperature setting...............................................................21

6.12 Bridging the timer .......................................................................................21

6.13 Changing the display language ..................................................................22

6.14 Error messages...........................................................................................22

7MAINTENANCE 23

7.1 Cleaning......................................................................................................23

7.2 Annual Inspection........................................................................................23

7.3 Replacing the fuse ………………………… …………………………………23

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 4of 23 Release: M. Klein

1 TYPE DESCRIPTION

The EHA Transprint HP2010 is a machine specially built for high quality hot stamping by

means of heat and pressure.

The machine has been developed to be used exclusively for the hot stamping of designated

vehicle number plates with embossed edges.

Identification

The machine has a type plate, a typical example is shown below. The type plate is located

on the side of the machine..

1.1 Introdruction

This user manual refers to the EHA Transprint HP2010. It contains information that is

important and useful for the proper operation and maintenance of the machine. In addition it

contains important instructions to prevent accidents and serious damage prior to and during

usage of the machine and it allows the machine to perform as safely and flawlessly as

possible. Read this manual carefully before starting the machine, familiarize yourself

thoroughly with the functioning of the machine and strictly follow the directions given.

If you have any questions or need more detailed information on specific aspects of the

machine, please do not hesitate to contact EHA Hoffmann International GmbH.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 5of 23 Release: M. Klein

Liability

The data included in this manual is based on the latest information available at the time of

writing. It may be subject to future changes.

We reserve the right to make changes to the design and / or construction of our products

without being obligated to adapt previously supplied machines.

Warranty

The warranty conditions that apply for this product are stated in the terms of delivery.

The warranty on your equipment will become null and void if:

Service and maintenance are not carried out strictly in accordance with the

instructions, repairs are not carried out by authorized personnel or have been made

without our consent;

the machine has been modified without our consent;

non-original parts have been used;

the equipment is used inexpertly, incorrectly, carelessly or not accordance with its

nature or intended use.

The warranty does not cover wearing parts.

The pressure roller has been coated with a high quality silicone rubber which ensures

excellent anti-stick properties. The durability of the silicone rubber is highly dependent on

the used materials. Therefore the warranty does not include the silicone coating of the

pressure roller.

Safety

Familiarize yourself with the pictograms (also see chapter 2: Safety).

The equipment is provided with safety and protection features. Even so, caution is required

when performing machine operations. Warning pictograms in the various chapters point to

potential dangers. You will find these pictograms near the text referring to the operations

that involve risks.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 6of 23 Release: M. Klein

Work safely!

EHA Hoffmann International GmbH had made every effort to inform you as correctly and

completely as possible on any dangers associated with the operation of the machine. You

must ensure and are responsible for compliance with these behavioural guidelines.

The buyer/user is obliged to familiarize operating, cleaning and maintenance personnel with

these instructions. After the instruction by the vendor / supplier, the purchaser must carry

out independent instructions when changing the operating personnel.

Upon their arrival, check deliveries for:

► Any damage and/or missing parts due to transport. Make sure that the carrier draws up a

transport damage report on the spot.

► Correctness and completeness; have all parts (additionally) ordered been supplied?

In case of damage, always contact EHA Hoffmann International GmbH.

1.2 Technical specifications EHA Transprint HP 2010

Dimensions / Weight

Machine:

Depth 530 mm (20,9”)

Höhe 920 mm (36,2”)

Width 550 mm (21,7“)

Net weight 75 kg

Power supply :

Power supply 230V, 50/60 Hz, 16A

Heating power 1300W

Motor power: 90W

Foil winding power: 60W

Temperature Control 0 - 220°C

Operating speed :

Maximal 5 m/min (16.4 ft/min)

Working width:

Maximal 120 mm (4,7”)

Shaft capacities :

Core diameter 25.4mm (1”)

Noise level : ≤70 dB (A)

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 7of 23 Release: M. Klein

2 SAFETY

The EHA Transprint HP 2010 is provided with safety equipment to ensure safe machine

operation. You should, however, take due note of the following:

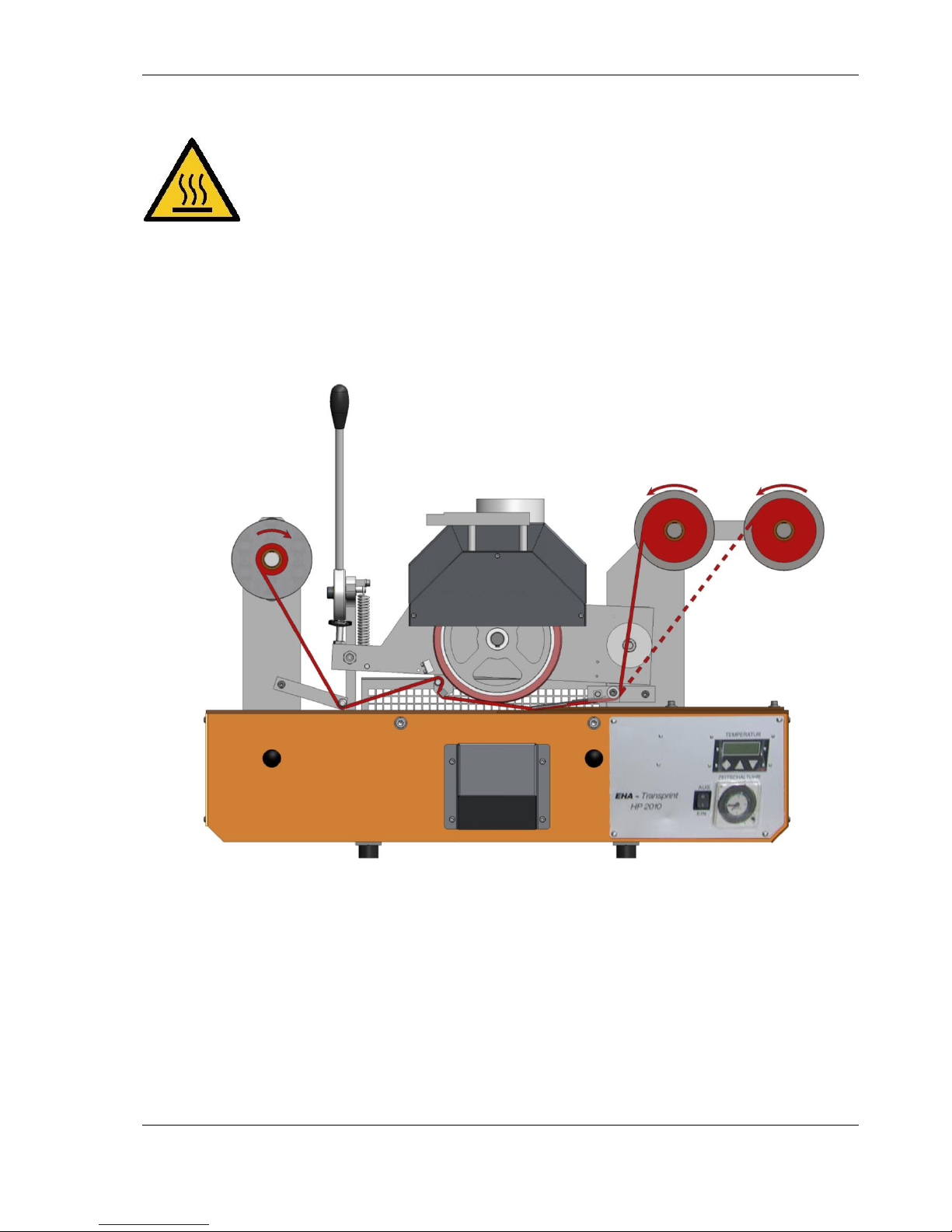

Danger of getting injured by hot parts.

Be careful with hot parts to avoid burns. The heated roller may have a

surface temperature of 220°C. Do not touch the rollers. Even after the

machine had been switched off, the roller will remain hot for a long time.

Danger of getting injured by rotating parts.

The machine is provided with a cover (protection cage) which are designed to

prevent contact with rotating parts. Make sure that this safety device is

always installed during operation of the machine.

Danger of getting injured by voltage.

Do not remove the back panels of the EHA Transprint HP2010, you may get

injured by voltage. Only remove the panels to carry out maintenance. In this

case be sure that the machine is de-energized.

Do not place heavy objects on the power supply cord.

2.1 Obligations of the owner

The owner of the machine has to make sure that the only people allowed to work with and

on the machine have understood and confirmed by their signature the basic regulations on

workplace safety and accident prevention. The owner will make sure that the personnel is

trained in the handling of the machine and have been familiarized with the operating and

safety instructions contained within this manual. The safety awareness of personnel shall

be reviewed at regular intervals.

2.2 Obligations of the personnel

All individuals working with and on the machine commit, and confirmed by their signature,

to be familiar with the basic regulations on workplace safety and accident prevention and

have read the section on safety contained within this manual.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 8of 23 Release: M. Klein

2.3 Dangers caused by operation of the machine

The EHA Transprint HP2010 is built according to accepted engineering standards and

safety regulations. Despite that operating the machine could result in danger for life and

limb of the operator or bystander or cause damage to the equipment or other property.

The machine shall be used only:

►For the intended use.

►In absolutely perfect condition.

Malfunctions or damage that may affect the safety must be serviced immediately.

2.4 Intended use

The EHA Transprint HP2010 is designed exclusively for the hot stamping of designated

vehicle number plates with embossing edges.

Any different or additional use of the machine is considered improper.

EHA Hoffmann International GmbH is not responsible for any resulting damage to machine

or individuals.

2.5 Safety features

Before start-up of the machine, make sure that the protection case is closed properly.

The Safety cover may only be removed when the machine is at a complete stop and

powered down.

2.6 Informal safety measures

The operating instructions must be kept with the machine.

In addition to the operating instruction, the local accident prevention regulations and

environmental regulations should be available and to be noted by the operator.

All safety instructions and warning pictograms must remain in legible condition.

2.7 Machine operating system

Do not make any modifications to the operating system of the machine under any

circumstances!

Settings on the timer and temperature shall be permitted only by qualified personnel.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 9of 23 Release: M. Klein

2.8 Safety measures for normal operation

Check the machine for obvious damage and the safety cover is being functional at least

once every shift.

Only operate the machine if the safety cover is fully functional.

Before start-up of the machine ensure that no other individuals are to be at risk.

Only operate the machine if the temperature comparison (target/actual) in the display are

the same.

2.9 Dangers caused by electricity

Maintenance on the electrical system should only be carried out by qualified mechanics.

If maintenance is required to live parts, a second individual must be present who in case of

emergency can turn off the main power.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 10 of 23 Release: M. Klein

3 MACHINE DESCRIPTION

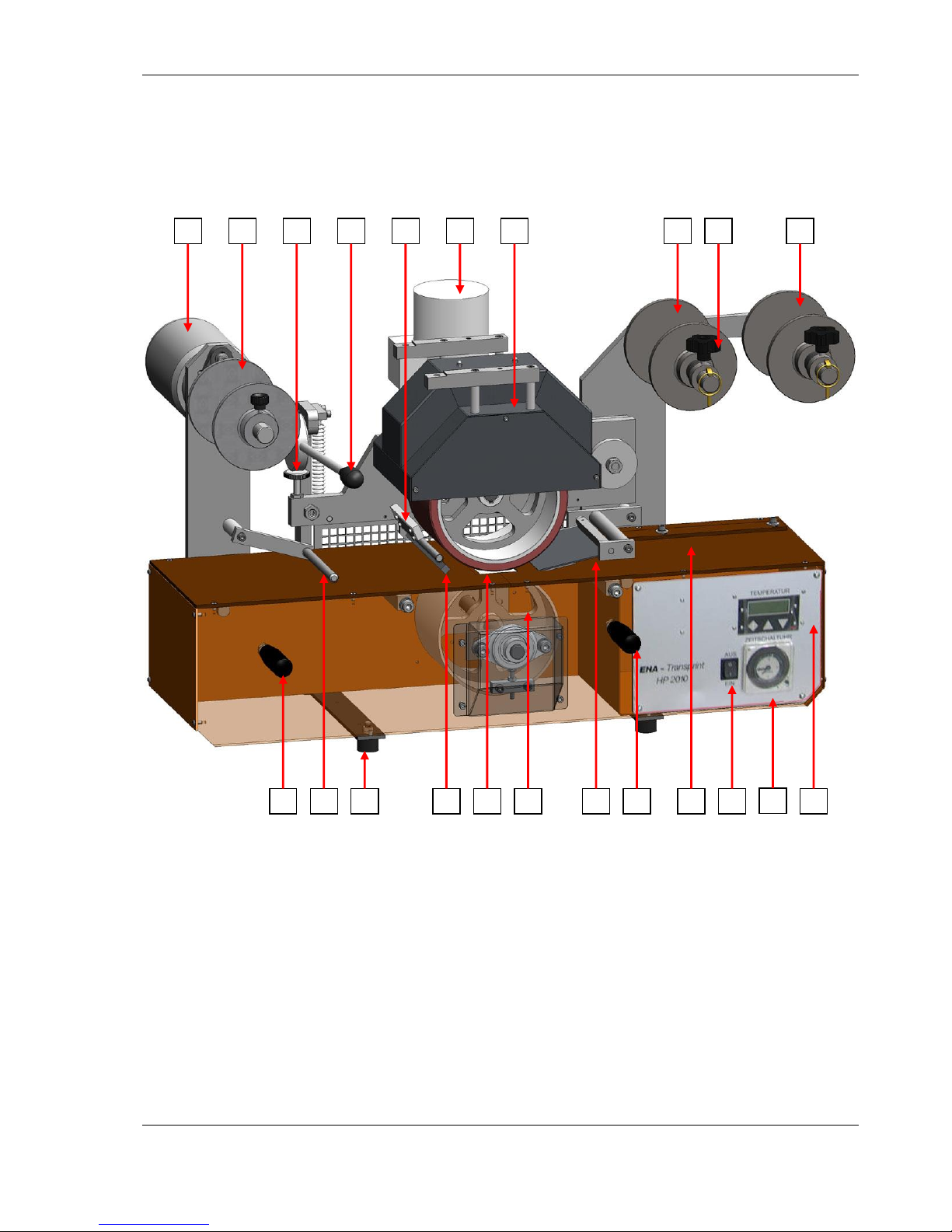

Description main components:

1. Wind up motor 12. Diversion axis

2. Wind up unit 13. Rubber feet

3. Setting Hot Stamping pressure 14. Guiding / Peeling shaft

4. Roller lever 15. Top roller (Silicone Rubber)

5. Infrared temperature sensor 16. Upper roller (Steel)

6. Drive motor 17. Guiding shaft with spring loaded

7. Heating element 18. Carrying handle

8. Unwind Foil 1 19. Number plate guiding

9. Unwind Foil 2 20. On / Off button

10.Adjustment unwind unit brake 21. Timer with week program

11.Carrying handle 22. Display with control panel

21

22

11

15

16

17

14

19

1

6

4

8

9

5

7

12

20

10

3

2

18

13

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 11 of 23 Release: M. Klein

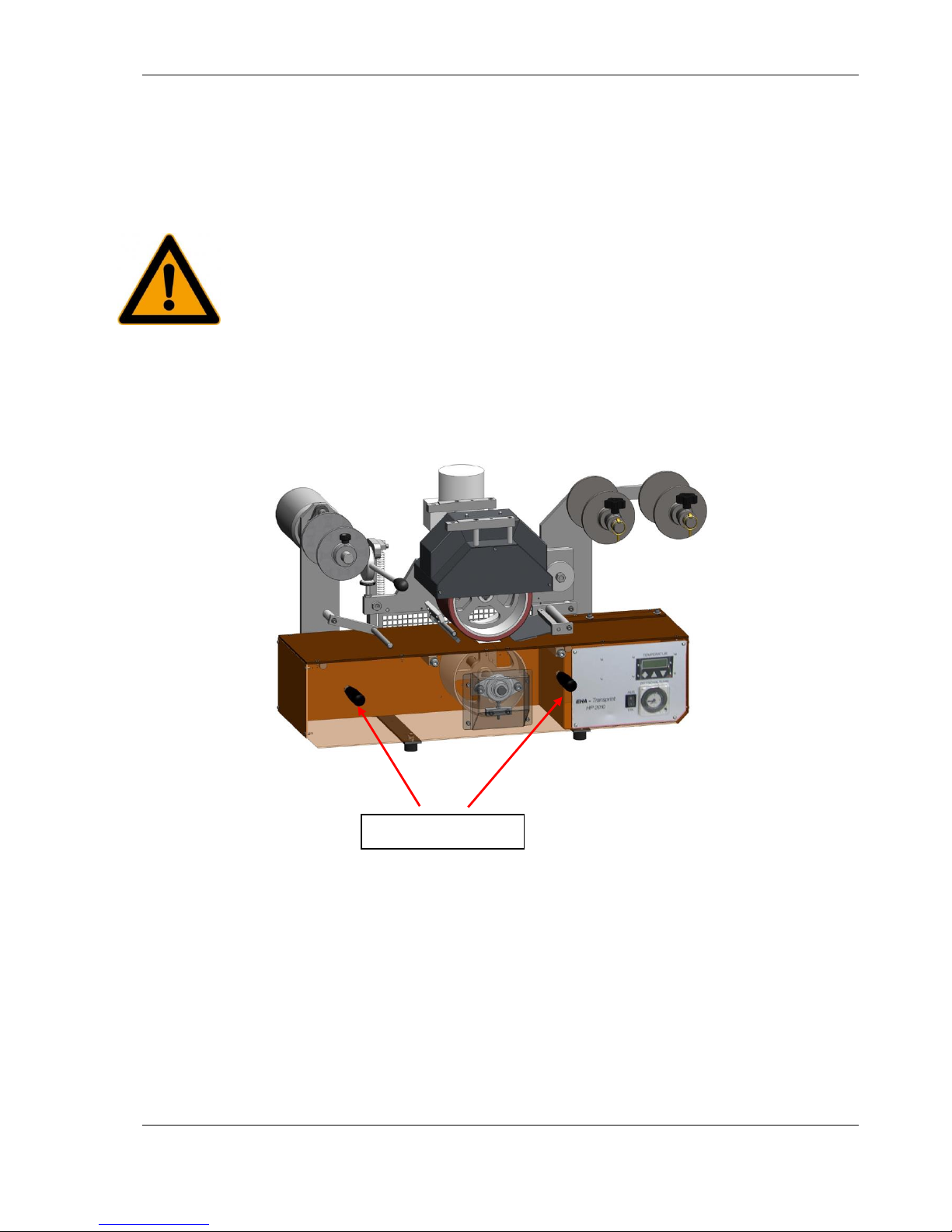

4 TRANSPORT

►Consider the weight when moving the machine.

►To move the machine consider the usage of devices that can lift it safely.

►The Hot Stamping Machine must be lifted with at least 2 people hand-

bulky. Use for it the carrying handles.

5 INSTALLATION

5.1 Installation area requirements

The installation should only be carried out by qualified personnel.

Free space

There must be sufficient free space around the machine surface area for installation

purposes and proper supply and output of films and number plates.

Carrying handles

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 12 of 23 Release: M. Klein

Operating conditions

Temperature: 10°C ~ 50°C (50°F ~ 122°F)

Do not expose the machine to direct sunlight; the temperature increase

may affect the final product.

Humidity: 30 % ~ 85 %

The humidity should ideally be maintained at 55% (no condensation).

Dust: Prevent a dusty environment. Since the films are easily electro

statically charged, they could attract dust. Work clean and tidy.

5.2 Installation

Place the machine on a sturdy table or frame for its permanent operating position.

Make sure that the machine is standing in a stable position on its rubber feet.

5.3 Installation of the power supply

The EHA Transprint HP2010 machine is supplied with a 2,5 m power cable with a socket

plug in accordance with the type plate.

The installation should only be carried out by qualified personnel.

Make sure the supplied voltage is within the required tolerances.

The connecting cable for the power supply has to be connected properly

(CE plug 230 V, 16 A, 2-pole).

1. Connect the cable for the power supply to a suitable socket (230 Volt).

2. Check if the correct fuses according to the electrical circuit diagram are installed and if

these are in working order.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 13 of 23 Release: M. Klein

6 GENERAL OPERATION

6.1 Start up

Turn the heating on for about 30 minutes in advance of using the machine to

ensure that the roller has the required temperature and is well heated

through.

► Only connect the power cable to a 230V, 50/60Hz socket, secured with a 16A fuse.

► Connect the power cable.

► Set the On / Off switch in the "I"-position (see capture 6.10).

► Select the temperature setting (see chapter 6.11)

Now all functions are put into operation.

► The roller rotates (depending on the choice of automatic or manual heating, see chapter

6.10.1 / 6.10.2) and the roller is heated to the selected temperature.

► The preset temperature of about 195°C is reached in approximately 7 minutes.

► After about 23 minutes the roller is sufficiently heated.

► The machine is now ready for use.

► All electrical and mechanical safety features must be in place and functional.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 14 of 23 Release: M. Klein

6.2 Insert foil

.

If the machine has already been in operation and the working

temperature has been reached the roller and the roller heating cover will

be hot.

► Pull the power plug of the machine before working with the foil.

► Insert the foil roll on the unwind shaft to the right of the roller, so that the foil runs to the

left.

► Feed the foil under the spring loaded in feed plate, put the foil under the roll around the

square bar, over the round bar, further around the next guiding shaft to the wind up unit.

►Attach the foil on the bottom left to the core already fitted on the wind up shaft by means

of sticky tape.

► Press the guiding flange against the core to clamp the core to the shaft.

► Align everything straight and free of wrinkles in the foil!

► Load the foil roll on the unwind shaft with a guiding flange.

► Clip on the pressure spring. Pretension the pressure spring with the adjusting ring so far

that the winding motor can not pull the foil roll straight.

►Connect the power cable.

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 15 of 23 Release: M. Klein

6.3 Prerequisites vehicle number plates

The vehicle number plates must be:

►equipped with hp-resistant reflective foil.

►uniformly shaped, straight and flat.

►have a top surface that is clean, dry, and free from dust and grease.

►at least 20°C (Room temperature).

►the roller operating temperature is about 195°C.

6.4 Hot stamping - normal operation

►Place the vehicle number plate on the table on the right and position it against the guiding

strip.

►Fully pull down the roller lever. (The wind up motor is turned on automatically)

►Push the vehicle number plate(s) to the roller until the plate is fixed and pulled through

the roller.

►Stay clear of the roller with your fingers.

Risk of being trapped!

►The next plate(s) can be fed into the machine. Remove the finished plates from the left

side.

►Put the roller lever back into the upward position after the hot stamping operation (The

wind up motor turns off automatically).

Brush off the loose pieces of foil from the plate if necessary.

6.5Changing the foil

►Put the second roll of foil on the outer unwind shaft right.

►Unwind the foil for a short distance and attach the foil to the first foil by means of sticky

tape in front of the spring loaded in feed plate.

►Cut the first foil over the mend.

►Unwind the foil by rotating the wind up shaft manually until the foil is positioned

underneath the roller.

►Load the foil roll on the unwind shaft with a guiding flange.

The machine is ready for use again.

6.6 Powering down the machine

►Manually turn off the machine (see chapter 6.10.1/6.10.2).

The heating is turned off.

Be aware that all machine components close to the roller will remain hot for

a considerable time during the Cooldown phase. Danger of burns!

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 16 of 23 Release: M. Klein

►The roller will continue to rotate for about 20 minutes to cool down.

(The control panel will show COOLDOWN in the display)

►After the Cooldown phase the machine will turn off and go into standby mode (The

control panel will show OFF in the display).

►Do not remove the power supply cable from the socket until the roller is

completely cooled down and maintenance work on the machine must be carried

out!

►Without power supply 230V the clock runs for maximum 2 days on emergency stream.

6.7 Winding up-Brake

Adjustment of the tension of winding up

The brake tension can be put by shifting the clamping ring. A good base setting is given if

with running winding motor the winding up brake is set that the winding up roll does not run

along any more.

The securing pin must be in operation in the arbor before the clamping ring is released.

Clamping ring

Operating button

Securing pin

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 17 of 23 Release: M. Klein

6.8 Setting of Hot Stamping Pressure

Loosen counter nut. (Spanner 13)

Adjusting screw upwards or downwards.

►Turn clockwise, Screw downwards = lower hot-stamping pressure

►Turn counter clockwise, Screw upwards = higher hot-stamping pressure

Fix the counter nut (Spanner 13)

Screw

Counter nut

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 18 of 23 Release: M. Klein

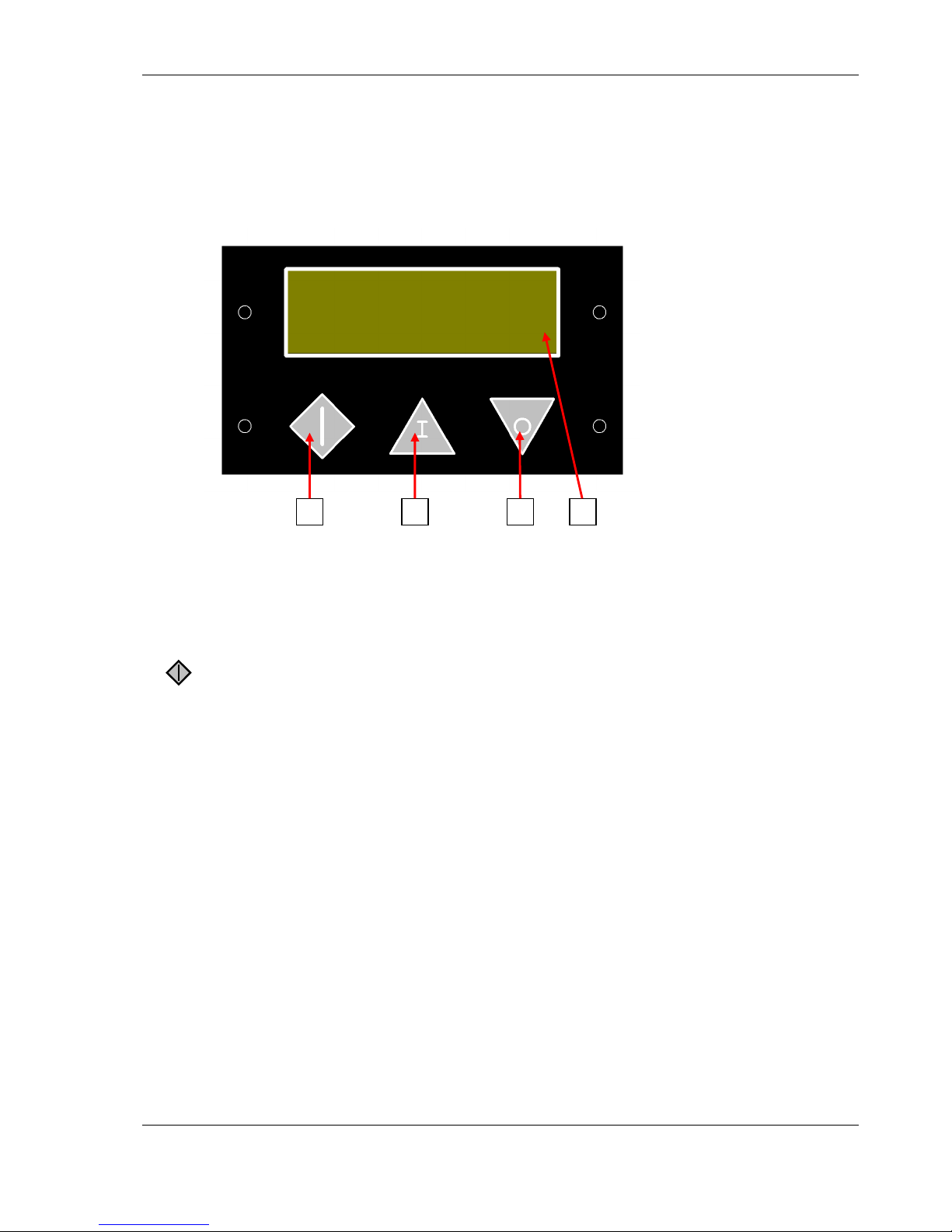

6.9 Control panel

The machine is equipped with a control panel:

Display and button functions

The functions of the buttons / display of the control panel are:

No. Function or display

1. = ENTER-button

2. Double function: - Increase temperature setting (press together with button 1)

- Switch on button for manual heating on after switch on the

rocker switch.

3. Double function: - Increase temperature setting (press together with button 1

- Switch Off button for bridge the timer.

4. Display (Status, Temperature, (Failure) Message).

4

1

2

3

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 19 of 23 Release: M. Klein

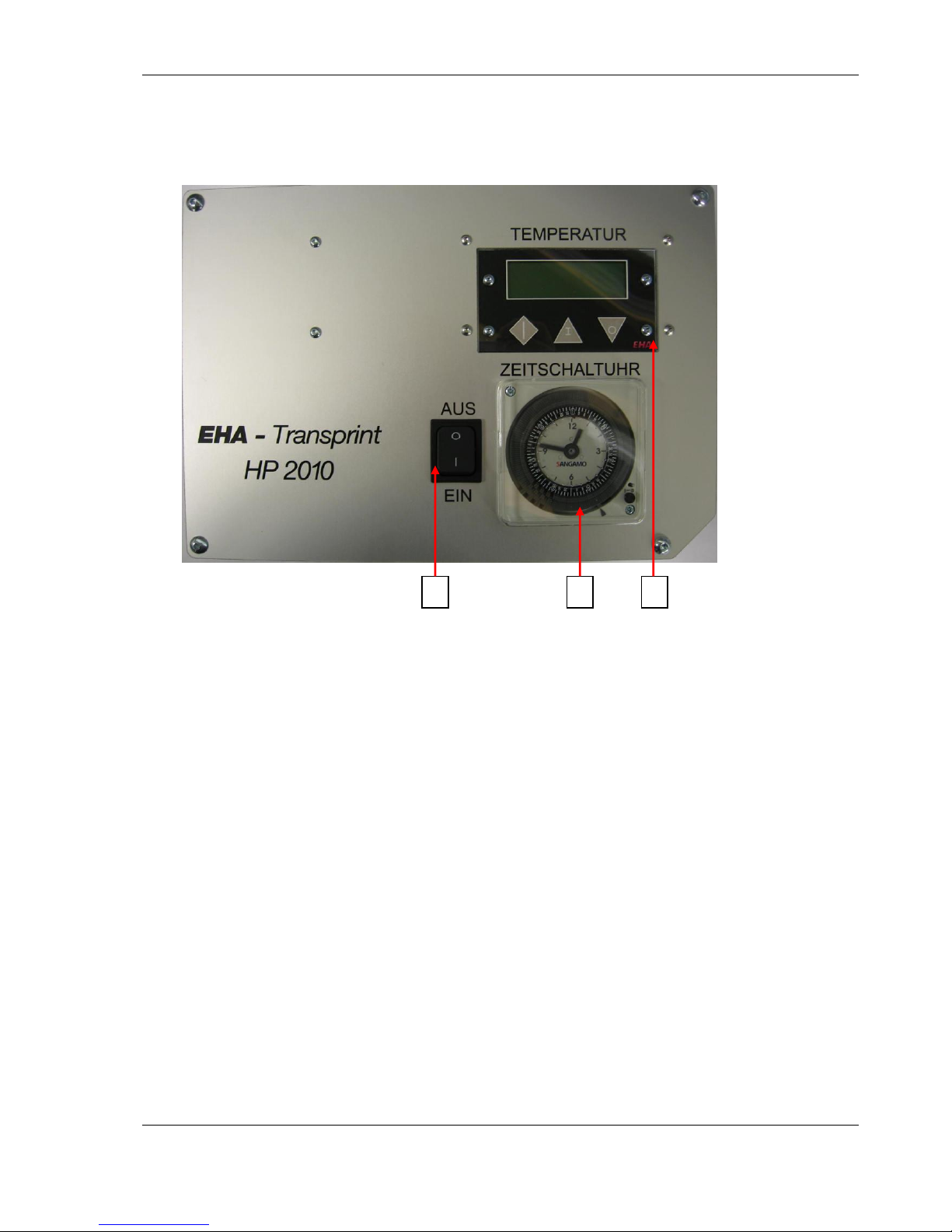

6.10 Activate control panel and turn the machine on

1. To activate the control panel and turn the machine on by setting the On / Off switch

in the "I"-position.

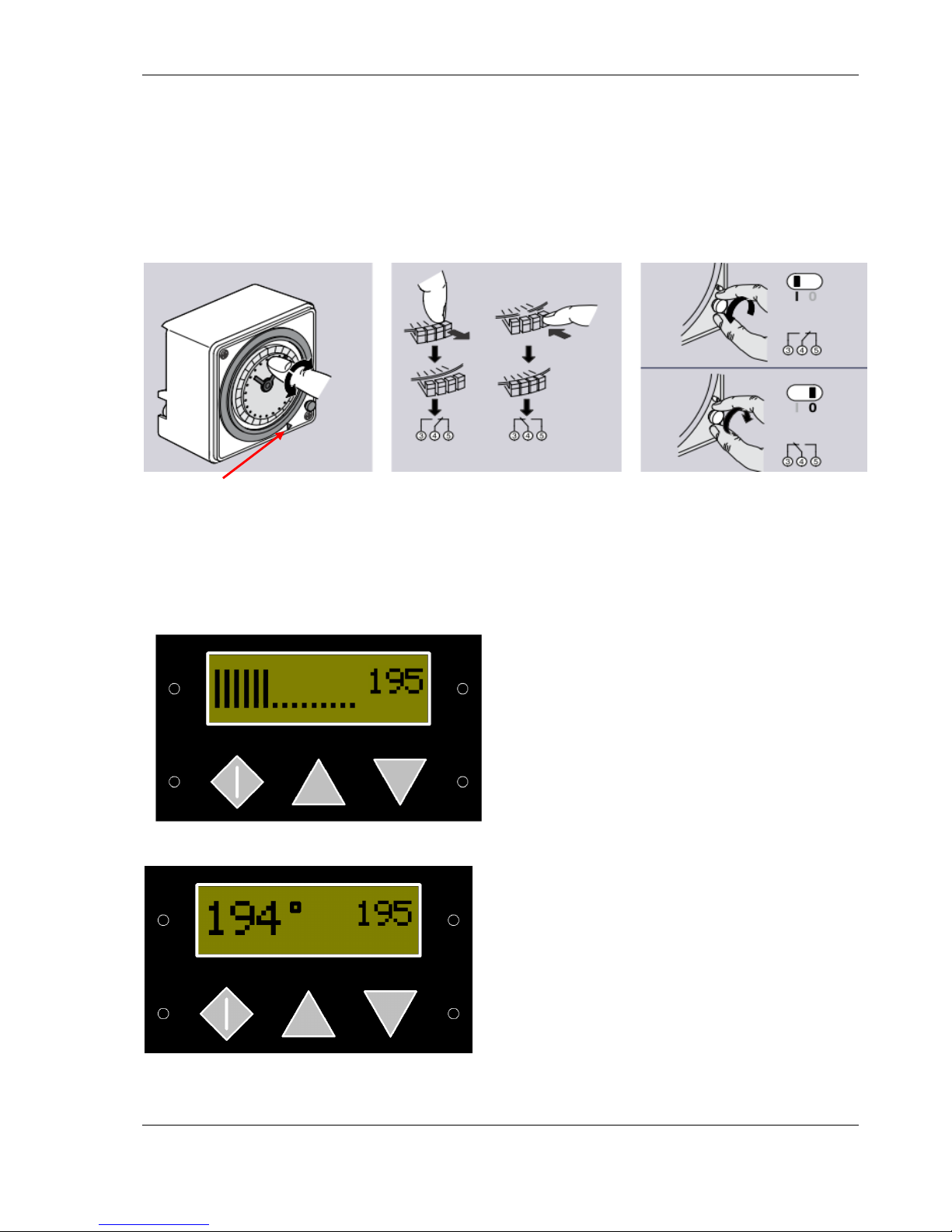

2. Timer with week program

3. Display / Control Panel for, beside others, the setting or temperature

6.10.1 Activate manual

The rocket Switch has to be OFF to start the machine manually.

Press the ▲ for a short time. The control panel is now activated, the roller will start to

rotate, the display will briefly show START UP and the heating starts to heat the roller. The

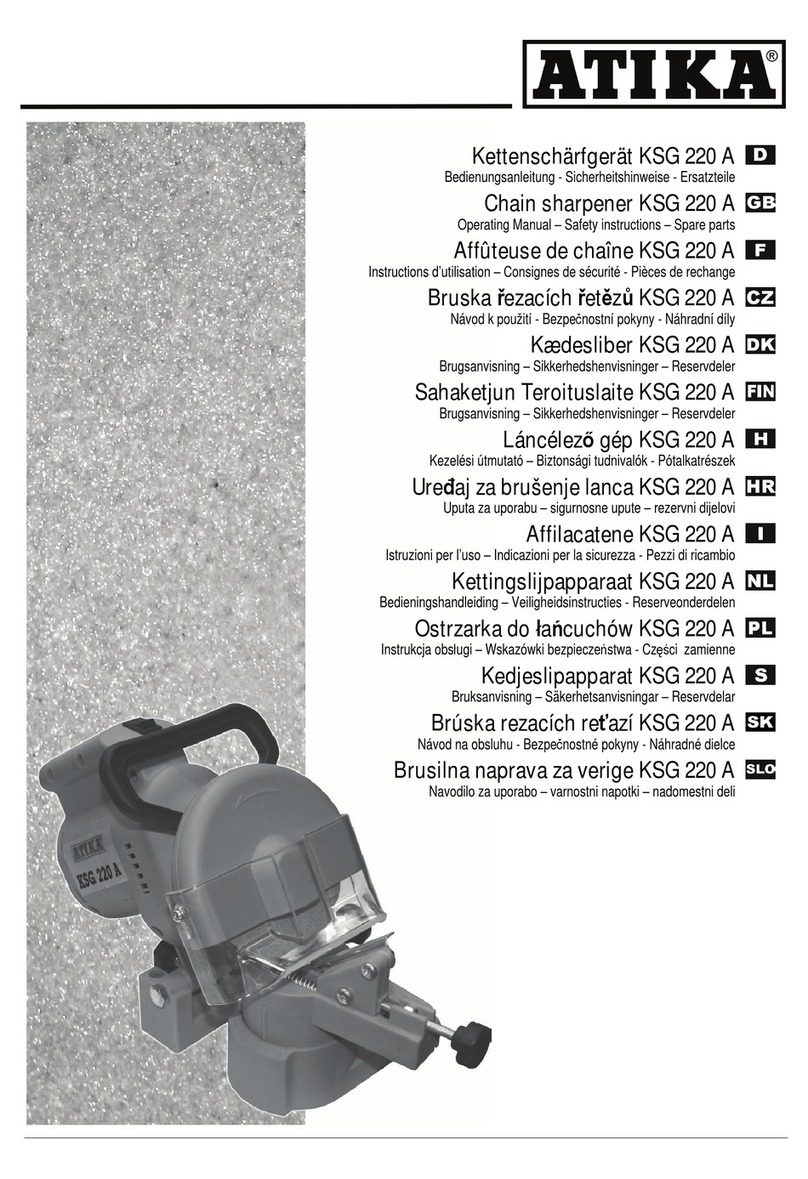

machine shows a time line during the warming up period. The temperature of 195°C is

reached in approximately 23 minutes. (Picture 9)

To turn off the heating and the machine set the On / Off switch in the "O"-position.

The heating is switched off and the machine will go into COOLDOWN to let the roller cool

down. The display shows COOLDOWN.

!! ATTENTION !!

To switch off the machine never pull the net plug. With it is guaranteed that the roller still

runs some time and evenly cools.

1

2

3

EHA Transprint HP 2010

Chapter: User manual Version: 01 Date: 02-12-2016

File: BAL-QS-004/ENG Page 20 of 23 Release: M. Klein

6.10.2 Activate Automatic with timer function

To activate the timer switch the rocker switch to ON.

Only then the machine switch on and off according to the setted weekly program.

If the rocker switch is OFF, the Timer is switched off and the HP machine will not be started

by the timer.

Current desired day and time Programming Timer

Display arrow current day and time

Every tab is one hour

Sliding inwards is OFF

Sliding outwards is ON

Anti clockwise direction = Bridge (I)

(Change into Automatic modus with the

next switching operation)

In clockwise direction = Automatic

modus (0)

Heating up phase

The machine will display this progression bar during the heating up phase.

Ready for operation

The machine will beep shortly and display the temperature when the heating up phase is

complete. Subsequently the machine is ready for use.

Table of contents

Popular Power Tools manuals by other brands

Clarke

Clarke Strong-Arm CSA15F Operating & maintenance instructions

DR. BENDER

DR. BENDER RX S operating manual

ATIKA

ATIKA KSG 220 A - operating manual

Atlas Copco

Atlas Copco ETP STB33-12-10-B Product instructions

Campbell Hausfeld

Campbell Hausfeld IN718303AV operating instructions

Altrad

Altrad BELLE MPC 300 Operator's manual