x

hD8625 8-5/8” 35K Tong

Technical Manual

Table ofillusTraTions

Illustration1.A.1:HD8625Tong................................................................................................................................................ 1.1

Illustration1.A.2:HD8625PowerTongDimensions................................................................................................................. 1.2

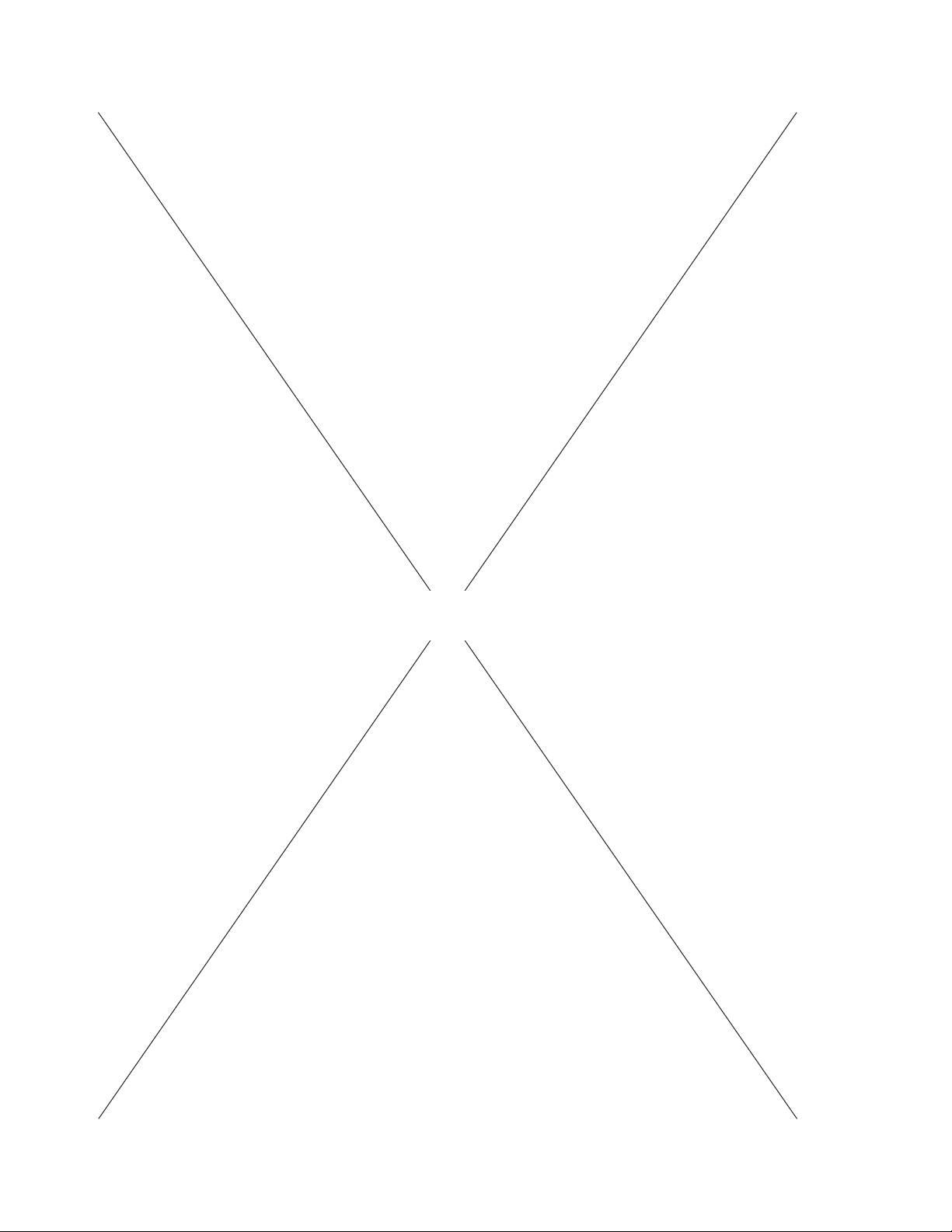

Illustration2.A.1:SlingAngle.................................................................................................................................................... 2.1

Illustration2.B.1:MajorComponentIdentication01............................................................................................................... 2.4

Illustration2.B.2:MajorComponentIdentication02............................................................................................................... 2.5

Illustration2.B.3:MajorComponentIdentication03............................................................................................................... 2.6

Illustration2.C.1:HydraulicSchematic..................................................................................................................................... 2.7

Illustration2.C.2:HydraulicComponentIdentication01......................................................................................................... 2.8

Illustration2.C.3:HydraulicComponentIdentication02......................................................................................................... 2.8

Illustration2.C.4:HydraulicComponentIdentication03......................................................................................................... 2.9

Illustration2.D.1:HydraulicConnections01............................................................................................................................. 2.9

Illustration2.D.2:HydraulicConnections02............................................................................................................................. 2.10

Illustration2.E.1:JawRemoval................................................................................................................................................ 2.11

Illustration2.F.1:TongSuspensionRelativeToAxialCentre................................................................................................... 2.12

Illustration2.F.2:TongSuspensionRelativeToVerticalCentre............................................................................................... 2.13

Illustration2.F.3:TongLeveling(Side-To-Side......................................................................................................................... 2.13

Illustration2.F.4:TongLeveling(Front-To-Rear....................................................................................................................... 2.14

Illustration2.G.1:TongRotationControlValve......................................................................................................................... 2.15

Illustration2.G.2:TongLiftCylinderControlValve................................................................................................................... 2.16

Illustration2.G.3:TongMotorSpeedControlValve................................................................................................................. 2.16

Illustration2.G.4:TongManualShiftControl............................................................................................................................ 2.17

Illustration2.H.1:MasterLiftingLink........................................................................................................................................ 2.18

Illustration2.H.2:BackingPinSetTo“Make-up”Position........................................................................................................ 2.19

Illustration2.H.3:LiftCylinderControl-Raise.......................................................................................................................... 2.19

Illustration2.H.4:OpeningTongDoor...................................................................................................................................... 2.20

Illustration2.H.5:MotorControl-Make-up............................................................................................................................... 2.21

Illustration2.H.6:MotorControl-ReleasingJaws................................................................................................................... 2.21

Illustration2.H.7:LiftCylinderControl-Lower......................................................................................................................... 2.22

Illustration2.H.8:SettingBackingPinTo“Break-Out”Position................................................................................................ 2.23

Illustration2.H.9:RotationControl-Break-out......................................................................................................................... 2.24

Illustration2.H.10:UsingMotorControlToReleaseTongJawsFollowingBreak-out&Un-threading.................................... 2.24

Illustration2.H.11:LoweringTongUsingLiftCylinderControl.................................................................................................. 2.25

Illustration3.D.1:CamFollowerLubrication............................................................................................................................. 3.2

Illustration3.D.2:SupportRollerLubrication............................................................................................................................ 3.2

Illustration3.D.3:RotaryIdlerLubrication................................................................................................................................ 3.3

Illustration3.D.4:PinionIdlerLubricationPoint........................................................................................................................ 3.3

Illustration3.D.5:PinionLubricationPoints.............................................................................................................................. 3.4

Illustration3.D.6:ClutchLubricationPoints.............................................................................................................................. 3.5

Illustration3.D.7:MotorMountLubricationPoint...................................................................................................................... 3.5

Illustration3.D.8:ShifterShaftLubrication............................................................................................................................... 3.6

Illustration3.D.9:TongDoorLubricationPoints....................................................................................................................... 3.6

Illustration3.D.10:DoorCylinder.............................................................................................................................................. 3.7

Illustration3.E.1:BrakeBandAdjustment................................................................................................................................ 3.7

Illustration3.E.2:TongDoorLatchAdjustment........................................................................................................................ 3.8

Illustration3.E.3:ShifterDetentForceAdjustment................................................................................................................... 3.8

Illustration3.H.1:TongAssembly-RotaryGearInstallation.................................................................................................... 3.12

Illustration3.H.2:TongAssembly-GearAssemblyPositioning............................................................................................... 3.13

Illustration3.H.3:TongAssembly-TopFastenerLocations..................................................................................................... 3.14

Illustration3.H.4:TongAssembly-SupportRollers(SecuringLegMounts............................................................................. 3.15

Illustration3.H.5:TongAssembly-FrontLegInstallation........................................................................................................ 3.15

Illustration3.H.6:TongAssembly-SupportRollers(BrakebandWeldments.......................................................................... 3.16

Illustration3.H.7:TongAssembly-TopShifterBushingAssembly.......................................................................................... 3.17

Illustration3.H.8:TongAssembly-FrontCagePlateSpacers................................................................................................. 3.18

Illustration3.H.9:TongAssembly-SafetyDoorValveInstallation........................................................................................... 3.19

Illustration3.H.10:TongAssembly-RigidSlingAdjustmentBoltInstallation........................................................................... 3.20

Illustration3.L.1:ShippingInstructions-Pallet......................................................................................................................... 3.29

Illustration3.L.2:ShippingInstructions-WrappingChainSling&StrappingToPallet............................................................ 3.30

Illustration4.B.1:ReliefValveTroubleshooting-TemporaryGaugeInstallation...................................................................... 4.2

Illustration6.A.1:TorqueGauge............................................................................................................................................... 6.1

Illustration6.A.2:TensionLoadCell......................................................................................................................................... 6.1

Illustration6.A.3:CompressionLoadCell................................................................................................................................ 6.1

Illustration6.A.4:TensionLoadCellExploded......................................................................................................................... 6.3

Illustration6.A.5:TurnCounterEncoderMountExploded....................................................................................................... 6.4