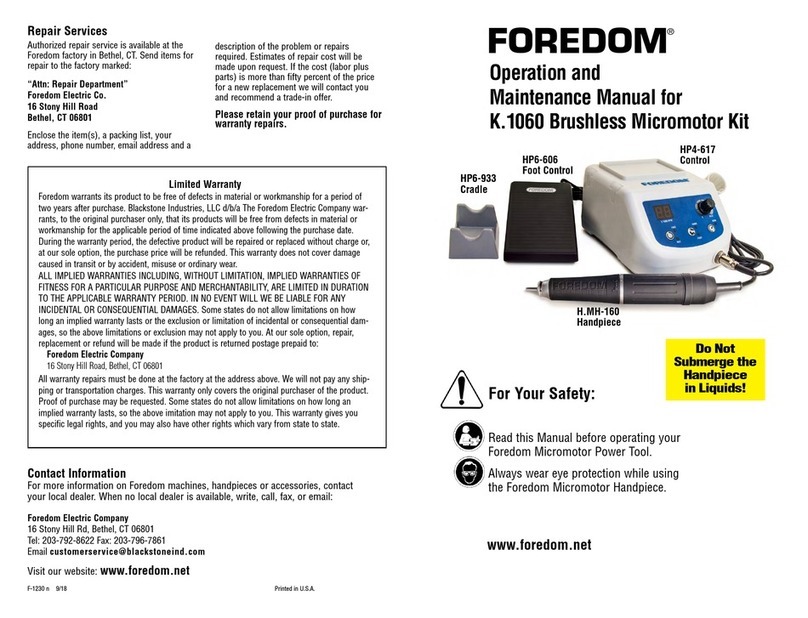

For Foredom®Handpiece H.30H

IMPORTANT INSTRUCTIONS

It takes a fairly strong grasp of the locking ring to

pull it back.

Be careful that your finger or thumb does not get

pinched when you release the locking ring.

Pull back the black locking ring toward the front end of

the handpiece while you insert the tip of the flex shaft.

The handpiece has a square slot that the square drive tip

fits into. You may need to rotate the handpiece slightly

until the square drive engages the spindle. Release the

locking ring when you feel the shaft connect to the

handpiece. You should hear a click.

To remove handpiece

Pull back the locking ring as described above with a firm

grip and pull the shaft and sheath from the handpiece.

Attaching H.30H Handpiece to the Flexible Shaft

Always wear proper eye protection while

using this handpiece. Wear safety glasses

or a face shield whenever you operate a

Foredom Flexible Shaft machine or any

power tool to prevent serious eye injury.

See your power tool owner’s manual

for complete instructions on use

and maintenance.

Before attaching this handpiece please

read these instructions. They should

always be followed to reduce the risk of

personal injury or damage to

the handpiece.

Always use a proper dust collection

system or wear a respirator to prevent

the inhalation of dust particles, or

other debris into the lungs.

Repair Service

Factory repairs are done promptly and at

reasonable cost. If you wish, you can send

your equipment directly to the factory marked

“Attention: Repair Department”. Be sure to

include a brief note describing the problem

and to give your phone number,email and

street address. Estimates will be made

upon request.

Never wear open shoes or sandals. Use

footwear that is tough enough to protect

your feet from falling tools.

Keep both hands and fingers away from

the cutting edge at all times.

Form 1298 n 1/12 Printed in USA

Do not wear loose fitting clothing or

jewelry. Loose clothing or jewelry can

be come entangled in the tool. Do not

wear items such as neckties or jewelry

when operating power tools. Secure or

tie back long hair.

Use both hands whenever possible to

hold and guide the tool.

Never use a damaged, bent, vibrating,

or out of balance accessory.

Avoid knots, imperfections in the wood

or metal objects like nails, which could

catch or damage the tool bit. Let the

speed of the tool

do the work.

For more information on this handpiece and other Foredom tools , contact your local

dealer.When no local dealer is available, write: The Foredom Electric Co.,

16 Stony Hill Rd., Bethel, CT 06801, call (203) 792-8622, fax (203) 796-7861,

Visit www.foredom.net for the latest information and how-to videos!

locking ring

pulled back toward

the front end of handpiece

locking ring

shaft and handpiece connected

square drive

tip of shaft

Maintenance and Lubrication

Handpieces: no lubrication is required. Putting oil or grease into the front or back of these

handpieces will damage their pre-lubricated ball bearings. The chuck of the handpiece should

be kept free of dirt, chips, dust or debris.

Flexible Shaft: Every50 hours of use: Unscrew outer

sheath connector nut (left hand thread) and

remove sheath.

Flexible Shaft Maintenance continued on reverse